- Home

- Semi Automatic Paper Faced Gypsum Plaster Cornice Production Line Machine

Semi Automatic Paper Faced Gypsum Plaster Cornice Production Line Machine Manufacturer

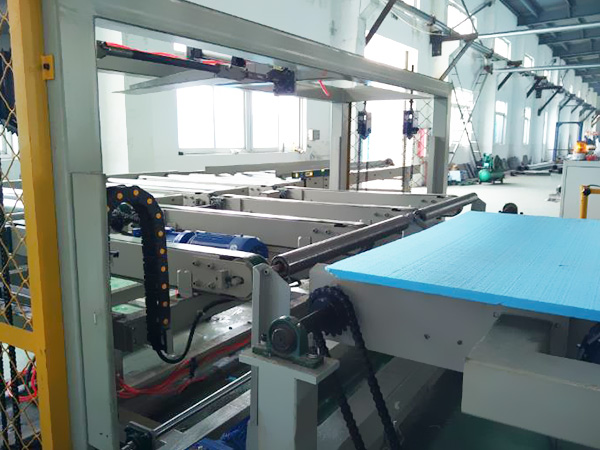

Hebei Greens Building Material Technology Development Co., Ltd. is a China-based manufacturer, supplier, and factory of a semi-automatic paper-faced gypsum plaster cornice production line machine. This production line is specially designed to produce high-quality paper-faced gypsum plaster cornice for interior decoration. The cornice produced by this machine has a smooth surface, high strength, and excellent fire resistance.

The machine is semi-automatic and can produce cornices of various shapes and sizes, depending on the customer's requirements. The production line is equipped with advanced technology and high-quality components that ensure stable and efficient production.

The semi-automatic paper-faced gypsum plaster cornice production line machine is easy to operate, and the production process is automated, which reduces labor costs and increases productivity. It also has a low failure rate and requires minimal maintenance. Overall, the semi-automatic paper-faced gypsum plaster cornice production line machine is an excellent investment for interior decoration manufacturers looking to produce high-quality and durable cornices.

HEBEI GREENS BUILDING MATERIAL TECHNOLOGY DEVELOPMENT CO., LTD.

Company News

Related News

Mgo Board Production Line

Looking for a reliable Mgo Board Production Line supplier? Look no further! We're a factory that offers quality production for all your construction needs.

Gypsum Board Lamination Machine

Looking for a reliable Gypsum Board Lamination Machine? Look no further! Our factory produces high-quality machines at competitive prices. Contact us today for more information.

XPS Foam Board Production Line

Looking for high-quality XPS foam board production line? Look no further! Our factory produces top-of-the-line equipment that will help you get the job done right. Contact us today to learn more.

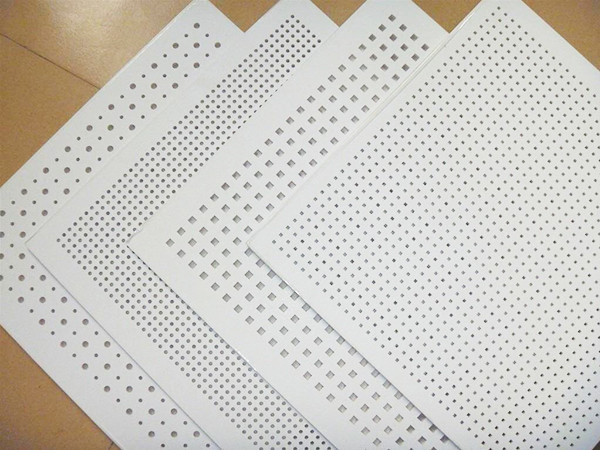

Gypsum Board Perforationg Machine

As a factory specializing in gypsum board perforating machines, we offer high-quality and efficient equipment for your perforation needs. Trust us to provide excellent service. #SEO #GypsumBoardPerforatingMachine

Fiber Cement Board Making Machine

Looking for a quality Fiber Cement Board Making Machine? Look no further than our factory. We manufacture durable and reliable machines designed to meet your every need. Contact us today for more information.

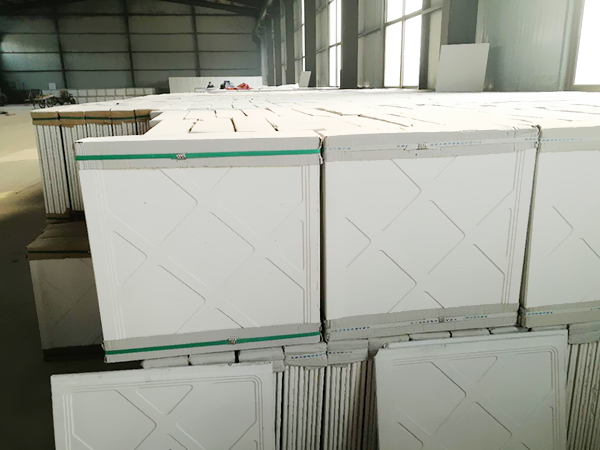

Gypsum Cornice Production Line

Looking for high-quality, durable Gypsum Cornice Production Line? Look no further! Our factory specializes in manufacturing top-of-the-line gypsum cornice production equipment. Buy today!

Gypsum Decorative Tile Machine

Looking for high-quality gypsum decorative tile machines? Look no further than our factory! We offer top-of-the-line products at competitive prices. Contact us today for more information.

Calcium Silicate Board Production Line

Looking for top-quality calcium silicate board production line? Look no further! We are a leading factory that offers reliable and efficient calcium silicate board production line solutions. Our products are designed to meet the highest industry standards. Get in touch to learn more!

PVC Vinyl Film

Looking for high-quality PVC Vinyl Film? Look no further than our factory! We produce top-quality film for a range of applications, with superior durability and performance. Contact us today to learn more!

Mineral Fiber Ceiling Board Production Line

Looking for a reliable Mineral Fiber Ceiling Board Production Line? Look no further than our factory! We specialize in producing high-quality, durable products that meet your needs.

- Semi Automatic Paper Faced Gypsum Plaster Cornice Production Line Machine Manufacturer - High-Quality Machinery from China

- Reviews

- Related Videos

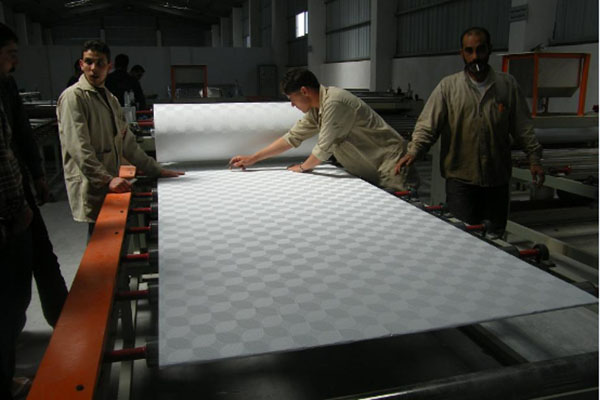

The semi-automatic paper-faced gypsum plaster cornice production line machine is an efficient and reliable equipment that is designed to produce high-quality cornice plaster. This machine is semi-automatic, meaning it can perform some tasks automatically while the operator manually oversees the production process. The machine comprises various components that work together to produce uniform and precise cornice plaster. These components include the mixing system, extrusion system, cutting system, drying system, and packing system. The mixing system is responsible for mixing the gypsum and other additives to form a consistent mixture, which is then transferred to the extrusion system. The extrusion system then shapes the mixture into the desired cornice shape, which is then cut to the required length and dried through the drying system. Finally, the finished cornice is packaged and ready for use. This semi-automatic paper-faced gypsum plaster cornice production line machine is relatively easy to operate and maintain, with minimal human intervention required. It is versatile and can produce different types of cornice profiles, depending on the mold used. Furthermore, it is energy-efficient, producing a high yield with minimal waste materials. Overall, this semi-automatic machine is a worthwhile investment for anyone in the construction industry, looking to produce high-quality cornice plaster. It saves time and reduces labor costs, leading to increased profitability and productivity.

The Semi Automatic Paper Faced Gypsum Plaster Cornice Production Line Machine is a very efficient and productive machine. It produces high-quality paper-faced gypsum plaster cornices with great accuracy. The machine is semi-automatic, which means that it requires minimal human intervention. The machine is easy to operate and maintain, ensuring that you get the most out of your investment. The production line is well-organized, which makes it easy to monitor the entire production process. The machine is also energy-efficient, making it an environmentally friendly option. Overall, this machine is an excellent choice for anyone looking to produce high-quality paper-faced gypsum plaster cornices efficiently and easily.

The Semi Automatic Paper Faced Gypsum Plaster Cornice Production Line Machine is an excellent investment for any business in the construction industry. With its high level of automation, this machinery greatly increases productivity and efficiency in the production of gypsum plaster cornices. The quality of the finished product is also top-notch, with the paper-faced surface providing a smooth and flawless finish. Additionally, this machine is easy to operate and maintain, making it a great asset for any workshop. Overall, I highly recommend the Semi Automatic Paper Faced Gypsum Plaster Cornice Production Line Machine for its reliability, high-quality output, and cost-effectiveness. It is certainly an investment worth considering for any business looking to improve its production capabilities.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours