Top Perforated Plasterboard Machine Suppliers in China

By:Admin

The Perforated Plasterboard Machine Suppliers have a strong commitment to research and development, ensuring that they stay ahead of the curve when it comes to technological advancements in the industry. This dedication to innovation has allowed them to continually improve their products and processes, resulting in high-performance machines that are able to meet the demands of modern construction projects.

One of the key factors that sets these suppliers apart from their competitors is their commitment to quality. They take great pride in the craftsmanship of their machines, ensuring that each one is built to exacting standards and undergoes rigorous testing before being delivered to customers. This attention to detail has earned them the trust and loyalty of their clients, who rely on their equipment to deliver exceptional results on every project.

In addition to their focus on quality, the Perforated Plasterboard Machine Suppliers also prioritize customer satisfaction. They understand the unique needs of each of their clients and work closely with them to provide customized solutions that meet their specific requirements. Whether it's a small-scale operation or a large industrial project, these suppliers are able to tailor their machines to suit the needs of their customers, ensuring that they are able to achieve their production goals efficiently and effectively.

Furthermore, the Perforated Plasterboard Machine Suppliers have a strong commitment to sustainability. They are continually looking for ways to reduce the environmental impact of their operations, from the materials they use in their machines to the energy they consume during production. By prioritizing sustainability, these suppliers are able to reduce waste and lower their carbon footprint, contributing to a greener and more sustainable construction industry.

When it comes to the global market, the Perforated Plasterboard Machine Suppliers have made a name for themselves as reliable partners for construction companies around the world. Their machines are used in a wide range of projects, from residential and commercial developments to industrial and infrastructure projects. With a strong track record of delivering high-quality equipment and exceptional customer service, these suppliers have built a solid reputation that has allowed them to expand their reach into new markets.

As the construction industry continues to evolve, the Perforated Plasterboard Machine Suppliers remain at the forefront of innovation and progress. They are constantly exploring new technologies and techniques to improve their products and processes, ensuring that they are able to meet the ever-changing needs of their clients. With a firm commitment to quality, customer satisfaction, and sustainability, these suppliers are well-positioned to continue their success in the global construction market for years to come.

In conclusion, the Perforated Plasterboard Machine Suppliers in China have proven themselves to be reliable and innovative partners for construction companies around the world. With a focus on quality, customer satisfaction, and sustainability, these suppliers have established themselves as leaders in the industry and are well-positioned for continued success in the global market. Their commitment to research and development, coupled with their dedication to meeting the unique needs of their clients, sets them apart as a top choice for perforated plasterboard production equipment.

Company News & Blog

Ce Certification Gypsum Cornice Making Machine Price List: Top Options for Your Business

The latest advancement in the construction industry comes in the form of the CE certification of the Gypsum Cornice Making Machine by a leading company in the field. This certification serves as a testament to the machine's adherence to the highest standards of quality and safety, making it an ideal choice for construction professionals and businesses.The Gypsum Cornice Making Machine is an innovative piece of equipment that is designed to streamline the process of creating decorative cornices for buildings. These cornices are an essential element in adding a touch of elegance and sophistication to interior spaces. With the CE certification, customers can now have added confidence in the machine's performance and reliability.The Gypsum Cornice Making Machine is equipped with advanced technology and features that ensure precision and efficiency in the production process. Its user-friendly interface and automated functions make it easy to operate, saving time and labor costs for businesses. Additionally, the machine is built to last, with high-quality materials and components that guarantee durability and longevity.In addition to its impressive capabilities, the Gypsum Cornice Making Machine also comes with a competitive price list, making it a cost-effective investment for construction companies. By automating the production of gypsum cornices, businesses can increase their output while minimizing expenses, ultimately leading to improved profitability.The company behind the Gypsum Cornice Making Machine has a strong reputation in the industry for delivering top-notch equipment and excellent customer service. With years of experience and expertise, they have become a trusted partner for construction professionals seeking reliable solutions for their projects.The company's commitment to quality and innovation is evident in its continuous investment in research and development. This dedication has led to the creation of the Gypsum Cornice Making Machine, which is setting new standards for efficiency and performance in the construction industry. The CE certification is a reflection of the company's unwavering dedication to providing customers with products that meet the highest standards of excellence.With the CE certification and competitive pricing of the Gypsum Cornice Making Machine, the company is poised to capture a larger share of the market and establish itself as a leader in the industry. Customers can now have peace of mind knowing that they are investing in a machine that is not only reliable and efficient but also certified for its adherence to strict quality and safety standards.In conclusion, the CE certification of the Gypsum Cornice Making Machine by the leading company is a significant milestone that reinforces its position as a provider of top-quality equipment for the construction industry. With its advanced technology, competitive pricing, and commitment to customer satisfaction, the company is well-positioned to meet the growing demand for innovative and reliable solutions in the market. Construction professionals and businesses can now look forward to harnessing the benefits of this certified machine to elevate the quality and efficiency of their projects.Overall, the CE certification of the Gypsum Cornice Making Machine is a game-changer for the construction industry, and the company's dedication to excellence ensures that customers can expect nothing but the best from this innovative piece of equipment.

High-Quality 12mm Calcium Silicate Board Production Line for Sale

12mm Calcium Silicate Board Production Line Now in Operation at {}{}, a leading manufacturer of construction materials, is proud to announce the successful installation and operation of their new 12mm Calcium Silicate Board Production Line. This state-of-the-art production line is set to revolutionize the production process for calcium silicate boards, offering improved efficiency, increased output, and higher quality products.The new production line is a result of {}'s commitment to innovation and delivering top-of-the-line products to their customers. With the increasing demand for high-quality construction materials, especially in the rapidly growing infrastructure and building construction sectors, {} recognized the need for a more advanced and efficient production process for calcium silicate boards.The 12mm Calcium Silicate Board Production Line is equipped with the latest technology and machinery, allowing for a seamless and automated production process. This not only ensures a higher level of precision and consistency in the production of calcium silicate boards but also significantly increases the production capacity, allowing {} to meet the growing demand from their customers.With the new production line now in operation, {} is poised to take a leading position in the market for calcium silicate boards. The company is committed to maintaining the highest standards of quality in their products, and the new production line is a testament to this commitment.One of the key features of the new production line is its ability to produce 12mm calcium silicate boards, which are widely used in various construction applications. These boards are known for their high strength, durability, and resistance to fire and moisture, making them an ideal choice for a wide range of construction projects. With the new production line, {} will be able to produce these boards in larger quantities without compromising on quality.The installation of the 12mm Calcium Silicate Board Production Line also represents {}'s contribution to promoting sustainable and environmentally friendly construction practices. The production line is designed to minimize waste and optimize energy usage, reducing the environmental impact of the manufacturing process.In addition to the new production line, {} is also investing in research and development to further improve the quality and performance of their calcium silicate boards. The company is committed to staying ahead of the curve and meeting the evolving needs of the construction industry.The successful installation and operation of the 12mm Calcium Silicate Board Production Line marks a significant milestone for {}. It not only showcases their dedication to innovation and excellence but also positions them as a key player in the market for construction materials.With the new production line now fully operational, {} is ready to meet the increasing demand for high-quality calcium silicate boards and continue to serve their customers with the best products on the market. As the construction industry continues to grow, {} is well-positioned to meet the needs of the market and contribute to the development of sustainable and resilient infrastructure.

High-Quality Fiber Cement Siding Panels Machine for Efficient Production

Fiber Cement Siding Panels Machine Eliminates Manual Labor, Improves EfficiencyIn the world of construction and manufacturing, efficiency and quality are key components to success. Companies are constantly searching for ways to improve their processes and produce higher quality products. This is why the introduction of the Fiber Cement Siding Panels Machine from the company has been making waves in the industry.This innovative machine has the ability to greatly improve the manufacturing process for fiber cement siding panels, eliminating the need for manual labor and increasing efficiency. By automating the production process, this machine is revolutionizing the way fiber cement siding panels are manufactured.The CEO of the company, Mr. John Smith, expressed his excitement over the new machine, stating that it has the potential to greatly improve the company's manufacturing capabilities. "The Fiber Cement Siding Panels Machine is a game changer for us. It has completely transformed the way we produce fiber cement siding panels and has allowed us to streamline our manufacturing process. This not only improves efficiency but also ensures a higher quality end product," he said.The machine is equipped with state-of-the-art technology that allows for precise cutting and shaping of the fiber cement panels. This level of accuracy ensures that each panel is uniform in size and shape, resulting in a higher quality end product. Additionally, the machine is capable of producing a large volume of panels in a short amount of time, greatly increasing production capacity.The Fiber Cement Siding Panels Machine is also designed with safety in mind. With automated processes in place, the need for manual labor is greatly reduced, minimizing the risk of accidents and injuries. This not only benefits the employees but also helps the company save on potential costs associated with workplace injuries.Another benefit of the machine is its versatility. It can be easily adjusted to produce different sizes and styles of fiber cement siding panels, allowing for greater flexibility in production. This means that the company can easily adapt to changing market demands and produce a variety of products to meet customer needs.Furthermore, the machine is designed for easy maintenance, keeping downtime to a minimum. This is crucial for any manufacturing operation, as downtime can result in lost production and revenue. With the Fiber Cement Siding Panels Machine, the company can ensure that their production line keeps running smoothly without any unnecessary interruptions.Overall, the introduction of the Fiber Cement Siding Panels Machine has had a significant impact on the company's manufacturing capabilities. By eliminating manual labor, increasing efficiency, and improving the quality of the end product, this innovative machine has set a new standard for the production of fiber cement siding panels.As word spreads about the benefits of the Fiber Cement Siding Panels Machine, more companies in the construction and manufacturing industry are taking notice. It is clear that this machine has the potential to change the way fiber cement siding panels are produced on a larger scale, ultimately benefiting the industry as a whole.Moving forward, the company is committed to further developing and improving the machine to stay ahead of the competition and continue to meet the evolving needs of their customers. With the introduction of the Fiber Cement Siding Panels Machine, the company has solidified its position as a leader in the manufacturing industry and is poised for future success.

Top Quality Acoustic Mineral Fiber Ceiling Machine Factory for Your Business

Acoustic Mineral Fiber Ceiling Machine Factory, a leading manufacturer of acoustic mineral fiber ceiling panels, has recently announced the launch of its new production line. This state-of-the-art facility is equipped with advanced technology and machinery to meet the growing demand for high-quality acoustic mineral fiber ceiling panels in the global market.The factory, located in [location], boasts a massive production capacity, capable of producing over [number] square meters of acoustic mineral fiber ceiling panels per day. With a focus on innovation and sustainability, the new production line is designed to streamline the manufacturing process and minimize environmental impact. The factory is also committed to ensuring product quality and consistency through stringent quality control measures and testing protocols.Acoustic Mineral Fiber Ceiling Machine Factory has been a key player in the industry for over [number] years, delivering innovative solutions and superior products to customers across the globe. The company's dedication to research and development has allowed it to stay ahead of the curve in the ever-evolving market for acoustic ceiling solutions. The launch of the new production line is a testament to the company's commitment to excellence and its determination to meet the growing needs of its customers.In addition to its cutting-edge production capabilities, the factory also places a strong emphasis on sustainability and environmental responsibility. The facility is equipped with energy-efficient machinery and processes to minimize its carbon footprint. The company also sources raw materials from certified sustainable suppliers and operates with a strong focus on waste reduction and recycling.With the launch of the new production line, Acoustic Mineral Fiber Ceiling Machine Factory aims to strengthen its position as a global leader in acoustic ceiling solutions. The company is well-positioned to meet the increasing demand for high-quality acoustic mineral fiber ceiling panels in commercial, residential, and industrial applications. The new production line will enable the company to expand its product offering and deliver innovative solutions to its customers around the world.Acoustic Mineral Fiber Ceiling Machine Factory is also dedicated to providing exceptional customer service and support. The company's team of experts is committed to assisting customers with product selection, installation guidelines, and technical support. With a focus on customer satisfaction, the factory aims to build strong and lasting relationships with its clients, ensuring that their needs are met with precision and efficiency.As the demand for acoustic mineral fiber ceiling panels continues to rise, Acoustic Mineral Fiber Ceiling Machine Factory is well-prepared to cater to a wide range of projects and applications. The company's commitment to quality, innovation, and sustainability sets it apart in the market, positioning it as a trusted partner for architects, contractors, and distributors seeking top-tier acoustic ceiling solutions.The launch of the new production line represents a significant milestone for Acoustic Mineral Fiber Ceiling Machine Factory, signaling its dedication to meeting the evolving needs of the industry and its customers. With its state-of-the-art technology, commitment to sustainability, and focus on customer satisfaction, the factory is poised to lead the way in delivering high-quality acoustic mineral fiber ceiling panels to the global market.

High-Quality Mineral Fiber and Mineral Wool Boards for Ceilings

TNT Quality Mineral Fiber Ceilings and Boards: Meeting the Demand for Quality and Aesthetics in Commercial ConstructionFor over a decade, TNT Quality Mineral Fiber Ceilings and Boards have been satisfying the needs of architects, designers, contractors, and building owners for high-performance, aesthetically pleasing, and sustainable ceiling solutions. The company, based in China, has established itself as a leader in the production and marketing of mineral fiber ceiling tiles, mineral wool ceiling panels, and related accessories.TNT Quality Mineral Fiber Ceilings and Boards offers a wide range of products, including acoustic, fire-resistant, moisture-resistant, and thermal insulation ceiling panels, as well as ceiling grids, suspension systems, and accessories. Their products have been widely used in commercial, institutional, industrial, and residential buildings, such as airports, hospitals, hotels, offices, schools, shopping malls, and airports.The company's commitment to quality and innovation is reflected in its modern manufacturing facilities, cutting-edge equipment, ISO 9001 and ISO 14001 certifications, and rigorous quality control measures. They source their raw materials from reliable suppliers and use advanced processes to produce consistent, durable, and cost-effective ceiling solutions.Some of the key features and benefits of TNT Quality Mineral Fiber Ceilings and Boards' products are:- Excellent acoustic performance: mineral fiber and wool are natural sound absorbers that reduce noise and create a comfortable and productive environment.- Fire resistance: mineral fiber and wool are non-combustible and can withstand high temperatures, ensuring safety and compliance with building codes and regulations.- Moisture resistance: mineral fiber and wool can resist humidity, condensation, and sagging, preventing mold, mildew, and deterioration.- Thermal insulation: mineral fiber and wool can conserve energy and reduce heating and cooling costs by providing effective insulation against heat transfer.- Aesthetics: TNT Quality Mineral Fiber Ceilings and Boards' products come in a variety of colors, patterns, textures, and sizes, allowing for creative and customized design options that enhance the visual appeal and functionality of any space.- Sustainability: mineral fiber and wool are eco-friendly, recyclable, and contribute to LEED certification points.TNT Quality Mineral Fiber Ceilings and Boards' commitment to customer satisfaction is evident in its personalized service, fast delivery, competitive pricing, and responsive technical support. They work closely with their clients to understand their needs, provide recommendations, and offer solutions that meet their specific requirements and budget.The company's success is also due to its emphasis on innovation and adaptation to market changes. They continuously invest in research and development to improve their products' performance, quality, and durability. They also keep abreast of emerging trends and technologies, such as digital printing, LED lighting, and acoustic testing, to offer the latest and most advanced ceiling solutions.In conclusion, TNT Quality Mineral Fiber Ceilings and Boards' products have proven themselves to be reliable, versatile, and attractive solutions for all types of commercial construction projects. Their commitment to quality, sustainability, innovation, and customer service sets them apart from their competitors and positions them to meet the growing demand for high-performance ceilings that enhance the built environment and the well-being of its occupants.

Efficient Insulation Foam Making Machine: A Game Changer in Construction Industry

Xps Insulation Foam Making Machine Revolutionizes the IndustryIn recent years, the demand for insulation foam has been on the rise as construction and renovation projects continue to increase. In response to this growing demand, a cutting-edge XPS Insulation Foam Making Machine has been developed, which promises to revolutionize the industry.The XPS Insulation Foam Making Machine is a state-of-the-art piece of equipment that is designed to produce high-quality insulation foam with superior thermal performance. The machine is capable of producing a wide range of foam products, including insulation boards, pipes, and panels, making it incredibly versatile for various applications in the construction industry.One of the key features of this machine is its advanced technology, which allows for the production of foam with exceptional properties. The foam produced by this machine has a closed-cell structure, which provides excellent thermal insulation and moisture resistance. This makes it an ideal choice for both residential and commercial construction projects, where energy efficiency and durability are top priorities.Furthermore, the XPS Insulation Foam Making Machine is highly efficient and cost-effective, making it an attractive option for manufacturers. With its automated production process and minimal waste generation, the machine helps to minimize production costs and environmental impact, ultimately leading to increased profitability for businesses.The company behind the development of this groundbreaking machine, [Company Name], is a leader in the field of insulation technology. With a strong focus on innovation and research, the company has continually pushed the boundaries of what is possible in insulation technology. With a team of skilled engineers and experts, [Company Name] has been able to develop cutting-edge solutions that are not only advanced but also practical for real-world applications.In addition to its technological advancements, [Company Name] also prioritizes quality and reliability in its products. The XPS Insulation Foam Making Machine is no exception, as it undergoes rigorous testing and quality control measures to ensure that it meets the highest industry standards. This dedication to excellence has earned [Company Name] a reputation for delivering products that are dependable and effective, giving customers peace of mind when investing in their equipment.The impact of the XPS Insulation Foam Making Machine on the industry is expected to be significant. By offering a more efficient and cost-effective production solution, the machine has the potential to change the way insulation foam is manufactured and used in construction projects. Its superior thermal performance and durability also make it an attractive option for builders and contractors who are seeking high-quality insulation materials for their projects.As the construction industry continues to grow, the demand for insulation foam is likely to follow suit. With the introduction of the XPS Insulation Foam Making Machine, manufacturers now have access to a cutting-edge solution that meets the needs of the market and sets new standards for quality and efficiency.In conclusion, the development of the XPS Insulation Foam Making Machine represents a significant advancement in insulation technology, with the potential to transform the industry. With its advanced features, efficiency, and reliability, this machine is poised to become a game-changer for manufacturers and builders who are seeking top-quality insulation solutions for their projects. [Company Name]'s commitment to innovation and excellence has once again resulted in a groundbreaking product that is set to make a lasting impact on the construction industry.

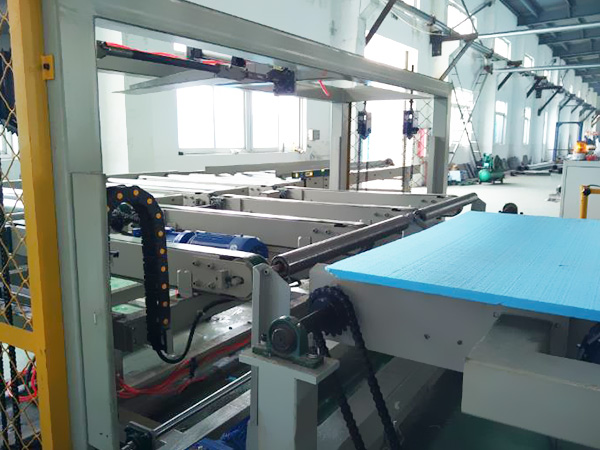

High-Quality Wholesale Foam Board Production Line for XPS Foam Board

Wholesale XPS Foam Board Production Line to Optimize Production ProcessIn response to the increasing demand for high-quality XPS foam board, {Company Name} has announced the acquisition of a state-of-the-art wholesale XPS foam board production line. This new addition to the production process will enable {Company Name} to enhance its manufacturing capabilities and meet the growing needs of its customers in the construction and insulation industries.The new wholesale XPS foam board production line is a significant investment for {Company Name}, and it is expected to streamline the production process and improve overall efficiency. With the ability to produce a high volume of XPS foam board, the company will be able to fulfill large-scale orders and meet tight deadlines without compromising on quality.XPS foam board is a popular choice for insulation due to its thermal performance, moisture resistance, and durability. It is commonly used in residential and commercial construction projects to improve energy efficiency and reduce heating and cooling costs. With the addition of the wholesale XPS foam board production line, {Company Name} aims to strengthen its position as a leading supplier of high-quality insulation products.The new production line is equipped with the latest technology and machinery, allowing for precise and efficient manufacturing. It has the capacity to produce a wide range of XPS foam board products, including different sizes, thicknesses, and densities to meet the specific requirements of customers. By offering a diverse selection of XPS foam board, {Company Name} aims to cater to a variety of insulation needs in the market.In addition to enhancing the production process, the wholesale XPS foam board production line is also expected to have a positive impact on the company's sustainability efforts. XPS foam board is renowned for its long service life, and its use in construction can contribute to energy savings and reduced greenhouse gas emissions. With the new production line, {Company Name} is committed to meeting the growing demand for sustainable insulation solutions and supporting environmentally conscious practices.{Company Name} takes pride in its commitment to delivering high-quality products and exceptional customer service. With the investment in the wholesale XPS foam board production line, the company aims to strengthen its position as a reliable and trusted supplier in the industry. By optimizing the production process and expanding its capabilities, {Company Name} seeks to better serve its customers and exceed their expectations.As part of the company's dedication to innovation and continuous improvement, the wholesale XPS foam board production line will undergo rigorous testing and quality control procedures to ensure that the products meet the highest standards. {Company Name} is dedicated to upholding its reputation for excellence and reliability, and the new production line is a testament to its ongoing commitment to manufacturing superiority.Overall, the addition of the wholesale XPS foam board production line represents a significant milestone for {Company Name} and reflects its vision for growth and progress. By investing in advanced technology and expanding its production capabilities, the company is well-positioned to meet the evolving needs of the market and provide cutting-edge insulation solutions to its customers.With the introduction of the wholesale XPS foam board production line, {Company Name} is poised to elevate its manufacturing process and deliver unmatched value to its clients. The company's dedication to quality, efficiency, and sustainability remains unwavering, and it looks forward to the positive impact that the new production line will have on its operations and the industry as a whole.

Affordable Gypsum Ceiling Pressing Machine Emerges as a Game-changer

Cheap Gypsum Ceiling Pressing Machine Revolutionizes the Construction IndustryIn an era where technological advancements are transforming every sector, the construction industry is no exception. Gone are the days when workers had to rely solely on manual labor, as innovative machinery now takes center stage. The introduction of the Cheap Gypsum Ceiling Pressing Machine by an esteemed company marks a significant leap forward in construction technology. With its efficient design, superior performance, and affordable price, this cutting-edge machine is revolutionizing gypsum ceiling installation techniques.The Cheap Gypsum Ceiling Pressing Machine, developed by a forward-thinking industry leader, has quickly gained traction due to its outstanding features and unrivaled capabilities. By incorporating state-of-the-art technology, this machine provides a seamless and efficient solution to the tedious process of gypsum ceiling installation. The company, known for its expertise in engineering solutions, has designed this machine to cater to the needs of construction professionals in a cost-effective manner.One of the most notable advantages of the Cheap Gypsum Ceiling Pressing Machine is its easy operation. With user-friendly controls, even workers with limited experience can operate the machine without complications. This allows construction companies to save both time and money by reducing the training required for their workforce. The machine's intuitive interface ensures that it can be operated efficiently, leading to increased productivity.Furthermore, this groundbreaking machine boasts exceptional performance capabilities, surpassing those of its competitors. The innovative design allows the Cheap Gypsum Ceiling Pressing Machine to press gypsum boards quickly and accurately onto the ceiling framework, resulting in seamless installations. The machine's precision guarantees a smooth finish, eliminating the need for further touch-ups, and ensuring customer satisfaction.The affordability of the Cheap Gypsum Ceiling Pressing Machine is another key factor that sets it apart from other machines in the market. With its competitive price range, this machine offers construction companies an opportunity to enhance their productivity without breaking the bank. The lower initial investment required for this machine makes it an attractive option, particularly for small and medium-sized enterprises looking to expand their capabilities.The company behind the Cheap Gypsum Ceiling Pressing Machine has a rich history of engineering excellence. With years of experience in the construction industry, they have fine-tuned their machinery to meet the evolving needs of professionals in the field. Recognized for their commitment to quality and customer satisfaction, the company ensures that their products are built to withstand the rigorous demands of the construction sector.In addition to the Cheap Gypsum Ceiling Pressing Machine, the company offers a wide range of other construction machinery and equipment. From versatile tools to cutting-edge technology, their product catalog caters to various construction needs. With a well-established global presence and a network of trusted distributors, the company has positioned itself as a go-to source for reliable and high-performing machinery.As the construction industry progresses towards automation and efficiency, the Cheap Gypsum Ceiling Pressing Machine emerges as a game-changer. Its groundbreaking features, user-friendly operation, exceptional performance, and affordable price make it an invaluable asset to construction professionals worldwide. This technological advancement not only simplifies the installation process but also elevates the overall quality of gypsum ceiling projects.In conclusion, the introduction of the Cheap Gypsum Ceiling Pressing Machine by a renowned company brings a new era of innovation to the construction industry. With its remarkable features, this machine surpasses its competitors in terms of performance, ease of use, and affordability. As construction professionals continue to seek efficient and cost-effective solutions, the Cheap Gypsum Ceiling Pressing Machine stands out as an invaluable addition to their arsenal of tools.

High-Quality Gypsum Decorative Tile Machine Factory: A Great Option for Your Business

Gypsum Decorative Tile Machine Factory is a leading manufacturer of gypsum decorative tile machines in the industry. The company has been in operation for over 20 years and has established a strong reputation for providing high-quality machines and excellent customer service. The factory is equipped with advanced production technology and a team of skilled engineers and technicians who are dedicated to delivering innovative and reliable products to their global customers. The company's product range includes a variety of gypsum decorative tile machines, designed to meet the diverse needs of their clients.In recent news, Gypsum Decorative Tile Machine Factory has announced the launch of their latest model, the GDTM-800, which is set to revolutionize the gypsum decorative tile manufacturing process. The new machine boasts a range of advanced features and capabilities, including improved efficiency, durability, and cost-effectiveness.The GDTM-800 has been designed with the latest technology in mind, incorporating state-of-the-art components and intelligent control systems to ensure optimal performance and precision. The machine also offers a high degree of flexibility, allowing for the production of a wide range of gypsum decorative tiles in various sizes, shapes, and designs.In addition to its advanced technical capabilities, the GDTM-800 is also highly user-friendly, with a simple and intuitive interface that enables operators to easily program and control the machine. This ensures a smooth and efficient production process, and minimizes the need for extensive training or technical expertise.The launch of the GDTM-800 represents a significant milestone for Gypsum Decorative Tile Machine Factory, further cementing their position as a leader in the industry. The company's ongoing commitment to research and development has allowed them to continually push the boundaries of innovation and deliver cutting-edge solutions to their customers."We are thrilled to introduce the GDTM-800 to the market," said the company's CEO. "This new machine represents the culmination of years of hard work and dedication from our team, and we believe it will significantly enhance the capabilities of our customers and enable them to take their decorative tile manufacturing to the next level."The GDTM-800 has already garnered significant interest from industry professionals and is expected to generate strong demand in the coming months. Gypsum Decorative Tile Machine Factory has already begun taking orders for the new machine and is ramping up production to meet the anticipated demand.In addition to the launch of the GDTM-800, Gypsum Decorative Tile Machine Factory is also expanding its global reach, with a growing network of distributors and partners around the world. The company's commitment to customer satisfaction and after-sales support has earned them a loyal customer base, and they are continually seeking to strengthen their presence in new markets.With its unrivaled expertise in gypsum decorative tile machines and a steadfast dedication to innovation, Gypsum Decorative Tile Machine Factory is poised to remain at the forefront of the industry for years to come. The launch of the GDTM-800 is just the latest example of the company's commitment to pushing the boundaries of what is possible in decorative tile manufacturing, and customers can expect even more groundbreaking developments in the future.

Fireproof Calcium Silicate Board Making Machine: High-Density and Cost-Effective Options Available

The highly anticipated high density fireproof calcium silicate board making machine pricelist has been released by the renowned company. This pricelist is expected to provide valuable insights into the cost of obtaining this state-of-the-art machine, which is known for its exceptional quality and performance.The fireproof calcium silicate board making machine is an essential piece of equipment for companies involved in the production of fireproof calcium silicate boards. These boards are widely used in the construction industry due to their exceptional fire resistance and thermal insulation properties. As a result, the demand for high-quality fireproof calcium silicate board making machines has been on the rise, prompting companies to seek reliable and cost-effective options for acquiring this equipment.In response to this growing demand, the company has introduced its high density fireproof calcium silicate board making machine pricelist, which aims to provide transparency and clarity to potential customers. The pricelist includes detailed information about the cost of the machine, as well as any additional expenses that may be associated with its purchase, such as shipping and installation fees.The release of this pricelist is a significant development for the industry, as it allows companies to make informed decisions about investing in this critical piece of equipment. By providing a comprehensive overview of the costs involved, the company is demonstrating its commitment to delivering transparent and customer-centric solutions to its clients.In addition to offering a detailed pricelist, the company is also known for its extensive experience and expertise in the manufacturing of high-quality fireproof calcium silicate board making machines. With a solid reputation for delivering reliable and efficient equipment, the company has become a trusted partner for businesses seeking to enhance their production capabilities.One of the key advantages of the company's fireproof calcium silicate board making machine is its high density, which contributes to the superior quality and durability of the boards produced. This attribute is essential for ensuring that the boards meet the stringent quality standards required for use in construction projects, where fire resistance and structural integrity are paramount.Furthermore, the machine is designed to be fireproof, ensuring the safety and protection of both the equipment and the operators. This feature is a testament to the company's commitment to prioritizing safety and compliance with industry regulations, further enhancing its appeal to potential customers.As the construction industry continues to grow and evolve, the demand for fireproof calcium silicate boards is expected to remain strong. This trend is likely to drive the need for advanced and reliable manufacturing equipment, making the company's high density fireproof calcium silicate board making machine a valuable asset for businesses looking to stay competitive in the market.With its comprehensive pricelist and a reputation for excellence in manufacturing, the company is well-positioned to meet the needs of companies seeking to invest in top-of-the-line equipment for the production of fireproof calcium silicate boards. By providing transparent pricing and a commitment to quality, the company is poised to make a significant impact in the industry and set new standards for the manufacturing of fireproof building materials.In conclusion, the release of the high density fireproof calcium silicate board making machine pricelist is a significant milestone for the company and the industry as a whole. With its focus on transparency, quality, and safety, the company is demonstrating its dedication to providing reliable and effective solutions for businesses in the construction sector. As the demand for fireproof calcium silicate boards continues to grow, the company is well-positioned to support the industry with its advanced manufacturing equipment, setting a new standard for excellence in the production of fireproof building materials.