Top Gypsum Decorative Tile Making Machine for Your Needs

By:Admin

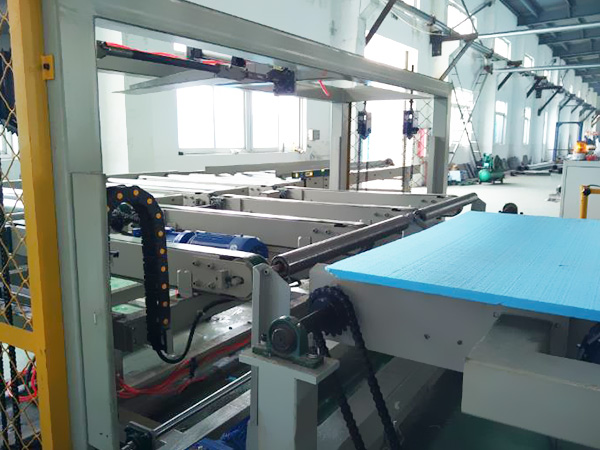

The gypsum decorative tile making machine has recently made waves in the industry for its cutting-edge technology and efficient production capabilities. This innovative machine has been hailed as a game-changer for manufacturers and producers in the decorative tile industry, significantly streamlining the production process and enhancing overall productivity.

This state-of-the-art machine, developed by a leading company in the industry, boasts advanced features that set it apart from traditional tile making machines. With its precise cutting and molding capabilities, the machine is able to create intricate and customized designs with remarkable accuracy and speed. This level of precision and detail has resulted in a significant reduction in production time and costs for manufacturers, as well as a considerable increase in the quality and consistency of the end product.

In addition to its technical superiority, the machine is also lauded for its user-friendly interface and intuitive operation. This has made it accessible to a wider range of industry professionals, allowing for increased production capacity and flexibility. The machine is also equipped with advanced safety features, ensuring a secure and reliable production environment for operators.

The company behind this groundbreaking machine has been a leader in the industry for many years, specializing in the development and production of innovative equipment for the manufacturing of decorative tiles. With a strong focus on research and development, the company has been able to consistently deliver cutting-edge solutions that meet the ever-evolving needs of the industry.

Furthermore, the company's dedication to customer satisfaction and after-sales service has earned it a reputation as a trusted and reliable partner for manufacturers and producers worldwide. With a global presence and a strong commitment to quality, the company continues to make strides in the industry, providing innovative solutions that drive progress and efficiency.

The introduction of the best gypsum decorative tile making machine has resulted in a notable shift in the industry, prompting manufacturers to reevaluate their production processes and consider the adoption of this new technology. Many industry professionals have embraced the machine as a means to improve their manufacturing capabilities and stay ahead of the competition.

The machine's ability to produce high-quality decorative tiles with intricate designs has also captured the attention of designers and architects, who see it as a tool to bring their creative visions to life. With its versatility and precision, the machine has opened up new possibilities for the design and application of decorative tiles in a wide range of architectural and interior design projects.

As the demand for decorative tiles continues to grow, the best gypsum decorative tile making machine is poised to play a pivotal role in shaping the future of the industry. Its impact on production efficiency, product quality, and design innovation is expected to drive significant advancements in the industry, paving the way for new opportunities and possibilities.

In conclusion, the introduction of the best gypsum decorative tile making machine marks a significant milestone in the industry, signaling a new era of innovation and progress. With its advanced technology and unparalleled capabilities, the machine is set to revolutionize the way decorative tiles are manufactured and utilized, setting a new standard for quality, efficiency, and design possibilities. As the industry continues to evolve, this groundbreaking machine is sure to remain at the forefront of progress, driving positive change and inspiring new developments for years to come.

Company News & Blog

Highly Efficient Gypsum Ceiling Board Production Line for Manufacturing

Gypsum Ceiling Board Production Line Revolutionizes Manufacturing ProcessIn the world of manufacturing, innovation is key to staying ahead of the competition. This is especially true in the production of gypsum ceiling boards, where efficiency and quality are paramount. As such, the introduction of the Gypsum Ceiling Board Production Line by [Company Name] has caused a significant stir in the industry.[Company Name] is a leading manufacturer of gypsum board production equipment, with a strong reputation for quality and innovation. The company has been at the forefront of the industry for many years, and their latest offering, the Gypsum Ceiling Board Production Line, is yet another example of their commitment to advancing the manufacturing process.The Gypsum Ceiling Board Production Line is a state-of-the-art system that is designed to automate and streamline the production of gypsum ceiling boards. It is capable of producing a wide range of board sizes and thicknesses, and can also be customized to meet the specific needs of different manufacturers. This level of flexibility is a key feature of the production line, as it allows manufacturers to tailor their production process to their exact requirements.One of the most impressive aspects of the Gypsum Ceiling Board Production Line is its efficiency. The system is capable of producing a large volume of boards in a relatively short amount of time, without sacrificing on quality. This is achieved through the use of advanced technology and precision engineering, which ensures that each board is of the highest standard.In addition to its efficiency, the Gypsum Ceiling Board Production Line also offers a number of environmental benefits. The system is designed to minimize waste and reduce energy consumption, making it a sustainable choice for manufacturers who are looking to reduce their environmental impact. This is in line with [Company Name]'s commitment to sustainability, and is a key selling point for the production line.Another advantage of the Gypsum Ceiling Board Production Line is its ease of use. The system is designed to be user-friendly, with a simple and intuitive interface that makes it easy for operators to control and monitor the production process. This not only increases productivity, but also reduces the need for extensive training, making it an accessible option for manufacturers of all sizes.The introduction of the Gypsum Ceiling Board Production Line is a significant development for the industry, and one that is sure to have a lasting impact. By combining advanced technology, efficiency, and sustainability, [Company Name] has once again proven itself to be a leader in the field of gypsum board production equipment. With this latest offering, manufacturers can expect to see improvements in their production processes, as well as their bottom line.Overall, the Gypsum Ceiling Board Production Line by [Company Name] represents a new era in manufacturing, one that is characterized by innovation, efficiency, and sustainability. This is a system that has the potential to revolutionize the industry, and one that is sure to be welcomed by manufacturers around the world. As the demand for high-quality gypsum ceiling boards continues to grow, the introduction of this advanced production line could not have come at a better time.

High-quality Gypsum Ceiling Board Machine from China<TextView>Title 2: Superior Gypsum Ceiling Board Machine Manufactured in China

China Gypsum Ceiling Board Machine (we will refer to it as the "Machine" for the purpose of this article) has been making waves in the construction industry with its advanced technology and high-quality products. The Machine, which is manufactured by [], has established itself as a leading provider of gypsum ceiling board manufacturing equipment in the market.With its headquarters located in China, [], the company has been at the forefront of innovation in the construction sector for years. The Machine is a testament to their commitment to delivering state-of-the-art products that meet the needs of their customers.The Machine is designed to produce high-quality gypsum ceiling boards, which are commonly used in interior construction for their durability and aesthetic appeal. With its advanced technology and precise manufacturing process, the Machine has set a new standard for gypsum ceiling board production.One of the key features of the Machine is its efficiency. It is capable of producing large quantities of gypsum ceiling boards in a short amount of time, making it an ideal choice for manufacturers looking to increase their production capacity.In addition to its high-speed production capabilities, the Machine also boasts a high level of precision and accuracy. This ensures that every gypsum ceiling board produced is of the highest quality, free from defects or imperfections.Another standout feature of the Machine is its versatility. It is capable of producing a wide range of gypsum ceiling board designs, allowing manufacturers to cater to different customer preferences and market demands. This flexibility has made the Machine a popular choice among construction companies and contractors.The Machine is also known for its reliability and low maintenance requirements. Its robust design and durable components make it a long-term investment for manufacturers, offering reliable performance and minimal downtime.In addition to its impressive technical capabilities, the Machine is also backed by comprehensive customer support and after-sales service from []. This ensures that customers receive the necessary assistance and guidance to make the most of their investment in the Machine.As a result of its advanced technology, high-quality production, and exceptional customer support, the Machine has earned a strong reputation in the construction industry. It has become a preferred choice for manufacturers looking to enhance their production capabilities and deliver superior gypsum ceiling boards to their clients.The success of the Machine can also be attributed to the continuous innovation and research efforts of []. The company is dedicated to staying ahead of the curve in the construction sector, constantly developing new technologies and solutions to meet the evolving needs of the industry.Looking ahead, the Machine is expected to continue making a significant impact on the construction industry, setting new standards for gypsum ceiling board production and contributing to the advancement of interior construction. With its cutting-edge technology and unwavering commitment to quality, the Machine is well-positioned to remain a leader in its field for years to come.In conclusion, the Machine from [] is a standout example of Chinese innovation and excellence in the construction industry. Its advanced technology, high-quality production, and comprehensive support have made it a preferred choice for manufacturers looking to elevate their gypsum ceiling board production. As the construction sector continues to evolve, the Machine is poised to play a pivotal role in shaping the future of interior construction.

High Quality 2 Inch XPS Foam Board Machine at Competitive Prices

The demand for XPS foam board machinery has been increasing in the market due to the growing construction industry and the need for insulation materials. In response to this demand, () is pleased to announce the release of their new 2 Inch XPS foam board machine. This new machine is designed to meet the needs of the market and provide high-quality XPS foam board for various construction and insulation applications.The 2 Inch XPS foam board machine is a state-of-the-art technology that is designed to produce high-density foam boards with precision and efficiency. It is equipped with advanced features that ensure the production of consistent and high-quality foam boards. The machine is also designed to be easy to operate and maintain, making it an ideal choice for manufacturers looking to enhance their production capabilities.One of the key features of the new 2 Inch XPS foam board machine is its production capacity. With this machine, manufacturers can produce a large volume of foam boards in a short amount of time, making it an ideal choice for meeting the demands of the market. The machine is also designed to be energy-efficient, helping manufacturers reduce their operating costs and improve their overall efficiency.In addition to its production capabilities, the 2 Inch XPS foam board machine is also designed to produce foam boards with excellent thermal insulation properties. This makes it an ideal choice for construction and insulation applications where high thermal performance is required. The machine is also designed to produce foam boards with high compressive strength, making them suitable for use in various construction projects.() is a leading manufacturer of XPS foam board machinery, with a strong reputation for producing high-quality and reliable machines. With over [number] years of experience in the industry, () has a deep understanding of the market and the needs of manufacturers. The company is committed to providing innovative and high-performance machinery that meets the evolving needs of the industry.The release of the new 2 Inch XPS foam board machine reflects ()'s dedication to innovation and its commitment to providing the market with advanced machinery. The company's team of experienced engineers and technicians have worked tirelessly to develop this new machine, ensuring that it meets the highest standards of quality and performance. With this new addition to their product lineup, () is well-positioned to meet the growing demand for XPS foam board machinery in the market.In conclusion, the release of the new 2 Inch XPS foam board machine by () is set to have a significant impact on the market. With its advanced technology, high production capacity, and excellent thermal insulation properties, this machine is poised to become a popular choice for manufacturers in the construction and insulation industry. ()'s commitment to innovation and quality is evident in this new release, and the company is poised to continue leading the market with its advanced XPS foam board machinery.

High Quality XPS Foam Board Production Line at Wholesale Prices

Wholesale Xps Foam Board Production Line Available for PurchaseThe global market for XPS foam board production line has seen a significant surge in demand in recent years, driven by the growing need for energy-efficient and sustainable building materials. As a response to this trend, a leading manufacturer has announced the availability of wholesale XPS foam board production lines, providing an opportunity for businesses to meet the rising market demand for this product.The XPS foam board production line is a key component in the manufacturing process of extruded polystyrene (XPS) foam boards, which are widely used in the construction industry for insulation and other applications. With the increasing focus on energy efficiency and sustainable building practices, the demand for XPS foam boards has been on the rise, creating a lucrative market opportunity for manufacturers and suppliers.The wholesale availability of XPS foam board production lines will enable businesses to capitalize on this growing market demand by establishing or expanding their production capacity. This move is expected to benefit not only the manufacturers of XPS foam boards but also the construction industry as a whole, as it will help meet the need for high-quality insulation materials to improve the energy efficiency of buildings.The production line offered by the company is known for its advanced technology, high efficiency, and reliable performance, making it a valuable asset for businesses looking to enter or expand in the XPS foam board market. The production line is capable of producing XPS foam boards with various specifications and sizes, catering to the diverse needs of customers in the construction industry.In addition to the wholesale availability of XPS foam board production lines, the company also provides comprehensive technical support and after-sales service to ensure the successful implementation and operation of the production line. This includes assistance with installation, training, and maintenance, as well as troubleshooting and spare parts supply, to help businesses maximize the performance and longevity of their production equipment.With a solid reputation in the industry and a track record of delivering high-quality products and services, the company is well-positioned to meet the needs of businesses seeking to invest in XPS foam board production lines. Its extensive experience and expertise in the manufacturing and supply of XPS foam board production equipment make it a trusted partner for businesses looking to capitalize on the opportunities in the market.The wholesale availability of XPS foam board production lines is expected to have a positive impact on the construction industry, as it will contribute to the availability of high-quality insulation materials for building projects. This, in turn, will help improve the energy efficiency and environmental sustainability of buildings, supporting the global push for greener and more sustainable construction practices.In conclusion, the wholesale availability of XPS foam board production lines presents a promising opportunity for businesses to meet the growing market demand for this essential building material. With advanced technology, high efficiency, and comprehensive support services, the production lines offered by the company are well-suited for businesses looking to enter or expand in the XPS foam board market. This development is expected to benefit the construction industry by enhancing the availability of energy-efficient and sustainable building materials, contributing to a more environmentally friendly built environment.

Affordable Foam Board Making Machine Factories for XPS

Cheap XPS Foam Board Making Machine FactoriesIn recent years, the demand for XPS foam board has been on the rise due to its versatile applications in the construction industry. In order to meet the increasing demand, several factories have been established to manufacture XPS foam board making machines. These factories have been playing a crucial role in the production and distribution of affordable and high-quality XPS foam board making machines.One of the leading XPS foam board making machine factories is located in China, where the company has gained a reputation for providing top-notch machines at competitive prices. The company has been at the forefront of technological advancements in the field of XPS foam board making machines and has been serving customers worldwide.The XPS foam board making machines produced by the company are known for their efficiency, durability, and precision. The machines are designed to produce XPS foam boards of various sizes and densities, catering to the diverse needs of the construction industry. In addition, the company offers customization options, allowing customers to tailor the machines according to their specific requirements.The XPS foam board making machine factories have been instrumental in the advancement of the construction industry, as they have made it possible for contractors and builders to access high-quality XPS foam board making machines at affordable prices. This has not only contributed to the growth of the construction industry but has also led to the development of eco-friendly and energy-efficient buildings.The XPS foam board making machine factories are committed to providing exceptional customer service, offering technical support, and maintenance services to ensure the smooth operation of their machines. Furthermore, the factories have a strong focus on continuous research and development, aiming to improve the efficiency and performance of their machines.In addition to manufacturing XPS foam board making machines, the factories also offer training and consultation services to their customers, equipping them with the necessary knowledge and skills to maximize the potential of the machines. This level of support and dedication sets the XPS foam board making machine factories apart from the competition, making them the go-to choice for construction companies and contractors.With the increasing demand for XPS foam board, the XPS foam board making machine factories are poised to play a significant role in the construction industry. Their commitment to innovation, quality, and affordability has made them indispensable partners for construction companies looking to enhance their production capabilities.In conclusion, the XPS foam board making machine factories have emerged as key players in the advancement of the construction industry. With their dedication to providing affordable and high-quality machines, they have become crucial enablers for the production of XPS foam board. As the demand for eco-friendly and energy-efficient construction materials continues to grow, the XPS foam board making machine factories are expected to play an even more prominent role in shaping the future of the industry. Their commitment to excellence and customer satisfaction makes them the preferred choice for construction companies and contractors worldwide.For more information on the XPS foam board making machine factories, please visit their website {} for details on their products and services.

Top Affordable Pvc Gypsum Ceiling Board Machine Manufacturers

The demand for affordable and high-quality PVC gypsum ceiling board machines is on the rise, and Cheap PVC Gypsum Ceiling Board Machine Factories (name removed for privacy) are stepping up to the challenge. With a reputation for providing top-notch machinery at competitive prices, they are making a name for themselves in the industry.The company, which was founded in the early 2000s, has established itself as one of the leading manufacturers of PVC gypsum ceiling board machines in the market. Their products are known for their reliability, efficiency, and affordability, making them a popular choice among businesses looking to invest in this type of machinery.The Cheap PVC Gypsum Ceiling Board Machine Factory has a state-of-the-art manufacturing facility, equipped with the latest technology and machinery to produce high-quality products. Their team of experienced engineers and technicians are dedicated to ensuring that each machine meets the highest standards of quality and performance.In addition to their focus on quality, the company also places a strong emphasis on customer satisfaction. They understand the importance of providing excellent customer service and support, and they work closely with their clients to understand their specific needs and requirements. This allows them to tailor their products to meet the unique demands of each customer, further enhancing their reputation as a reliable and customer-oriented manufacturer.The Cheap PVC Gypsum Ceiling Board Machine Factory offers a wide range of products to cater to the diverse needs of their clients. Their product line includes a variety of PVC gypsum ceiling board machines, each designed to meet different production capacities and specifications. They also offer customization options for clients who have specific requirements for their machinery.One of the key factors that sets the Cheap PVC Gypsum Ceiling Board Machine Factory apart from its competitors is its commitment to innovation. They continuously invest in research and development to improve their products and stay ahead of industry trends. This dedication to innovation has resulted in the development of cutting-edge machinery that delivers superior performance and efficiency.The company's dedication to quality, customer satisfaction, and innovation has earned them a strong reputation in the industry. They have built a loyal customer base and have established long-standing relationships with many businesses in the global market.Furthermore, the Cheap PVC Gypsum Ceiling Board Machine Factory understands the importance of environmental sustainability. They have implemented eco-friendly practices in their manufacturing process, such as reducing waste and energy consumption. They are committed to playing their part in promoting a greener and more sustainable manufacturing industry.As the demand for PVC gypsum ceiling board machines continues to grow, the Cheap PVC Gypsum Ceiling Board Machine Factory is well-positioned to meet this demand. Their commitment to quality, customer satisfaction, innovation, and sustainability sets them apart as a reliable and reputable manufacturer in the industry.In conclusion, Cheap PVC Gypsum Ceiling Board Machine Factory (name removed) is a leading manufacturer of high-quality, affordable PVC gypsum ceiling board machines. Their dedication to quality, customer satisfaction, innovation, and sustainability makes them a trusted choice for businesses looking to invest in this type of machinery. With a strong reputation in the industry, they are well-positioned to meet the growing demand for their products and continue to make a positive impact on the manufacturing sector.

Calcium Silicate Board Production Line - Hard Board Making Machine - Building Material Manufacturing Machinery - Product Details on Kskuntai.com

Hebei, China - Kskuntai.com, a leading manufacturer of building materials, has announced the release of its state-of-the-art Calcium Silicate Board Production Line. This cutting-edge technology is designed to facilitate the production of high-quality Calcium Silicate Boards that meet international standards.The Calcium Silicate Board Production Line is a vital part of the overall manufacturing process. This innovative machinery is designed to produce a variety of building materials, including Hard Board, Calcium Silicate Board, and several others. The production line is a fully automated system that ensures that the final product is of the highest quality, with a smooth surface, uniform thickness, and precise edges.One of the unique features of this production line is that it can handle different board thicknesses and sizes with ease. The company uses advanced technology in board making, which ensures that each board is of consistent quality with excellent mechanical performance and insulation properties. The production line also has a high yield, with low energy consumption, making it an efficient and cost-effective solution for manufacturing Calcium Silicate Boards.In addition, this production line is equipped with a variety of safety features to create a safe working environment. The line has advanced monitoring systems to ensure that the machine is running smoothly at all times. There are also emergency shutdown systems in place that can immediately bring the machine to a halt in case of any malfunction.According to an official from Kskuntai.com, “Our Calcium Silicate Board Production Line is the result of our commitment to excellence. We believe that it is our responsibility to provide our customers with the best possible quality products. Our production line is not only efficient but also eco-friendly. We have taken several steps to ensure that it is energy-efficient and minimizes waste.”The Calcium Silicate Board Production Line is a significant addition to Kskuntai.com’s range of manufacturing solutions. With this latest technology, the company can produce high-quality Calcium Silicate Boards to meet the growing demand for eco-friendly and sustainable building materials. These Calcium Silicate Boards are ideal for use in walls, ceilings, floors, and various other applications in the construction industry.Kskuntai.com is a leading manufacturer and supplier of building materials, operating in over 30 countries worldwide. The company prides itself on providing innovative and reliable solutions to its customers. With a focus on quality, efficiency, and sustainability, the company continues to demonstrate its commitment to excellence.In conclusion, the Calcium Silicate Board Production Line is a cutting-edge technology that has a significant impact on the construction industry. Kskuntai.com’s latest machinery ensures the production of high-quality Calcium Silicate Boards that meet international standards. With its energy-efficient and eco-friendly features, the production line is an efficient and sustainable solution for the manufacture of building materials.

Effective Slurry Distribution for Multiple Screens: PU Dewatering Screen with Vibrating Motor

As the demand for high-quality mineral fiber ceiling board increases, so does the need for efficient and reliable production equipment. Fortunately, there are now several top-grade Mineral Fiber Ceiling Board Machine factories that offer state-of-the-art production machinery and systems designed to meet the demands of modern manufacturing.One of the best ways to achieve high-quality ceiling boards is by using mineral fiber materials, which are known for their sound absorption, fire resistance, and thermal insulation properties. These materials are derived from naturally occurring minerals, such as basalt, perlite, and volcanic rock, which are then processed and combined with various binders, such as starch or resin.To produce mineral fiber ceiling boards, a Mineral Fiber Ceiling Board Machine is used to mix and form the materials into panels or tiles of varying sizes and densities. These machines utilize advanced technologies, such as heating and pressing, to create a strong and durable product that meets the required specifications.When selecting a Mineral Fiber Ceiling Board Machine factory, it is essential to consider some critical factors that will ensure optimal performance, reliability, and cost-effectiveness. Some of these factors include:Quality of the MachinesA high-quality Mineral Fiber Ceiling Board Machine should be durable, reliable, and easy to operate. The quality of the materials used in the manufacturing process is also critical, as low-quality materials can lead to frequent breakdowns and maintenance issues.Production CapacityThe production capacity of the Mineral Fiber Ceiling Board Machine should meet the needs of your manufacturing facility. It is essential to choose a machine that can handle your desired output without compromising on quality or efficiency.Maintenance and SupportChoosing a reputable Mineral Fiber Ceiling Board Machine factory that offers reliable maintenance and technical support ensures minimal downtime and maximum productivity. It is essential to choose a factory that provides regular maintenance and repair services and offers quick response times in case of any technical issues.Cost-effectivenessThe cost of the equipment and its maintenance should be within your budget. Choosing a Mineral Fiber Ceiling Board Machine factory that offers affordable solutions without compromising on quality or efficiency is critical to the success of your manufacturing plant.ConclusionMineral fiber ceiling board production has come a long way in recent years, thanks to advanced Mineral Fiber Ceiling Board Machine technology. By selecting a quality Mineral Fiber Ceiling Board Machine factory, you can ensure that your manufacturing plant produces high-quality, cost-effective, and efficient mineral fiber ceiling boards. Contact a reputable factory today to get the best mineral fiber ceiling board production machinery for your facility.

High-Quality Mgo Board Equipment Pricing Guide

Mgo Board Equipment Pricelist Revealed by Leading ManufacturerAs a leading manufacturer in the construction materials industry, our company has recently announced the release of the pricelist for our state-of-the-art Mgo board equipment. This news has generated tremendous excitement within the industry, as the Mgo board equipment is known for its high quality and efficiency in production.The Mgo board, also known as magnesium oxide board, is a type of building material that has been gaining popularity due to its impressive fire resistance, mold resistance, and strength. As the demand for Mgo board continues to rise, our company has been at the forefront of providing advanced equipment for the manufacturing process.Our Mgo board equipment pricelist includes a range of machinery and tools that are essential for the production of high-quality Mgo boards. This includes the Mgo board production line, which is designed to efficiently mix raw materials, form the boards, and complete the curing process. Additionally, our pricelist also features cutting-edge equipment for surface finishing, edge sealing, and board stacking, ensuring that manufacturers have everything they need to produce superior Mgo boards.One of the key highlights of our Mgo board equipment pricelist is the competitive pricing. Our company is committed to providing cost-effective solutions for manufacturers looking to invest in Mgo board production. By offering a comprehensive range of equipment at competitive prices, we aim to support the growth of businesses within the construction materials industry.Furthermore, our company takes pride in the quality and reliability of our Mgo board equipment. Each piece of machinery is carefully engineered and tested to ensure optimal performance and durability. With our advanced equipment, manufacturers can enhance their production capabilities and meet the increasing demand for Mgo boards in the market.In addition to the release of the pricelist, our company also wishes to highlight our dedication to superior customer service. We understand that investing in new equipment is a significant decision for any business, which is why we strive to provide exceptional support to our customers. Whether it is technical assistance, training, or maintenance, our team is committed to helping manufacturers maximize the potential of their Mgo board equipment.Overall, the release of the Mgo board equipment pricelist marks an important milestone for our company as we continue to lead the way in providing innovative solutions for the construction materials industry. With our high-quality equipment, competitive pricing, and commitment to customer satisfaction, we are confident that manufacturers will find value in investing in our Mgo board production machinery.In conclusion, the unveiling of the Mgo board equipment pricelist by our company represents a significant opportunity for manufacturers to enhance their production capabilities and meet the growing demand for high-quality Mgo boards. We are excited to offer our advanced machinery and tools at competitive prices, further solidifying our position as a trusted provider of Mgo board equipment in the industry. As the construction materials market continues to evolve, our company remains dedicated to empowering manufacturers with the best solutions for Mgo board production.

Durable Gypsum Cornice Making Machine for Moisture-Proof House Decoration

In recent years, the demand for moisture-proof house decoration has been on the rise, as people seek to protect their homes from potential water damage and create a more comfortable living environment. To meet this growing need, {} has developed a state-of-the-art Gypsum Cornice Making Machine, designed to produce moisture-proof cornices that are perfect for house decoration.{} is a leading manufacturer and supplier of machinery and equipment for the construction and decoration industry. With years of experience and a commitment to innovation, the company has earned a reputation for excellence and reliability in the market. Their Gypsum Cornice Making Machine is the latest addition to their product line, and it promises to revolutionize the way moisture-proof house decoration is done.The machine is designed to produce gypsum cornices that are not only visually appealing but also highly resistant to moisture, making them an ideal choice for house decoration. The use of high-quality materials and advanced technology ensures that the cornices are durable and long-lasting, providing homeowners with a cost-effective solution for protecting their homes from water damage.One of the key features of the Gypsum Cornice Making Machine is its ability to produce a wide range of designs and patterns, allowing for greater flexibility and customization in house decoration. Whether it's a simple, classic design or a more intricate and ornate pattern, the machine can accommodate various styles and preferences, catering to the diverse needs of homeowners and decorators.Moreover, the machine is equipped with advanced moisture-proofing technology, ensuring that the gypsum cornices are able to withstand high humidity levels and resist mold and mildew growth. This not only enhances the longevity of the cornices but also contributes to a healthier indoor environment for the residents of the house.In addition to its technical capabilities, the Gypsum Cornice Making Machine is designed for easy operation and maintenance, making it an accessible and user-friendly option for businesses and professionals in the construction and decoration industry. Its efficient production process and low energy consumption also contribute to its cost-effectiveness, providing a valuable asset for companies looking to enhance their product offerings and expand their market reach.With the launch of the Gypsum Cornice Making Machine, {} has once again demonstrated its commitment to delivering superior quality and innovative solutions to the construction and decoration industry. The machine is set to raise the standards for moisture-proof house decoration, offering a reliable and efficient means of producing high-quality gypsum cornices that meet the demands of modern homeowners and businesses.As the demand for moisture-proof house decoration continues to grow, {} is well-positioned to capitalize on this trend and provide industry-leading solutions that set new benchmarks for excellence and performance. With its Gypsum Cornice Making Machine, the company is paving the way for a new era of house decoration, where quality, durability, and aesthetics converge to create spaces that are not only visually stunning but also resilient to the challenges of moisture and humidity.In conclusion, by introducing the Gypsum Cornice Making Machine, {} is reaffirming its status as a pioneer and innovator in the construction and decoration industry. The machine's advanced capabilities and superior performance make it a valuable asset for businesses and professionals looking to stay ahead of the curve and meet the evolving needs of the market. With {} at the forefront, the future of moisture-proof house decoration looks brighter than ever.