Top Gypsum Ceiling Board Machine: A Comprehensive Guide

By:Admin

The company behind this cutting-edge machine is a well-established and reputable manufacturer with a strong presence in the construction industry. With years of experience and expertise in the field, they have gained a solid reputation for delivering high-quality products and excellent customer service. Their commitment to innovation and continuous improvement has led to the development of the gypsum ceiling board machine, which promises to revolutionize the production of gypsum ceiling boards.

The gypsum ceiling board machine is equipped with the latest technology and state-of-the-art features that ensure high efficiency and precision in the production process. It is designed to operate with minimal human intervention, making it easy to use and highly productive. The machine is also built to withstand the rigors of high-volume production, ensuring a reliable and consistent output of gypsum ceiling boards.

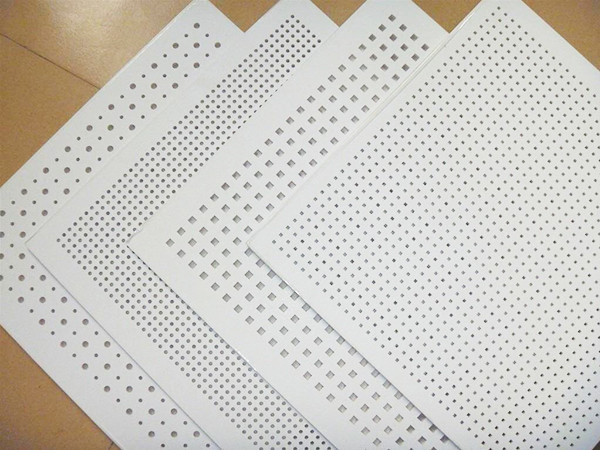

One of the key advantages of the gypsum ceiling board machine is its ability to produce customized designs and patterns, allowing for a high degree of flexibility in meeting the specific requirements of different construction projects. Whether it's a simple and elegant design for a residential property or a more intricate and ornate pattern for a commercial building, the machine can produce a wide variety of gypsum ceiling boards to suit different aesthetic preferences.

Furthermore, the gypsum ceiling board machine is designed with sustainability in mind. It employs environmentally friendly production processes and materials, ensuring that the production of gypsum ceiling boards has minimal impact on the environment. This is in line with the company's commitment to sustainability and corporate social responsibility, further enhancing its appeal to environmentally conscious customers.

In addition to its advanced features and environmental benefits, the gypsum ceiling board machine is also backed by a comprehensive support system provided by the manufacturer. This includes training and technical assistance to ensure that customers can fully utilize the machine and maximize its production capabilities. With a dedicated team of experts on hand to provide guidance and support, customers can be confident in the performance and reliability of the gypsum ceiling board machine.

Overall, the introduction of the gypsum ceiling board machine represents a significant advancement in the construction industry. With its cutting-edge technology, customizable design options, sustainability, and strong support system, it is set to raise the bar for the production of gypsum ceiling boards. As the demand for high-quality interior decoration materials continues to grow, this innovative machine is well positioned to meet the needs of construction projects both now and in the future.

Company News & Blog

Automated Equipment for Affordable Gypsum Cornice Designs

Cheap Gypsum Cornice Design Automatic Equipment Promises Enhanced EfficiencyIn line with the latest technological advancements in the construction industry, {Company Name} is proud to announce the launch of its new Cheap Gypsum Cornice Design Automatic Equipment. This state-of-the-art machinery is set to revolutionize the gypsum cornice manufacturing process, promising enhanced efficiency and cost-effectiveness.With a focus on innovation and customer satisfaction, {Company Name} has been a leading manufacturer and supplier of construction equipment for several years. By leveraging cutting-edge technology and maintaining a strong commitment to quality, the company has established itself as a trusted name in the industry.The newly unveiled Cheap Gypsum Cornice Design Automatic Equipment is designed to streamline the production process, allowing for faster and more efficient manufacturing of gypsum cornices. This fully automated system eliminates the need for manual intervention, thereby reducing the margin for error and ensuring consistent quality across all products.In addition to enhancing productivity, the automatic equipment also offers cost-saving benefits for manufacturers. By optimizing resource utilization and minimizing wastage, companies can expect to see a significant reduction in production expenses, ultimately contributing to improved profitability.Furthermore, the advanced technology incorporated into the equipment enables customization of gypsum cornice designs, catering to the diverse needs and preferences of customers. This versatility allows manufacturers to stay ahead of market trends and offer a wide range of options to their clients, thereby enhancing their competitive edge.{Company Name} has always placed a strong emphasis on sustainability, and the new automatic equipment is no exception. By optimizing energy consumption and minimizing environmental impact, the company is committed to ensuring that its products align with eco-friendly practices, contributing to a greener and more sustainable future for the construction industry.Speaking about the significance of the new equipment, a spokesperson for {Company Name} stated, "We are thrilled to introduce our Cheap Gypsum Cornice Design Automatic Equipment, which represents a significant leap forward in the manufacturing process. Our aim is to empower our customers with the latest technology, allowing them to enhance their operations, reduce costs, and deliver superior quality products to their clients."The spokesperson added, "We believe that this new equipment will not only benefit manufacturers in terms of efficiency and cost-effectiveness but also contribute to overall industry growth. By providing the means for innovation and customization, we are paving the way for a more dynamic and competitive market landscape."In line with its commitment to customer satisfaction, {Company Name} offers comprehensive support and training for the operators of the automatic equipment, ensuring that they are equipped with the knowledge and skills to maximize its potential. This dedication to customer service has been a hallmark of the company's success, establishing long-lasting relationships with clients and partners.As the construction industry continues to evolve, it is imperative for manufacturers to embrace technological advancements that drive progress and innovation. The introduction of the Cheap Gypsum Cornice Design Automatic Equipment by {Company Name} is a testament to its dedication to staying at the forefront of industry trends and providing solutions that empower its customers.With its promise of enhanced efficiency, cost-effectiveness, and customization capabilities, the new automatic equipment is poised to make a significant impact on the gypsum cornice manufacturing sector. {Company Name} looks forward to the opportunities that lie ahead, as it continues to push the boundaries of what is possible in the construction equipment industry.

High-quality Gypsum Ceiling Board Machine Offers Efficient Production

China Gypsum Ceiling Board Machine (CGCBM) has become a leading provider of high-quality gypsum ceiling board manufacturing machines in the industry. The company has earned a reputation for delivering reliable and efficient solutions to meet the growing demand for gypsum ceiling boards globally. With a strong focus on innovation and customer satisfaction, CGCBM is committed to continuously improving its products and services to remain at the forefront of the market.The gypsum ceiling board machine is designed to produce high-quality gypsum ceiling boards with precision and efficiency. It utilizes advanced technology and state-of-the-art manufacturing processes to ensure that each board meets the highest standards of quality and durability. With the ability to produce a wide range of sizes and designs, the machine offers flexible solutions to meet the specific needs of customers in different markets.One of the key features of the gypsum ceiling board machine is its high level of automation, which allows for seamless operation and consistent output quality. The machine is equipped with advanced control systems and monitoring devices to ensure that each board meets the required specifications. This level of automation also helps to improve production efficiency and reduce the risk of defects, resulting in cost savings for customers.In addition to its advanced technical capabilities, CGCBM also provides comprehensive services to support its customers throughout the entire manufacturing process. From initial consultation and planning to installation and after-sales support, the company is committed to delivering a seamless and reliable experience for its customers. This includes technical training and support to ensure that customers are fully equipped to operate the gypsum ceiling board machine effectively.With a strong emphasis on quality and performance, CGCBM has established itself as a trusted partner for customers in the gypsum ceiling board manufacturing industry. The company is dedicated to delivering solutions that help its customers enhance their production capabilities and achieve their business goals. By leveraging its expertise and experience, CGCBM continues to drive innovation and progress in the industry.As the global demand for gypsum ceiling boards continues to rise, CGCBM is well-positioned to capitalize on this trend with its advanced gypsum ceiling board machine. The company remains committed to providing leading-edge solutions that enable its customers to stay ahead in the competitive market. With a focus on continuous improvement and customer satisfaction, CGCBM is poised to maintain its leadership position in the industry and expand its presence in new markets.Overall, China Gypsum Ceiling Board Machine (CGCBM) is a company that is dedicated to delivering high-quality, reliable, and efficient gypsum ceiling board manufacturing solutions. With a strong focus on innovation and customer satisfaction, the company is well-positioned to meet the growing demand for gypsum ceiling boards globally. By leveraging its advanced technology, comprehensive services, and commitment to excellence, CGCBM continues to drive progress and innovation in the industry.

PVC Laminated Gypsum Board - Plasterboard Ceiling in 595*595 and 603*603mm Sizes

PVC Laminated Gypsum Ceiling Tiles have become increasingly popular due to their durability and aesthetic appeal. It is a type of construction material that is made by laminating a thin sheet of polyvinyl chloride (PVC) onto a gypsum board to create a waterproof and fire-resistant roof covering. With the demand for PVC Laminated Gypsum Ceiling Tiles increasing, the production of these tiles has also increased, leading to a rise in Pvc Laminated Gypsum Ceiling Tiles machine factories.PVC Laminated Gypsum Ceiling Tiles are widely used in commercial and residential buildings, including offices, shopping malls, hospitals, homes, and more. Apart from being waterproof and fire-resistant, these ceiling tiles are also easy to install and maintain. They are available in different sizes and patterns, making them suitable for various interior design requirements.As the demand for PVC Laminated Gypsum Ceiling Tiles continues to soar, more and more factories are emerging to meet the market's needs. These factories are equipped with advanced technology and machines that produce high-quality PVC Laminated Gypsum Ceiling Tiles at affordable prices. The emergence of these factories has made it possible for builders and construction companies to get PVC Laminated Gypsum Ceiling Tiles at a cheaper price.If you are looking for PVC Laminated Gypsum Ceiling Tiles at a competitive price, then you should consider buying from a factory. These factories offer better prices than retailers as they eliminate middlemen. Therefore, they can sell products at a cheaper price while maintaining their quality standards.When selecting a factory to buy PVC Laminated Gypsum Ceiling Tiles, it is essential to consider the factory's reputation. You should choose a factory with a good reputation for providing high-quality products. Also, choose a factory that offers a wide range of products to select from to ensure you get your desired product.In conclusion, PVC Laminated Gypsum Ceiling Tiles have become a popular construction material due to their durability, aesthetic appeal, and ease of installation and maintenance. With the increasing demand for these tiles, more and more Pvc Laminated Gypsum Ceiling Tiles machine factories are emerging, providing high-quality products at affordable prices. Therefore, if you are looking for a cheaper option, then you should consider purchasing from these factories. Remember, when selecting a factory to purchase from, consider the factory's reputation and range of products to get the best quality.

Easy-to-Operate Machine for Making Decorative Gypsum Plaster Mouldings and Cornices

Decorative Gypsum Plaster Mouldings / Cornice Making Machine Easy To Operation: A Game-Changer in the Construction IndustryThe construction industry has experienced a tremendous transformation over the years. The introduction of innovative technologies and equipment has revolutionized the way building structures are erected. Indeed, this industry has become more efficient, cost-effective, and environmentally friendly. Recently, a Chinese company, Hebei Greens Building Material Technology Development Co., Ltd., has launched a cutting-edge machine designed to make decorative gypsum plaster mouldings and cornices with ease. The Decorative Gypsum Plaster Mouldings / Cornice making machine is a game-changer in the construction industry. This machine is programmed to achieve precision and high-quality production of gypsum plaster mouldings and cornices. Its operation is straightforward, even for novices. This newly introduced machine has attracted a lot of attention from the construction industry in China and beyond.Hebei Greens Building Material Technology Development Co., Ltd. is a renowned Chinese company with rich experience in producing building materials. The company has always strived to manufacture high-quality building materials at competitive prices. In recent years, Hebei Greens has invested heavily in research and development to enhance its product offerings, including the Decorative Gypsum Plaster Moulding/Cornice Making Machine. This newly introduced machine is a perfect example of Hebei Greens' commitment to innovation and product excellence. The Decorative Gypsum Plaster Moulding/Cornice Making Machine boasts of several unique features that set it apart from other cornice-making devices on the market. One of its most impressive features is its ease of use. Even novice operators can operate the machine to achieve precision and high-quality production of gypsum plaster mouldings and cornices.Not only is the Decorative Gypsum Plaster Moulding/Cornice Making machine easy to use, but it also boasts of high production efficiency and cost-effectiveness. With the machine's automated production process, users can produce high volumes of decorative gypsum plaster mouldings and cornices in a short period. This feature is especially critical for large-scale construction projects with tight deadlines.Furthermore, the quality of the gypsum plaster mouldings and cornices produced by this machine is unparalleled. The Decorative Gypsum Plaster Moulding/Cornice Making machine produces high-quality, smooth, and durable gypsum plaster creations that can withstand the test of time. In conclusion, the Decorative Gypsum Plaster Mouldings / Cornice Making Machine, manufactured by Hebei Greens Building Material Technology Development Co., Ltd., is a game-changer in the construction industry. Its ease of operation, high production efficiency, and unparalleled quality make it an attractive option for construction companies and contractors worldwide. Moreover, its competitive pricing makes it a cost-effective investment option for businesses looking to save on construction costs. In a world where innovations and efficiency dominate every industry, the Decorative Gypsum Plaster Moulding/Cornice Making Machine is a timely and necessary addition to the building and construction sector.

Top Co2 Foam Xps Extrusion Board Line for High-Quality Insulation

The Best Co2 Foam XPS Extrusion Board Line, developed by [Company], is set to revolutionize the foam board manufacturing industry with its innovative technology and advanced features. This new product is designed to meet the growing demand for high-performance and sustainable insulation materials in construction and other industries.[Company] is a leading manufacturer of extrusion equipment and has a strong track record of developing cutting-edge solutions for the foam board industry. With years of experience and expertise in the field, the company has continuously worked to improve the efficiency and sustainability of their products, and the Best Co2 Foam XPS Extrusion Board Line is another step in that direction.The new extrusion board line offers several key features that set it apart from traditional products. One of the most significant is the incorporation of CO2 foam technology, which allows for the production of a closed-cell foam that is more durable and has a higher R-value than standard extruded polystyrene (XPS) foam boards. This not only makes the foam boards more effective in insulation applications but also reduces their environmental impact by using CO2 as a blowing agent instead of the more common HFCs or HCFCs.Furthermore, the Best Co2 Foam XPS Extrusion Board Line is equipped with state-of-the-art control systems and automation, allowing for precise and consistent manufacturing processes. This results in higher quality foam boards that meet the strictest industry standards, ensuring the safety and performance of the final products.In addition to its technical features, the new extrusion board line also offers greater flexibility in production, allowing for customized board sizes and thicknesses to meet the specific requirements of different projects and applications. This means that builders and contractors can rely on [Company] to provide them with high-quality foam boards that are tailored to their unique needs, ultimately contributing to the efficiency and durability of their constructions.[Company] has always been committed to sustainability and environmental responsibility, and the development of the Best Co2 Foam XPS Extrusion Board Line is a testament to that commitment. By reducing the carbon footprint of foam board production and ensuring the recyclability of its products, [Company] is taking a proactive approach to addressing the environmental challenges facing the industry.Furthermore, the company has also invested in research and development to continuously improve the performance and efficiency of its foam board manufacturing processes. By embracing innovation and cutting-edge technology, [Company] is positioning itself as an industry leader in the production of sustainable and high-performance insulation materials.The release of the Best Co2 Foam XPS Extrusion Board Line is a significant milestone for [Company] and the foam board industry as a whole. With its advanced technology, superior performance, and commitment to sustainability, this new product is set to reshape the market and provide customers with a more reliable and environmentally friendly solution for their insulation needs.As [Company] continues to push the boundaries of foam board manufacturing, it is clear that the Best Co2 Foam XPS Extrusion Board Line is just the beginning of a new era of sustainable and high-performance insulation materials. With a focus on innovation, quality, and environmental responsibility, [Company] is poised to make a lasting impact on the industry and contribute to a more sustainable future for construction and beyond.

Affordable Gypsum Cornice Making Machine for Sale

The demand for gypsum cornice machines has been on the rise in recent years as the construction industry continues to grow. With this in mind, a company based in China has developed a solution to meet this demand with their affordable and efficient gypsum cornice machine.The machine, which was developed by the company, is designed to produce high-quality gypsum cornices at a low cost. This is achieved through the use of advanced manufacturing techniques and high-quality materials, resulting in a machine that is both reliable and cost-effective.The company has a long history of providing innovative solutions for the construction industry. With a team of experienced engineers and designers, they have been able to develop a wide range of products that meet the needs of their customers. Their commitment to quality and customer satisfaction has earned them a solid reputation in the industry.In addition to their gypsum cornice machine, the company also offers a range of other products and services. These include a variety of construction machinery, equipment, and tools, all of which are designed to improve efficiency and reduce costs for their customers.One of the key features of their gypsum cornice machine is its ease of use. The machine is designed to be simple and straightforward, allowing for quick and efficient production of gypsum cornices. This is particularly important for small and medium-sized construction companies that may not have the resources to invest in more complex machinery.Furthermore, the machine is also highly customizable, allowing for the production of a wide range of gypsum cornices in different shapes and sizes. This flexibility allows construction companies to meet the specific needs of their projects, whether they are working on residential, commercial, or industrial buildings.The affordability of the gypsum cornice machine is also a major selling point for the company. By keeping the cost of the machine low, they are able to provide their customers with a high-quality product at a competitive price. This has made their machine a popular choice for construction companies and contractors looking to streamline their operations and save on production costs.The company is committed to providing excellent customer service and support to all of their customers. They have a dedicated team of professionals who are available to answer any questions and provide assistance with the installation and operation of their machines. This level of support has helped them build long-lasting relationships with their customers, many of whom continue to rely on their products and services for their construction needs.In conclusion, the affordable gypsum cornice machine developed by the company is an excellent option for construction companies looking to improve their production processes and reduce costs. With its high-quality construction and ease of use, this machine has become a popular choice in the industry. The company's commitment to customer satisfaction and support further solidifies their position as a leader in the construction machinery market.

Fully Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine

The cutting-edge technology and innovative design of the Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine have been making waves in the industry. This state-of-the-art machine features advanced automatic functions that streamline the laminating process, making it more efficient and cost-effective for manufacturers.The Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine has been designed to meet the growing demand for high-quality laminated gypsum boards in the construction and interior design industries. With its fully automatic operation, this machine is capable of laminating PVC film and aluminum foil onto gypsum boards with precision and consistency, ensuring a flawless finish every time.The advanced features of this machine include automatic feeding, gluing, laminating, cutting, and stacking, reducing the need for manual labor and significantly increasing production capacity. This makes it an ideal investment for manufacturers looking to improve their productivity and meet the increasing demand for laminated gypsum boards.The Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine also offers a high degree of customization, allowing manufacturers to adjust the settings and parameters to meet their specific production requirements. This flexibility makes it suitable for a wide range of applications, from small-scale operations to large manufacturing facilities.In addition to its advanced technological capabilities, this machine is also designed with efficiency and sustainability in mind. It features energy-saving components and a streamlined production process, reducing waste and minimizing environmental impact. This aligns with the company's commitment to sustainable manufacturing practices and reducing its carbon footprint.The cutting-edge technology and innovative design of the Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine have positioned the company as a leader in the industry. With a focus on research and development, the company has consistently introduced new and improved products to meet the evolving needs of its customers.As a leading manufacturer of laminating equipment, the company has established a strong reputation for delivering high-quality, reliable machines that streamline the production process and improve overall efficiency. Its dedication to innovation and customer satisfaction has earned it the trust and loyalty of customers around the world.With a global presence and a diverse portfolio of products, the company continues to expand its reach and strengthen its position as a market leader. Its commitment to excellence and investment in cutting-edge technology have allowed it to stay ahead of the competition and anticipate the needs of the industry.In conclusion, the Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine represents a significant advancement in the manufacturing process for laminated gypsum boards. Its innovative design, advanced automatic functions, and commitment to efficiency and sustainability make it an ideal investment for manufacturers seeking to improve their production capabilities and meet the growing demand for high-quality laminated products.As the industry continues to evolve, the company remains at the forefront of innovation, driving progress and setting new standards for excellence. With its dedication to research and development, commitment to customer satisfaction, and a strong global presence, the company is well-positioned to lead the way in the laminating equipment market for years to come.

High-Quality Lamination Machines for Gypsum Board Glue Spreading and mgo Board Lamination Production in China

China's industrial landscape is constantly evolving, with a host of manufacturers and suppliers emerging in different sectors of the industry. In recent years, the Chinese manufacturing industry has seen a significant surge in demand for high-quality laminating equipment and machinery.Amid this market growth, China is emerging as a frontrunner in the laminating machinery and equipment space. In particular, the creation of high-quality Gypsum Board Glue Spreading Board and MgO Board Lamination Machines is a testament to the country's manufacturing prowess.The Gypsum Board Glue Spreading Board and MgO Board Lamination Machines are being manufactured using advanced technology and innovative techniques that are highly efficient, reliable, and durable. These machines are designed to be easy to operate and maintain, making them ideal for businesses that need to increase their production capacity. Additionally, the machines are also very versatile, meaning they can be used in a wide range of industrial settings. This flexibility has made them popular with entrepreneurs looking to start manufacturing businesses in various sectors.The Gypsum Board Glue Spreading Board and MgO Board Lamination Machines are also designed to ensure that they operate safely and securely on the production floor. Each machine is fitted with modern safety features that guarantee protection to operators and other employees working in the production system. These safety features include automatic shut-offs, alarms, and other safety measures that prevent accidents and reduce the risk of injury.Companies producing these laminating machines adhere to strict quality control guidelines to ensure they comply with international safety and quality standards. Each machine is tested comprehensively to guarantee that they meet the required standards before they are released to the market.The manufacturers of Gypsum Board Glue Spreading Board and MgO Board Lamination Machines in China take pride in their products. With a keen focus on innovative technology and high-quality standards, these manufacturers provide businesses with reliable and long-lasting machines to enhance their production capabilities.The success of these machines in the global market has led to a significant increase in demand. As a result, manufacturers have been optimizing their production capacity to keep up with the ever-growing demand for these machines. Many businesses from around the world are sourcing their laminating machinery from China to benefit from high-quality machines.The Chinese producer of the laminating machines, which earned significant success in recent years, has been producing some of the most cutting-edge industrial machinery through advanced manufacturing procedures and techniques. Their Gypsum Board Glue Spreading Board and MgO Board Lamination Machines are some of the most advanced and reliable products on the market.These machines are designed to offer exceptional versatility, safety, and reliability, making them ideal for businesses of all sizes. Whether it is a small startup or a large conglomerate, these lamination machines can optimize productivity and enhance manufacturing operations.In conclusion, the Gypsum Board Glue Spreading Board and MgO Board Lamination Machines from China are an excellent testimony to the country’s continued excellence in the manufacturing industry. These laminating machines deliver exceptional quality and performance, guaranteeing long-lasting reliability and ease of operation. With surging demand for these machines globally, China is set to continue its dominance in the machinery and equipment manufacturing industry for the foreseeable future.

Durable and Eco-Friendly Board Production Line

Mgo Board Production Line Revolutionizing the Construction IndustryIn recent years, there has been a growing demand for construction materials that are not only durable and cost-effective but also environmentally friendly. In response to this demand, {Company Name}, a leading manufacturer in the construction industry, has introduced an innovative Mgo Board Production Line that is set to revolutionize the way buildings are constructed.The Mgo Board Production Line has been developed with state-of-the-art technology and is capable of producing high-quality magnesium oxide (Mgo) boards at an unprecedented speed and efficiency. These boards are widely used in the construction industry as an alternative to traditional materials such as plywood and drywall, due to their superior strength, fire resistance, and resistance to mold and mildew.One of the key features of the Mgo Board Production Line is its ability to produce boards of varying thickness and size, making it highly versatile and suitable for a wide range of construction applications. This flexibility allows builders and developers to customize the boards according to their specific project requirements, thereby reducing waste and optimizing material usage.Furthermore, the production line is equipped with advanced quality control systems that ensure the boards meet the highest industry standards. This means that builders can have confidence in the reliability and consistency of the boards, leading to safer and more durable construction projects.In addition to its technical capabilities, the Mgo Board Production Line is also designed with sustainability in mind. The production process minimizes waste and energy consumption, and the boards themselves are made from natural and renewable materials, making them a more eco-friendly choice compared to traditional construction materials. This aligns with {Company Name}'s commitment to environmental stewardship and corporate social responsibility.{Company Name} is dedicated to continuously improving its production processes and product offerings, and the introduction of the Mgo Board Production Line is a testament to this commitment. The company's investment in innovation and technology underscores its position as a leader in the construction industry, and sets a new standard for the production of high-performance, sustainable building materials.With the launch of the Mgo Board Production Line, {Company Name} aims to not only meet the current needs of the construction industry but also to anticipate and address future trends and challenges. The company recognizes the importance of staying ahead of the curve in a rapidly evolving market and is confident that the new production line will further strengthen its position as a trusted partner for builders and developers around the world.As the construction industry continues to evolve, the demand for innovative and sustainable building materials is only expected to grow. The Mgo Board Production Line represents a significant step forward in meeting this demand, offering a solution that combines performance, efficiency, and environmental responsibility.In conclusion, the introduction of the Mgo Board Production Line by {Company Name} marks a significant milestone in the construction industry. With its advanced technology, versatility, and sustainability, the production line is poised to transform the way buildings are constructed, setting a new standard for quality and performance. As builders and developers seek more efficient and eco-friendly solutions, the Mgo Board Production Line presents a compelling option that is poised to shape the future of construction.

Affordable Gypsum Ceiling Board Making Machine Price Revealed in Latest News

Title: Cutting-Edge Gypsum Ceiling Board Machine Revolutionizes Affordable DecorationIntroduction:In a bid to offer cost-effective solutions to the construction industry, a leading company has unveiled its latest innovation – the state-of-the-art Cheap Decoration Gypsum Ceiling Board Machine. Due to its exceptional features and competitive pricing, this revolutionary device is well-positioned to transform the gypsum ceiling board manufacturing sector and provide an affordable avenue for interior decoration.Company Overview:With a focus on research, development, and manufacturing of construction machinery, our company has gained recognition as a leading player in the industry. Boasting a team of experts and advanced technology, we have continually strived to meet the evolving needs of our customers. Committed to quality, reliability, and affordability, our company constantly endeavors to provide innovative solutions to the market.The Cheap Decoration Gypsum Ceiling Board Machine:Our latest product, the Cheap Decoration Gypsum Ceiling Board Machine, has garnered attention due to its unique capabilities that enhance the production of gypsum ceiling boards. Engineered with cutting-edge technology, this advanced machine offers a cost-effective solution to meet the rising demand for decorative interior construction materials.Key Features:1. High Efficiency: The machine demonstrates admirable productivity, boasting an efficient production capacity that reduces manufacturing time and boosts overall output. This enables faster completion of interior decoration projects and meets strict deadlines.2. Precision Cutting: The device is equipped with a precision cutting system, ensuring accurate dimensions for each gypsum ceiling board produced. This feature eliminates the need for additional trimming or adjustments, resulting in substantial time and cost savings.3. Versatile Design: Our gypsum ceiling board machine offers versatility, accommodating various board dimensions, thicknesses, and patterns. This flexibility gives customers the freedom to fulfill unique interior design requirements while maintaining cost-efficiency.4. User-Friendly Interface: Equipped with an intuitive interface, the machine ensures ease of operation for professionals and technicians. Minimal training is required to navigate its features, thereby reducing labor and training costs.5. Automation and Control: Automated features significantly reduce the reliance on manual labor, further streamlining the manufacturing process. The machine's control systems and sensors ensure consistent product quality, reducing material wastage and minimizing errors.Benefits of the Cheap Decoration Gypsum Ceiling Board Machine:The introduction of this innovative machine brings forth several advantages to the gypsum ceiling board manufacturing sector and beyond:1. Cost Reduction: The affordability of the machine and optimized manufacturing processes result in significant cost reductions for manufacturers. This, in turn, translates to lower prices for consumers seeking gypsum ceiling boards, making interior decoration more budget-friendly.2. Enhanced Product Quality: The machine's precision cutting capabilities, combined with the consistent automation and control systems, ensure superior product quality and dimensional accuracy. This enables manufacturers to deliver high-quality gypsum ceiling boards, meeting customer expectations.3. Accelerated Project Timelines: With increased production capacity and efficient manufacturing processes, interior decoration projects can be completed within shorter timelines. Contractors and builders can meet project deadlines effectively, enhancing overall customer satisfaction.4. Sustainable Solution: The machine's precision and automated control systems reduce material wastage, contributing to a more sustainable manufacturing process. By minimizing resource consumption, manufacturers can lessen their environmental impacts.Conclusion:The introduction of the Cheap Decoration Gypsum Ceiling Board Machine marks a significant milestone in the construction industry. Its remarkable features and competitive pricing are set to revolutionize the gypsum ceiling board manufacturing sector and make interior decoration more accessible. As consumers seek cost-effective solutions, this innovative machine offers improved efficiency, superior product quality, and environmental sustainability. With the unveiling of this cutting-edge technology, our company is proud to contribute to the evolution of the construction industry and meet the ever-growing demand for affordable yet exceptional decorative materials.