Top Factories Cutting XPS Foam Production Lines - Find Out Why

By:Admin

The company, a leading manufacturer in the foam industry, has been a pioneer in producing high-quality XPS foam products for various applications. With a strong commitment to innovation and customer satisfaction, the company has built a solid reputation for delivering reliable and efficient foam solutions to its clients.

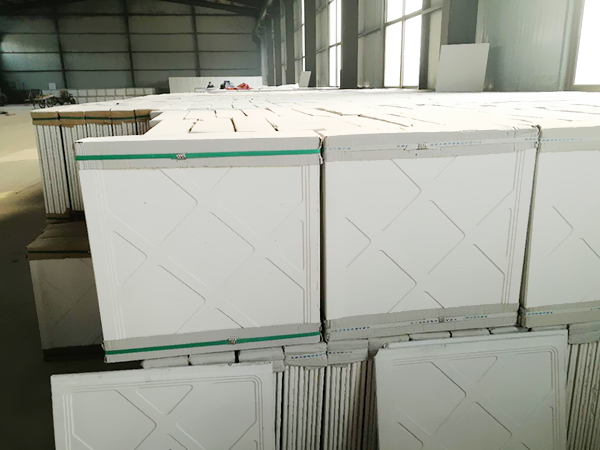

Despite the success and recognition in the market, the company has recognized the need to reevaluate its production line and make strategic decisions to enhance its overall business performance. Cutting Xps Foam Production Line Factories is a part of this strategic initiative to drive efficiency, reduce costs, and optimize resources effectively.

By streamlining its production line, the company aims to improve operational efficiency, reduce lead times, and enhance product quality. The decision to cut Xps Foam Production Line Factories is not taken lightly, and the company has carefully evaluated the potential impact on its employees, clients, and business partners.

The company understands that such decisions can have ripple effects on various stakeholders, and it is committed to managing the transition in a responsible and supportive manner. The company plans to provide support to the affected employees and explore opportunities for redeployment within the organization or provide assistance in finding alternative employment opportunities.

Furthermore, the company reassures its clients and business partners that the decision to cut Xps Foam Production Line Factories will not compromise its commitment to delivering high-quality products and excellent customer service. The company remains dedicated to meeting the needs of its clients and maintaining its position as a trusted and reliable supplier in the market.

In addition to the operational changes, the company is also investing in research and development to innovate new products and explore sustainable and environmentally friendly solutions. The company believes that focusing on innovation and sustainability will not only benefit the business but also contribute to a greener and more sustainable future for the industry and the society as a whole.

The decision to Cut Xps Foam Production Line Factories aligns with the company's long-term vision and commitment to staying ahead of market trends, adapting to changing business dynamics, and ensuring sustained growth and profitability. The company believes that by making such strategic decisions, it can position itself for long-term success and continued leadership in the foam industry.

As the company moves forward with its strategic initiatives, it remains confident in its ability to navigate the evolving market landscape and continue to provide value to its customers. The company aims to emerge stronger and more resilient, with a renewed focus on its core strengths and a clear vision for the future.

In conclusion, Cutting Xps Foam Production Line Factories is a strategic move for the company to enhance its operational efficiency, reduce costs, and drive sustainable growth. The company remains committed to its clients, employees, and business partners and is confident in its ability to navigate the transition responsibly and emerge as a stronger and more competitive player in the foam industry.

Company News & Blog

Mineral Fiber Ceiling Board Machine Receives CE Certification and Priced Competitively

Ce Certification Mineral Fiber Ceiling Board Machine PricelistThe mineral fiber ceiling board machine is a piece of equipment that is used in the production of high-quality mineral fiber ceiling boards. These boards are widely used in the construction industry for their soundproofing and fireproofing properties. The ce certification mineral fiber ceiling board machine pricelist is now available at our company, and we are proud to offer our clients this highly advanced equipment at a competitive price.Our company has been in the business of manufacturing and supplying mineral fiber ceiling board machines for over two decades. We specialize in the design and production of high-quality machines that are built to last. Our machines are not only reliable and efficient, but they are also environmentally friendly and energy-saving.We have a team of highly skilled engineers who work around the clock to ensure that our machines are up to the highest standards. Each machine is rigorously tested before it leaves our factory to ensure that it meets our strict quality control standards. We are confident in the durability and reliability of our machines and offer our clients a comprehensive warranty program that covers any defects in workmanship or materials.Our mineral fiber ceiling board machines are designed to be easy to use, with a user-friendly interface that simplifies the production process. We understand that time is of the essence in the construction industry, which is why we have designed our machines to be as automated as possible. This not only speeds up the production process but also reduces the risk of errors or accidents. Our machines can produce up to 6,000 square meters of mineral fiber ceiling boards per day.The mineral fiber ceiling board machine pricelist is highly competitive, reflecting our commitment to providing our clients with the best value for their investment. We offer a range of machines to suit different production needs and budgets. Our clients can choose from our standard range of machines or opt for a custom-built machine that is tailored to their specific needs.In addition to our mineral fiber ceiling board machines, we also offer a range of ancillary equipment, including cutting machines, edge-sealing machines, laminating machines, and packing machines. This allows our clients to have everything they need to complete the production process under one roof, making it easier and more efficient.At our company, we are committed to providing our clients with exceptional customer service. We understand that the purchase of a mineral fiber ceiling board machine is a significant investment, and we are here to support our clients every step of the way. We offer technical support, training, and maintenance services to ensure that our clients get the most out of their investment.In conclusion, the ce certification mineral fiber ceiling board machine pricelist is now available at our company, and we are proud to offer our clients this highly advanced equipment at a competitive price. Our machines are built to last and are designed to be easy to use, environmentally friendly, and energy-saving. We offer a comprehensive warranty program, ancillary equipment, and exceptional customer service to ensure that our clients get the best value for their investment. Contact us today to learn more about our mineral fiber ceiling board machines and how we can help your business grow.

Newly Developed 2 Inch XPS Foam Board Machine in China

Title: Chinese Manufacturer Introduces Cutting-edge 2 Inch XPS Foam Board MachineIntroductionChina is known for its rapid advancements in manufacturing technologies, and one such example is the recent introduction of the state-of-the-art 2-inch XPS foam board machine. Developed by a leading Chinese company, this innovative machinery represents a significant breakthrough in the foam insulation industry. With its advanced features and superior quality, the 2-inch XPS foam board machine is poised to revolutionize the insulation market and meet the growing demand for energy-efficient building materials worldwide.Company: A Pioneer in Manufacturing ExcellenceWith a rich history in producing high-quality machinery, the company behind the 2-inch XPS foam board machine has consistently been at the forefront of manufacturing excellence. With a strong commitment to research and development, the company has successfully delivered cutting-edge solutions to various industries worldwide.Harnessing the latest advancements in technology, the company strives to promote sustainable and environmentally friendly practices in the manufacturing arena. By adhering to international quality standards, the company has gained recognition for its exceptional products that consistently exceed customer expectations.Advancements in XPS Foam Board MachineryXPS foam board, an acronym for Extruded Polystyrene insulation, is a popular choice for its superior insulation properties and durability. The 2-inch XPS foam board machine developed by the Chinese manufacturer is specifically designed to meet the increasing demand for insulation materials in the construction industry.1. Enhanced Efficiency: The state-of-the-art XPS foam board machine maximizes efficiency by utilizing advanced automation technology. This ensures smooth operations, increased output, and reduced labor requirements, streamlining the manufacturing process.2. Precise Control System: The machine's precision control system allows for accurate configuration and adjustment of critical parameters, ensuring consistent foam quality and thickness. This advanced control system also aids in minimizing material waste, contributing to cost efficiency.3. Innovative Extrusion Process: The 2-inch XPS foam board machine employs a cutting-edge extrusion process, resulting in foam boards with superior insulation properties. The precise process ensures uniform cell structure, high compressive strength, and excellent resistance to moisture, making it an ideal choice for a wide range of applications.4. Energy Efficiency: The machine's design incorporates energy-saving technologies, promoting sustainability within the production process. By optimizing power consumption and reducing resource wastage, the manufacturing unit significantly lowers carbon emissions, aligning with global environmental goals.Global Impact and Market PotentialThe introduction of the 2-inch XPS foam board machine by the Chinese manufacturer holds immense potential for the global insulation market. As the demand for energy-efficient construction materials continues to rise, this cutting-edge machinery offers a promising solution to meet the growing needs of builders, architects, and contractors around the world.The foam insulation market is projected to see substantial growth, driven by government energy regulations and the increasing focus on sustainable building practices. The 2-inch XPS foam board machine positions the Chinese manufacturer at the forefront of this industry, providing them with a competitive advantage and significant market share.ConclusionWith its commitment to manufacturing excellence and innovation, the Chinese company's introduction of the 2-inch XPS foam board machine revolutionizes the foam insulation industry. This cutting-edge machinery, with its advanced features, precision control, and energy efficiency, is set to meet the rising global demand for sustainable building materials. The impact of this revolutionary technology on the insulation market is poised to drive growth and shape environmentally conscious construction practices worldwide.

Mineral Fiber Sheet Equipment: Latest Prices and Pricelist

Mineral fiber sheet equipment pricelist was recently released by a well-known company in the industry. This pricelist is expected to have a significant impact on the market and industry standards. The company, (company name), is known for its high-quality mineral fiber sheet equipment and has been a trusted supplier to the industry for many years.The pricelist includes a range of equipment for the production of mineral fiber sheets, including cutting machines, drying ovens, and other essential machinery. The company has always been at the forefront of innovation and has a proven track record of providing reliable and efficient equipment to its customers.The release of the pricelist comes at a time when the demand for mineral fiber sheets is on the rise. With the growing focus on sustainable and energy-efficient building materials, mineral fiber sheets have become an increasingly popular choice for insulation and acoustical applications. As a result, the market for mineral fiber sheet equipment is also experiencing growth, and companies are looking for reliable and cost-effective solutions to meet this demand.According to the pricelist, (company name) offers competitive pricing for its mineral fiber sheet equipment, making it an attractive option for businesses looking to invest in high-quality machinery. The company also provides excellent customer service and technical support, ensuring that its customers have a smooth and efficient experience from the purchase of equipment to its installation and maintenance.In addition to its extensive range of equipment, (company name) also offers customization options to meet the specific needs of its customers. This flexibility is a crucial factor for businesses looking to invest in equipment that can adapt to their unique production requirements. The company's commitment to providing tailored solutions sets it apart from its competitors and has contributed to its strong reputation in the industry.(Company name) has a long-standing history of delivering reliable and durable mineral fiber sheet equipment. The company's machines are known for their efficiency, precision, and low maintenance requirements, making them a cost-effective choice for businesses of all sizes. Moreover, the company prioritizes the use of high-quality materials and state-of-the-art technology in its manufacturing process, ensuring that its equipment meets the highest industry standards.The release of the pricelist is expected to generate significant interest from businesses looking to invest in mineral fiber sheet equipment. With its reputation for quality and reliability, (company name) is well-positioned to capitalize on the growing market demand and expand its customer base. Additionally, the company's commitment to innovation and customer satisfaction sets it apart as a top choice for businesses in the industry.In conclusion, the release of the pricelist for mineral fiber sheet equipment by (company name) is a significant development for the industry. With its competitive pricing, high-quality machinery, and commitment to customer satisfaction, the company is poised to maintain its leading position in the market. As the demand for mineral fiber sheets continues to grow, businesses can rely on (company name) to provide them with reliable and efficient equipment to meet their production needs.

Innovative CO2 XPS Foam Board Machine for Next Generation

scoop.New Generation CO2 XPS Foam Board Machine Set to Revolutionize the Building Industry[Company Name], a leading engineering company specializing in the manufacturing of plastic extrusion and recycling machines, has unveiled its latest innovation – the new generation CO2 XPS foam board machine.The machine, which was officially launched on August 22, 2021, is set to revolutionize the construction industry with its state-of-the-art technology, energy efficiency, and eco-friendliness.According to [Company Name] CEO, Mr. X, the new generation CO2 XPS foam board machine is a breakthrough in the field of polystyrene foam extrusion. He said, "The machine represents the coming together of cutting-edge technology, green energy, and environmental consciousness. It is our way of contributing to the building of a sustainable future."The CO2 XPS foam board machine is designed to produce extruded polystyrene foam boards, commonly used in the building and construction industry for insulation and other applications. The machine uses a unique closed loop system, where carbon dioxide is used as the blowing agent instead of the traditional HCFC (hydrochlorofluorocarbon). This makes the process more environmentally friendly while reducing the carbon footprint.In addition, the machine is designed to maximize energy efficiency by utilizing a heat recovery system that recycles the heat generated during the extrusion process, which helps to reduce energy consumption and operating costs.The new generation CO2 XPS foam board machine boasts some amazing features that make it stand out among its peers. For example:- It has a high output capacity of up to 500kg/h, making it ideal for large-scale extrusion production.- It has a low density of 28-40 kg/m3.- It can produce extruded polystyrene foam boards with a thickness range of 20-120mm and a width of 600-1200mm, making it more versatile than traditional machines.- It has a highly automated control system that can monitor and control the entire extrusion process, ensuring consistency in quality and quantity.Furthermore, the machine is designed to be user-friendly, with a simple interface that is easy to operate and maintain. It is also highly reliable, with a low maintenance cost, making it an ideal investment for businesses looking to increase their productivity and cut costs.The launch of the new generation CO2 XPS foam board machine comes at a time when there is an increasing global focus on sustainability and environmental responsibility. The use of CO2 as a blowing agent and the heat recovery system are examples of [Brand Name]'s commitment to environmental consciousness while providing a solution that addresses the needs of the construction industry.The new generation CO2 XPS foam board machine has already generated a lot of interest from the building and construction industry, with [Brand Name] receiving numerous inquiries and orders from clients across the globe. This is a testament to the growing demand for sustainable and energy-efficient solutions, and [Brand Name] is well-positioned to meet this demand.In conclusion, the new generation CO2 XPS foam board machine is a game-changer in the extruded polystyrene foam board production industry. With its cutting-edge technology, energy efficiency, and eco-friendly features, it is a step towards building a sustainable future. [Brand Name] is proud to be at the forefront of this innovation, and we look forward to contributing to the growth and development of the construction industry.

Xps Foam Board Extrusion Line in China: Latest News and Updates

China XPS Foam Board Extrusion LineThe demand for XPS foam board is increasing in the construction industry due to its excellent thermal insulation properties. In response to this growing demand, a leading manufacturer in China has announced the launch of a new XPS foam board extrusion line. This state-of-the-art production line is set to revolutionize the manufacturing process of XPS foam boards and meet the rising needs of the construction industry.The newly launched XPS foam board extrusion line is equipped with the latest technology and advanced features to ensure the production of high-quality foam boards. It boasts a high level of automation, which enhances production efficiency while maintaining product consistency. The extrusion line is also designed to minimize energy consumption, making it a cost-effective and eco-friendly solution for XPS foam board production.In addition to its advanced technology, the extrusion line offers a high level of flexibility in product customization. This means that it can produce a wide range of XPS foam boards with varying thicknesses, densities, and specifications to meet the specific requirements of different construction projects. This versatility makes it a valuable asset for manufacturers looking to cater to diverse customer needs.The launch of the XPS foam board extrusion line is expected to have a significant impact on the market. With its production capacity and capabilities, the manufacturer aims to meet the growing demand for XPS foam boards both domestically and internationally. The extrusion line is poised to enhance the company's position as a leading supplier of XPS foam boards in the global market.The company, {}, is a renowned manufacturer of plastic extrusion machinery, with a strong focus on innovation and technology. With years of experience in the industry, the company has built a solid reputation for delivering high-quality and reliable extrusion equipment. Its commitment to research and development has led to the development of cutting-edge solutions that meet the evolving needs of various industries, including construction, packaging, and automotive.The launch of the XPS foam board extrusion line further demonstrates the company's dedication to staying ahead of the curve and providing its customers with advanced manufacturing solutions. By investing in state-of-the-art technology, the company aims to not only meet the current market demand for XPS foam boards but also to anticipate future requirements and trends in the construction industry.In addition to the technological advancements offered by the new extrusion line, the company is also committed to providing comprehensive support and service to its customers. This includes technical assistance, training, and aftersales support to ensure the smooth operation of the equipment and the production of high-quality XPS foam boards.The launch of the XPS foam board extrusion line is a testament to the company's dedication to driving innovation in the field of plastic extrusion. By combining its technical expertise with market insights, the company is well-positioned to address the changing needs of the construction industry and continue to be a valued partner for manufacturers looking for reliable and efficient production solutions.As the demand for energy-efficient and sustainable construction materials continues to grow, the launch of the XPS foam board extrusion line comes at a crucial time. It is expected to not only meet the current requirements for high-quality XPS foam boards but also to contribute to the overall advancement of the construction industry by providing a reliable and efficient solution for thermal insulation materials.In conclusion, the launch of the XPS foam board extrusion line by {} marks a significant development in the manufacturing of XPS foam boards. With its advanced technology, flexibility, and commitment to customer support, the company is set to make a lasting impact in the construction industry and reinforce its position as a leading provider of plastic extrusion solutions.

Automated Equipment for Affordable Gypsum Cornice Designs

Cheap Gypsum Cornice Design Automatic Equipment Promises Enhanced EfficiencyIn line with the latest technological advancements in the construction industry, {Company Name} is proud to announce the launch of its new Cheap Gypsum Cornice Design Automatic Equipment. This state-of-the-art machinery is set to revolutionize the gypsum cornice manufacturing process, promising enhanced efficiency and cost-effectiveness.With a focus on innovation and customer satisfaction, {Company Name} has been a leading manufacturer and supplier of construction equipment for several years. By leveraging cutting-edge technology and maintaining a strong commitment to quality, the company has established itself as a trusted name in the industry.The newly unveiled Cheap Gypsum Cornice Design Automatic Equipment is designed to streamline the production process, allowing for faster and more efficient manufacturing of gypsum cornices. This fully automated system eliminates the need for manual intervention, thereby reducing the margin for error and ensuring consistent quality across all products.In addition to enhancing productivity, the automatic equipment also offers cost-saving benefits for manufacturers. By optimizing resource utilization and minimizing wastage, companies can expect to see a significant reduction in production expenses, ultimately contributing to improved profitability.Furthermore, the advanced technology incorporated into the equipment enables customization of gypsum cornice designs, catering to the diverse needs and preferences of customers. This versatility allows manufacturers to stay ahead of market trends and offer a wide range of options to their clients, thereby enhancing their competitive edge.{Company Name} has always placed a strong emphasis on sustainability, and the new automatic equipment is no exception. By optimizing energy consumption and minimizing environmental impact, the company is committed to ensuring that its products align with eco-friendly practices, contributing to a greener and more sustainable future for the construction industry.Speaking about the significance of the new equipment, a spokesperson for {Company Name} stated, "We are thrilled to introduce our Cheap Gypsum Cornice Design Automatic Equipment, which represents a significant leap forward in the manufacturing process. Our aim is to empower our customers with the latest technology, allowing them to enhance their operations, reduce costs, and deliver superior quality products to their clients."The spokesperson added, "We believe that this new equipment will not only benefit manufacturers in terms of efficiency and cost-effectiveness but also contribute to overall industry growth. By providing the means for innovation and customization, we are paving the way for a more dynamic and competitive market landscape."In line with its commitment to customer satisfaction, {Company Name} offers comprehensive support and training for the operators of the automatic equipment, ensuring that they are equipped with the knowledge and skills to maximize its potential. This dedication to customer service has been a hallmark of the company's success, establishing long-lasting relationships with clients and partners.As the construction industry continues to evolve, it is imperative for manufacturers to embrace technological advancements that drive progress and innovation. The introduction of the Cheap Gypsum Cornice Design Automatic Equipment by {Company Name} is a testament to its dedication to staying at the forefront of industry trends and providing solutions that empower its customers.With its promise of enhanced efficiency, cost-effectiveness, and customization capabilities, the new automatic equipment is poised to make a significant impact on the gypsum cornice manufacturing sector. {Company Name} looks forward to the opportunities that lie ahead, as it continues to push the boundaries of what is possible in the construction equipment industry.

Gypsum Cornice Production Line Prices in China

China has emerged as a global leader in the production of gypsum cornice, a key component in the construction industry. With the increasing demand for high-quality gypsum cornice, manufacturers in China have been at the forefront of developing innovative production lines to meet the growing needs of the market. As a result, China's gypsum cornice production line has become a popular choice for builders and contractors around the world.One of the leading companies in China's gypsum cornice production industry is {}, a well-established manufacturer with a strong reputation for delivering top-notch products. The company has recently introduced its latest gypsum cornice production line, which has garnered considerable attention from industry professionals and observers. With its advanced technology and high production capacity, the new production line is expected to set a new standard in the industry.The company's gypsum cornice production line is designed to maximize efficiency and productivity while maintaining the highest standards of quality. The production line is equipped with state-of-the-art machinery and equipment, ensuring that each piece of gypsum cornice is precisely manufactured to meet the exact specifications and requirements of customers. Additionally, the production line incorporates the latest automation and control systems, allowing for seamless operation and minimal human intervention, further enhancing the overall efficiency of the manufacturing process.In addition to its exceptional technical capabilities, the company's gypsum cornice production line is also notable for its environmental sustainability. The production line is designed to minimize waste and energy consumption, incorporating eco-friendly practices to reduce its environmental impact. As sustainability becomes an increasingly important consideration in the construction industry, the company's commitment to environmentally conscious production methods is viewed as a significant advantage in the market.The introduction of the new gypsum cornice production line has generated significant interest among industry professionals and potential customers. With its impressive technical specifications and commitment to quality and sustainability, the production line is poised to make a significant impact on the global gypsum cornice market. Builders and contractors around the world are expected to benefit from the availability of high-quality gypsum cornice produced by the company's advanced production line.In a statement, a spokesperson for the company highlighted the significance of the new gypsum cornice production line, emphasizing its potential to meet the evolving needs of the construction industry. The spokesperson noted that the company is dedicated to delivering the highest quality products to its customers, and the new production line represents a significant step forward in achieving that goal. The company's investment in advanced technology and sustainable manufacturing practices is a reflection of its commitment to innovation and excellence.Industry analysts have also taken note of the company's new gypsum cornice production line, recognizing it as a game-changing development in the industry. The advanced capabilities of the production line and its potential to drive efficiency and quality in gypsum cornice manufacturing have positioned the company as a leading player in the global market. As the demand for high-quality gypsum cornice continues to rise, the company's new production line is anticipated to play a key role in meeting that demand and solidifying China's position as a dominant force in the industry.Overall, the introduction of the new gypsum cornice production line by {} represents a significant milestone in the construction industry. With its advanced technology, commitment to quality and sustainability, and potential to meet the evolving needs of the market, the production line is set to make a lasting impact on the global gypsum cornice industry. Builders, contractors, and industry professionals can look forward to accessing high-quality gypsum cornice products manufactured by the company's state-of-the-art production line, contributing to the advancement of construction practices and standards around the world.

Get the Latest Updates on Certified Plasterboard Ceiling Machines

CE Certification Plasterboard Ceiling Machine Ensuring Quality and Efficiency in Construction Industry[City, Date] – In an era where technological advancements play a significant role in improving efficiency and quality, the introduction of the CE Certification Plasterboard Ceiling Machine by [Company Name] is revolutionizing the construction industry. This state-of-the-art machine is equipped with cutting-edge features, granting construction companies easy access to high-quality plasterboard ceiling production.The CE certification is testament to the machine's adherence to European safety, health, and environmental protection standards. With this certification, [Company Name] demonstrates their commitment to providing reliable and safe equipment, ensuring the utmost satisfaction for their customers.The plasterboard ceiling machine allows construction companies to streamline their production processes, significantly reducing time and labor costs. With its advanced automation capabilities, this machine eliminates the need for manual intervention, resulting in enhanced efficiency and precision. [Company Name], a renowned manufacturer with expertise in construction machinery, has developed this machine to meet the diverse needs of the construction sector.Key Features of the CE Certification Plasterboard Ceiling MachineThe innovative and intelligent design of the plasterboard ceiling machine offers numerous features that make it a standout product in the market. These features include:1. High-Speed Production: The advanced automation system allows the machine to produce plasterboard ceilings at an impressive speed, significantly increasing overall productivity.2. Accurate Measurements: Equipped with precise measurement mechanisms, the machine ensures the outputted plasterboard ceilings meet the required specifications, eliminating rework and wastage.3. Easy Operation: The user-friendly interface of the machine enables effortless operation, reducing the need for specialized training and facilitating the smooth integration of the machine into existing production lines.4. Enhanced Durability: The plasterboard ceiling machine is designed and manufactured with robust and durable materials, providing longevity and reliability for years, reinforcing its status as a wise investment for construction companies.5. Customization Options: [Company Name] acknowledges the diverse needs of their customers. To cater to these requirements, the machine offers customization options, allowing construction companies to produce plasterboard ceilings of various sizes, shapes, and designs.[Company Name] – Industry Leader in Construction MachineryWith a strong presence in the construction machinery sector, [Company Name] has been consistently delivering high-quality and reliable equipment to customers worldwide. The introduction of the CE Certification Plasterboard Ceiling Machine further solidifies their position as an industry leader.[Company Name] values customer satisfaction and ensures that their machines go through rigorous quality checks at every stage of production. By adhering to international standards and cultivating an environment of constant innovation, [Company Name] excels at providing cutting-edge solutions that meet the evolving needs of the construction industry.The company's commitment to research and development, coupled with its extensive expertise, has allowed them to introduce an array of construction machinery that caters to various construction needs. These products have gained recognition for their reliability, efficiency, and cost-effectiveness.ConclusionThe CE Certification Plasterboard Ceiling Machine by [Company Name] is set to bring a wave of transformation to the construction industry. With its advanced features, commitment to quality, and compliance with international standards, construction companies can guarantee enhanced productivity and efficiency in plasterboard ceiling production.[Company Name] continues to be a frontrunner in providing construction machinery that meets the highest industry standards. Embracing innovation and quality, they reaffirm their dedication to assisting companies in achieving excellence in construction projects.

High quality PVC laminated gypsum ceiling tiles machine factories

PVC Laminated Gypsum Ceiling Tiles Machine Factories have been making headlines recently, and for good reason. These factories are at the forefront of producing high-quality, versatile, and durable ceiling tiles that are perfect for a variety of applications. With their state-of-the-art machinery and innovative techniques, these factories are changing the game when it comes to ceiling tile production.One such factory that has been making waves in the industry is the one operated by {}. With years of experience and a commitment to excellence, this factory has become a leader in the production of PVC laminated gypsum ceiling tiles. Their dedication to quality and customer satisfaction has set them apart from the competition and has helped them to establish a strong reputation in the industry.The machinery used in the production process is one of the key factors that sets this factory apart. With advanced technology and precision engineering, they are able to produce ceiling tiles that are not only visually stunning but also incredibly durable and long-lasting. This is essential for a product that is designed to provide both aesthetic appeal and practical functionality in a variety of settings.In addition to their cutting-edge machinery, the factory also prides itself on its commitment to sustainability. They are continually looking for ways to minimize their environmental impact and reduce waste in the production process. This dedication to sustainability has earned them recognition and praise from both customers and industry peers, and has further solidified their position as a forward-thinking and responsible manufacturer.One of the most impressive aspects of this factory is the level of customization and flexibility they offer. Their machinery is capable of producing a wide range of sizes, designs, and finishes, allowing them to meet the unique needs and preferences of their customers. Whether it's a sleek, modern look for a commercial space or a more traditional aesthetic for a residential setting, this factory can deliver the perfect ceiling tiles for any project.It's not just the machinery and production capabilities that make this factory stand out, however. The team behind the operation is equally impressive. Comprised of skilled and knowledgeable professionals, they bring a level of expertise and attention to detail that is second to none. From the initial design phase right through to the final quality checks, every member of the team is dedicated to ensuring that the end product meets the highest standards.With all of these factors combined, it's easy to see why PVC Laminated Gypsum Ceiling Tiles Machine Factories, such as the one operated by {}, are making such a big impact in the industry. Their commitment to quality, sustainability, customization, and customer satisfaction has earned them a strong reputation and a loyal customer base. As they continue to push the boundaries of what is possible in ceiling tile production, there's no doubt that they will remain a force to be reckoned with in the years to come.

Affordable Full Automatic Laminating Machine for PVC Aluminum Foil Gypsum-Board

Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine - Revolutionizing the IndustryIn recent years, the construction industry has witnessed a growing demand for high-quality gypsum-board laminating machines that can efficiently produce laminated panels for various applications. Meeting this demand, [Company Name]'s state-of-the-art Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine has revolutionized the industry with its advanced technology and superior performance.This innovative machine is designed to streamline the production process, offering a cost-effective and efficient solution for laminating gypsum boards with PVC aluminum foil. With its fully automatic operation, it can significantly increase productivity and reduce labor costs, making it an ideal choice for manufacturers looking to enhance their production capabilities.One of the standout features of this machine is its precision and accuracy in laminating PVC aluminum foil onto gypsum boards. The advanced technology incorporated in the machine ensures uniform lamination, resulting in high-quality panels that meet the industry's stringent standards. This is crucial for applications where the aesthetics and durability of the laminated panels play a vital role, such as in residential and commercial construction projects.In addition to its superior lamination capabilities, the Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine is also designed for ease of use and maintenance. Its user-friendly interface and intuitive controls make operation simple and hassle-free, while its robust construction and durable components ensure long-lasting performance with minimal downtime.Furthermore, this cutting-edge machine is equipped with safety features to protect operators and maintain a safe working environment. From emergency stop mechanisms to protective guards, [Company Name] has prioritized the well-being of its users while ensuring optimal productivity.The Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine aligns with [Company Name]'s commitment to delivering innovative solutions that cater to the evolving needs of the construction industry. With a focus on research and development, the company has continuously strived to push the boundaries of technology, resulting in game-changing products that elevate the industry standards.[Company Name] has established itself as a leader in the manufacturing of advanced machinery for the construction sector, with a reputation for excellence and reliability. The Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine is a testament to the company's dedication to engineering cutting-edge solutions that address the challenges faced by manufacturers in the industry.By investing in this groundbreaking machine, manufacturers can expect to enhance their production capabilities, improve the quality of their laminated panels, and ultimately gain a competitive edge in the market. The Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine is a game-changer for the construction industry, setting new benchmarks for efficiency, quality, and performance.In conclusion, [Company Name]'s Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine represents a significant advancement in the field of construction machinery. With its advanced technology, precision lamination capabilities, and user-friendly design, this machine is poised to transform the way gypsum boards are laminated, offering manufacturers a reliable and efficient solution to meet the demands of the industry. As the construction sector continues to evolve, [Company Name] remains at the forefront of innovation, driving progress and delivering solutions that shape the future of the industry.