Physical Foamed Board Production Line Price List: Get the Best Deals Now!

By:Admin

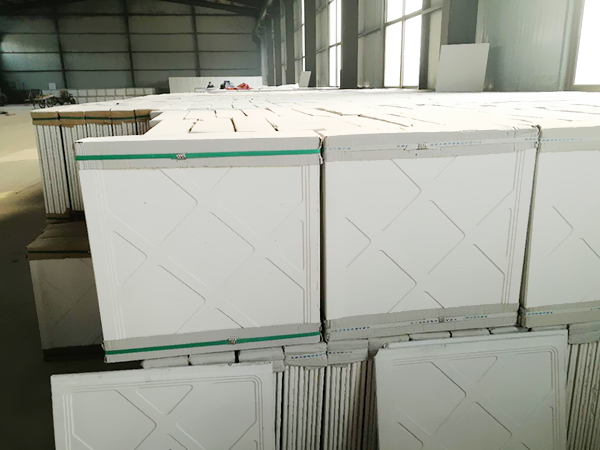

The production line is equipped with state-of-the-art machinery and equipment, allowing for the efficient and precise manufacturing of Xps physical foamed boards. The system is designed to produce boards with excellent thermal insulation properties, high compressive strength, and low water absorption, making them ideal for a wide range of applications.

One of the key features of this production line is its ability to produce boards with a dense, closed-cell structure, which significantly enhances their insulation performance. This makes them an ideal choice for use in buildings and construction projects, where energy efficiency and thermal insulation are of utmost importance.

Furthermore, the production line is capable of producing boards of various thicknesses and densities, allowing for flexibility in meeting the specific requirements of different applications. Whether it is for insulating walls, roofs, floors, or for use in other industrial applications, this production line can tailor the boards to meet the desired specifications.

In addition to its advanced manufacturing capabilities, the Xps Physical Foamed Board Production Line also boasts a high degree of automation and efficiency. This means that the production process is not only streamlined but also highly reliable, ensuring consistent quality and performance of the boards.

The company behind this cutting-edge production line has a strong track record of delivering high-quality machinery and equipment to industries worldwide. With years of experience and expertise in the field, they have earned a reputation for excellence and innovation, and their products are widely recognized for their reliability and performance.

Furthermore, the company is committed to providing comprehensive after-sales support, including installation, training, and technical assistance, ensuring that their customers can maximize the benefits of their investment in the production line.

As the demand for high-quality thermal insulation materials continues to grow, the Xps Physical Foamed Board Production Line is set to play a pivotal role in meeting this demand. Its advanced technology, efficient production process, and exceptional quality make it a preferred choice for industries looking to enhance their insulation capabilities.

In conclusion, the Xps Physical Foamed Board Production Line represents a significant advancement in the manufacturing of physical foamed boards. With its advanced technology, efficient production process, and exceptional quality, it is poised to meet the growing demand for high-quality insulation materials in various industries. Supported by a reputable and experienced company, this production line is set to deliver reliable and innovative solutions to meet the evolving needs of the market.

Company News & Blog

Affordable Co2 Xps Foam Board Machine Factories for New Generation Technology

Cheap New Generation Co2 Xps Foam Board Machine FactoriesIn recent years, there has been a growing demand for XPS foam board, a widely used building material known for its thermal insulation properties. To meet this demand, numerous factories have emerged to produce XPS foam board machines. Among these factories, {} stands out as a leader in providing affordable and efficient new generation CO2 XPS foam board machines.With a focus on innovation and customer satisfaction, {} has established itself as a reliable source for high-quality XPS foam board machines at competitive prices. The company's commitment to providing cost-effective solutions has allowed it to become a preferred choice for customers worldwide.{} takes pride in its state-of-the-art manufacturing facilities that are equipped with the latest technology and machinery. This enables the company to produce XPS foam board machines that are not only affordable, but also of superior quality. By utilizing CO2 technology, {} has been able to develop a new generation of XPS foam board machines that are more energy-efficient and environmentally friendly.One of the key advantages of {}'s new generation CO2 XPS foam board machines is their ability to produce boards with higher density and better thermal insulation properties. This makes them suitable for a wide range of applications, including roofing, flooring, and wall insulation. In addition, the machines are designed to be user-friendly, making them easy to operate and maintain.As a customer-focused company, {} places a strong emphasis on providing excellent after-sales service. This includes technical support, training, and spare parts availability to ensure that customers can maximize the performance and lifespan of their XPS foam board machines.In addition to its commitment to quality and affordability, {} prioritizes sustainability in its manufacturing processes. The company takes proactive measures to minimize its environmental impact and reduce carbon emissions. By embracing CO2 technology, {} is able to produce XPS foam board machines in a more eco-friendly manner, contributing to a greener and more sustainable future.With a strong track record of delivering reliable products and services, {} has built a solid reputation in the industry. The company's dedication to innovation, affordability, and sustainability has positioned it as a leading manufacturer of XPS foam board machines.As the demand for XPS foam board continues to rise, {} remains committed to meeting the needs of its customers by continuously improving its products and services. By offering cheap, new generation CO2 XPS foam board machines, the company is contributing to the growth and development of the construction industry.In conclusion, {} has successfully carved a niche for itself in the market by providing affordable and efficient new generation CO2 XPS foam board machines. With a strong focus on innovation, quality, and sustainability, the company has emerged as a reliable partner for customers seeking cost-effective solutions for their XPS foam board production needs. With a bright future ahead, {} is set to continue its success in the industry and make a positive impact on the construction sector.

High-Quality Perforated Plasterboard Machine for Sale in China

China Perforated Plasterboard Machine: Revolutionizing the Construction IndustryThe construction industry is constantly evolving, with new technologies and innovations emerging to improve the efficiency and quality of construction projects. One such innovation is the China Perforated Plasterboard Machine, a cutting-edge piece of equipment that has the potential to revolutionize the construction industry.The China Perforated Plasterboard Machine is a state-of-the-art machine that is designed to produce high-quality perforated plasterboard, also known as drywall or gypsum board. This machine is a game-changer in the construction industry, as it is capable of producing perforated plasterboard at an unprecedented speed and with unmatched precision.The company behind this groundbreaking machine is a leading manufacturer of construction machinery in China. With years of experience in the industry, the company has established itself as a trusted and reliable provider of high-quality construction machinery. Their commitment to innovation and excellence has led to the development of the China Perforated Plasterboard Machine, which is set to transform the way plasterboard is produced and used in construction projects.The China Perforated Plasterboard Machine is a versatile piece of equipment that is suitable for use in a wide range of construction projects. Whether it is used in residential, commercial, or industrial construction, this machine is capable of producing perforated plasterboard that meets the highest quality standards. Its innovative design and advanced technology make it a valuable asset for construction companies looking to enhance their productivity and efficiency.One of the key features of the China Perforated Plasterboard Machine is its speed and accuracy. Unlike traditional methods of producing perforated plasterboard, which can be time-consuming and labor-intensive, this machine is capable of producing large quantities of plasterboard in a fraction of the time. This not only reduces production costs but also enables construction projects to be completed more quickly, saving time and resources for the construction companies.In addition to its speed, the China Perforated Plasterboard Machine is also known for its precision. The machine is equipped with advanced technology that ensures the perforations in the plasterboard are consistent and precise, resulting in a high-quality finished product. This level of precision is crucial in construction projects, as it ensures that the plasterboard can be easily installed and provides a smooth and seamless finish to the walls and ceilings of the building.Furthermore, the China Perforated Plasterboard Machine is designed with ease of use in mind, making it accessible to construction companies of all sizes. Its user-friendly interface and intuitive controls make it easy for operators to learn how to use the machine quickly and efficiently. This means that construction companies can integrate the China Perforated Plasterboard Machine into their operations with minimal disruption and maximum impact.Overall, the China Perforated Plasterboard Machine is set to revolutionize the construction industry by providing construction companies with a reliable and efficient solution for producing high-quality perforated plasterboard. Its speed, precision, and ease of use make it a valuable asset for any construction project, and its potential to streamline construction processes and improve productivity is unparalleled.As the construction industry continues to evolve, the China Perforated Plasterboard Machine stands out as a beacon of innovation and progress. With its advanced technology and unparalleled performance, this machine is set to redefine the way perforated plasterboard is produced and used in construction projects, setting a new standard for efficiency and quality in the industry.

High-Quality Machinery for Mgo Board Production

Mgo Board Machinery Factory is a leading manufacturer of machinery for producing Mgo (Magnesium Oxide) boards. The company has been in the industry for over 20 years and has gained a reputation for producing high-quality and efficient machinery for the construction material industry. The factory is located in an industrial zone, covering an area of 10,000 square meters, and employs over 100 skilled workers.The machinery produced by Mgo Board Machinery Factory is used for the production of Mgo boards, which are widely used in the construction industry for their fire-resistant, waterproof, and durable properties. The company's machinery is designed with the latest technology and is known for its high efficiency and low energy consumption.Recently, the factory has been making headlines in the industry for its latest innovation in Mgo board production machinery. The company has introduced a new fully automated production line that is set to revolutionize the Mgo board manufacturing process. This new production line is capable of producing Mgo boards of various sizes and thickness with minimal human intervention, significantly increasing production efficiency and reducing labor costs.The new automated production line is equipped with state-of-the-art sensors and control systems that ensure the precise mixing of raw materials and accurate pressing of the Mgo boards. The machinery is also designed for easy maintenance and has a user-friendly interface, making it easy for operators to monitor and control the production process.According to the company's spokesperson, the new automated production line is a result of years of research and development. The company's team of engineers and technical experts have worked tirelessly to design and build a production line that meets the growing demand for Mgo boards in the construction industry.The introduction of the new automated production line is expected to have a significant impact on the market. With the increased efficiency and reduced labor costs, manufacturers of Mgo boards will be able to produce higher volumes at a lower cost, making the construction material more affordable and accessible to a wider range of customers.In addition to the new automated production line, Mgo Board Machinery Factory is also known for its excellent after-sales service and technical support. The company has a team of experienced engineers who provide on-site installation and training for customers, ensuring that the machinery is set up and operated correctly for optimal performance.The company's commitment to innovation and customer satisfaction has earned it a strong reputation in the industry. Many Mgo board manufacturers and construction companies rely on the machinery produced by Mgo Board Machinery Factory for their production needs.Looking ahead, Mgo Board Machinery Factory is focused on further research and development to continue improving its machinery and staying ahead of the competition. The company aims to expand its reach to new markets and work closely with customers to meet their specific production requirements.With its latest innovation in Mgo board production machinery, Mgo Board Machinery Factory is set to maintain its position as a leader in the industry and drive the growth of the construction material market. The company's dedication to quality, efficiency, and customer satisfaction makes it a reliable partner for manufacturers and construction companies looking to invest in top-of-the-line machinery for Mgo board production.

Gypsum Board Lamination Machine for Ceiling Board Production - EC21

Gypsum board ceiling tiles are a popular choice for many commercial and residential buildings due to their durability, fire resistance, and ability to be easily transformed to fit any design. Gypsum ceiling board making machines are essential to producing high-quality gypsum board ceiling tiles. In this article, we will discuss the features and benefits of investing in a double side gypsum board ceiling tiles laminating machine.Features and Benefits of Double Side Gypsum Board Ceiling Tiles Laminating Machine1. High-Quality Lamination: Double side gypsum board ceiling tiles laminating machine is designed to produce high-quality laminated gypsum board ceiling tiles. The machine uses advanced technology to ensure that the lamination is even, smooth, and free from bubbles.2. Increased Efficiency: The machine is equipped with high-speed rollers that enable fast lamination of the gypsum board ceiling tiles. This feature helps to increase the production capacity of the machine, reducing the time taken to produce a significant number of tiles.3. Easy to Use: The double side gypsum board ceiling tiles laminating machine is user-friendly, and operators require minimal training to operate the machine. The machine's simple design and automated features make it easy for operators to produce high-quality tiles with minimal supervision.4. Cost-Effective: Investing in a double side gypsum board ceiling tiles laminating machine is a cost-effective solution for businesses involved in the production of gypsum board ceiling tiles. The machine's high production capacity ensures that companies can produce a significant number of tiles in a short period, increasing their revenue.5. Versatile: The double side gypsum board ceiling tiles laminating machine can be used to produce a variety of gypsum board ceiling tiles, making it a versatile machine. The machine's flexibility allows businesses to accommodate different customer preferences and design requirements easily.Investing in a double side gypsum board ceiling tiles laminating machine is an excellent decision for companies involved in the production of gypsum board ceiling tiles. The machine's advanced features, high-speed rollers, ease of use, cost-effectiveness, and versatility make it an ideal choice for businesses looking to increase their production capacity and revenue. The keyword "Double Side Gypsum Board Ceiling Tiles Laminating Machine" is an essential aspect of this article and can help increase the article's visibility, especially in search engines.

Professional Plastering Services for New Builds, Repairs, and Renovations

Brad McKinnon Plastering: The Leading Plastering Service ProviderLooking to renovate your home or building a new house from scratch? Then, Brad McKinnon Plastering has got you covered! Providing top-notch plastering services, Brad McKinnon Plastering is the leading company in New Zealand, known for delivering quality and timely services to clients.At Brad McKinnon Plastering, we understand the vital role that plastering plays in the construction industry, and our dedicated team of experts takes great pride in providing top-quality services that exceed our clients' expectations. Our commitment to quality and excellence has made us one of the most preferred plastering providers in the industry.New Build ServicesBuilding a house from scratch is a significant investment in one's life, and we understand that. Hence, we offer New Build services like no other. Our team of experts is knowledgeable, reliable and equipped with the latest technology and tools to ensure that your new build is perfect. We pay attention to every detail, from layout to design, and from plastering to painting. We ensure that our clients' vision comes to fruition, and their dream home is realized.Repair ServicesAt some point, even the most robust of buildings require repairs. Whether it's a small crack or significant damage, fret no more, as Brad McKinnon Plastering offers reliable repair services to maintain the aesthetics and integrity of your walls and ceilings. Our team of experts is equipped with the necessary skills and tools to tackle any repair job, no matter how big or small the issue may seem.Renovation ServicesThinking of a home makeover? Brad McKinnon Plastering is here to help. Our renovation services are bespoke and tailored to suit our clients' needs. We understand that every client has unique taste, and we take pride in listening and working with our clients to achieve their desired results. We employ the latest techniques to ensure that the result is not only visually appealing but exceeds our clients' expectations.Full Skim Level 5 ServicesIf you require the most polished finish, then our Full Skim Level 5 services are perfect for you. Our experts use the latest technology and tools to provide beautiful, level five finishes that will leave your walls and ceiling with the most beautiful, polished finish. Our team is dedicated to delivering exceptional work and will ensure that every detail is perfect.GIB CoveBrad McKinnon Plastering offers GIB Cove services, one of the most distinguishing features of any room. Our expert team ensures that the GIB Cove in your room is bespoke and tailored to your requirements and style. With our GIB Cove services, you can rest assured that your room will be transformed into a beautiful space.Plaster CorniceOne of the most essential aspects of plastering is Plaster Cornice. It enhances the aesthetics of any room and provides that extra finishing touch that can make all the difference. At Brad McKinnon Plastering, we specialize in Plaster Cornice and offer bespoke services that will transform your room.ConclusionBrad McKinnon Plastering is the most trusted and reliable plastering service provider in New Zealand. Our team of dedicated experts is equipped with the latest technology and tools to ensure that every job is perfect. We pay great attention to detail and are committed to delivering quality and timely services that exceed our clients' expectations. Contact us today, and let's help you transform your home.

Latest Technology for Producing Fireproof Magnesium Oxide Board

Fireproof Magnesium Oxide Board Machine: Revolutionizing Construction IndustryIn recent years, the demand for fireproof building materials has been on the rise, and one company at the forefront of meeting this demand is {Company Name}. Their innovative Fireproof Magnesium Oxide Board Machine is revolutionizing the construction industry by providing a reliable and sustainable solution for building safer and more durable structures.{Company Name} is a leading manufacturer of construction machinery and equipment. With years of experience and a commitment to innovation, they have developed a state-of-the-art Fireproof Magnesium Oxide Board Machine that is changing the way buildings are constructed. The machine is designed to produce fireproof magnesium oxide boards, which are becoming increasingly popular in the construction industry due to their superior fire resistance and durability.The Fireproof Magnesium Oxide Board Machine is a result of extensive research and development by {Company Name}’s team of engineers and experts in the field of construction materials. The machine is equipped with advanced technology and automation, allowing for efficient and precise production of fireproof magnesium oxide boards. This not only ensures high-quality output but also increases productivity and reduces production costs.The use of fireproof magnesium oxide boards in construction offers numerous benefits. Unlike traditional building materials such as wood or drywall, magnesium oxide boards are non-combustible and can withstand high temperatures, making them an ideal choice for fire-resistant construction. Additionally, these boards are highly durable and resistant to water, mold, and impact, making them suitable for a wide range of applications in both residential and commercial buildings.The Fireproof Magnesium Oxide Board Machine from {Company Name} is also environmentally friendly, as it utilizes sustainable and recyclable materials in the production process. This aligns with the growing trend towards sustainable and eco-friendly construction practices, making the machine a preferred choice for environmentally conscious builders and developers.Furthermore, {Company Name} offers comprehensive customer support and training for the Fireproof Magnesium Oxide Board Machine, ensuring that their clients are equipped with the necessary knowledge and expertise to operate the machine efficiently. This commitment to customer satisfaction has made {Company Name} a trusted partner for construction companies and developers worldwide.As the demand for fireproof building materials continues to grow, the Fireproof Magnesium Oxide Board Machine from {Company Name} is well-positioned to meet this demand and make a significant impact on the construction industry. With its cutting-edge technology, sustainable approach, and exceptional performance, the machine is set to revolutionize the way buildings are constructed, offering a safer and more sustainable alternative to traditional building materials.In conclusion, the Fireproof Magnesium Oxide Board Machine from {Company Name} represents a significant advancement in construction technology, offering a reliable and sustainable solution for the growing demand for fireproof building materials. With its innovative design, advanced features, and commitment to customer satisfaction, the machine is poised to make a lasting impact on the construction industry, paving the way for safer and more durable buildings in the future.

High-quality Wall Board Machine Manufacturer for Mgo Boards

Mgo Wall Board Machine Manufacturer, a leading manufacturer of construction machinery, recently announced the launch of their new state-of-the-art Mgo Wall Board Machine. The company has been known for its high-quality construction equipment and this latest addition to their product line is no exception.The Mgo Wall Board Machine is designed to produce high-quality Magnesium Oxide Wall Boards, which are widely used in the construction industry for their fire resistance, water resistance, and durability. The machine is equipped with the latest technology and is capable of producing a large volume of Mgo Wall Boards with a high degree of precision and efficiency.The company has invested heavily in research and development to ensure that the Mgo Wall Board Machine meets the highest industry standards. The machine is equipped with advanced features such as automatic feeding, mixing, and molding, as well as precise control of temperature and pressure during the production process. This ensures that the Mgo Wall Boards produced are of consistent quality and meet all the necessary specifications for construction applications.In addition to its advanced technology, the Mgo Wall Board Machine is also designed with user-friendly features that make it easy to operate and maintain. The machine is equipped with a user-friendly interface and is designed for minimal downtime, allowing for continuous production without interruptions.The launch of the Mgo Wall Board Machine is a significant milestone for the company, as it further strengthens their position as a leading manufacturer of construction machinery. With the increasing demand for high-quality construction materials, the company is confident that the Mgo Wall Board Machine will be well-received in the market.The company has a strong focus on customer satisfaction and has a dedicated team of professionals who are committed to providing excellent service and support to their customers. With a global network of sales and service partners, the company is well-equipped to meet the needs of customers around the world.The Mgo Wall Board Machine is the latest addition to the company's comprehensive product line, which includes a wide range of construction machinery such as drywall machines, plasterboard production lines, and other building materials production equipment. The company takes pride in offering a complete solution for the construction industry, providing customers with everything they need to meet their production needs.With a strong track record of delivering high-quality products and exceptional customer service, the company has established itself as a trusted partner for construction companies worldwide. The launch of the Mgo Wall Board Machine is a testament to the company's commitment to innovation and excellence in manufacturing.The company's dedication to quality and innovation has earned them a solid reputation in the industry, and they are continuously striving to stay ahead of the competition by investing in new technologies and expanding their product offerings.In conclusion, the launch of the Mgo Wall Board Machine by Mgo Wall Board Machine Manufacturer is a significant development that further solidifies the company's position as a leading manufacturer of construction machinery. With its advanced technology, user-friendly features, and commitment to customer satisfaction, the Mgo Wall Board Machine is set to make a lasting impact in the construction industry.

Affordable Roof Panel Roll Forming Machine Manufacturers and Suppliers in China with Stock Availability

If you're searching for affordable, high-quality roof panel roll forming machines, look no further than Xinhonghua. As a leading manufacturer and supplier of roll forming machines in China, we offer a comprehensive range of machines specifically designed to meet the needs of roofing contractors and others working in the construction industry. With our cheap prices and extensive inventory of machines, you're sure to find the perfect roll forming machine for your application.Our roof panel roll forming machines are meticulously designed and crafted to ensure high-quality, precision performance. We use only the best materials and components, and our machines are engineered to provide long-lasting, reliable service. Whether you're looking for a machine to produce metal roofing panels, corrugated panels, or other types of roofing panels, we have the perfect machine to meet your needs.In addition to roof panel roll forming machines, we also offer a range of other roll forming machines, including Cheap Mgo Board Forming Machine Pricelist. Our MGO board forming machines are designed to produce high-quality, fire-resistant MGO boards that are perfect for use in construction, interior finishing, and other applications. With our MGO board forming machines, you can easily produce high-volume quantities of boards quickly and efficiently.At Xinhonghua, we pride ourselves on our dedication to quality, reliability, and customer service. We understand that our success depends on the satisfaction of our customers, and we work tirelessly to ensure that our machines are up to the highest standards of excellence. Whether you're a small contractor or a large construction firm, we have the expertise and experience to provide you with the products and services you need to succeed.So if you're in the market for a new roof panel roll forming machine or Cheap Mgo Board Forming Machine Pricelist, be sure to contact us today. Our friendly and knowledgeable staff are always on hand to answer any questions you may have, and we're committed to providing you with the best possible service and support. Let us help you transform your construction business with high-quality, affordable rolling forming machines from Xinhonghua.

High-Quality Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery from China's Leading Manufacturer

Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery: The Perfect Solution for Your Manufacturing NeedsThe world of manufacturing has evolved significantly in recent years. With the advent of new technologies, the process of producing goods has become more efficient, effective, and streamlined. One such technology that has gained immense popularity in recent years is the Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery. This cutting-edge equipment is the perfect solution for all your manufacturing needs and has revolutionized the industry in many ways.What is Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery?Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is a state-of-the-art machinery used for manufacturing MgO board door cores and frames. This fully automated equipment is designed to produce high-quality MgO board door cores and frames with precision and accuracy. The machinery is equipped with advanced technology to ensure the highest standards of quality and performance. It is the perfect solution for businesses seeking to improve their manufacturing processes and increase their productivity levels.Features of Fully Automatic Mgo Board Door Core Frame Vacuum Forming MachineryThe Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is designed with several features that make it a standout product. Some of its key features include:1. Fully Automated: The machinery is fully automated, which means it requires little or no human intervention during the manufacturing process. This feature ensures that the entire process is fast, efficient, and error-free.2. High-Quality Output: The machinery produces high-quality MgO board door cores and frames that meet industry standards. The equipment is designed to produce precise and accurate products that are of superior quality and durability.3. Cost-Effective: The Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is a cost-effective solution for businesses seeking to improve their manufacturing processes. The machinery saves time, reduces waste, and minimizes production costs, making it a profitable investment for any business.4. Easy to Operate: The machinery is easy to operate, even for those with little or no experience in manufacturing. The user-friendly interface makes it easy to set up, operate, and maintain.Benefits of Fully Automatic Mgo Board Door Core Frame Vacuum Forming MachineryThe Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery offers numerous benefits to businesses seeking to improve their manufacturing processes. These benefits include:1. Increased Productivity: The machinery is designed to produce high-quality products quickly and efficiently, increasing productivity levels and reducing lead times.2. Cost Savings: The equipment saves businesses money by minimizing production costs associated with waste, labor, and maintenance.3. Improved Quality: The machinery produces high-quality products that meet industry standards, ensuring customer satisfaction and reducing product recalls.4. Better Control: The machinery provides better control over the manufacturing process, allowing for adjustments and modifications as needed.Mgo Board Forming Machine PricelistThe price of Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery varies depending on the manufacturer, model, and features. In general, the price ranges from $50,000 to $150,000. However, it is advisable to request a quote from the manufacturer for a more accurate price estimate.ConclusionThe Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is the perfect solution for businesses seeking to improve their manufacturing processes and increase their productivity levels. With its advanced technology, high-quality output, and cost-effective features, the machinery offers numerous benefits to businesses of all sizes. If you are looking for a reliable and efficient solution for your manufacturing needs, consider investing in Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery.

Durable Aluminum Foil Gypsum-Board Laminating Machine for Efficient Production

Aluminum Foil Gypsum-Board Laminating Machine Revolutionizes Manufacturing ProcessIn the world of manufacturing, innovation is key to staying ahead of the competition. This is especially true for companies in the construction materials industry, where efficiency and quality are of utmost importance. Recently, a groundbreaking new technology has emerged that is set to revolutionize the way gypsum boards are produced. The Aluminum Foil Gypsum-Board Laminating Machine, developed by a leading machinery manufacturer, is set to streamline the production process and improve the overall quality of gypsum boards.This state-of-the-art machine is designed to laminate aluminum foil onto gypsum boards, providing a durable and efficient finishing solution. The machine is equipped with cutting-edge technology and advanced automation features, allowing for precise and consistent lamination of the aluminum foil onto the gypsum boards. This not only enhances the appearance of the boards but also improves their durability and resistance to water and fire.The Aluminum Foil Gypsum-Board Laminating Machine is a game-changer for companies involved in the production of gypsum boards. Its innovative design and advanced capabilities make it a valuable addition to any manufacturing facility. With this machine, manufacturers can significantly increase their production output while maintaining high standards of quality. This is achieved through the machine's high-speed lamination process, which ensures that each gypsum board is finished to perfection in a fraction of the time it would take with traditional methods.The company behind this revolutionary machine is dedicated to providing cutting-edge solutions for the construction materials industry. With a strong focus on research and development, the company continuously strives to push the boundaries of innovation and deliver products that meet the evolving needs of the market. The Aluminum Foil Gypsum-Board Laminating Machine is a testament to this commitment, offering manufacturers a means to streamline their production process and improve the overall quality of their products.In addition to its advanced technology, the company's reputation for excellence and reliability is also a driving force behind the success of the Aluminum Foil Gypsum-Board Laminating Machine. With a track record of delivering high-quality machinery and exceptional customer service, the company has earned the trust and loyalty of manufacturers worldwide. This, combined with its dedication to innovation, makes the company a leader in the industry and a go-to source for advanced manufacturing solutions.The introduction of the Aluminum Foil Gypsum-Board Laminating Machine comes at a time when the construction materials industry is experiencing rapid growth and increased demand for high-quality products. With a focus on sustainability and efficiency, manufacturers are seeking innovative solutions that can help them meet this growing demand while reducing their environmental impact. The Aluminum Foil Gypsum-Board Laminating Machine is well-positioned to address these needs, offering a sustainable and efficient solution for the production of gypsum boards.Looking ahead, the Aluminum Foil Gypsum-Board Laminating Machine is poised to have a significant impact on the construction materials industry. Its innovative technology and advanced capabilities make it a valuable asset for manufacturers looking to stay ahead of the competition and meet the demands of a rapidly evolving market. As the industry continues to grow and evolve, the Aluminum Foil Gypsum-Board Laminating Machine is sure to play a key role in shaping its future.In conclusion, the Aluminum Foil Gypsum-Board Laminating Machine represents a major advancement in the production of gypsum boards. With its cutting-edge technology and advanced automation features, it offers manufacturers a means to streamline their production process and improve the overall quality of their products. As a leading machinery manufacturer, the company behind this innovative machine is committed to delivering solutions that meet the evolving needs of the construction materials industry. The Aluminum Foil Gypsum-Board Laminating Machine is a testament to this commitment, offering manufacturers a sustainable and efficient solution for the production of gypsum boards. Its introduction is set to revolutionize the manufacturing process and have a lasting impact on the industry as a whole.