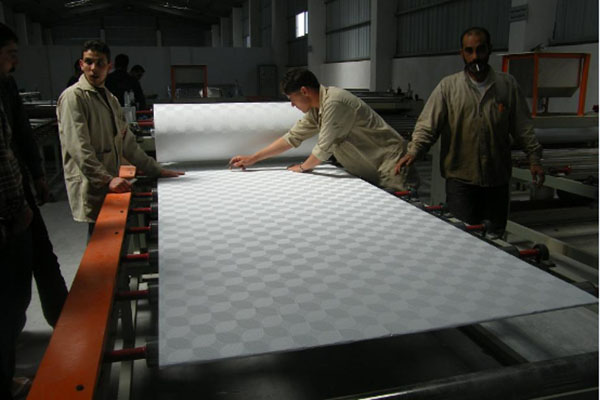

Physical foamed board production line for XPS materials

By:Admin

The Xps physical foamed board production line is a cutting-edge manufacturing system that is revolutionizing the production of foam boards. With its innovative technology and state-of-the-art machinery, this production line is setting new industry standards for efficiency, productivity, and product quality.

The production line is designed to produce XPS (Extruded Polystyrene) foam boards, which are widely used in the construction industry for insulation, moisture resistance, and durability. The boards are known for their high compressive strength, low water absorption, and excellent thermal performance, making them an ideal choice for a range of construction applications.

The company behind this advanced production line is a leader in the manufacturing of foam board machinery, with a strong focus on research and development. Their commitment to innovation and technological advancement has earned them a reputation for delivering high-quality, reliable, and efficient production solutions to their customers.

With the introduction of the Xps physical foamed board production line, the company is once again demonstrating their ability to stay ahead of the curve in the industry. The new production line is a testament to the company's dedication to providing cutting-edge manufacturing solutions that meet the evolving needs of their customers.

The Xps physical foamed board production line is equipped with advanced features that optimize the production process and enhance the quality of the final product. The line is capable of producing foam boards of varying thicknesses and densities, allowing for greater flexibility in meeting customer requirements.

One of the key advantages of this production line is its high level of automation, which significantly reduces the need for manual labor and minimizes the risk of human error. This not only increases efficiency and productivity but also ensures consistent product quality and performance.

Additionally, the production line is designed with energy efficiency in mind, utilizing advanced technology to minimize energy consumption and reduce environmental impact. This aligns with the company's commitment to sustainability and responsible manufacturing practices.

The introduction of the Xps physical foamed board production line is welcomed by the industry, as it offers a much-needed boost in production capacity and product quality. The innovative technology and advanced features of the production line are expected to set a new standard for foam board manufacturing, driving progress and excellence in the industry.

The company is poised to meet the growing demand for high-quality foam boards with the launch of this state-of-the-art production line. By offering a solution that combines cutting-edge technology, efficiency, and sustainability, they are well-positioned to solidify their reputation as a leading provider of foam board manufacturing solutions.

In conclusion, the introduction of the Xps physical foamed board production line represents a significant milestone for the company and the industry as a whole. This advanced manufacturing system is set to redefine the production of foam boards, offering enhanced efficiency, productivity, and product quality. As the company continues to push the boundaries of innovation, they are shaping the future of foam board manufacturing and setting new standards for the industry.

Company News & Blog

High-Quality Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery from China's Leading Manufacturer

Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery: The Perfect Solution for Your Manufacturing NeedsThe world of manufacturing has evolved significantly in recent years. With the advent of new technologies, the process of producing goods has become more efficient, effective, and streamlined. One such technology that has gained immense popularity in recent years is the Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery. This cutting-edge equipment is the perfect solution for all your manufacturing needs and has revolutionized the industry in many ways.What is Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery?Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is a state-of-the-art machinery used for manufacturing MgO board door cores and frames. This fully automated equipment is designed to produce high-quality MgO board door cores and frames with precision and accuracy. The machinery is equipped with advanced technology to ensure the highest standards of quality and performance. It is the perfect solution for businesses seeking to improve their manufacturing processes and increase their productivity levels.Features of Fully Automatic Mgo Board Door Core Frame Vacuum Forming MachineryThe Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is designed with several features that make it a standout product. Some of its key features include:1. Fully Automated: The machinery is fully automated, which means it requires little or no human intervention during the manufacturing process. This feature ensures that the entire process is fast, efficient, and error-free.2. High-Quality Output: The machinery produces high-quality MgO board door cores and frames that meet industry standards. The equipment is designed to produce precise and accurate products that are of superior quality and durability.3. Cost-Effective: The Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is a cost-effective solution for businesses seeking to improve their manufacturing processes. The machinery saves time, reduces waste, and minimizes production costs, making it a profitable investment for any business.4. Easy to Operate: The machinery is easy to operate, even for those with little or no experience in manufacturing. The user-friendly interface makes it easy to set up, operate, and maintain.Benefits of Fully Automatic Mgo Board Door Core Frame Vacuum Forming MachineryThe Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery offers numerous benefits to businesses seeking to improve their manufacturing processes. These benefits include:1. Increased Productivity: The machinery is designed to produce high-quality products quickly and efficiently, increasing productivity levels and reducing lead times.2. Cost Savings: The equipment saves businesses money by minimizing production costs associated with waste, labor, and maintenance.3. Improved Quality: The machinery produces high-quality products that meet industry standards, ensuring customer satisfaction and reducing product recalls.4. Better Control: The machinery provides better control over the manufacturing process, allowing for adjustments and modifications as needed.Mgo Board Forming Machine PricelistThe price of Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery varies depending on the manufacturer, model, and features. In general, the price ranges from $50,000 to $150,000. However, it is advisable to request a quote from the manufacturer for a more accurate price estimate.ConclusionThe Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is the perfect solution for businesses seeking to improve their manufacturing processes and increase their productivity levels. With its advanced technology, high-quality output, and cost-effective features, the machinery offers numerous benefits to businesses of all sizes. If you are looking for a reliable and efficient solution for your manufacturing needs, consider investing in Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery.

Affordable Foam Board Making Machine Factories for XPS

Cheap XPS Foam Board Making Machine FactoriesIn recent years, the demand for XPS foam board has been on the rise due to its versatile applications in the construction industry. In order to meet the increasing demand, several factories have been established to manufacture XPS foam board making machines. These factories have been playing a crucial role in the production and distribution of affordable and high-quality XPS foam board making machines.One of the leading XPS foam board making machine factories is located in China, where the company has gained a reputation for providing top-notch machines at competitive prices. The company has been at the forefront of technological advancements in the field of XPS foam board making machines and has been serving customers worldwide.The XPS foam board making machines produced by the company are known for their efficiency, durability, and precision. The machines are designed to produce XPS foam boards of various sizes and densities, catering to the diverse needs of the construction industry. In addition, the company offers customization options, allowing customers to tailor the machines according to their specific requirements.The XPS foam board making machine factories have been instrumental in the advancement of the construction industry, as they have made it possible for contractors and builders to access high-quality XPS foam board making machines at affordable prices. This has not only contributed to the growth of the construction industry but has also led to the development of eco-friendly and energy-efficient buildings.The XPS foam board making machine factories are committed to providing exceptional customer service, offering technical support, and maintenance services to ensure the smooth operation of their machines. Furthermore, the factories have a strong focus on continuous research and development, aiming to improve the efficiency and performance of their machines.In addition to manufacturing XPS foam board making machines, the factories also offer training and consultation services to their customers, equipping them with the necessary knowledge and skills to maximize the potential of the machines. This level of support and dedication sets the XPS foam board making machine factories apart from the competition, making them the go-to choice for construction companies and contractors.With the increasing demand for XPS foam board, the XPS foam board making machine factories are poised to play a significant role in the construction industry. Their commitment to innovation, quality, and affordability has made them indispensable partners for construction companies looking to enhance their production capabilities.In conclusion, the XPS foam board making machine factories have emerged as key players in the advancement of the construction industry. With their dedication to providing affordable and high-quality machines, they have become crucial enablers for the production of XPS foam board. As the demand for eco-friendly and energy-efficient construction materials continues to grow, the XPS foam board making machine factories are expected to play an even more prominent role in shaping the future of the industry. Their commitment to excellence and customer satisfaction makes them the preferred choice for construction companies and contractors worldwide.For more information on the XPS foam board making machine factories, please visit their website {} for details on their products and services.

Automatic Gypsum Cornice Equipment with CE Certification: Pricelist and Details

ce Certification Automatic Gypsum Cornice Equipment PricelistIn recent news, the {company name} is proud to announce the release of their automatic gypsum cornice equipment, which has received CE certification. This certification marks a significant achievement for the company and demonstrates their commitment to providing high-quality, reliable products to their customers.The automatic gypsum cornice equipment is designed to streamline the production process and improve efficiency for manufacturers of gypsum cornices. With the CE certification, customers can have confidence in the safety and reliability of this equipment, knowing that it meets the stringent requirements of the European Union.The company has also released a pricelist for the automatic gypsum cornice equipment, making it easier for potential customers to understand the investment required for this innovative technology. The pricelist offers transparency and clarity, allowing customers to make informed decisions about the purchase of this equipment.In addition to the CE certification and pricelist release, the {company name} would like to take this opportunity to introduce themselves to those who may not be familiar with their brand. As a leading manufacturer of gypsum processing equipment, {company name} has a strong reputation for delivering cutting-edge solutions that meet the needs of their customers.With a focus on innovation and quality, {company name} has developed a range of products that have been widely adopted by manufacturers in the gypsum industry. Their automatic gypsum cornice equipment is the latest addition to their portfolio, showcasing their ongoing commitment to advancing the industry with advanced technology.The company takes pride in their ability to provide comprehensive solutions for gypsum processing, from raw material preparation to finished product packaging. Their expertise and dedication to customer satisfaction have earned them a loyal customer base and a reputation as a trusted partner in the industry.{Company name} is known for their technical expertise, responsive customer service, and willingness to collaborate with customers to address their unique needs. The release of the CE-certified automatic gypsum cornice equipment and the accompanying pricelist reflects their dedication to transparency, quality, and providing value to their customers.As the company continues to grow and expand their product offerings, they remain committed to upholding the highest standards of excellence in their manufacturing processes. By achieving CE certification for their automatic gypsum cornice equipment, {company name} has once again demonstrated their commitment to producing top-quality equipment that meets international safety and performance standards.In conclusion, the release of the CE-certified automatic gypsum cornice equipment pricelist by {company name} represents an important milestone for the company and the industry. With a reputation for innovation, quality, and customer-focused solutions, {company name} is poised to continue leading the way in providing advanced equipment for gypsum processing.For more information about {company name} and their products, including the automatic gypsum cornice equipment, interested parties are encouraged to reach out to the company directly or visit their website for details.

Affordable Mgo Board Equipment: A Cost-Effective Solution

With a strong focus on innovation and quality, [Company Name] has recently announced the launch of their new line of affordable Mgo boards, catering to the needs of the construction and building industry. The [Company Name] Mgo board equipment has been designed to meet the demands of modern construction projects, offering a cost-effective and durable solution for various building applications.Mgo boards, also known as magnesium oxide boards, are becoming increasingly popular in the construction industry due to their remarkable properties. These boards are known for their strength, fire resistance, and resistance to environmental factors such as water and mold. With the growing demand for sustainable and resilient building materials, Mgo boards have emerged as a preferred choice for architects and contractors.The [Company Name] Mgo board equipment stands out in the market due to its affordability without compromising on quality. The company has invested in state-of-the-art manufacturing technology to ensure that their Mgo boards meet the highest industry standards. This commitment to quality is reflected in the performance of the boards, making them suitable for a wide range of applications including wall and ceiling panels, exterior cladding, and fire-rated assemblies.In addition to their exceptional performance, the [Company Name] Mgo boards are also environmentally friendly. As a company that prioritizes sustainability, [Company Name] ensures that their manufacturing processes adhere to the highest environmental standards. This means that the Mgo boards are not only durable and cost-effective but also contribute to a greener building industry.Speaking about the new product line, [Spokesperson Name], the CEO of [Company Name], expressed his enthusiasm for the market introduction of their Mgo board equipment. "We are thrilled to bring our new line of Mgo boards to the market. With the increasing demand for sustainable and resilient building materials, we saw an opportunity to provide a cost-effective solution without compromising on quality. Our Mgo board equipment is a testament to our commitment to innovation and sustainability in the construction industry."The [Company Name] Mgo board equipment is set to disrupt the market by offering a budget-friendly alternative to traditional building materials. As the construction industry continues to evolve, there is a growing need for innovative solutions that meet the demands of modern architecture. The launch of the Mgo board equipment is a step in this direction, providing builders and contractors with a reliable and affordable option for their projects.Furthermore, [Company Name] has earned a reputation for delivering exceptional customer service and technical support. With a team of experienced professionals, the company is dedicated to ensuring that their clients receive the guidance and assistance they need when using the Mgo board equipment. This commitment to customer satisfaction sets [Company Name] apart from its competitors and has contributed to its success in the industry.In conclusion, the introduction of the new line of affordable Mgo board equipment from [Company Name] is a significant development in the construction industry. With a focus on quality, sustainability, and affordability, the company is poised to make a positive impact on the market. As the demand for resilient and environmentally friendly building materials continues to grow, the [Company Name] Mgo board equipment is well-positioned to meet the needs of the industry and establish itself as a preferred choice for construction projects.

Customized Abs Board Extrusion Line for XPS Heat Insulation Foamed Plate Production

Qingdao JBD Machinery is a leading manufacturer and supplier of extrusion lines that are used to produce various types of foam boards. With the advanced technology and cutting-edge machinery, the company provides a diverse range of innovative and high-performance extrusion lines to meet the growing demands of the market. The Factory Customized Abs Board Extrusion Line and XPS Heat Insulation Foamed Plate Production Line are some of its popular products with excellent performance and high reliability.The Factory Customized Abs Board Extrusion Line is designed to produce high-quality ABS foam boards, which can be used in a variety of applications such as automotive dashboards, instrument panels, and interior parts. The machine is equipped with a high-quality screw and barrel that ensures the homogeneity and consistency of the mixing process. The production line is also equipped with a precision cut-off system that produces a precise cut and ensures the uniformity of the board thickness.The XPS Heat Insulation Foamed Plate Production Line is one of the best products offered by Qingdao JBD Machinery. The extrusion line is designed to produce lightweight and strong XPS foamed boards, which are widely used as heat insulation and soundproofing materials in construction, refrigeration, and packaging industries. The board offers incomparable heat insulation traits, non-water absorption, high compressive strength, excellent heat preservation performance, and low cost. The foamed plate production line is easy and quick to execute, making it an ideal solution for various industrial applications.The XPS Heat Insulation Foamed Plate Production Line is a fully automatic extrusion line with high productivity and efficiency. The machine is equipped with a high-quality screw and barrel that ensures the uniformity of the foaming process and the homogeneity of the foam structure. The production line also features a precise cutting system that produces high-quality foam boards with uniform thickness and size. The machine can be customized according to customer requirements and can produce boards of different sizes and shapes.Qingdao JBD Machinery is committed to providing customers with high-quality products and services. The company has a team of highly qualified professionals who have extensive experience in manufacturing and designing extrusion lines. The company also provides excellent after-sales service to ensure customer satisfaction. As a leading manufacturer in China, the company has been exporting its products to different parts of the world, including North America, South America, Europe, Asia, Africa, and Oceania. The company has established long-term relationships with its customers by providing them with high-quality products, prompt delivery, and excellent service. In conclusion, Qingdao JBD Machinery is a reputable and reliable manufacturer of extrusion lines that produces high-quality products such as Factory Customized Abs Board Extrusion Line and XPS Heat Insulation Foamed Plate Production Line. The company is committed to providing innovative and cost-effective solutions to its customers, and its products are widely used in various industrial applications. With its cutting-edge technology and excellent service, Qingdao JBD Machinery is poised to become a leading player in the extrusion line manufacturing industry.

High-Quality Equipment for Manufacturing Gypsum Cornice Automatically

Title: Advanced Automatic Gypsum Cornice Equipment Revolutionizes Manufacturing ProcessIntroduction:In a remarkable leap towards streamlining the manufacturing process of gypsum cornices, an innovative new Automatic Gypsum Cornice Equipment has been introduced by a prominent industry player. This cutting-edge machinery promises to revolutionize the sector, offering increased efficiency, precision, and cost-effectiveness.Body:1. Background of the Automatic Gypsum Cornice Equipment: The Automatic Gypsum Cornice Equipment is a breakthrough development that aims to improve the traditional manufacturing process of gypsum cornices. This advanced system integrates modern machinery and technology, harnessing automation and precision to produce high-quality cornices with minimal human intervention.2. Features and Benefits of the Automatic Gypsum Cornice Equipment: a. Streamlined Production: The equipment's automated nature ensures a significant reduction in production time, as well as a streamlined workflow that eliminates human errors and inconsistencies. b. Enhanced Precision: Utilizing state-of-the-art technology, the equipment guarantees exceptional precision and accuracy in the manufacturing process. This ensures uniformity of every cornice produced, meeting the highest standards of quality. c. Cost-Effectiveness: By optimizing the production process and minimizing wastage, the automatic equipment enables manufacturers to operate more efficiently, reducing overall costs and enhancing the profitability of the business. d. Minimal Maintenance: The equipment incorporates robust engineering design, resulting in a reliable and low-maintenance system that maximizes uptime and minimizes downtime.3. Key Industries Benefitting from the Automatic Gypsum Cornice Equipment: a. Construction Industry: The construction sector is one of the primary beneficiaries of this advanced equipment. Gypsum cornices hold a significant place in interior decoration, and with the rapid pace of construction globally, the demand for efficient manufacturing solutions is higher than ever. b. Interior Designers and Architects: Design professionals can now rely on the consistency and accuracy offered by this innovative machinery, allowing them to achieve their creative visions with ease. The equipment empowers them to provide clients with bespoke gypsum cornices, tailored to their unique requirements. c. Export Market: With the ability to produce high-quality gypsum cornices at a faster rate, manufacturers using the automatic equipment gain a competitive edge in the export market. This technology puts them in a position to meet increased demand from overseas customers, further bolstering the industry's growth.4. Environmental Benefits of the Automatic Gypsum Cornice Equipment: This advanced machinery not only enhances manufacturing processes but also contributes to eco-friendliness: a. Reduced Material Waste: With precise measurements and automated cutting, the equipment minimizes material waste, effectively utilizing resources, and reducing environmental impact. b. Energy Efficiency: The Automatic Gypsum Cornice Equipment incorporates energy-saving measures, reducing power consumption during production, in line with sustainable manufacturing practices.5. Company's Commitment to Innovation: The company behind this revolutionary equipment has a proven track record of innovation and a commitment to driving the industry forward. By investing in research and development, they continuously strive to improve their products and stay ahead of market trends. In addition, adherence to international quality standards ensures customer satisfaction and trust in their offerings.Conclusion:The introduction of the Automatic Gypsum Cornice Equipment marks a significant milestone in the gypsum cornice manufacturing sector. Its advanced features, improved efficiency, and reduced costs have propelled the industry into a new era of production. With the ability to meet global demand with precision and reliability, the equipment is set to solidify its position as a game-changer in manufacturing technology.

Advanced Fully Automatic Machine for Coating and Laminating PVC Gypsum Ceilings

Title: Cutting-Edge Technology Improves Efficiency and Quality: Full Automatic PVC Gypsum Ceiling Coating and Laminating Machine Revolutionizes the IndustryIntroduction:In today's fast-paced world, the demand for efficiency, quality, and innovation in manufacturing processes is higher than ever before. Companies, both large and small, are constantly striving to evolve and incorporate cutting-edge technologies to stay competitive. In this regard, one such breakthrough has caught the attention of the construction industry – the Full Automatic PVC Gypsum Ceiling Coating and Laminating Machine.Innovative Features and Functionality:The Full Automatic PVC Gypsum Ceiling Coating and Laminating Machine, developed by a visionary team of engineers, revolutionizes the coating and laminating process for gypsum ceilings. With its state-of-the-art technology, this machine offers unparalleled efficiency, impeccable quality, and reduced labor costs. Combining the latest advancements in robotics, automation, and precision engineering, it has become a game-changer for manufacturers across the globe.Efficiency: The machine boasts a fully automatic operation, eliminating the need for manual labor and reducing production time significantly. Equipped with intelligent sensors, it precisely measures the dimensions of each gypsum ceiling, ensuring accurate coating and laminating without any wastage. This automation not only increases efficiency but also minimizes human errors, resulting in consistent output throughout the production process.Quality:The Full Automatic PVC Gypsum Ceiling Coating and Laminating Machine guarantees a superior finish every time. Using cutting-edge technology, it applies a flawless PVC coating onto the gypsum ceilings, resulting in a smooth, seamless appearance. The automated laminating feature ensures consistent adhesion, preventing peeling or detachment in the long run. By minimizing human intervention, this machine minimizes the risk of imperfections and improves the overall quality of the end product, satisfying even the most discerning customers.Reduced Labor Costs:Traditionally, coating and laminating gypsum ceilings required a significant amount of manual labor, leading to higher labor costs and an increased risk of errors or inconsistencies. However, with the Full Automatic PVC Gypsum Ceiling Coating and Laminating Machine, companies can now save substantial labor expenses. By automating the entire process, manufacturers can allocate resources more efficiently, redirecting human personnel to tasks that require creativity and problem-solving skills.Environmental Benefits:Apart from its efficiency and quality, the Full Automatic PVC Gypsum Ceiling Coating and Laminating Machine also presents environmental advantages. By accurately measuring and applying coatings, it reduces material wastage, promoting sustainability in the construction industry. Additionally, the machine's automated nature ensures proper adherence to safety regulations, further minimizing the environmental impact associated with human error or mishaps.Market Impact:The introduction of the Full Automatic PVC Gypsum Ceiling Coating and Laminating Machine has sparked excitement within the construction industry. Manufacturers are eager to adopt this innovative technology to gain a competitive edge. The machine's ability to improve efficiency, ensure quality, and reduce labor costs aligns perfectly with the market's increasing demands for more cost-effective and sustainable solutions. As a result, it has already garnered significant attention from key industry players.Future Prospects:As the construction industry continues to grow at a rapid pace, technological advancements such as the Full Automatic PVC Gypsum Ceiling Coating and Laminating Machine are set to become indispensable. The machine's potential for further improvements is vast, with possibilities of integrating artificial intelligence for even more precise measurements, adapting to varying ceiling designs, and enhancing productivity. By constantly pushing the boundaries of innovation, manufacturers can meet the evolving demands of the sector and achieve new heights of success.In conclusion, the Full Automatic PVC Gypsum Ceiling Coating and Laminating Machine heralds a new era in the construction industry. Its ability to enhance efficiency, maintain superior quality, and reduce labor costs positions it at the forefront of technological innovation. The machine's potential for further advancements ensures a promising future, where construction processes become increasingly streamlined and sustainable. The industry eagerly awaits the immense impact this groundbreaking technology will have on manufacturing operations worldwide.

Top Gypsum Ceiling Board Machine for Decorative Home Improvement

The demand for high-quality gypsum ceiling board machines has been on the rise in recent years as the construction industry continues to experience growth and development. In response to this demand, {Company Name}, a leading manufacturer of gypsum machinery, has launched a new and innovative gypsum ceiling board machine that stands out for its exceptional quality and advanced features.The new gypsum ceiling board machine is designed to provide the highest level of precision and efficiency in the production of gypsum ceiling boards. It is equipped with state-of-the-art technology and a sophisticated production process that ensures the boards are consistently of the highest quality. The machine is capable of producing a wide range of gypsum ceiling board designs, from traditional to modern, and can be customized to meet the specific needs of different customers.{Company Name} has a long-standing reputation for excellence in the manufacturing of gypsum machinery. With over 20 years of experience in the industry, the company has established itself as a trusted and reliable provider of gypsum machinery solutions. Its team of highly skilled engineers and technicians are dedicated to designing and producing top-of-the-line equipment that meets the highest standards of quality and performance.The new gypsum ceiling board machine is the latest addition to {Company Name}'s extensive product line, which includes a wide range of gypsum machinery such as gypsum board production line, gypsum powder production line, and gypsum block production line. The company's commitment to innovation and continuous improvement is evident in the advanced technology and superior quality of its machinery.In addition to its focus on product quality, {Company Name} also places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific needs and requirements, and to provide customized solutions that meet their individual production goals. {Company Name} takes pride in its ability to deliver turnkey solutions that include equipment installation, training, and after-sales support to ensure that its customers are able to maximize the performance of their machinery.The launch of the new gypsum ceiling board machine is a testament to {Company Name}'s dedication to pushing the boundaries of innovation and excellence in the gypsum machinery industry. The company is committed to staying at the forefront of technological advancements in order to provide its clients with the most advanced and efficient machinery solutions available in the market.{Company Name}'s new gypsum ceiling board machine is set to make a significant impact in the industry, offering a level of quality, precision, and versatility that is unmatched by other machines on the market. With its cutting-edge technology and commitment to customer satisfaction, {Company Name} is poised to remain a leader in the gypsum machinery industry for years to come.

Create Custom Decorative Gypsum Ceiling Tiles with this Machine

Decorative Gypsum Ceiling Tiles Machine Revolutionizes the Construction IndustryThe construction industry has seen a significant revolution in recent years, and the introduction of the Decorative Gypsum Ceiling Tiles Machine has further cemented this change. The machine, developed by a leading company in the industry, has become a game-changer in the production of decorative gypsum ceiling tiles, breathing new life into the construction and interior design sectors.The machine, which leverages cutting-edge technology and innovative design, has redefined the production process of decorative gypsum ceiling tiles. It boasts high efficiency, precision, and versatility, allowing for the creation of intricate and unique designs that were once thought to be unattainable. This has enabled construction and design professionals to push the boundaries of creativity and offer clients a wide range of stunning and visually appealing options for their projects.In addition to revolutionizing the production process, the Decorative Gypsum Ceiling Tiles Machine has also had a significant impact on the overall quality of the tiles produced. The machine ensures that each tile is uniform in shape and size, with crisp and clean edges, resulting in an impeccable finish that is sure to impress even the most discerning clients. This level of precision and consistency has raised the bar for the industry, setting a new standard for excellence in decorative gypsum ceiling tiles.The company behind the Decorative Gypsum Ceiling Tiles Machine has a long-standing reputation for excellence and innovation in the construction and interior design industries. With a focus on customer satisfaction and a commitment to quality, the company has consistently pushed the boundaries of what is possible in the production of building materials and interior decor. This latest innovation is a testament to their dedication to advancing the industry and providing clients with the best products and solutions available.In addition to their technical expertise, the company also prides itself on its commitment to sustainability and environmental responsibility. The Decorative Gypsum Ceiling Tiles Machine is designed with energy efficiency in mind, minimizing waste and reducing the environmental impact of the production process. This aligns with the company's overarching goal of promoting sustainable and eco-friendly practices within the construction and design sectors, ensuring that they are not only meeting the needs of their clients but also contributing to a more sustainable future.The impact of the Decorative Gypsum Ceiling Tiles Machine is already being felt across the industry, with construction and design professionals embracing the new possibilities it offers. Clients are also reaping the rewards, with access to a wider range of high-quality, visually striking decorative gypsum ceiling tiles for their projects. The machine has sparked a new wave of creativity and innovation, inspiring a fresh approach to interior design and construction that is sure to shape the industry for years to come.With the introduction of the Decorative Gypsum Ceiling Tiles Machine, the company has once again positioned itself as a leader in the construction and interior design sectors. Their dedication to excellence, innovation, and sustainability has paid off, resulting in a groundbreaking development that is reshaping the way decorative gypsum ceiling tiles are produced. As the industry continues to evolve, it is clear that the company will remain at the forefront, driving progress and setting new standards for quality and creativity.

Affordable Mineral Fiber Ceiling Tiles Machine: An Overview

The demand for cost-effective and high-quality ceiling tiles has seen a significant rise in recent years. As a result, companies are constantly looking for innovative and efficient ways to produce these products. In response to this growing market, [Company Name] has launched its latest innovation – the Cheap Mineral Fiber Ceiling Tiles Machine.The Cheap Mineral Fiber Ceiling Tiles Machine is a state-of-the-art production system designed to manufacture high-quality mineral fiber ceiling tiles at a fraction of the cost. This cutting-edge technology is set to revolutionize the industry by providing a cost-effective solution for producing top-notch ceiling tiles.[Company Name] is a leading manufacturer of machinery and equipment for the construction industry. With a strong focus on innovation and technology, the company has been at the forefront of developing advanced solutions for various construction needs. The launch of the Cheap Mineral Fiber Ceiling Tiles Machine is a testament to [Company Name]'s commitment to providing sustainable and efficient solutions for the construction sector.The Cheap Mineral Fiber Ceiling Tiles Machine is equipped with advanced features and capabilities that set it apart from traditional production systems. With its high-speed production capabilities, the machine is capable of producing a large number of ceiling tiles in a short amount of time. This not only increases productivity but also reduces production costs, making it an ideal choice for companies looking to streamline their operations.In addition to its impressive production capabilities, the Cheap Mineral Fiber Ceiling Tiles Machine also offers enhanced flexibility and customization options. The machine can be easily configured to produce a wide range of ceiling tile designs and specifications, allowing companies to meet the diverse needs of their customers. This level of adaptability is a game-changer for manufacturers who are looking to stay ahead of the competition in a rapidly changing market.Furthermore, the Cheap Mineral Fiber Ceiling Tiles Machine is designed with sustainability in mind. By incorporating energy-efficient and environmentally friendly features, [Company Name] has ensured that the machine meets the highest standards of eco-friendliness. This aligns with the company's commitment to promoting sustainability and reducing the environmental impact of construction processes.The launch of the Cheap Mineral Fiber Ceiling Tiles Machine is expected to have a significant impact on the construction industry. With its cutting-edge technology and cost-effective production capabilities, the machine is set to become a game-changer for ceiling tile manufacturers and suppliers. It offers a compelling solution for companies looking to improve their production efficiency and deliver high-quality products to their customers.[Company Name] has always been at the forefront of innovation in the construction industry, and the launch of the Cheap Mineral Fiber Ceiling Tiles Machine is further evidence of the company's commitment to driving positive change in the sector. By offering a sustainable, efficient, and cost-effective solution for producing ceiling tiles, [Company Name] is once again proving its leadership in the industry.In conclusion, the launch of the Cheap Mineral Fiber Ceiling Tiles Machine is a significant development for the construction industry. With its advanced features and capabilities, the machine is set to revolutionize the production of ceiling tiles, providing a cost-effective and sustainable solution for manufacturers. As [Company Name] continues to lead the way in innovation and technology, the Cheap Mineral Fiber Ceiling Tiles Machine stands as a testament to the company's commitment to driving positive change in the construction sector.