Improving Productivity: A Comprehensive Guide to Mgo Board Production Line

By:Admin

Introduction:

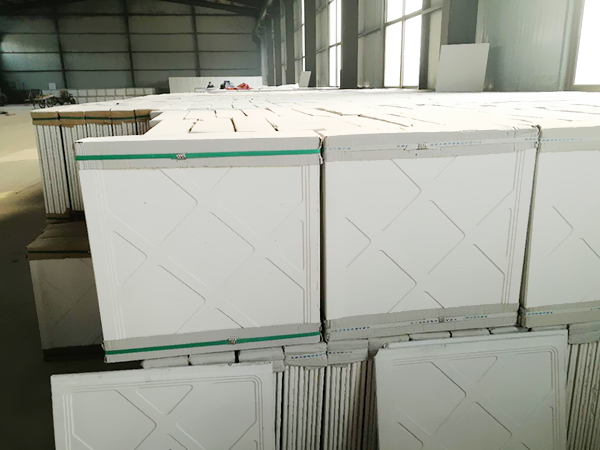

In a rapidly evolving industry, it is crucial for companies to invest in advanced technologies to maintain a competitive edge. One such innovation, the Mgo Board production line, has captured the attention of manufacturers worldwide. This versatile production line, unveiled by an industry-leading manufacturer, has revolutionized the production of Magnesium Oxide (Mgo) boards. Offering remarkable efficiency, increased productivity, and exceptional product quality, the new Mgo Board production line is transforming the construction and building materials sector.

Efficiency Redefined:

The newly developed Mgo Board production line incorporates state-of-the-art technology, reducing the production process time significantly. By leveraging automation and precision engineering, the line offers faster board production from raw materials to the final output. This unprecedented speed ensures manufacturers can meet market demand efficiently, ultimately boosting their revenue.

Unparalleled Product Quality:

The Mgo Board production line introduces cutting-edge techniques that guarantee consistent, high-quality boards. The precision control systems integrated into the production process ensure accurate measurements, resulting in Mgo boards with superior strength, durability, and fire-resistance. These boards are increasingly preferred by builders and architects for their exceptional performance and safety features.

Enhanced Productivity:

With the Mgo Board production line, manufacturers can substantially increase their daily output without compromising on quality. The line's seamless integration of raw material handling, mixing, molding, and finishing operations optimizes productivity while reducing waste. The versatility of the production line allows customization of board sizes, thicknesses, and surface finishes to cater to varying project requirements.

Streamlined Operation:

This innovative production line is engineered with user-friendliness in mind. Automated processes, coupled with an intuitive control panel, facilitate smooth operation and minimize human error. Moreover, the line features comprehensive safety measures, ensuring a secure working environment for the production staff.

Environmental Sustainability:

The Mgo Board production line exemplifies the manufacturer's commitment to sustainability. The line incorporates eco-friendly practices, such as efficient energy consumption and reduced water usage, minimizing its environmental footprint. Furthermore, the Mgo boards produced by this line are non-toxic, making them an ideal choice for environmentally conscious projects.

Market Implications:

The introduction of the Mgo Board production line is projected to have widespread implications for the construction and building materials industry. With its efficient production process and superior product quality, this innovative solution is anticipated to stimulate growth in the sector. Manufacturers can now efficiently meet the increasing demand for environmentally friendly and durable building materials, while simultaneously contributing to sustainable development.

Global Reach:

The appeal of the Mgo Board production line extends far beyond national borders. The industry-leading manufacturer plans to market this innovative solution worldwide, targeting regions with burgeoning construction projects. By establishing partnerships and collaborations with industry players globally, the manufacturer aims to create a global network that revolutionizes the construction industry.

Conclusion:

The Mgo Board production line represents a breakthrough in the manufacturing of Magnesium Oxide boards, capitalizing on cutting-edge technology to transform the construction and building materials sector. With improved efficiency, exceptional product quality, and enhanced productivity, this innovative solution offers manufacturers a competitive advantage. Furthermore, its eco-friendly design aligns with the growing global emphasis on sustainability. As this revolutionary production line reaches international markets, it is set to reshape the way construction projects are executed worldwide.

Company News & Blog

Revolutionary Automatic Equipment for Gypsum Board Cornice Production

Title: Revolutionizing Gypsum Board Cornice Production with Innovative Automatic Equipment Introduction:In the rapidly evolving construction industry, technological advancements continue to drive innovation and revolutionize traditional manufacturing processes. Among these innovations, the introduction of automatic equipment for gypsum board cornice production has emerged as a game-changer. This breakthrough solution, developed by an industry-leading company, is set to streamline production, enhance efficiency, and guarantee superior quality in the production of gypsum board cornices.Revolutionizing the Gypsum Board Cornice Manufacturing Process:The new automatic equipment, developed by an industry leader (), simplifies the labor-intensive and time-consuming process of creating gypsum board cornices. This cutting-edge equipment combines advanced technology with precision engineering to bring unprecedented efficiency to the production line. With its innovative features, the device is poised to transform the gypsum board cornice production landscape.Efficiency and Precision through Automation:The automatic equipment boasts an impressive array of features that optimize productivity and ensure consistent quality. Through automation, it eliminates the need for manual labor, significantly reducing production time and costs. By automating key steps such as gypsum mixture preparation, molding, drying, and finishing, the equipment guarantees precise and flawless results.Moreover, this state-of-the-art machinery eliminates human errors, such as inconsistencies in measurements and imprecise cutting. By adhering to pre-programmed instructions, the device ensures standardized dimensions and shapes for each cornice produced. This not only enhances the visual appeal of the final product but also reduces wastage, thus contributing to a greener and more sustainable manufacturing process.Intuitive Control System for Seamless Operation:The automatic equipment incorporates an intuitive control system that enables operators to effortlessly manage and monitor the entire production process. The user-friendly interface provides easy access to crucial parameters such as temperature, humidity, and drying time, allowing operators to make necessary adjustments on the go.Furthermore, the equipment's control system includes built-in safety features to safeguard operators and the overall production line. From emergency stops to error detection, the system effectively mitigates potential risks, ensuring a safe working environment for all involved.Reliable Durability and Low Maintenance:One of the key advantages of this automatic equipment is its exceptional durability. Constructed from high-quality materials and engineered to withstand demanding production environments, this equipment promises longevity and minimal downtime. Additionally, the machinery requires minimal maintenance and is built to withstand daily wear and tear, further reducing operational costs and maximizing productivity.The Company's Commitment to Innovation:The company behind this revolutionary automatic equipment has a strong focus on research and development to meet the ever-evolving needs of the construction industry. With years of experience and a track record of excellence, they have established themselves as pioneers in their field.By continuously investing in cutting-edge technologies, the company strives to push boundaries and exceed customer expectations. Their commitment to innovation is clearly showcased by the introduction of this groundbreaking automatic equipment, which revolutionizes gypsum board cornice production.Conclusion:The introduction of automatic equipment for gypsum board cornice production marks a significant milestone in the construction industry. With its ability to streamline manufacturing processes, enhance efficiency, and guarantee superior quality, this innovation promises to reshape the way gypsum board cornices are produced. As construction companies look for ways to improve their operation's efficiency and output, this automatic equipment provides an ideal solution that not only optimizes productivity but also ensures remarkable precision and consistency.

High-Quality Decorative Plastic Ceiling Tiles and PVC Gypsum Board Building Materials from China

Decorative Plastic Ceiling Tiles from China, The Perfect Building Material for a Cost-effective Interior DesignHomeowners and construction companies are increasingly turning to China for decorative plastic ceiling tiles and other building materials. The country's production capacity has been nurtured over years of consistent investment, enabling it to produce high-quality products that are durable and affordable.For anyone searching for affordable, but stylish ceiling solutions, China's PVC gypsum board building material is the perfect choice. Its decorative plastic ceiling tiles mimic the look and feel of plaster, tin, or wood without the added costs of installation, cleaning, and maintenance. And with strict quality control measures in place, customers can be assured that every product matches their design preferences and complies with industry standards.A leading PVC Ceiling Tiles manufacturer in China is dedicated to providing top-of-the-range products for clients from all around the world. They operate under strict quality control measures and adhere to global quality standards that ensure their decorative plastic ceiling tiles are safe, sustainable, and stand the test of time. They offer a wide range of PVC gypsum board building material and related products to cater to different styles and tastes.Their PVC gypsum board building material is designed to reduce noise, made from eco-friendly materials, and built to last. Their Decorative Plastic Ceiling Tiles, Pvc Gypsum Board Building Material, is a perfect example of their commitment to excellence. These tiles are easy to install, fire-resistant, and can withstand frequent cleaning without damage.Unlike traditional ceiling materials, PVC gypsum board building materials require low maintenance, which makes them a perfect fit for any building project from commercial buildings, homes, educational institutions, and recreational facilities.According to the CEO of the leading PVC Ceiling Tiles manufacturers in China, they aim to offer customers quality products that restore dignity to the building industry while also being environmentally friendly. The company achieves this by using environmentally sound materials and production practices that are free from toxic pollutants.In an industry that is increasingly turning to sustainable and environmentally friendly products, PVC gypsum board building materials stand out in their capacity to reduce the environmental impact of construction without compromising on quality and affordability.But as the CEO of the leading PVC Ceiling Tiles manufacturer in China points out, quality control measures are key in meeting the growing demand for these products. "We have invested in cutting-edge quality control technologies to ensure that our decorative plastic ceiling tiles meet the highest standards in the industry. We are dedicated to maintaining our reputation as a leading supplier of PVC gypsum board building materials and other related products."The CEO also highlights the company's commitment to innovation and the development of new and exciting products that offer customers value for their money. With a global reach, the leading PVC Ceiling Tiles manufacturer in China is confident that their products will continue to serve customers worldwide and maintain their reputation as a reliable supplier of high-quality building materials.In conclusion, the demand for affordable and sustainable building materials that can enhance interior design without compromising on quality is growing worldwide. China's PVC gypsum board building materials like Decorative Plastic Ceiling Tiles are the perfect solution to these needs. They are affordable, eco-friendly, and customizable to fit different styles and tastes. The leading PVC Ceiling Tiles manufacturer in China is devoted to providing high-quality products that meet and exceed industry standards while prioritizing environmental sustainability. They are confident that their products will continue to serve customers worldwide and build a reputation as a reliable supplier of quality building materials.

Vinyl Faced PVC Gypsum Board for Acoustic Insulation: A Comprehensive Guide

Vinyl Faced PVC Gypsum Board (Acoustic Insulation) - A Boon for Construction and Decoration IndustryThe construction and decoration industry has been booming lately, and with it comes the need for high-quality materials that can provide not only strength but also security and elegance. One such material that has become popular in recent years is the Vinyl Faced PVC Gypsum Board (Acoustic Insulation). This product has proved to be an excellent choice for various construction and decoration projects, from simple indoor renovations to complex commercial buildings. Here are some of the reasons why vinyl faced PVC gypsum boards are becoming increasingly popular among people looking for efficient construction and decoration solutions:Acoustic Insulation:One of the primary reasons that vinyl faced PVC gypsum boards are in high demand is their excellent acoustic insulation. The board itself is designed to have a soundproof core, which means that it can significantly reduce the amount of noise transmitted through it. When installed as a ceiling or partition wall, the board can help create a quiet and comfortable environment by reducing the amount of noise emanating from adjacent rooms. This makes it an ideal option for people seeking to avoid disturbance.Durable:PVC gypsum boards are known for their durability and strength. Made of high-quality materials, the boards are highly resistant to wear and tear and can withstand considerable stress and strain. They are also resistant to moisture and can be used in a diverse range of environments, including those with high humidity levels. Because of their sturdy nature, vinyl faced PVC gypsum boards can be used for a long time without requiring any maintenance or repair.Easy to Install:Another advantage of vinyl faced PVC gypsum boards is their ease of installation. Unlike traditional drywall, which requires special tools and expertise to install, these boards are quite simple to work with. They can be easily cut and sized according to the required dimensions, making them easy to fit in areas of any size. Additionally, the vinyl laminated surface is easy to clean, making it ideal in spaces such as kitchens and bathrooms.Low Cost:In comparison to other construction materials, vinyl faced PVC gypsum boards are affordable, making them a budget-friendly option for various decoration and construction projects. They are relatively inexpensive to install, and the materials themselves are low cost, making them an ideal choice for property owners and builders looking to cut costs.Aesthetically Pleasing:Finally, one of the most appealing aspects of vinyl faced PVC gypsum boards is that they look great. Designed for both functionality and beauty, these boards are available in a range of colors and textures, providing endless design options. They can be used in any space, regardless of the style, and can give any area an elegant and professional look.Xinsdi.com is one of the leading manufacturers and suppliers of vinyl faced PVC gypsum boards. If you're looking to improve the insulation and aesthetic appeal of your space, then you can trust this company to deliver the highest-quality products. With their years of experience, the professionals at Xinsdi.com are dedicated to meeting the needs of their clients and providing them with innovative and sustainable solutions. Contact them today to find out more!

Efficient Mgo Board Production Line for High-Quality Output

MGO Board Manufacturing Machine Supplier: Innovative Solutions for the Construction Industry In the rapidly evolving construction industry, the demand for high-quality building materials is on the rise. One popular choice among architects, builders, and contractors is Magnesium Oxide (MgO) board. This versatile material offers exceptional durability, fire resistance, and eco-friendliness, making it an ideal choice for a wide range of applications.To meet the growing demand for MgO board, manufacturers need reliable and efficient production solutions. This is where the automatic MGO board production line, offered by a leading global supplier, comes into play. With its fashionable design, reasonable structure, and stable running, this machine is revolutionizing the MgO board manufacturing process.The production line is equipped with innovative double ways roll-in technology, ensuring the production of even thickness boards. This advanced feature eliminates any inconsistencies in the board thickness, resulting in superior quality products. The shaking device further enhances the production process by ensuring the uniform distribution of materials and facilitating efficient board formation.Reliability and efficiency are essential when it comes to MgO board production, and this production line delivers on both fronts. With its high-speed capabilities, it enables large-scale production, meeting the requirements of even the most demanding construction projects. The machine's automated functions minimize human error and maximize productivity, significantly reducing production time and costs.Furthermore, this MGO board manufacturing machine adheres to strict environmental standards. The eco-friendly design ensures minimal waste and optimized energy consumption, making it a sustainable choice for any environmentally conscious manufacturer. As the global construction industry increasingly embraces green practices, this production line is a testament to the commitment of suppliers to provide eco-friendly solutions.When choosing a supplier for an MGO board manufacturing machine, various factors should be considered. One crucial aspect is the supplier's expertise and experience in the field. Look for a supplier with a solid reputation and a long history of delivering high-quality machinery to the construction industry. Additionally, it is essential to consider the supplier's commitment to customer satisfaction. A reliable supplier will provide comprehensive technical support, ensuring smooth installation and operation of the production line. They should also offer regular maintenance services to optimize machine performance, extending its lifespan and reducing downtime.In conclusion, the automatic MGO board production line offered by a prominent supplier is revolutionizing the construction industry. With its advanced technology, efficient production process, and eco-friendly design, it meets the demands of modern construction projects. Investing in this machine not only ensures high-quality MgO board production but also demonstrates a commitment to sustainability and innovation.If you are a construction manufacturer looking for an MGO board manufacturing machine supplier, look no further. Contact us today and explore the possibilities of this cutting-edge production line. Experience the benefits of reliability, efficiency, and environmental consciousness in your manufacturing process. Let us help you make your mark in the construction industry with our top-of-the-line machinery.

China Manufactures MgO Sulfate Wall Panel Making Machine for Sale

article about the MgO Sulfate Wall Panel Making Machine.Hebei Greens Building Material Technology Development Co.,Ltd, a leading manufacturer and supplier of building materials in China, has launched its latest MgO Sulfate Wall Panel Making Machine. The machine is specially designed for producing high-quality wall panels that are durable and fire-resistant.The MgO Sulfate Wall Panel Making Machine is equipped with advanced technology that ensures the production of high-quality wall panels in large quantities. The machine is easy to operate and can be controlled through a simple touch screen panel. It has a high degree of automation, which minimizes the possibility of errors and reduces the need for human intervention during the production process.One of the key features of the machine is its ability to produce smooth and parallel surfaces on both sides of the wall panel. The machine ensures that the wall panels produced have a uniform thickness and width throughout their length. This ensures that the panel fits perfectly on the wall, which reduces the need for additional cutting and trimming during installation.The MgO Sulfate Wall Panel Making Machine has a high production capacity, which enables it to produce large volumes of wall panels in a short time. It can produce wall panels of different sizes and shapes, depending on the needs of the customer. The machine can also produce wall panels with different surface finishes, including smooth, textured, and decorative finishes.The wall panels produced by the MgO Sulfate Wall Panel Making Machine are ideal for use in a wide range of applications. They are suitable for both residential and commercial buildings, and can be used for both interior and exterior walls. The wall panels are fire-resistant, which makes them ideal for use in buildings where fire safety is a concern.The MgO Sulfate Wall Panel Making Machine is also eco-friendly. It uses magnesium oxide, which is a natural and environmentally friendly material, as its main raw material. The machine also minimizes the production of waste, which reduces the environmental impact of the manufacturing process.Hebei Greens Building Material Technology Development Co.,Ltd has a proven track record of delivering high-quality building materials to customers around the world. The company is committed to providing its customers with innovative and sustainable building materials that are of the highest quality.The launch of the MgO Sulfate Wall Panel Making Machine is a testament to the company's commitment to innovation and sustainability. With this machine, the company aims to provide its customers with high-quality wall panels that are both functional and eco-friendly.In conclusion, the MgO Sulfate Wall Panel Making Machine from Hebei Greens Building Material Technology Development Co.,Ltd is a game-changer in the building materials industry. The machine's advanced technology, high production capacity, and eco-friendliness make it a valuable asset for any construction project. With this machine, builders can produce high-quality wall panels that are durable, fire-resistant, and eco-friendly, thereby ensuring the safety and comfort of building occupants.

Calcium Silicate Board Production Line - Hard Board Making Machine - Building Material Manufacturing Machinery - Product Details on Kskuntai.com

Hebei, China - Kskuntai.com, a leading manufacturer of building materials, has announced the release of its state-of-the-art Calcium Silicate Board Production Line. This cutting-edge technology is designed to facilitate the production of high-quality Calcium Silicate Boards that meet international standards.The Calcium Silicate Board Production Line is a vital part of the overall manufacturing process. This innovative machinery is designed to produce a variety of building materials, including Hard Board, Calcium Silicate Board, and several others. The production line is a fully automated system that ensures that the final product is of the highest quality, with a smooth surface, uniform thickness, and precise edges.One of the unique features of this production line is that it can handle different board thicknesses and sizes with ease. The company uses advanced technology in board making, which ensures that each board is of consistent quality with excellent mechanical performance and insulation properties. The production line also has a high yield, with low energy consumption, making it an efficient and cost-effective solution for manufacturing Calcium Silicate Boards.In addition, this production line is equipped with a variety of safety features to create a safe working environment. The line has advanced monitoring systems to ensure that the machine is running smoothly at all times. There are also emergency shutdown systems in place that can immediately bring the machine to a halt in case of any malfunction.According to an official from Kskuntai.com, “Our Calcium Silicate Board Production Line is the result of our commitment to excellence. We believe that it is our responsibility to provide our customers with the best possible quality products. Our production line is not only efficient but also eco-friendly. We have taken several steps to ensure that it is energy-efficient and minimizes waste.”The Calcium Silicate Board Production Line is a significant addition to Kskuntai.com’s range of manufacturing solutions. With this latest technology, the company can produce high-quality Calcium Silicate Boards to meet the growing demand for eco-friendly and sustainable building materials. These Calcium Silicate Boards are ideal for use in walls, ceilings, floors, and various other applications in the construction industry.Kskuntai.com is a leading manufacturer and supplier of building materials, operating in over 30 countries worldwide. The company prides itself on providing innovative and reliable solutions to its customers. With a focus on quality, efficiency, and sustainability, the company continues to demonstrate its commitment to excellence.In conclusion, the Calcium Silicate Board Production Line is a cutting-edge technology that has a significant impact on the construction industry. Kskuntai.com’s latest machinery ensures the production of high-quality Calcium Silicate Boards that meet international standards. With its energy-efficient and eco-friendly features, the production line is an efficient and sustainable solution for the manufacture of building materials.

Top-Quality Automatic Fiber Cement Board Production Line from China

When it comes to building a sustainable and durable house, one of the most important materials to consider is the fiber cement board. This material is commonly used as siding, roofing, and even as a base for flooring. With its strength and resistance to weathering, it is a perfect choice for prefabricated houses that need to withstand harsh environmental conditions. Thanks to the latest technology, fulla Automatic Fiber Cement Board with Deep Process Lamination Production Line is now available to manufacture high-quality fiber cement boards.Fulla Automatic Fiber Cement Board with Deep Process Lamination Production Line is one of the latest advancements in the construction industry. It is a machine designed to manufacture fiber cement board efficiently and effectively. The machine is equipped with the latest technology that ensures the production of high-quality fiber cement board. The full-automatic production line can produce fiber cement boards in various sizes and thicknesses as per the customer’s requirement.The deep process lamination production line of the fulla automatic fiber cement board enhances the strength and durability of the boards. The process of lamination involves the use of high-pressure rollers that compress the fiber cement board layers. This process not only intensifies the strength of the board but also makes it more resistant to weather and moisture.One of the advantages of using fulla Automatic Fiber Cement Board with Deep Process Lamination Production Line is that it can produce a large quantity of panels in a short time. This machine can produce up to thousands of panels per day. This feature makes it ideal for mass production, especially for prefabricated housing industries.The fulla Automatic Fiber Cement Board with Deep Process Lamination Production Line is also energy-efficient. The machine is designed to reduce energy consumption, thus reducing production costs. The use of this machine ensures that the manufacturing process is environmentally friendly, as it reduces the amount of waste generated.The fulla Automatic Fiber Cement Board with Deep Process Lamination Production Line is user-friendly. It requires minimal training to operate, which means that even novice operators can operate it easily. Its user-friendly interface allows operators to monitor the production process closely.The prefabricated house industry is one of the fastest-growing sectors in the construction industry, and fiber cement boards are an essential material in building such houses. The use of fulla Automatic Fiber Cement Board with Deep Process Lamination Production Line ensures that the production of these boards is efficient, cost-effective, and environmentally friendly. The boards produced by this machine will ensure the construction of sustainable and durable prefabricated houses.In conclusion, fulla Automatic Fiber Cement Board with Deep Process Lamination Production Line is a game-changer in the construction industry. It is a machine that can produce high-quality fiber cement boards efficiently and effectively. The machine is user-friendly and energy-efficient, making it ideal for mass production. With its advanced technology, the fulla Automatic Fiber Cement Board with Deep Process Lamination Production Line ensures that the manufactured boards are durable, sustainable, and ideal for the construction of prefabricated houses.

PVC Laminated Gypsum Board for Ceiling Construction - Various Sizes

If you're looking for a cost-effective solution to enhance the appearance of your ceiling, then you might want to consider PVC laminated gypsum ceiling boards. These boards offer many benefits and are becoming increasingly popular in the construction industry.What are PVC Laminated Gypsum Ceiling Boards?PVC laminated gypsum ceiling boards are made of high-quality paper-faced gypsum board with a layer of PVC on the surface. The gypsum board is a composite material made of gypsum plaster and a paper backing. PVC is a synthetic plastic polymer that is resistant to water, chemical damage, fire, and weathering.Advantages of PVC Laminated Gypsum Ceiling Boards1. Fire Resistance:One of the biggest advantages of PVC laminated gypsum ceiling boards is their fire resistance. Gypsum board has a natural resistance to fire, and when combined with PVC, it becomes even more fire-resistant. In case of a fire, these boards will slow the spread of flames, providing you with valuable time to evacuate the building.2. Moisture Resistant:PVC laminated gypsum ceiling boards also have good moisture resistance. With their PVC coating layer, they resist water and moisture, making them ideal for use in humid environments such as bathrooms, kitchens, and basements.3. Easy to Install:PVC laminated gypsum ceiling boards are easy to install and require minimal tools. They can be glued directly onto the ceiling or attached using furring strips. This makes them a popular choice for DIY enthusiasts and project managers alike.4. Versatile:PVC laminated gypsum ceiling boards come in a variety of sizes and designs, making them a versatile option for all kinds of residential and commercial projects. They are available in both square and rectangular shapes, allowing you to choose the size that best fits your ceiling.5. Cost-Effective:PVC laminated gypsum ceiling boards are a cost-effective option compared to other ceiling materials such as wood, metal, or plaster. They are a great way to add a decorative touch to your home or office without breaking the bank.Cheap PVC Gypsum Ceiling MachineIf you're looking for a cheap PVC gypsum ceiling machine, you're in luck. There are quite a few manufacturers producing affordable machines that can make your PVC laminated gypsum ceiling boards quickly and efficiently.When looking for a cheap PVC gypsum ceiling machine, it's essential to choose a reliable manufacturer. Ensure that the machine comes with a warranty and meets all the necessary safety standards.In conclusion, PVC laminated gypsum ceiling boards are a fantastic alternative to traditional ceiling materials. They are fire-resistant, moisture-resistant, easy to install, versatile, and cost-effective. If you're considering upgrading your ceiling, PVC laminated gypsum ceiling boards are undoubtedly worth considering. Combine that with a cheap PVC gypsum ceiling machine, and you have a winning combination that can provide a beautiful, functional, and affordable solution for your construction project.

High Quality PVC Laminated Gypsum Ceiling Board - 595*595 603*603mm

On May 15, 2021, a new product was launched by a renowned construction materials company, a PVC laminated gypsum board that has gained significant attention in the market. This new product promises to revolutionize the construction industry and serve as an answer to the demand for innovative and quality materials.The PVC laminated gypsum board, available in two standard sizes- 595*595mm and 603*603mm, is designed to meet the needs of builders and architects looking to create an exquisite and elegant interior design for their projects. This gypsum ceiling tile is made from high-quality paper-faced gypsum board and then laminated with PVC materials.The PVC laminate on the board provides a smooth and uniform surface while no dust will be generated during the installation process, which makes it a clean and simple installation option. This feature saves time and allows the builders to achieve excellent coverage with low costs, making the PVC laminated gypsum board more reasonable in pricing than other similar products available in the market.The PVC laminated gypsum board offers a durable finish with excellent finish coordination for the entire design scheme. Its waterproof and fire resistance properties make it suitable to install in areas with a high risk of moisture and fire, such as kitchens and bathrooms, medical facilities, and laboratories.Additionally, it is designed to provide insulation, which limits the spread of noise throughout the building, making it ideal for commercial and residential buildings. Its unique surface characteristic reduces the effect of impact sounds and eliminates any problems of sound reverberation providing a comfortable interior space for customers.This new building material solution is also highly customizable, and therefore ideal for creative and artistic designs, which open up new possibilities for building interiors. This means that it is possible to achieve any desired appearance, whether traditional or modern, bright or subtle, matt or glossy, by choosing from a wide range of colors, patterns, and finishes. As a result, it is perfect for use in a range of environments, including luxurious hotel rooms, sport centers, offices, shopping malls, and government buildings. The PVC laminated gypsum board has passed numerous environmental tests, and has been certified as a green material, meaning that it is safe for both builders and customers. It is made from natural resources, which make it a sustainable option for future generations while also meeting the LEED requirements for green building construction standard.The launch of the PVC laminated gypsum board is a significant milestone for the building construction industry. The availability of such a high-quality material that meets all the needs and functions required of today's modern interior design has to come as a welcome development. The advance technology and creativity that went into developing this building material are evident in its outstanding features and design quality, which makes it suitable for a wide range of applications.In conclusion, the PVC laminated gypsum board is a game-changer not only for interior design but also for sustainable building construction. It offers impressive benefits with its durability, waterproofing properties, insulations, and ability to reduce noise and fire hazards making it a perfect choice for builders, architects, and homeowners alike. If you want a building material for your project that combines affordability, superior quality, and sustainability, then the PVC laminated gypsum board is the right choice for you.

Latest Magnesium Oxide Board for Sale - Premium Quality MgO Board

, Magnesium Oxide Wall Board, Fireproof Board, Mgo Board Supplier.MgO Board is a high-quality, eco-friendly building material that has become increasingly popular in recent years. As more and more people become aware of its many benefits, the demand for MgO Board continues to grow. If you are in the market for MgO Board, then you need to check out Chinsunmgoboard.com. This website is a leading supplier of MgO Board and has a wide range of products to offer.One of the main reasons why MgO Board is so popular is because of its fire-resistant properties. MgO Board is made from magnesium oxide and is a non-combustible material. This makes it perfect for use in fire-prone areas. MgO Board also has excellent insulation properties, which means that it can help to keep your home or business warm in the winter and cool in the summer.At Chinsunmgoboard.com, you will find a range of MgO Board products to choose from. There are MgO Drywall Board Making Machines, Magnesium Oxide Wall Board, Fireproof Board, and MgO Board Suppliers. By offering such a wide range of products, Chinsunmgoboard.com is able to cater to the needs of all its customers.If you are looking for an eco-friendly building material that is both durable and fire-resistant, then MgO Board is the perfect choice. And if you want to find the best MgO Board suppliers, then look no further than Chinsunmgoboard.com. With their high-quality products and excellent customer service, you can be sure that you will be getting the best value for your money. So why not check them out today and see what they have to offer?