Highly Efficient and Innovative Fiber Cement Board Manufacturing Machine

By:Admin

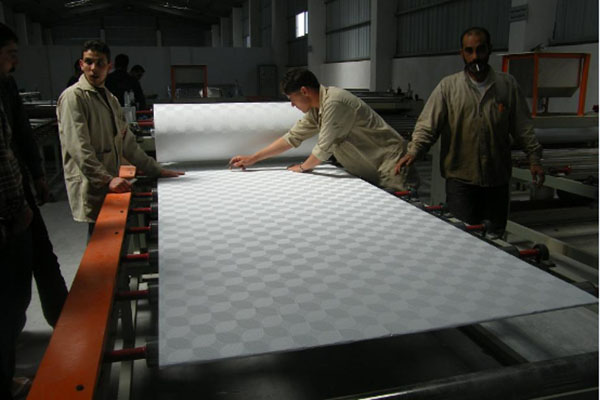

Fiber cement boards have been prevalent in the construction industry for decades, mainly due to their durability, versatility, and fire resistance. However, production processes involved in creating these boards require extensive labor and time, making it a tedious and costly process. This is where the Fiber Cement Board Making Machine comes in.

The machine's operation is simple and straightforward. First, the raw materials are mixed and combined into a slurry that is poured onto a mesh on the machine's conveyor belt. The slurry is then compressed by a roller before passing through a vacuum system for water drainage. The machine's automated cutting system then splits the board into the desired length.

An added advantage of this machine is its adaptability to produce different types of fiber cement boards, such as siding, roofing, and flooring. This versatility makes it an attractive option for builders and construction companies looking to diversify their product range.

The company behind this innovation is a prominent construction machinery manufacturer with a rich history of over a decade. The company's mission is to provide quality, solutions-driven machinery to construction companies worldwide, ensuring they achieve maximum productivity and profitability.

In line with that mission, the Fiber Cement Board Making Machine boasts of several features that make it a top-quality product. These include its heavy-duty steel frame, precision electronic control system, and adjustable speed motor for better control. The machine is also energy-efficient, with a low carbon emissions footprint, contributing to the company's commitment to sustainable manufacturing practices.

The Fiber Cement Board Making Machine has already gained traction in markets worldwide, with construction companies in Europe, Asia, and America choosing it for its ease of use, reliability, and high-quality output.

One company in the United States reported significant results after acquiring the machine. "We had always used traditional board-making processes that required a lot of labor and time to create our fiber cement boards. But since we acquired the Fiber Cement Board Making Machine, we have seen a tremendous improvement in productivity, and our products have also improved in quality," said the company's CEO.

The Fiber Cement Board Making Machine has also stirred interest in emerging markets, where the demand for quality and affordable building materials is high. The company's commitment to providing after-sales support and training in operating and maintaining the machine has made it an ideal solution for businesses seeking to invest in sustainable and profitable machinery.

In conclusion, the Fiber Cement Board Making Machine is a game-changer in the construction industry, providing a cost-effective, efficient, and sustainable solution for creating fiber cement boards. The machine's adaptability and quality output make it an attractive option for builders and construction companies worldwide looking to diversify their product range and maximize their profitability.

Company News & Blog

Affordable and Lightweight Yarn Recommendations for a Warm Winter Shawl

article focusing on affordable and lightweight yarn options for winter knitting projects.)Winter is the perfect season for knitting cozy shawls, scarves and blankets. But when it comes to choosing the right yarn for the project, many knitters face a dilemma. On one hand, you want a material that will keep you warm and snug, but on the other hand, you don't want it to be too heavy or expensive. The good news is that there are plenty of affordable and lightweight yarn options to choose from, as we explore in this article.Merino WoolOne of the most popular options for winter knitting is merino wool. This soft and warm yarn is made from the wool of merino sheep, known for their fine fleece. Merino wool is lightweight and breathable, making it ideal for layering and wearing indoors. It also has natural moisture-wicking properties, which means it will keep you dry and comfortable. Although merino wool can be on the pricier side, it's worth investing in for its durability and versatility.Acrylic YarnFor those looking for a more affordable option, acrylic yarn is a great choice. This man-made fiber is lightweight, easy to wash and available in a wide variety of colors and textures. Acrylic yarn is also hypoallergenic, making it a great option for those with sensitive skin. While it may not be as warm as some other fibers, it's a great option for layering or for wearing in milder winter weather.Alpaca YarnAlpaca yarn is another excellent option for winter knitting. This soft and insulating fiber comes from the fleece of the alpaca, a South American animal that's related to the llama. Alpaca yarn is incredibly warm and lightweight, making it ideal for winter accessories like scarves and hats. It is also hypoallergenic and comes in a variety of natural shades. While it can be more expensive than some other fibers, it's worth the investment for its warmth and comfort.Cotton YarnWhile many knitters associate cotton yarn with warm weather projects, it can also be a great option for winter knitting. Cotton is lightweight and breathable, making it ideal for layering or wearing indoors. It's also a more affordable option than some other fibers. While cotton may not be as warm as wool or alpaca, it's a great option for those who prefer natural fibers and want to avoid itchiness and irritation that can come from other materials.Bamboo YarnFinally, bamboo yarn is a great option for those looking for a lightweight and eco-friendly material. Bamboo is a sustainable and renewable resource, and bamboo yarn is incredibly soft and comfortable. It's also naturally antibacterial and hypoallergenic, making it a great option for those with sensitive skin. While it may not be as warm as other fibers, it's a great option for layering or for warmer winter weather.In conclusion, when it comes to finding the right yarn for your winter knitting project, there are plenty of affordable and lightweight options to choose from. Whether you prefer natural fibers like wool and alpaca, or man-made fibers like acrylic and bamboo, there's a yarn out there that's perfect for your needs. So stock up on your favorite materials and get ready to create cozy and stylish accessories to keep you warm all winter long.

Quality Wood Plastic Door Production Line for Board, Profile, and Frame Manufacturing in China

Wood Plastic Door Production Line (Board/Profile/Frame) China ManufacturerAs people become more aware of environmental issues and sustainable resources, there has been a growing demand for innovation in the construction industry. One of the latest trends taking the industry by storm is the wood plastic door production line. This technology combines the benefits of wood and plastic to create a durable and eco-friendly material that's perfect for doors, frames, and profiles. In this article, we'll explore the benefits of this technology and the leading China manufacturer of wood plastic door production line.What is a Wood Plastic Door Production Line?A wood plastic door production line is a modern manufacturing technology that combines natural wood fibers with plastic to create a composite material that's durable, lightweight, and eco-friendly. The wood fibers come from sustainable sources like sawdust, wood chips, or agricultural waste, which are then mixed with thermoplastic materials like PVC, PE, or PP. The resulting composite material has a higher strength-to-weight ratio than traditional wood and is resistant to water, decay, and insects.The wood plastic door production line can produce a range of products, including boards, profiles, and frames. These products can be used for different applications, such as doors, windows, decking, fencing, and more. The wood plastic composite products have a natural wood-like appearance and can be painted or stained to match any design requirement.Benefits of a Wood Plastic Door Production Line1. Eco-Friendly: One of the main benefits of a wood plastic door production line is that it's eco-friendly. The use of sustainable materials like wood fibers and recycled plastics reduces the carbon footprint of the production process and helps preserve natural resources. Moreover, the wood plastic composite products are recyclable, which further enhances their sustainability.2. Durability: Another benefit of a wood plastic door production line is that it produces products that are durable and long-lasting. The composite material is resistant to water, decay, and insects, which makes it ideal for outdoor applications. The products have a longer lifespan than traditional wood and require less maintenance, which saves time and money in the long run.3. Design Versatility: Wood plastic door production line can produce a wide range of designs and color options. The natural wood-like appearance of the products gives them a warm and inviting look, and they can be painted or stained to match any design requirement. The products can be molded into different shapes and sizes, which gives designers more flexibility in their projects.China Manufacturer of Wood Plastic Door Production LineIf you're looking for a reliable manufacturer of wood plastic door production line in China, then look no further than (need remove brand name). As a leading manufacturer and supplier of composite machinery, they have years of experience in the industry and are committed to providing high-quality products and services to customers worldwide.Their wood plastic door production line is designed to produce fireproof, waterproof, and eco-friendly products that meet international standards. The production line can manufacture a wide range of products, including boards, profiles, and frames, that are suitable for indoor and outdoor applications.Their wood plastic door production line is equipped with advanced machinery, such as twin-screw extruders, cooling baths, and cutting machines. The production process is fully automated, which ensures quality control and reduces the risk of errors.ConclusionIn conclusion, the wood plastic door production line is a modern technology that combines the benefits of wood and plastic to create a durable and eco-friendly material that's perfect for doors, frames, and profiles. The products produced by this line are eco-friendly, durable, and versatile, making them an ideal choice for designers and builders. If you're looking for a reliable manufacturer of wood plastic door production line in China, then (need remove brand name) is your go-to source. Their products are designed to meet international standards, and they're committed to providing high-quality products and services to customers worldwide.

Professional Plastering Services for New Builds, Repairs, and Renovations

Brad McKinnon Plastering: The Leading Plastering Service ProviderLooking to renovate your home or building a new house from scratch? Then, Brad McKinnon Plastering has got you covered! Providing top-notch plastering services, Brad McKinnon Plastering is the leading company in New Zealand, known for delivering quality and timely services to clients.At Brad McKinnon Plastering, we understand the vital role that plastering plays in the construction industry, and our dedicated team of experts takes great pride in providing top-quality services that exceed our clients' expectations. Our commitment to quality and excellence has made us one of the most preferred plastering providers in the industry.New Build ServicesBuilding a house from scratch is a significant investment in one's life, and we understand that. Hence, we offer New Build services like no other. Our team of experts is knowledgeable, reliable and equipped with the latest technology and tools to ensure that your new build is perfect. We pay attention to every detail, from layout to design, and from plastering to painting. We ensure that our clients' vision comes to fruition, and their dream home is realized.Repair ServicesAt some point, even the most robust of buildings require repairs. Whether it's a small crack or significant damage, fret no more, as Brad McKinnon Plastering offers reliable repair services to maintain the aesthetics and integrity of your walls and ceilings. Our team of experts is equipped with the necessary skills and tools to tackle any repair job, no matter how big or small the issue may seem.Renovation ServicesThinking of a home makeover? Brad McKinnon Plastering is here to help. Our renovation services are bespoke and tailored to suit our clients' needs. We understand that every client has unique taste, and we take pride in listening and working with our clients to achieve their desired results. We employ the latest techniques to ensure that the result is not only visually appealing but exceeds our clients' expectations.Full Skim Level 5 ServicesIf you require the most polished finish, then our Full Skim Level 5 services are perfect for you. Our experts use the latest technology and tools to provide beautiful, level five finishes that will leave your walls and ceiling with the most beautiful, polished finish. Our team is dedicated to delivering exceptional work and will ensure that every detail is perfect.GIB CoveBrad McKinnon Plastering offers GIB Cove services, one of the most distinguishing features of any room. Our expert team ensures that the GIB Cove in your room is bespoke and tailored to your requirements and style. With our GIB Cove services, you can rest assured that your room will be transformed into a beautiful space.Plaster CorniceOne of the most essential aspects of plastering is Plaster Cornice. It enhances the aesthetics of any room and provides that extra finishing touch that can make all the difference. At Brad McKinnon Plastering, we specialize in Plaster Cornice and offer bespoke services that will transform your room.ConclusionBrad McKinnon Plastering is the most trusted and reliable plastering service provider in New Zealand. Our team of dedicated experts is equipped with the latest technology and tools to ensure that every job is perfect. We pay great attention to detail and are committed to delivering quality and timely services that exceed our clients' expectations. Contact us today, and let's help you transform your home.

Lightweight Wall Panel Production Line for Mgo Board - Benefits and Cost Analysis

Jinan Zhongke Building Material Machinery Co., Ltd., a leading building material machinery manufacturer in China, has recently launched its latest Mgo Board Light Weight Wall Panel Production Line. The product line is designed to produce high-quality wall panels that are lightweight, fire-resistant, waterproof, and energy-efficient.The company has invested heavily in research and development to create a leading-edge Mgo Board Light Weight Wall Panel Production Line that is capable of producing wall panels of up to 3660mm*1220mm*3mm size at a rate of 1-30m/min. The production line is energy-efficient, cost-effective, and requires minimal labor for operation.According to the benefit analysis conducted by Jinan Zhongke Building Material Machinery Co., Ltd., the cost accounting for producing one wall panel includes raw material cost, water-electricity fee, and labor cost. The raw material cost for one panel is 15 yuan/piece, which is significantly lower than the price of traditional wall panels. The water-electricity fee is 0.2 yuan/piece, and the labor cost is 1.5 yuan/piece. Therefore, the total cost for one panel is 16.7 yuan/piece, which is much lower than the cost of traditional wall panels.Moreover, the Mgo Board Light Weight Wall Panel Production Line is fully automated, requiring only two workers for its operation. Thus, the labor cost is reduced, leading to higher profits for the manufacturers. The production line also has a low energy consumption rate, which reduces the overall manufacturing costs and is environmentally friendly.Jinan Zhongke Building Material Machinery Co., Ltd. is a reputable manufacturer that prioritizes customer satisfaction. The company has a team of experienced and professional engineers who provide customization services to meet the specific requirements of its clients.The Mgo Board Light Weight Wall Panel Production Line is suitable for manufacturing various types of lightweight wall panels, including partition walls, external walls, internal walls, and fire-resistant walls. The wall panels can be used in various residential and commercial buildings, such as hotels, schools, hospitals, and office complexes.In conclusion, Jinan Zhongke Building Material Machinery Co., Ltd.'s latest Mgo Board Light Weight Wall Panel Production Line is a revolutionary product that will transform the construction industry. It is cost-effective, energy-efficient, and produces high-quality wall panels that have numerous benefits over traditional wall panels. The product line's superior quality design, advanced technology, and customization services set it apart from its competitors, making it the go-to product for all lightweight wall panel needs.

Affordable Machine for Manufacturing Magnesium Wall Panels

Title: New Magnesium Wall Panels Manufacturing Machine Revolutionizes Construction IndustryIntroduction:In a groundbreaking development for the construction industry, an innovative company recently unveiled an advanced magnesium wall panels making machine. This cutting-edge technology promises to streamline the production process of magnesium-based building materials, revolutionizing the construction sector.The Importance of Magnesium Wall Panels:Magnesium wall panels have gained rapid popularity in recent years due to their exceptional properties. These panels are lightweight, fire-resistant, and possess excellent acoustic qualities. They are also resistant to mold and pests, making them an ideal solution for both residential and commercial projects.Company Background:{Company Name}, a well-established and renowned manufacturing company, has long been recognized as a leading provider of advanced construction materials. With a strong commitment to innovation, they have invested heavily in research and development, constantly striving to deliver superior products that address industry challenges.Introduction of the Magnesium Wall Panels Making Machine:{Company Name}'s latest breakthrough comes in the form of a highly efficient automated machine specifically designed for the mass-production of magnesium wall panels. This state-of-the-art equipment integrates advanced technology with precision engineering to meet the rising demands of the construction industry.Key Features and Advantages:This new machine offers several key features and advantages, cementing its position as a game-changer in the field of construction materials:1. Increased Production Capacity: The machine allows for a significant increase in production output, fulfilling market demands more efficiently than ever before. This will help alleviate supply shortages and reduce project completion time.2. Enhanced Precision and Quality: By employing advanced automation and artificial intelligence, the machine ensures precise molding and cutting, resulting in consistently high-quality magnesium wall panels. This will provide builders and contractors with reliable and durable construction materials.3. Reduced Labor Requirements: With automated processes, the need for extensive manual labor is greatly minimized. This reduces overall production costs and allows employees to focus on more intricate tasks, ensuring greater productivity.4. Environmentally Friendly: Magnesium wall panels are inherently sustainable due to their low carbon footprint. The new manufacturing machine is designed to further optimize resource utilization, minimizing waste and decreasing energy consumption during production.Impact on the Construction Industry:The introduction of this revolutionary manufacturing machine is set to have a transformative impact on the construction industry. Key benefits include:1. Cost-effectiveness: The increased production capacity and reduced labor requirements will result in significant cost savings for builders and developers. This, in turn, will enable more affordable housing options and stimulate economic growth.2. Enhanced Safety: Magnesium wall panels are renowned for their fire-resistant properties. Widespread adoption of this technology can lead to safer buildings, reducing the risk of fire-related incidents and improving overall occupant safety.3. Sustainable Development: The machine's eco-friendly features align with global efforts to promote sustainable development. With greater accessibility to high-quality magnesium wall panels, the construction industry can contribute to a greener built environment.Conclusion:The unveiling of {Company Name}'s advanced magnesium wall panels making machine marks a major milestone in the construction sector. With its focus on increased production capacity, enhanced precision, and reduced labor requirements, this technology is poised to transform the industry landscape. As the demand for cost-effective and sustainable building materials continues to rise, this innovation promises to meet these evolving needs and shape the future of construction.

Revolutionary Automatic Equipment for Gypsum Board Cornice Production

Title: Revolutionizing Gypsum Board Cornice Production with Innovative Automatic Equipment Introduction:In the rapidly evolving construction industry, technological advancements continue to drive innovation and revolutionize traditional manufacturing processes. Among these innovations, the introduction of automatic equipment for gypsum board cornice production has emerged as a game-changer. This breakthrough solution, developed by an industry-leading company, is set to streamline production, enhance efficiency, and guarantee superior quality in the production of gypsum board cornices.Revolutionizing the Gypsum Board Cornice Manufacturing Process:The new automatic equipment, developed by an industry leader (), simplifies the labor-intensive and time-consuming process of creating gypsum board cornices. This cutting-edge equipment combines advanced technology with precision engineering to bring unprecedented efficiency to the production line. With its innovative features, the device is poised to transform the gypsum board cornice production landscape.Efficiency and Precision through Automation:The automatic equipment boasts an impressive array of features that optimize productivity and ensure consistent quality. Through automation, it eliminates the need for manual labor, significantly reducing production time and costs. By automating key steps such as gypsum mixture preparation, molding, drying, and finishing, the equipment guarantees precise and flawless results.Moreover, this state-of-the-art machinery eliminates human errors, such as inconsistencies in measurements and imprecise cutting. By adhering to pre-programmed instructions, the device ensures standardized dimensions and shapes for each cornice produced. This not only enhances the visual appeal of the final product but also reduces wastage, thus contributing to a greener and more sustainable manufacturing process.Intuitive Control System for Seamless Operation:The automatic equipment incorporates an intuitive control system that enables operators to effortlessly manage and monitor the entire production process. The user-friendly interface provides easy access to crucial parameters such as temperature, humidity, and drying time, allowing operators to make necessary adjustments on the go.Furthermore, the equipment's control system includes built-in safety features to safeguard operators and the overall production line. From emergency stops to error detection, the system effectively mitigates potential risks, ensuring a safe working environment for all involved.Reliable Durability and Low Maintenance:One of the key advantages of this automatic equipment is its exceptional durability. Constructed from high-quality materials and engineered to withstand demanding production environments, this equipment promises longevity and minimal downtime. Additionally, the machinery requires minimal maintenance and is built to withstand daily wear and tear, further reducing operational costs and maximizing productivity.The Company's Commitment to Innovation:The company behind this revolutionary automatic equipment has a strong focus on research and development to meet the ever-evolving needs of the construction industry. With years of experience and a track record of excellence, they have established themselves as pioneers in their field.By continuously investing in cutting-edge technologies, the company strives to push boundaries and exceed customer expectations. Their commitment to innovation is clearly showcased by the introduction of this groundbreaking automatic equipment, which revolutionizes gypsum board cornice production.Conclusion:The introduction of automatic equipment for gypsum board cornice production marks a significant milestone in the construction industry. With its ability to streamline manufacturing processes, enhance efficiency, and guarantee superior quality, this innovation promises to reshape the way gypsum board cornices are produced. As construction companies look for ways to improve their operation's efficiency and output, this automatic equipment provides an ideal solution that not only optimizes productivity but also ensures remarkable precision and consistency.

China Supplier of PVC Crust Foam Board Extrusion Line for Sale

If you're in the market for a high-quality PVC crust foam board production line, look no further than JEEBO Machinery. With a commitment to excellence and innovation, JEEBO Machinery is a leading manufacturer of PVC crust foam board extrusion lines in China.Using celuka technology to foam, the PVC crust foam board has a flat and smooth surface that is much stronger than the free foaming body. This makes it a great choice for a wide range of applications, from furniture to signage to construction materials.At JEEBO Machinery, we offer a top-of-the-line PVC crust foam board extrusion line that is designed for maximum efficiency and production capabilities. Our production line includes a range of advanced features, including a high-precision control system, automatic vacuum calibration table, and a multi-roller hauling machine, among others.One of the key benefits of our PVC crust foam board extrusion line is its versatility. It can be used to produce a range of different board types, including furniture boards, building boards, advertising boards, and more. Plus, with an output of up to 600kg per hour, our production line can handle even the most demanding production requirements.At JEEBO Machinery, we are committed to providing our customers with the highest quality products and services at competitive prices. That's why we offer a comprehensive pricelist for our PVC crust foam board extrusion line, making it easy for you to compare our products and choose the one that best meets your needs and budget.If you're interested in learning more about our PVC crust foam board extrusion line or any of our other products and services, please contact us today. Our team of experts is always available to answer your questions and help you find the perfect solution for your specific needs. Thank you for choosing JEEBO Machinery!

High-Quality Lamination Machines for Gypsum Board Glue Spreading and mgo Board Lamination Production in China

China's industrial landscape is constantly evolving, with a host of manufacturers and suppliers emerging in different sectors of the industry. In recent years, the Chinese manufacturing industry has seen a significant surge in demand for high-quality laminating equipment and machinery.Amid this market growth, China is emerging as a frontrunner in the laminating machinery and equipment space. In particular, the creation of high-quality Gypsum Board Glue Spreading Board and MgO Board Lamination Machines is a testament to the country's manufacturing prowess.The Gypsum Board Glue Spreading Board and MgO Board Lamination Machines are being manufactured using advanced technology and innovative techniques that are highly efficient, reliable, and durable. These machines are designed to be easy to operate and maintain, making them ideal for businesses that need to increase their production capacity. Additionally, the machines are also very versatile, meaning they can be used in a wide range of industrial settings. This flexibility has made them popular with entrepreneurs looking to start manufacturing businesses in various sectors.The Gypsum Board Glue Spreading Board and MgO Board Lamination Machines are also designed to ensure that they operate safely and securely on the production floor. Each machine is fitted with modern safety features that guarantee protection to operators and other employees working in the production system. These safety features include automatic shut-offs, alarms, and other safety measures that prevent accidents and reduce the risk of injury.Companies producing these laminating machines adhere to strict quality control guidelines to ensure they comply with international safety and quality standards. Each machine is tested comprehensively to guarantee that they meet the required standards before they are released to the market.The manufacturers of Gypsum Board Glue Spreading Board and MgO Board Lamination Machines in China take pride in their products. With a keen focus on innovative technology and high-quality standards, these manufacturers provide businesses with reliable and long-lasting machines to enhance their production capabilities.The success of these machines in the global market has led to a significant increase in demand. As a result, manufacturers have been optimizing their production capacity to keep up with the ever-growing demand for these machines. Many businesses from around the world are sourcing their laminating machinery from China to benefit from high-quality machines.The Chinese producer of the laminating machines, which earned significant success in recent years, has been producing some of the most cutting-edge industrial machinery through advanced manufacturing procedures and techniques. Their Gypsum Board Glue Spreading Board and MgO Board Lamination Machines are some of the most advanced and reliable products on the market.These machines are designed to offer exceptional versatility, safety, and reliability, making them ideal for businesses of all sizes. Whether it is a small startup or a large conglomerate, these lamination machines can optimize productivity and enhance manufacturing operations.In conclusion, the Gypsum Board Glue Spreading Board and MgO Board Lamination Machines from China are an excellent testimony to the country’s continued excellence in the manufacturing industry. These laminating machines deliver exceptional quality and performance, guaranteeing long-lasting reliability and ease of operation. With surging demand for these machines globally, China is set to continue its dominance in the machinery and equipment manufacturing industry for the foreseeable future.

Effective Slurry Distribution for Multiple Screens: PU Dewatering Screen with Vibrating Motor

As the demand for high-quality mineral fiber ceiling board increases, so does the need for efficient and reliable production equipment. Fortunately, there are now several top-grade Mineral Fiber Ceiling Board Machine factories that offer state-of-the-art production machinery and systems designed to meet the demands of modern manufacturing.One of the best ways to achieve high-quality ceiling boards is by using mineral fiber materials, which are known for their sound absorption, fire resistance, and thermal insulation properties. These materials are derived from naturally occurring minerals, such as basalt, perlite, and volcanic rock, which are then processed and combined with various binders, such as starch or resin.To produce mineral fiber ceiling boards, a Mineral Fiber Ceiling Board Machine is used to mix and form the materials into panels or tiles of varying sizes and densities. These machines utilize advanced technologies, such as heating and pressing, to create a strong and durable product that meets the required specifications.When selecting a Mineral Fiber Ceiling Board Machine factory, it is essential to consider some critical factors that will ensure optimal performance, reliability, and cost-effectiveness. Some of these factors include:Quality of the MachinesA high-quality Mineral Fiber Ceiling Board Machine should be durable, reliable, and easy to operate. The quality of the materials used in the manufacturing process is also critical, as low-quality materials can lead to frequent breakdowns and maintenance issues.Production CapacityThe production capacity of the Mineral Fiber Ceiling Board Machine should meet the needs of your manufacturing facility. It is essential to choose a machine that can handle your desired output without compromising on quality or efficiency.Maintenance and SupportChoosing a reputable Mineral Fiber Ceiling Board Machine factory that offers reliable maintenance and technical support ensures minimal downtime and maximum productivity. It is essential to choose a factory that provides regular maintenance and repair services and offers quick response times in case of any technical issues.Cost-effectivenessThe cost of the equipment and its maintenance should be within your budget. Choosing a Mineral Fiber Ceiling Board Machine factory that offers affordable solutions without compromising on quality or efficiency is critical to the success of your manufacturing plant.ConclusionMineral fiber ceiling board production has come a long way in recent years, thanks to advanced Mineral Fiber Ceiling Board Machine technology. By selecting a quality Mineral Fiber Ceiling Board Machine factory, you can ensure that your manufacturing plant produces high-quality, cost-effective, and efficient mineral fiber ceiling boards. Contact a reputable factory today to get the best mineral fiber ceiling board production machinery for your facility.