High-Quality Wholesale Foam Board Production Line for XPS Foam Board

By:Admin

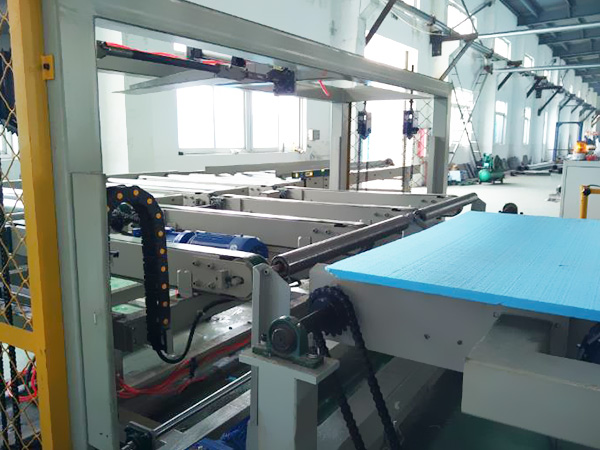

In response to the increasing demand for high-quality XPS foam board, {Company Name} has announced the acquisition of a state-of-the-art wholesale XPS foam board production line. This new addition to the production process will enable {Company Name} to enhance its manufacturing capabilities and meet the growing needs of its customers in the construction and insulation industries.

The new wholesale XPS foam board production line is a significant investment for {Company Name}, and it is expected to streamline the production process and improve overall efficiency. With the ability to produce a high volume of XPS foam board, the company will be able to fulfill large-scale orders and meet tight deadlines without compromising on quality.

XPS foam board is a popular choice for insulation due to its thermal performance, moisture resistance, and durability. It is commonly used in residential and commercial construction projects to improve energy efficiency and reduce heating and cooling costs. With the addition of the wholesale XPS foam board production line, {Company Name} aims to strengthen its position as a leading supplier of high-quality insulation products.

The new production line is equipped with the latest technology and machinery, allowing for precise and efficient manufacturing. It has the capacity to produce a wide range of XPS foam board products, including different sizes, thicknesses, and densities to meet the specific requirements of customers. By offering a diverse selection of XPS foam board, {Company Name} aims to cater to a variety of insulation needs in the market.

In addition to enhancing the production process, the wholesale XPS foam board production line is also expected to have a positive impact on the company's sustainability efforts. XPS foam board is renowned for its long service life, and its use in construction can contribute to energy savings and reduced greenhouse gas emissions. With the new production line, {Company Name} is committed to meeting the growing demand for sustainable insulation solutions and supporting environmentally conscious practices.

{Company Name} takes pride in its commitment to delivering high-quality products and exceptional customer service. With the investment in the wholesale XPS foam board production line, the company aims to strengthen its position as a reliable and trusted supplier in the industry. By optimizing the production process and expanding its capabilities, {Company Name} seeks to better serve its customers and exceed their expectations.

As part of the company's dedication to innovation and continuous improvement, the wholesale XPS foam board production line will undergo rigorous testing and quality control procedures to ensure that the products meet the highest standards. {Company Name} is dedicated to upholding its reputation for excellence and reliability, and the new production line is a testament to its ongoing commitment to manufacturing superiority.

Overall, the addition of the wholesale XPS foam board production line represents a significant milestone for {Company Name} and reflects its vision for growth and progress. By investing in advanced technology and expanding its production capabilities, the company is well-positioned to meet the evolving needs of the market and provide cutting-edge insulation solutions to its customers.

With the introduction of the wholesale XPS foam board production line, {Company Name} is poised to elevate its manufacturing process and deliver unmatched value to its clients. The company's dedication to quality, efficiency, and sustainability remains unwavering, and it looks forward to the positive impact that the new production line will have on its operations and the industry as a whole.

Company News & Blog

Affordable Fully Automatic Gypsum Plaster Cornice Manufacturing Machine Factories

Title: Introduction of Budget-Friendly, Fully Automatic Gypsum Plaster Cornice Manufacturing MachinesIntroduction:In a bid to streamline the manufacturing process and cater to the growing demand for decorative gypsum plaster cornices, a number of factories have introduced cost-effective, fully automatic gypsum plaster cornice manufacturing machines. These high-tech machines have revolutionized the industry, allowing manufacturers to produce high-quality cornices efficiently, while maintaining affordable pricing, thus benefiting both consumers and businesses.Company Overview:One such company, with extensive experience in the manufacturing and supply of gypsum plaster cornice manufacturing machines, has become a pioneer in this industry. With a strong focus on research and development, this company has consistently delivered state-of-the-art machines that automate the previously complex and time-consuming manufacturing processes. Their commitment to affordability and quality has made them a go-to choice for factories looking to enhance their production capabilities.Efficiency and Cost-Effectiveness:The fully automatic gypsum plaster cornice manufacturing machines have significantly increased productivity rates, reducing the overall manufacturing time. These machines are capable of seamlessly producing intricate cornice designs with precision, surpassing previous manual methods. By eliminating human error and minimizing material wastage, manufacturers can save both time and money.Furthermore, these machines have an automated plaster mixing system, which ensures consistent plaster quality throughout the production process. This eliminates the need for manual plaster mixing, greatly enhancing efficiency and productivity. The use of fully automatic machines also allows factories to expand their production capabilities without the need for additional labor, contributing to a well-optimized manufacturing operation.Quality and Customization:Despite the affordability of these machines, there is no compromise on the quality of the final product. The automated process ensures consistent and precise results, guaranteeing the highest standards of craftsmanship. Additionally, manufacturers can customize the machines to create unique designs, enabling them to cater to a wider range of customer preferences.The machines offer a high degree of flexibility, allowing manufacturers to produce cornices of various sizes and styles. This versatility ensures that there is a cornice for every architectural need, be it modern, traditional, or contemporary. By minimizing limitations in design and sizing, these machines enable businesses to meet diverse market demands, ultimately driving growth and profitability.Sustainable Manufacturing:In line with the increasing emphasis on sustainable practices, many manufacturers are now incorporating eco-friendly features into their gypsum plaster cornice manufacturing machines. These machines are designed to minimize energy consumption and reduce waste. By prioritizing sustainable manufacturing, factories can not only contribute to the preservation of the environment but also enhance their brand reputation.Conclusion:The introduction of affordable, fully automatic gypsum plaster cornice manufacturing machines has revolutionized the industry. The combination of efficiency, cost-effectiveness, quality, and customization makes these machines invaluable to manufacturers seeking to meet the demands of an ever-evolving market. As more factories adopt this technology, the production of gypsum plaster cornices is expected to become more accessible and diverse, benefitting both businesses and consumers alike.

Gypsum Board Production Line Supplier for Ceiling Boards

Gypsum Ceiling Board Production Line SupplierIf you are looking for high-quality gypsum board production line, then you must find the right supplier. A reliable supplier will offer you all the necessary equipment that you need to make gypsum ceiling board production without any complications.A gypsum ceiling board production line is a complex process that requires expertise and precision equipment. So, when looking for gypsum board equipment, you need to make sure that you choose a trustworthy supplier that can deliver the latest technologies without compromising the quality.Gypsum Ceiling Board Equipment PricelistWhen it comes to buying gypsum ceiling board equipment, pricing is a critical factor to consider. Therefore, you need to find a supplier that offers reasonable prices without compromising the quality of the equipment.A good supplier should provide a gypsum ceiling board equipment pricelist to help you budget for the project. This pricelist should include all the necessary equipment for gypsum board production, including the production line, raw materials, and additives. Moreover, the supplier should also provide you with all the necessary training on how to operate the equipment safely and efficiently. This will ensure that you get the most out of your investment and produce high-quality gypsum ceiling boards that meet all the relevant industry standards.Hengshui Decheng Machinery & Equipment Co., Ltd.One of the most reliable suppliers of gypsum board production equipment is Hengshui Decheng Machinery & Equipment Co., Ltd. This company has been in the business of manufacturing and selling gypsum board equipment for many years.They offer a wide range of gypsum ceiling board equipment, including the gypsum board production line, raw materials, and additives. They also provide complete solutions for the manufacturing of gypsum board, including installation, commissioning, and technical support.What makes Hengshui Decheng Machinery & Equipment Co., Ltd stand out from the rest is their commitment to quality. All their gypsum ceiling board equipment is made from high-quality materials, and they use the latest technologies to ensure that their products perform at the highest levels.ConclusionIn conclusion, finding the right gypsum ceiling board production line supplier is crucial to the success of your project. You need to find a reliable supplier that can offer you the latest equipment, reasonable prices, and excellent customer service.Hengshui Decheng Machinery & Equipment Co., Ltd is one of the leading suppliers of gypsum board production equipment. They offer a wide range of equipment, including the gypsum board production line, raw materials, and additives, at competitive prices.Therefore, if you are planning to invest in gypsum board production equipment, you can trust Hengshui Decheng Machinery & Equipment Co., Ltd to provide you with the best equipment and services for your project.

High-Quality Equipment for Xps Production

The production of XPS (Extruded Polystyrene) insulation board requires specialized equipment that is able to efficiently and effectively produce high-quality insulation products. {Company} is a leading manufacturer and supplier of equipment for the production of XPS, and they have recently introduced a new line of machinery that is set to revolutionize the industry.The equipment offered by {Company} is designed to meet the growing demand for XPS insulation products in various industries, including construction, automotive, and packaging. The new machinery boasts advanced features that not only enhance the efficiency of the production process but also improve the overall quality of the insulation boards.{Company} takes pride in their commitment to innovation and excellence, and their latest line of equipment for the production of XPS is a testament to their dedication to providing top-of-the-line solutions for their clients. With a team of experienced engineers and technicians, {Company} continuously strives to design and manufacture machinery that meets the evolving needs of the market.The newly introduced equipment for the production of XPS by {Company} incorporates state-of-the-art technologies that ensure precision and consistency in the manufacturing process. The machinery is capable of producing XPS insulation boards of varying thickness and density, catering to the diverse requirements of different applications.Apart from its high precision capabilities, the equipment also focuses on energy efficiency and environmental sustainability. {Company} recognizes the importance of reducing energy consumption and minimizing the environmental impact of production processes. As a result, the new line of machinery is designed to operate with optimal energy efficiency, contributing to a greener and more sustainable approach to XPS insulation board manufacturing.Moreover, {Company} provides comprehensive technical support and training for their clients to ensure the seamless integration and operation of the new equipment. Their team of experts is dedicated to assisting customers in optimizing the performance of the machinery and maximizing the output of high-quality XPS insulation boards.With the introduction of this new line of machinery for the production of XPS, {Company} aims to further solidify its position as a leading provider of equipment for the insulation industry. The company's unwavering commitment to innovation and customer satisfaction is reflected in the continuous development of cutting-edge solutions that address the evolving needs of the market.In conclusion, the launch of the new equipment for the production of XPS by {Company} represents a significant advancement in the insulation industry. The state-of-the-art machinery offers unparalleled precision, energy efficiency, and sustainability, catering to the growing demand for high-quality XPS insulation products. As {Company} continues to lead the way in innovation and excellence, their latest line of equipment is set to elevate the standards of XPS manufacturing and set a new benchmark for the industry.

Buy Affordable 90mm Cornice Cove from Top Suppliers in Brisbane and Ipswich

When it comes to enhancing a room's aesthetics, a cornice can do wonders. Cornices are plastered decorative moldings that add depth, character, and elegance to any ceiling or wall. And if you're looking to purchase some premium-quality cornices in Brisbane and Ipswich, look no further than BetaBoard.BetaBoard is a leading supplier of plaster cornices, and their 90mm Cornice Cove is one of their best offerings. This particular cornice is ideal for rooms that have ceiling heights ranging from 2.7m to 3.3m, making it the perfect option for nearly any property and application. And the best part? You can buy it at the best prices in the market.If you're wondering how to install these cornices, you'll be surprised at how easy it is. All you need is an adhesive, a small trowel or glue spreader, and a little bit of patience. Before you begin, it's important to ensure the surface you're applying the cornice on is flat and clean.Next, apply the adhesive to the back of the cornice using the small trowel or glue spreader. Apply enough adhesive to ensure that the cornice sticks firmly and doesn't fall off. Then, align the cornice with the position you want it and press it against the surface. You can use a piece of wood or a similar object to tap the corners of the cornice gently to further fix it in place.Now, let's talk about the machinery that makes these beautiful cornices. BetaBoard uses some of the best automatic gypsum cornice making machines in the industry. These machines use state-of-the-art technology that ensures precision, speed, and accuracy in the production process.The best thing about using automatic gypsum cornice making machines is that they can make thousands of cornices in a single day, without compromising on quality. Plus, it reduces human error and increases productivity, thereby reducing overall production costs.In conclusion, if you want to add some elegance and character to your home or office space, try installing BetaBoard's 90mm Cornice Cove. It's easy to install, affordable, and made using some of the best automatic gypsum cornice making machines in the market today. You won't be disappointed.

High-Quality Equipment for Manufacturing Gypsum Cornice Automatically

Title: Advanced Automatic Gypsum Cornice Equipment Revolutionizes Manufacturing ProcessIntroduction:In a remarkable leap towards streamlining the manufacturing process of gypsum cornices, an innovative new Automatic Gypsum Cornice Equipment has been introduced by a prominent industry player. This cutting-edge machinery promises to revolutionize the sector, offering increased efficiency, precision, and cost-effectiveness.Body:1. Background of the Automatic Gypsum Cornice Equipment: The Automatic Gypsum Cornice Equipment is a breakthrough development that aims to improve the traditional manufacturing process of gypsum cornices. This advanced system integrates modern machinery and technology, harnessing automation and precision to produce high-quality cornices with minimal human intervention.2. Features and Benefits of the Automatic Gypsum Cornice Equipment: a. Streamlined Production: The equipment's automated nature ensures a significant reduction in production time, as well as a streamlined workflow that eliminates human errors and inconsistencies. b. Enhanced Precision: Utilizing state-of-the-art technology, the equipment guarantees exceptional precision and accuracy in the manufacturing process. This ensures uniformity of every cornice produced, meeting the highest standards of quality. c. Cost-Effectiveness: By optimizing the production process and minimizing wastage, the automatic equipment enables manufacturers to operate more efficiently, reducing overall costs and enhancing the profitability of the business. d. Minimal Maintenance: The equipment incorporates robust engineering design, resulting in a reliable and low-maintenance system that maximizes uptime and minimizes downtime.3. Key Industries Benefitting from the Automatic Gypsum Cornice Equipment: a. Construction Industry: The construction sector is one of the primary beneficiaries of this advanced equipment. Gypsum cornices hold a significant place in interior decoration, and with the rapid pace of construction globally, the demand for efficient manufacturing solutions is higher than ever. b. Interior Designers and Architects: Design professionals can now rely on the consistency and accuracy offered by this innovative machinery, allowing them to achieve their creative visions with ease. The equipment empowers them to provide clients with bespoke gypsum cornices, tailored to their unique requirements. c. Export Market: With the ability to produce high-quality gypsum cornices at a faster rate, manufacturers using the automatic equipment gain a competitive edge in the export market. This technology puts them in a position to meet increased demand from overseas customers, further bolstering the industry's growth.4. Environmental Benefits of the Automatic Gypsum Cornice Equipment: This advanced machinery not only enhances manufacturing processes but also contributes to eco-friendliness: a. Reduced Material Waste: With precise measurements and automated cutting, the equipment minimizes material waste, effectively utilizing resources, and reducing environmental impact. b. Energy Efficiency: The Automatic Gypsum Cornice Equipment incorporates energy-saving measures, reducing power consumption during production, in line with sustainable manufacturing practices.5. Company's Commitment to Innovation: The company behind this revolutionary equipment has a proven track record of innovation and a commitment to driving the industry forward. By investing in research and development, they continuously strive to improve their products and stay ahead of market trends. In addition, adherence to international quality standards ensures customer satisfaction and trust in their offerings.Conclusion:The introduction of the Automatic Gypsum Cornice Equipment marks a significant milestone in the gypsum cornice manufacturing sector. Its advanced features, improved efficiency, and reduced costs have propelled the industry into a new era of production. With the ability to meet global demand with precision and reliability, the equipment is set to solidify its position as a game-changer in manufacturing technology.

Top Affordable Pvc Gypsum Ceiling Board Machine Manufacturers

The demand for affordable and high-quality PVC gypsum ceiling board machines is on the rise, and Cheap PVC Gypsum Ceiling Board Machine Factories (name removed for privacy) are stepping up to the challenge. With a reputation for providing top-notch machinery at competitive prices, they are making a name for themselves in the industry.The company, which was founded in the early 2000s, has established itself as one of the leading manufacturers of PVC gypsum ceiling board machines in the market. Their products are known for their reliability, efficiency, and affordability, making them a popular choice among businesses looking to invest in this type of machinery.The Cheap PVC Gypsum Ceiling Board Machine Factory has a state-of-the-art manufacturing facility, equipped with the latest technology and machinery to produce high-quality products. Their team of experienced engineers and technicians are dedicated to ensuring that each machine meets the highest standards of quality and performance.In addition to their focus on quality, the company also places a strong emphasis on customer satisfaction. They understand the importance of providing excellent customer service and support, and they work closely with their clients to understand their specific needs and requirements. This allows them to tailor their products to meet the unique demands of each customer, further enhancing their reputation as a reliable and customer-oriented manufacturer.The Cheap PVC Gypsum Ceiling Board Machine Factory offers a wide range of products to cater to the diverse needs of their clients. Their product line includes a variety of PVC gypsum ceiling board machines, each designed to meet different production capacities and specifications. They also offer customization options for clients who have specific requirements for their machinery.One of the key factors that sets the Cheap PVC Gypsum Ceiling Board Machine Factory apart from its competitors is its commitment to innovation. They continuously invest in research and development to improve their products and stay ahead of industry trends. This dedication to innovation has resulted in the development of cutting-edge machinery that delivers superior performance and efficiency.The company's dedication to quality, customer satisfaction, and innovation has earned them a strong reputation in the industry. They have built a loyal customer base and have established long-standing relationships with many businesses in the global market.Furthermore, the Cheap PVC Gypsum Ceiling Board Machine Factory understands the importance of environmental sustainability. They have implemented eco-friendly practices in their manufacturing process, such as reducing waste and energy consumption. They are committed to playing their part in promoting a greener and more sustainable manufacturing industry.As the demand for PVC gypsum ceiling board machines continues to grow, the Cheap PVC Gypsum Ceiling Board Machine Factory is well-positioned to meet this demand. Their commitment to quality, customer satisfaction, innovation, and sustainability sets them apart as a reliable and reputable manufacturer in the industry.In conclusion, Cheap PVC Gypsum Ceiling Board Machine Factory (name removed) is a leading manufacturer of high-quality, affordable PVC gypsum ceiling board machines. Their dedication to quality, customer satisfaction, innovation, and sustainability makes them a trusted choice for businesses looking to invest in this type of machinery. With a strong reputation in the industry, they are well-positioned to meet the growing demand for their products and continue to make a positive impact on the manufacturing sector.

Magnesium Oxide Board Selling Leads - Find Quality Exporters at EC21

Are you in search of high-quality Mgo board exporters? Look no further than EC21, where you can choose from a wide array of exporters who offer top-notch Mgo board products. Mgo board is becoming increasingly popular in the construction industry due to its exceptional features. It is a versatile and cost-effective building material that is perfect for a wide range of applications.Whether you are working on residential, commercial, or industrial construction projects, Mgo board is an excellent choice. It is a non-toxic, fire-resistant, and durable building material that resists moisture, mold, and mildew. Mgo board also offers excellent sound insulation and thermal insulation properties, making it an excellent choice for energy-efficient buildings.If you are searching for Mgo board exporters, the first step is to consider the quality of their products. The quality of the boards will depend on the type of equipment used in the manufacturing process. That’s where Mgo board machine comes into play.Mgo board machine is a high-tech piece of equipment that is specifically designed for the production of Mgo board. It is an essential component of the production process and plays a vital role in ensuring the quality of the final output. The machine has a control panel that allows you to monitor various parameters, such as temperature, pressure, and speed. This ensures that the manufacturing process is consistent and produces high-quality boards.When looking for Mgo board exporters, it is essential to inquire about the type of Mgo board machine they use. Manufacturers who use modern and advanced equipment typically produce better quality boards than those who use outdated technology. The machine's price is also a crucial factor to consider, as it can significantly impact the final cost of the product.At EC21, you can find various Mgo board machine pricelist options, allowing you to choose a machine that best suits your budget. The price will depend on the size, capacity, and technology of the machine. The pricelist will enable you to compare prices from different manufacturers and choose the one that offers the best value for your money.In conclusion, Mgo board is an excellent building material that offers fantastic properties for a wide range of applications. If you are searching for Mgo board exporters, make sure to inquire about the quality of their products and the type of Mgo board machine they use. You can find a range of Mgo board exporters on EC21, with various pricelist options for Mgo board machine. Choose the one that fits your needs and budget to ensure a successful construction project.

High-Quality PVC Laminated Gypsum Ceiling Board for Construction and Decoration

PVC Laminated Gypsum Ceiling Board: Affordable and Durable SolutionIf you are searching for an affordable and durable solution for ceiling installation, then PVC laminated gypsum ceiling board is the answer. These boards are available in different sizes, including 595*595 and 603*603mm. They offer many benefits, from easy installation to excellent sound insulation, fire resistance, and moisture resistance. If you are looking for a low-cost yet high-quality ceiling board, the PVC laminated gypsum ceiling board is the perfect match for you.What is PVC Laminated Gypsum Ceiling Board?PVC laminated gypsum ceiling board is a composite material made of high-quality paper-faced gypsum board with a layer of PVC on the surface. This material is specially designed for interior ceiling decoration, providing an elegant and stylish look to any room.The paper-faced gypsum board acts as a base layer, making the board strong and durable. At the same time, the PVC layer provides an aesthetic finish for the ceiling board. It is an affordable, lightweight, and easy-to-install solution for ceiling decoration.Advantages of PVC Laminated Gypsum Ceiling Board1. AffordablePVC laminated gypsum ceiling board is a low-cost option as compared to other ceiling materials like plaster, wood, or metal. It is an economical solution that doesn't compromise on quality.2. Easy to InstallInstallation of PVC laminated gypsum ceiling board is a breeze. These boards are lightweight, making them easy to handle and install. They come with pre-drilled holes, which makes the installation process fast and simple.3. Moisture ResistantPVC laminated gypsum ceiling board is resistant to moisture, which is why they are perfect for use in areas such as bathrooms, kitchens, and laundry rooms. They don't absorb moisture or water, which prevents the growth of mold and mildew.4. Fire ResistantPVC laminated gypsum ceiling board is also fire-resistant, ensuring the safety of your building. It doesn't catch fire quickly, and even if it does, it doesn't produce toxic gases. This makes it a safe solution for commercial and residential spaces.5. Sound InsulationThe gypsum layer in PVC laminated gypsum ceiling board provides excellent sound insulation. It reduces noise pollution and creates a quiet and comfortable atmosphere.6. Aesthetically PleasingThe PVC layer on the surface of PVC laminated gypsum ceiling board provides an elegant and attractive look to the ceiling. It is available in various designs and colors, giving you the flexibility to choose the best one that matches your style.Cheap PVC Laminated Gypsum Ceiling Board Machine Price listIf you are interested in producing PVC laminated gypsum ceiling boards, you can buy a machine that does this job. The market is full of different machines, and the price list varies depending on the machine's features, capacity, and automation level.You can find a cheap PVC laminated gypsum ceiling board machine on the market. However, keep in mind that cheap doesn't always mean high-quality. It is crucial to choose a machine that meets your needs, budget, and quality standards.In conclusion, PVC laminated gypsum ceiling board is an excellent solution for those who are looking for an affordable and durable ceiling material. It offers many benefits, from easy installation to excellent sound insulation, moisture resistance, and fire resistance. Moreover, if you are interested in producing PVC laminated gypsum ceiling boards, you can search for a cheap PVC Laminated Gypsum Ceiling Board machine on the market.

Ce Certification Gypsum Cornice Making Machine Price List: Top Options for Your Business

The latest advancement in the construction industry comes in the form of the CE certification of the Gypsum Cornice Making Machine by a leading company in the field. This certification serves as a testament to the machine's adherence to the highest standards of quality and safety, making it an ideal choice for construction professionals and businesses.The Gypsum Cornice Making Machine is an innovative piece of equipment that is designed to streamline the process of creating decorative cornices for buildings. These cornices are an essential element in adding a touch of elegance and sophistication to interior spaces. With the CE certification, customers can now have added confidence in the machine's performance and reliability.The Gypsum Cornice Making Machine is equipped with advanced technology and features that ensure precision and efficiency in the production process. Its user-friendly interface and automated functions make it easy to operate, saving time and labor costs for businesses. Additionally, the machine is built to last, with high-quality materials and components that guarantee durability and longevity.In addition to its impressive capabilities, the Gypsum Cornice Making Machine also comes with a competitive price list, making it a cost-effective investment for construction companies. By automating the production of gypsum cornices, businesses can increase their output while minimizing expenses, ultimately leading to improved profitability.The company behind the Gypsum Cornice Making Machine has a strong reputation in the industry for delivering top-notch equipment and excellent customer service. With years of experience and expertise, they have become a trusted partner for construction professionals seeking reliable solutions for their projects.The company's commitment to quality and innovation is evident in its continuous investment in research and development. This dedication has led to the creation of the Gypsum Cornice Making Machine, which is setting new standards for efficiency and performance in the construction industry. The CE certification is a reflection of the company's unwavering dedication to providing customers with products that meet the highest standards of excellence.With the CE certification and competitive pricing of the Gypsum Cornice Making Machine, the company is poised to capture a larger share of the market and establish itself as a leader in the industry. Customers can now have peace of mind knowing that they are investing in a machine that is not only reliable and efficient but also certified for its adherence to strict quality and safety standards.In conclusion, the CE certification of the Gypsum Cornice Making Machine by the leading company is a significant milestone that reinforces its position as a provider of top-quality equipment for the construction industry. With its advanced technology, competitive pricing, and commitment to customer satisfaction, the company is well-positioned to meet the growing demand for innovative and reliable solutions in the market. Construction professionals and businesses can now look forward to harnessing the benefits of this certified machine to elevate the quality and efficiency of their projects.Overall, the CE certification of the Gypsum Cornice Making Machine is a game-changer for the construction industry, and the company's dedication to excellence ensures that customers can expect nothing but the best from this innovative piece of equipment.

Mineral Fiber Ceiling Board Machine Receives CE Certification and Priced Competitively

Ce Certification Mineral Fiber Ceiling Board Machine PricelistThe mineral fiber ceiling board machine is a piece of equipment that is used in the production of high-quality mineral fiber ceiling boards. These boards are widely used in the construction industry for their soundproofing and fireproofing properties. The ce certification mineral fiber ceiling board machine pricelist is now available at our company, and we are proud to offer our clients this highly advanced equipment at a competitive price.Our company has been in the business of manufacturing and supplying mineral fiber ceiling board machines for over two decades. We specialize in the design and production of high-quality machines that are built to last. Our machines are not only reliable and efficient, but they are also environmentally friendly and energy-saving.We have a team of highly skilled engineers who work around the clock to ensure that our machines are up to the highest standards. Each machine is rigorously tested before it leaves our factory to ensure that it meets our strict quality control standards. We are confident in the durability and reliability of our machines and offer our clients a comprehensive warranty program that covers any defects in workmanship or materials.Our mineral fiber ceiling board machines are designed to be easy to use, with a user-friendly interface that simplifies the production process. We understand that time is of the essence in the construction industry, which is why we have designed our machines to be as automated as possible. This not only speeds up the production process but also reduces the risk of errors or accidents. Our machines can produce up to 6,000 square meters of mineral fiber ceiling boards per day.The mineral fiber ceiling board machine pricelist is highly competitive, reflecting our commitment to providing our clients with the best value for their investment. We offer a range of machines to suit different production needs and budgets. Our clients can choose from our standard range of machines or opt for a custom-built machine that is tailored to their specific needs.In addition to our mineral fiber ceiling board machines, we also offer a range of ancillary equipment, including cutting machines, edge-sealing machines, laminating machines, and packing machines. This allows our clients to have everything they need to complete the production process under one roof, making it easier and more efficient.At our company, we are committed to providing our clients with exceptional customer service. We understand that the purchase of a mineral fiber ceiling board machine is a significant investment, and we are here to support our clients every step of the way. We offer technical support, training, and maintenance services to ensure that our clients get the most out of their investment.In conclusion, the ce certification mineral fiber ceiling board machine pricelist is now available at our company, and we are proud to offer our clients this highly advanced equipment at a competitive price. Our machines are built to last and are designed to be easy to use, environmentally friendly, and energy-saving. We offer a comprehensive warranty program, ancillary equipment, and exceptional customer service to ensure that our clients get the best value for their investment. Contact us today to learn more about our mineral fiber ceiling board machines and how we can help your business grow.