High-Quality Pvc Vinyl Film Factory: A Closer Look at the Production Process

By:Admin

The PVC Vinyl Film Factory, a leading manufacturer in the industry, has announced the release of a groundbreaking new product line that is set to redefine industry standards. With a focus on innovation and quality, the company has leveraged its extensive expertise and cutting-edge technology to create a range of PVC vinyl films that offer superior performance and durability.

Established over a decade ago, the PVC Vinyl Film Factory has built a strong reputation for delivering high-quality products that meet the diverse needs of its customers. The company's state-of-the-art manufacturing facilities and commitment to research and development have allowed it to stay at the forefront of industry trends and advancements. This dedication to innovation has positioned the PVC Vinyl Film Factory as a trusted partner for businesses across various sectors, including construction, automotive, packaging, and more.

The new product line, which comes after extensive research and development, showcases the PVC Vinyl Film Factory's continued commitment to excellence. The films are designed to offer unparalleled versatility, with properties that make them suitable for a wide range of applications. Whether it's for use in outdoor signage, protective coatings, or decorative finishes, the new PVC vinyl films are engineered to deliver outstanding results.

One of the key highlights of the new product line is its enhanced durability. The films boast exceptional resistance to environmental factors, such as UV radiation, moisture, and temperature fluctuations. This makes them an ideal choice for long-term outdoor applications, where traditional materials may deteriorate over time. Additionally, the PVC vinyl films offer excellent adhesion properties, ensuring a secure bond to various substrates for reliable performance in demanding conditions.

"We are thrilled to introduce our latest range of PVC vinyl films, which represent a significant leap forward in terms of product innovation and quality," said the spokesperson for the PVC Vinyl Film Factory. "Our team has invested substantial time and resources into perfecting these films, and we are confident that they will set new benchmarks for performance and reliability in the industry. We believe that our customers will appreciate the countless ways in which these films can add value to their projects."

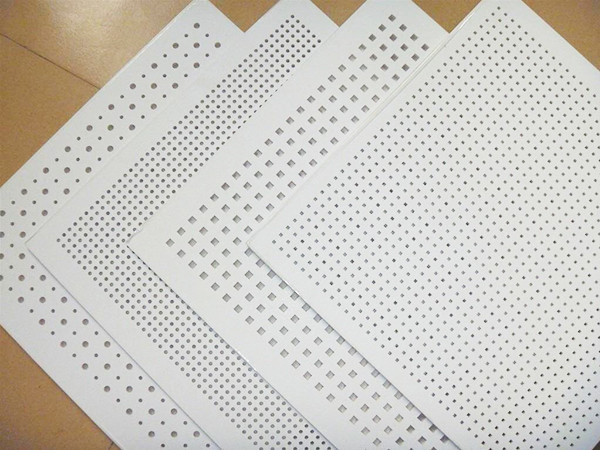

In addition to their exceptional performance, the new PVC vinyl films are available in an extensive selection of colors, finishes, and textures, allowing for endless design possibilities. This versatility opens up a world of creative opportunities for architects, designers, and manufacturers seeking to differentiate their products and projects. Furthermore, the films are easy to work with, offering superb printability, cuttability, and weldability for seamless integration into various production processes.

The introduction of the groundbreaking product line underscores the PVC Vinyl Film Factory's ongoing commitment to meeting the evolving needs of its customers. By staying ahead of market trends and investing in continuous improvement, the company aims to provide solutions that empower businesses to achieve excellence in their respective endeavors. With a focus on sustainability and performance-driven innovation, the PVC Vinyl Film Factory is well-positioned to lead the industry into a new era of possibilities.

As the demand for high-quality PVC vinyl films continues to grow across different sectors, the release of the innovative product line marks a significant milestone for the PVC Vinyl Film Factory. With its unwavering dedication to excellence and a proven track record of delivering value to customers, the company is poised to make a lasting impact on the industry landscape. As businesses seek reliable partners that can help them stay ahead of the curve, the PVC Vinyl Film Factory stands out as a trusted ally that is committed to shaping a brighter future for the industry as a whole.

Company News & Blog

High-Quality Equipment for Xps Production

The production of XPS (Extruded Polystyrene) insulation board requires specialized equipment that is able to efficiently and effectively produce high-quality insulation products. {Company} is a leading manufacturer and supplier of equipment for the production of XPS, and they have recently introduced a new line of machinery that is set to revolutionize the industry.The equipment offered by {Company} is designed to meet the growing demand for XPS insulation products in various industries, including construction, automotive, and packaging. The new machinery boasts advanced features that not only enhance the efficiency of the production process but also improve the overall quality of the insulation boards.{Company} takes pride in their commitment to innovation and excellence, and their latest line of equipment for the production of XPS is a testament to their dedication to providing top-of-the-line solutions for their clients. With a team of experienced engineers and technicians, {Company} continuously strives to design and manufacture machinery that meets the evolving needs of the market.The newly introduced equipment for the production of XPS by {Company} incorporates state-of-the-art technologies that ensure precision and consistency in the manufacturing process. The machinery is capable of producing XPS insulation boards of varying thickness and density, catering to the diverse requirements of different applications.Apart from its high precision capabilities, the equipment also focuses on energy efficiency and environmental sustainability. {Company} recognizes the importance of reducing energy consumption and minimizing the environmental impact of production processes. As a result, the new line of machinery is designed to operate with optimal energy efficiency, contributing to a greener and more sustainable approach to XPS insulation board manufacturing.Moreover, {Company} provides comprehensive technical support and training for their clients to ensure the seamless integration and operation of the new equipment. Their team of experts is dedicated to assisting customers in optimizing the performance of the machinery and maximizing the output of high-quality XPS insulation boards.With the introduction of this new line of machinery for the production of XPS, {Company} aims to further solidify its position as a leading provider of equipment for the insulation industry. The company's unwavering commitment to innovation and customer satisfaction is reflected in the continuous development of cutting-edge solutions that address the evolving needs of the market.In conclusion, the launch of the new equipment for the production of XPS by {Company} represents a significant advancement in the insulation industry. The state-of-the-art machinery offers unparalleled precision, energy efficiency, and sustainability, catering to the growing demand for high-quality XPS insulation products. As {Company} continues to lead the way in innovation and excellence, their latest line of equipment is set to elevate the standards of XPS manufacturing and set a new benchmark for the industry.

Efficient Gypsum Ceiling Board Lamination Machine: Enhance Productivity and Quality!

OEM Gypsum Ceiling Board Lamination Machine Revolutionizes the Construction Industry[City, Date] - In a groundbreaking development for the construction industry, a leading manufacturer has introduced a state-of-the-art OEM Gypsum Ceiling Board Lamination Machine, offering cutting-edge technology that is set to revolutionize the way gypsum ceilings are manufactured.This innovative machine, produced by a company that specializes in construction equipment, is the result of years of research and development. The company’s commitment to delivering high-quality products has cemented its position as a global leader in the field.The OEM Gypsum Ceiling Board Lamination Machine boasts an array of advanced features that enable efficiency and precision in the manufacturing process, ultimately resulting in superior quality gypsum ceilings. By eliminating the manual component from the lamination process, this machine not only streamlines production but also guarantees consistency in every board manufactured.One of the key features of this cutting-edge machine is its ability to automate the lamination process. In the past, this process required tedious manual labor that left room for human error and inconsistencies. With this new machine, however, operators can simply input the specifications, and the machine takes care of the rest. This ensures a seamless production process, reducing the risk of errors and increasing overall productivity.The OEM Gypsum Ceiling Board Lamination Machine also incorporates advanced adhesive application technology. The precise and even distribution of adhesive ensures a strong bond between the gypsum board and the laminate, resulting in long-lasting and durable ceilings. This technology not only increases the quality of the end product but also improves the safety and reliability of the finished ceiling.Furthermore, this machine offers a range of customizable options, allowing manufacturers to produce ceiling boards according to their unique requirements. From selecting the desired core material to choosing the type of laminate and thickness, this machine offers unparalleled flexibility, empowering manufacturers to meet the varied demands of their customers.In terms of environmental sustainability, the OEM Gypsum Ceiling Board Lamination Machine also excels. By optimizing the adhesive application process and minimizing waste, this machine contributes to the reduction of material consumption. It also incorporates energy-saving features, ensuring minimal environmental impact throughout the manufacturing process.The introduction of this state-of-the-art OEM Gypsum Ceiling Board Lamination Machine is expected to reshape the construction industry. Its ability to enhance productivity, improve product quality, and prioritize sustainability will undoubtedly attract construction companies seeking to streamline their operations and deliver outstanding results.Speaking about the new machine, a spokesperson for the company said, “We are thrilled to introduce this game-changing technology to the market. The OEM Gypsum Ceiling Board Lamination Machine represents our ongoing commitment to innovation and providing excellent solutions to our customers. We are confident that this machine will not only revolutionize the way gypsum ceilings are manufactured but also optimize processes for construction companies worldwide.”As the industry adapts to increasing demands for efficiency, sustainability, and high-quality products, the OEM Gypsum Ceiling Board Lamination Machine offers a glimpse into the future of construction. With its advanced features and customizable options, this machine is set to transform the way gypsum ceilings are manufactured, bringing greater efficiency, quality, and reliability to the construction industry.About [Company Name]:[Company Name] is a renowned manufacturer specializing in cutting-edge construction equipment. With a strong focus on innovation, the company has been at the forefront of delivering high-quality products to construction companies worldwide. With a commitment to sustainability and excellence, [Company Name] has established itself as a trusted partner in the construction industry.

High quality PVC laminated gypsum ceiling tiles machine factories

PVC Laminated Gypsum Ceiling Tiles Machine Factories have been making headlines recently, and for good reason. These factories are at the forefront of producing high-quality, versatile, and durable ceiling tiles that are perfect for a variety of applications. With their state-of-the-art machinery and innovative techniques, these factories are changing the game when it comes to ceiling tile production.One such factory that has been making waves in the industry is the one operated by {}. With years of experience and a commitment to excellence, this factory has become a leader in the production of PVC laminated gypsum ceiling tiles. Their dedication to quality and customer satisfaction has set them apart from the competition and has helped them to establish a strong reputation in the industry.The machinery used in the production process is one of the key factors that sets this factory apart. With advanced technology and precision engineering, they are able to produce ceiling tiles that are not only visually stunning but also incredibly durable and long-lasting. This is essential for a product that is designed to provide both aesthetic appeal and practical functionality in a variety of settings.In addition to their cutting-edge machinery, the factory also prides itself on its commitment to sustainability. They are continually looking for ways to minimize their environmental impact and reduce waste in the production process. This dedication to sustainability has earned them recognition and praise from both customers and industry peers, and has further solidified their position as a forward-thinking and responsible manufacturer.One of the most impressive aspects of this factory is the level of customization and flexibility they offer. Their machinery is capable of producing a wide range of sizes, designs, and finishes, allowing them to meet the unique needs and preferences of their customers. Whether it's a sleek, modern look for a commercial space or a more traditional aesthetic for a residential setting, this factory can deliver the perfect ceiling tiles for any project.It's not just the machinery and production capabilities that make this factory stand out, however. The team behind the operation is equally impressive. Comprised of skilled and knowledgeable professionals, they bring a level of expertise and attention to detail that is second to none. From the initial design phase right through to the final quality checks, every member of the team is dedicated to ensuring that the end product meets the highest standards.With all of these factors combined, it's easy to see why PVC Laminated Gypsum Ceiling Tiles Machine Factories, such as the one operated by {}, are making such a big impact in the industry. Their commitment to quality, sustainability, customization, and customer satisfaction has earned them a strong reputation and a loyal customer base. As they continue to push the boundaries of what is possible in ceiling tile production, there's no doubt that they will remain a force to be reckoned with in the years to come.

Top XPS Equipment Options for Polystyrene Foam Board

The demand for XPS equipment for Polystyrene Foam Board has been rising in the construction industry. This equipment is essential for shaping and cutting polystyrene foam boards to fit specific requirements in building and insulation projects. With the increasing need for energy-efficient and sustainable construction practices, the demand for XPS equipment has been on the rise.One company that has been leading the way in providing high-quality XPS equipment for Polystyrene Foam Board is {}. They have been at the forefront of the industry, providing cutting-edge solutions for shaping and cutting polystyrene foam boards with precision and efficiency.{} has been in the business for over a decade, and their commitment to quality and innovation has positioned them as a trusted name in the industry. They offer a wide range of XPS equipment, including hot wire cutting machines, CNC routers, and 3D cutting machines, all designed to meet the diverse needs of their customers.The hot wire cutting machines offered by {} are designed for cutting and shaping polystyrene foam boards with precision. These machines use a heated wire to cut through the foam, ensuring clean and accurate cuts every time. The CNC routers, on the other hand, are ideal for more complex cutting and shaping tasks, allowing for intricate designs and patterns to be achieved with ease. Additionally, their 3D cutting machines are capable of creating three-dimensional shapes and cuts, adding a new dimension to the possibilities of working with polystyrene foam boards.With a focus on research and development, {} has continuously innovated their XPS equipment to ensure that they meet the evolving needs of the construction industry. Their state-of-the-art manufacturing facilities and experienced team of engineers and technicians enable them to produce high-quality and reliable equipment that can withstand the demands of heavy-duty usage in construction projects.In addition to their cutting-edge equipment, {} also provides comprehensive customer support and after-sales services. They offer training and technical support to their clients, ensuring that they are able to maximize the capabilities of the equipment and achieve the best results in their projects. This commitment to customer satisfaction has earned them a loyal customer base and a reputation for excellence in the industry.As the construction industry continues to prioritize energy efficiency and sustainable building practices, the demand for XPS equipment for Polystyrene Foam Board is expected to grow even further. {} is well-positioned to meet this demand with their innovative solutions and commitment to quality. They continue to push the boundaries of what is possible with polystyrene foam board shaping and cutting, and their dedication to excellence sets them apart as a leader in the industry.With a track record of success and a dedication to innovation, {} is set to continue making significant contributions to the construction industry, providing the tools and equipment needed to achieve energy-efficient and sustainable building practices. As the demand for XPS equipment continues to grow, {} is poised to remain at the forefront, driving innovation and setting the standard for quality in the industry.

Automatic Gypsum Cornice Equipment Factories Achieve CE Certification

The automatic gypsum cornice equipment produced by a leading manufacturer in the industry has recently obtained CE certification, marking a significant milestone for the company. This certification not only demonstrates the company's commitment to quality and innovation but also opens up new opportunities for market expansion and business growth.The CE certification, which stands for Conformité Européenne (European Conformity), is a mandatory conformity mark for products sold within the European Economic Area (EEA). It indicates that the product complies with the essential health and safety requirements set out in European Directives. This certification is recognized by the European Union, as well as by other countries outside the EU, making it a valuable asset for manufacturers seeking to export their products to international markets.The automatic gypsum cornice equipment manufactured by the company is a state-of-the-art production line designed for the efficient and precise manufacturing of gypsum cornices. Gypsum cornices are decorative moldings used to add aesthetic appeal to ceilings and walls, and they are in high demand in the construction and design industries. The company's equipment is known for its advanced technology, high production capacity, and superior quality output.With the CE certification in hand, the company is now poised to capitalize on the growing demand for gypsum cornice equipment in the European market and beyond. The certification will provide a competitive edge, as it assures customers of the product's compliance with European standards for safety and performance. This will be particularly beneficial for the company's export business, as it will facilitate easier market access and help build trust with international customers.In addition to the CE certification, the company's reputation for excellence and reliability further solidifies its position as a leader in the industry. With years of experience and a track record of delivering top-notch equipment to customers worldwide, the company has established itself as a trusted partner for businesses involved in gypsum cornice production. Its dedication to continuous innovation and customer satisfaction has garnered the company a strong and loyal customer base.Furthermore, the company's commitment to sustainability and environmental responsibility sets it apart as a socially conscious manufacturer. The automatic gypsum cornice equipment is designed to minimize waste, energy consumption, and environmental impact, aligning with the company's ethos of sustainable production. This resonates well with modern consumers who prioritize eco-friendly and ethical business practices, giving the company a distinct advantage in the market.Looking ahead, the company plans to leverage the CE certification to expand its presence in the European market and enhance its global competitiveness. By participating in trade shows, industry exhibitions, and targeted marketing efforts, the company aims to raise awareness of its certified automatic gypsum cornice equipment and forge new partnerships with distributors, contractors, and construction firms across the EEA.In conclusion, the attainment of CE certification for the automatic gypsum cornice equipment is a significant achievement for the company, signaling its readiness to tap into new opportunities in the European market and beyond. With a strong focus on quality, innovation, and sustainability, the company is well-positioned to meet the growing demand for efficient and reliable gypsum cornice production equipment. As it continues to build on its success and expand its global footprint, the company remains dedicated to upholding the highest standards of excellence and delivering value to its customers.

High-quality Wall Board Machine Manufacturer for Mgo Boards

Mgo Wall Board Machine Manufacturer, a leading manufacturer of construction machinery, recently announced the launch of their new state-of-the-art Mgo Wall Board Machine. The company has been known for its high-quality construction equipment and this latest addition to their product line is no exception.The Mgo Wall Board Machine is designed to produce high-quality Magnesium Oxide Wall Boards, which are widely used in the construction industry for their fire resistance, water resistance, and durability. The machine is equipped with the latest technology and is capable of producing a large volume of Mgo Wall Boards with a high degree of precision and efficiency.The company has invested heavily in research and development to ensure that the Mgo Wall Board Machine meets the highest industry standards. The machine is equipped with advanced features such as automatic feeding, mixing, and molding, as well as precise control of temperature and pressure during the production process. This ensures that the Mgo Wall Boards produced are of consistent quality and meet all the necessary specifications for construction applications.In addition to its advanced technology, the Mgo Wall Board Machine is also designed with user-friendly features that make it easy to operate and maintain. The machine is equipped with a user-friendly interface and is designed for minimal downtime, allowing for continuous production without interruptions.The launch of the Mgo Wall Board Machine is a significant milestone for the company, as it further strengthens their position as a leading manufacturer of construction machinery. With the increasing demand for high-quality construction materials, the company is confident that the Mgo Wall Board Machine will be well-received in the market.The company has a strong focus on customer satisfaction and has a dedicated team of professionals who are committed to providing excellent service and support to their customers. With a global network of sales and service partners, the company is well-equipped to meet the needs of customers around the world.The Mgo Wall Board Machine is the latest addition to the company's comprehensive product line, which includes a wide range of construction machinery such as drywall machines, plasterboard production lines, and other building materials production equipment. The company takes pride in offering a complete solution for the construction industry, providing customers with everything they need to meet their production needs.With a strong track record of delivering high-quality products and exceptional customer service, the company has established itself as a trusted partner for construction companies worldwide. The launch of the Mgo Wall Board Machine is a testament to the company's commitment to innovation and excellence in manufacturing.The company's dedication to quality and innovation has earned them a solid reputation in the industry, and they are continuously striving to stay ahead of the competition by investing in new technologies and expanding their product offerings.In conclusion, the launch of the Mgo Wall Board Machine by Mgo Wall Board Machine Manufacturer is a significant development that further solidifies the company's position as a leading manufacturer of construction machinery. With its advanced technology, user-friendly features, and commitment to customer satisfaction, the Mgo Wall Board Machine is set to make a lasting impact in the construction industry.

High-Quality Mgo Board Equipment Pricing Guide

Mgo Board Equipment Pricelist Revealed by Leading ManufacturerAs a leading manufacturer in the construction materials industry, our company has recently announced the release of the pricelist for our state-of-the-art Mgo board equipment. This news has generated tremendous excitement within the industry, as the Mgo board equipment is known for its high quality and efficiency in production.The Mgo board, also known as magnesium oxide board, is a type of building material that has been gaining popularity due to its impressive fire resistance, mold resistance, and strength. As the demand for Mgo board continues to rise, our company has been at the forefront of providing advanced equipment for the manufacturing process.Our Mgo board equipment pricelist includes a range of machinery and tools that are essential for the production of high-quality Mgo boards. This includes the Mgo board production line, which is designed to efficiently mix raw materials, form the boards, and complete the curing process. Additionally, our pricelist also features cutting-edge equipment for surface finishing, edge sealing, and board stacking, ensuring that manufacturers have everything they need to produce superior Mgo boards.One of the key highlights of our Mgo board equipment pricelist is the competitive pricing. Our company is committed to providing cost-effective solutions for manufacturers looking to invest in Mgo board production. By offering a comprehensive range of equipment at competitive prices, we aim to support the growth of businesses within the construction materials industry.Furthermore, our company takes pride in the quality and reliability of our Mgo board equipment. Each piece of machinery is carefully engineered and tested to ensure optimal performance and durability. With our advanced equipment, manufacturers can enhance their production capabilities and meet the increasing demand for Mgo boards in the market.In addition to the release of the pricelist, our company also wishes to highlight our dedication to superior customer service. We understand that investing in new equipment is a significant decision for any business, which is why we strive to provide exceptional support to our customers. Whether it is technical assistance, training, or maintenance, our team is committed to helping manufacturers maximize the potential of their Mgo board equipment.Overall, the release of the Mgo board equipment pricelist marks an important milestone for our company as we continue to lead the way in providing innovative solutions for the construction materials industry. With our high-quality equipment, competitive pricing, and commitment to customer satisfaction, we are confident that manufacturers will find value in investing in our Mgo board production machinery.In conclusion, the unveiling of the Mgo board equipment pricelist by our company represents a significant opportunity for manufacturers to enhance their production capabilities and meet the growing demand for high-quality Mgo boards. We are excited to offer our advanced machinery and tools at competitive prices, further solidifying our position as a trusted provider of Mgo board equipment in the industry. As the construction materials market continues to evolve, our company remains dedicated to empowering manufacturers with the best solutions for Mgo board production.

Top XPS Foam Production Line Factories Facing Cuts in Production

Cutting Xps Foam Production Line FactoriesIn response to the growing demand for XPS foam insulation products, {Company name} has announced the expansion of its production line factories. The company, a leading manufacturer of XPS foam insulation, is scaling up its operations to meet the increasing needs of the construction industry for high-quality insulation solutions.{Company name} has been at the forefront of producing XPS foam insulation for several years. The company has established a strong reputation for delivering innovative and reliable insulation products that meet the highest industry standards. With a focus on sustainability and energy efficiency, {Company name} has become a trusted partner for construction companies, contractors, and developers looking for superior insulation solutions.The expansion of {Company name}'s production line factories comes at a time when the demand for XPS foam insulation is on the rise. With a growing emphasis on energy-efficient building practices, the construction industry is increasingly turning to XPS foam insulation as a reliable and effective way to improve the thermal performance of buildings. As a result, {Company name} is ramping up its production capacity to ensure that it can meet the needs of its customers and continue to deliver superior insulation products.The expansion of {Company name}'s production line factories will enable the company to increase its output of XPS foam insulation products and streamline its manufacturing processes. By investing in state-of-the-art production equipment and technology, {Company name} aims to enhance its efficiency and productivity, ultimately allowing the company to meet the growing demand for its products. This expansion will also create opportunities for job growth and economic development in the areas where {Company name} operates its production facilities."We are excited to announce the expansion of our production line factories," said {Name}, CEO of {Company name}. "This investment underscores our commitment to meeting the needs of our customers and supporting the growing demand for high-quality XPS foam insulation. We are confident that this expansion will allow us to continue delivering innovative and sustainable insulation solutions to the construction industry."{Company name} is known for its dedication to quality and innovation in the insulation industry. The company's XPS foam insulation products are designed to provide superior thermal performance, moisture resistance, and durability, making them an ideal choice for a wide range of construction projects. By expanding its production line factories, {Company name} is reaffirming its position as a leader in the manufacturing of XPS foam insulation and its commitment to meeting the evolving needs of the construction industry.The expansion of {Company name}'s production line factories is expected to have a significant impact on the company's ability to serve its customers and the industry as a whole. With increased production capacity and enhanced manufacturing capabilities, {Company name} is well-positioned to continue meeting the demand for high-quality XPS foam insulation and contributing to the advancement of energy-efficient building practices.As the construction industry continues to prioritize energy efficiency and sustainability, the demand for high-quality insulation solutions like XPS foam insulation is only expected to grow. {Company name}'s expansion of its production line factories is a strategic move that will not only enable the company to keep pace with this growing demand but also to reinforce its position as a leading provider of innovative and sustainable insulation products.

Affordable Automatic Gypsum Cornice Equipment Manufacturers: Enhance Search Engine Optimization

Title: Leading Automatic Gypsum Cornice Equipment Factories Revolutionize Manufacturing ProcessIntroduction:Gypsum cornices are an integral part of interior design, adding a touch of elegance and sophistication to any space. In an exciting development, a leading automatic gypsum cornice equipment factory is transforming the manufacturing process, propelling the industry forward. This groundbreaking technology, combined with the company's commitment to innovation, is revolutionizing the production of gypsum cornices. With unmatched precision and efficiency, these state-of-the-art equipment factories are shaping the future of interior decor.Body:1. The Rise of Automatic Gypsum Cornice Equipment Manufacturing:Over the past decade, there has been a considerable increase in the demand for high-quality gypsum cornices. To meet this growing demand, automatic gypsum cornice equipment factories have emerged, catering to the needs of interior designers, architects, and construction companies. These factories utilize cutting-edge technology to streamline production processes, ensuring increased efficiency and reduced costs.2. Cutting-Edge Technology and Manufacturing Process:The automatic gypsum cornice equipment factories incorporate advanced machinery and automation systems to optimize the manufacturing process. By utilizing computer numerical control (CNC) and robotics, these factories can produce gypsum cornices with unparalleled precision, consistency, and intricate designs. This groundbreaking technology not only enhances the overall quality but also significantly reduces manual labor.3. Benefits of Automatic Gypsum Cornice Equipment:a. Improved Efficiency: The use of automatic equipment has revolutionized gypsum cornice manufacturing, enabling factories to produce a larger quantity of products in a shorter period. This efficiency boost results in an enhanced customer experience and increased satisfaction levels.b. Consistent Quality: The precision offered by automatic machinery ensures consistent quality across all gypsum cornices produced by these factories. Each product adheres to the highest standards, showcasing fine details and impeccable craftsmanship.c. Cost-Effective: By combining automation with precise material usage, these factories can minimize material waste, thereby reducing costs. This cost-effectiveness translates to competitive pricing for customers, attracting a broader range of clients and promoting widespread adoption of gypsum cornices.4. Focus on Innovation:The leading automatic gypsum cornice equipment factories are driven by a relentless focus on innovation and research. They continuously strive to improve their manufacturing processes, developing new techniques and machinery to push the boundaries of what is possible within the industry. By investing in research and development, these companies ensure that their customers have access to the latest advancements in gypsum cornice manufacturing.5. Sustainability and Environmental Responsibility:In addition to technological advancements, automatic gypsum cornice equipment factories also prioritize sustainable production methods. By adhering to environmentally friendly practices, these factories minimize waste, reduce energy consumption, and utilize recyclable materials wherever possible. This commitment to sustainability aligns with contemporary demands for eco-friendly construction materials and contributes to the preservation of our planet.Conclusion:The automatic gypsum cornice equipment factories have ushered in a new era of manufacturing, bringing innovation, precision, and efficiency to the production of gypsum cornices. By embracing cutting-edge technology and focusing on sustainability, these factories provide a competitive advantage while meeting customer demands. With their commitment to innovation, these industry leaders are undoubtedly shaping the future of interior decor, transforming spaces with bespoke gypsum cornice designs that reflect a perfect combination of artistry and automation.

Rigid Foam Board Making Machine for XPS - Everything You Need to Know

Xps Rigid Foam Board Making MachineThe Xps Rigid Foam Board Making Machine is a revolutionary piece of equipment that has been developed to meet the growing demand for XPS foam board in the construction industry. This advanced machine is capable of producing high-quality XPS foam boards with superior insulation properties, making it an essential tool for modern building projects.The Xps Rigid Foam Board Making Machine is manufactured by a leading company in the industry, with a strong focus on innovation and technological advancement. The company has a rich history of producing top-of-the-line machinery for various industries, and the Xps Rigid Foam Board Making Machine is a testament to their commitment to excellence.One of the key features of the Xps Rigid Foam Board Making Machine is its ability to produce XPS foam boards with exceptional strength and durability. This is achieved through a precise and efficient manufacturing process, which ensures that each XPS foam board meets the highest quality standards. The resulting foam boards are highly resistant to moisture, heat, and impact, making them an ideal choice for insulating buildings and structures.In addition to its superior quality, the Xps Rigid Foam Board Making Machine is also designed for maximum efficiency and productivity. It is equipped with state-of-the-art technology that allows for continuous operation and rapid production of XPS foam boards. This means that building projects can proceed at a faster pace, while still maintaining the highest standards of insulation and energy efficiency.Furthermore, the Xps Rigid Foam Board Making Machine is designed to be user-friendly and easy to operate. Its intuitive controls and automated processes allow for seamless production, with minimal downtime and maintenance requirements. This makes it an ideal investment for construction companies and manufacturers, as it can significantly increase their production capacity and overall efficiency.The company behind the Xps Rigid Foam Board Making Machine is dedicated to providing comprehensive support and service to its customers. From installation and training to maintenance and troubleshooting, the company offers a complete range of services to ensure that the machine operates at its best. They also provide ongoing technical support and expertise to assist customers in achieving optimal results with their XPS foam board production.With the growing demand for high-quality insulation materials in the construction industry, the Xps Rigid Foam Board Making Machine is poised to be a game-changer. Its cutting-edge technology, superior quality, and exceptional efficiency make it a valuable asset for any construction project. As the industry continues to prioritize energy efficiency and sustainability, the Xps Rigid Foam Board Making Machine is set to play a crucial role in meeting these objectives.In conclusion, the Xps Rigid Foam Board Making Machine represents a significant advancement in the production of XPS foam boards for the construction industry. Its innovative design, superior quality, and efficient operation make it an indispensable tool for building projects of all sizes. With the backing of a reputable and experienced company, the Xps Rigid Foam Board Making Machine is set to make a lasting impact on the construction industry and contribute to its continued growth and development.