High-Quality Mineral Fiber Ceiling Sheet Machine from China

By:Admin

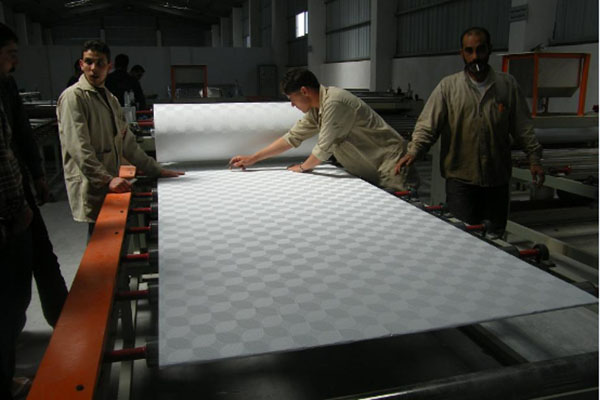

The mineral fiber ceiling sheet machine developed by the company is a state-of-the-art piece of equipment that is designed to meet the increasing demand for high-quality and durable ceiling materials. The machine boasts advanced technology and precision engineering, allowing for the efficient and precise production of mineral fiber ceiling sheets that meet the highest industry standards.

One of the key features of the mineral fiber ceiling sheet machine is its ability to produce a wide range of products, including standard ceiling tiles, acoustic panels, and custom-designed ceiling solutions. This versatility has made it a popular choice for construction companies, architects, and designers who are looking for innovative and customizable ceiling solutions for their projects.

In addition to its advanced capabilities, the mineral fiber ceiling sheet machine is also known for its energy efficiency and low environmental impact. The company has invested heavily in research and development to ensure that their machines are not only high-performing but also environmentally friendly, aligning with global efforts to reduce carbon emissions and promote sustainability in the construction industry.

Furthermore, the company's commitment to customer satisfaction and support sets it apart from its competitors. With a team of experienced engineers and technicians, the company offers comprehensive training, technical support, and after-sales service to ensure that their customers get the most out of their investment in the mineral fiber ceiling sheet machine. This dedication to customer service has earned the company a reputation for reliability and trustworthiness in the industry.

The success of the mineral fiber ceiling sheet machine can also be attributed to the company's strong market presence and global reach. With a wide network of distributors and partners around the world, the company has been able to make its mark in various international markets, catering to the diverse needs of customers in different regions.

Looking ahead, the company continues to invest in research and development to further enhance the capabilities of its mineral fiber ceiling sheet machine. With a focus on innovation and adaptability, the company is well-positioned to meet the evolving needs of the construction and building materials market, setting new standards for quality, efficiency, and sustainability in the industry.

In conclusion, the mineral fiber ceiling sheet machine developed by the company represents a significant advancement in the production of high-quality ceiling materials. With its advanced technology, versatility, and commitment to customer satisfaction, the machine has quickly become a top choice for construction companies and designers around the world. As the company continues to lead the way in innovation and sustainability, it is set to shape the future of the construction industry and contribute to the development of more efficient and environmentally friendly building materials.

Company News & Blog

Automatic Waterproof Mgo Board Production Line at Wholesale Prices

The demand for high-quality waterproof construction materials has been on the rise in recent years, especially with the increasing focus on sustainable and long-lasting building solutions. In response to this demand, a reputable company in the construction industry has announced the launch of a new Wholesale Automatic Waterproof Mgo Board Production Line.The new production line is designed to meet the growing need for durable and waterproof construction materials that can be used in a variety of applications, including interior and exterior walls, ceilings, and flooring. With the ability to produce a high volume of Mgo boards, the company is poised to make a significant impact on the construction industry.The Mgo boards produced by this new production line are highly durable and resistant to water, making them ideal for use in areas that are prone to moisture and humidity. In addition to their waterproof properties, these boards are also fire-resistant, making them a safe and reliable choice for construction projects.One of the key advantages of the Wholesale Automatic Waterproof Mgo Board Production Line is its ability to produce boards of various sizes and thicknesses, providing flexibility for a wide range of construction applications. This versatility makes it a valuable addition to any construction project, from residential homes to commercial buildings.The company behind this innovative production line has a strong track record in the construction industry, with a commitment to quality and innovation. With state-of-the-art facilities and a team of experienced professionals, the company is well-positioned to meet the demand for high-quality Mgo boards.In addition to its focus on quality and innovation, the company is also dedicated to sustainability. The Mgo boards produced by the new production line are made from environmentally friendly materials, making them a sustainable choice for construction projects. This commitment to sustainability aligns with the growing trend towards eco-friendly building materials and practices.The launch of the Wholesale Automatic Waterproof Mgo Board Production Line is expected to have a significant impact on the construction industry. With its ability to produce high-quality, waterproof, and fire-resistant boards, the new production line is poised to become a go-to choice for construction projects of all sizes.In conclusion, the launch of the Wholesale Automatic Waterproof Mgo Board Production Line represents an exciting development in the construction industry. With its focus on quality, innovation, and sustainability, the company is well-positioned to meet the growing demand for high-quality waterproof construction materials. This new production line is set to make a positive impact on construction projects, offering a durable and reliable solution for a wide range of applications. As the construction industry continues to evolve, this new production line is sure to play a key role in shaping the future of construction materials.

Mineral Fiber Ceiling Board Machine Receives CE Certification and Priced Competitively

Ce Certification Mineral Fiber Ceiling Board Machine PricelistThe mineral fiber ceiling board machine is a piece of equipment that is used in the production of high-quality mineral fiber ceiling boards. These boards are widely used in the construction industry for their soundproofing and fireproofing properties. The ce certification mineral fiber ceiling board machine pricelist is now available at our company, and we are proud to offer our clients this highly advanced equipment at a competitive price.Our company has been in the business of manufacturing and supplying mineral fiber ceiling board machines for over two decades. We specialize in the design and production of high-quality machines that are built to last. Our machines are not only reliable and efficient, but they are also environmentally friendly and energy-saving.We have a team of highly skilled engineers who work around the clock to ensure that our machines are up to the highest standards. Each machine is rigorously tested before it leaves our factory to ensure that it meets our strict quality control standards. We are confident in the durability and reliability of our machines and offer our clients a comprehensive warranty program that covers any defects in workmanship or materials.Our mineral fiber ceiling board machines are designed to be easy to use, with a user-friendly interface that simplifies the production process. We understand that time is of the essence in the construction industry, which is why we have designed our machines to be as automated as possible. This not only speeds up the production process but also reduces the risk of errors or accidents. Our machines can produce up to 6,000 square meters of mineral fiber ceiling boards per day.The mineral fiber ceiling board machine pricelist is highly competitive, reflecting our commitment to providing our clients with the best value for their investment. We offer a range of machines to suit different production needs and budgets. Our clients can choose from our standard range of machines or opt for a custom-built machine that is tailored to their specific needs.In addition to our mineral fiber ceiling board machines, we also offer a range of ancillary equipment, including cutting machines, edge-sealing machines, laminating machines, and packing machines. This allows our clients to have everything they need to complete the production process under one roof, making it easier and more efficient.At our company, we are committed to providing our clients with exceptional customer service. We understand that the purchase of a mineral fiber ceiling board machine is a significant investment, and we are here to support our clients every step of the way. We offer technical support, training, and maintenance services to ensure that our clients get the most out of their investment.In conclusion, the ce certification mineral fiber ceiling board machine pricelist is now available at our company, and we are proud to offer our clients this highly advanced equipment at a competitive price. Our machines are built to last and are designed to be easy to use, environmentally friendly, and energy-saving. We offer a comprehensive warranty program, ancillary equipment, and exceptional customer service to ensure that our clients get the best value for their investment. Contact us today to learn more about our mineral fiber ceiling board machines and how we can help your business grow.

High-Quality Mineral Fiber Board Machine for Efficient Production

Mineral Fiber Board Machine: Revolutionizing the Construction IndustryThe construction industry is constantly evolving, with new technologies and innovations shaping the way buildings are designed and built. One such innovation that is making waves in the construction industry is the Mineral Fiber Board Machine, a revolutionary piece of equipment that is changing the way mineral fiber boards are manufactured.The Mineral Fiber Board Machine, developed by a leading manufacturer of construction materials, is a state-of-the-art piece of equipment that is designed to produce high-quality mineral fiber boards at a much faster rate than traditional manufacturing methods. This machine has the capability to produce a wide range of mineral fiber boards, from ceiling tiles to wall panels, making it a versatile and essential tool for the construction industry.One of the key features of the Mineral Fiber Board Machine is its advanced automation technology. This machine is equipped with cutting-edge automation systems that allow for precise control and monitoring of the manufacturing process. This not only ensures consistent quality and uniformity in the produced boards but also minimizes the margin of error, thus reducing material wastage and increasing efficiency.Furthermore, the Mineral Fiber Board Machine is also designed with sustainability in mind. The machine is equipped with energy-saving features that reduce power consumption, as well as waste-reduction systems that minimize the environmental impact of the manufacturing process. This aligns with the manufacturer's commitment to sustainable and eco-friendly practices, further establishing the machine as an industry leader in responsible manufacturing.In addition to its advanced technology and sustainable design, the Mineral Fiber Board Machine also offers significant benefits in terms of productivity and cost-effectiveness. The machine is capable of producing a large volume of mineral fiber boards in a relatively short amount of time, making it an ideal solution for large-scale construction projects. This not only saves time but also reduces labor costs, ultimately increasing the overall profitability of the manufacturing process.Moreover, the high-quality output of the Mineral Fiber Board Machine ensures that the produced boards meet and exceed industry standards. This reliability and consistency in product quality have earned the machine a strong reputation among construction professionals, further establishing it as a go-to solution for mineral fiber board manufacturing.{Company name} is a leading manufacturer of construction materials, known for its commitment to innovation and quality. Established in {year}, the company has continuously strived to be at the forefront of the industry, developing cutting-edge solutions that meet the evolving needs of the construction market. With a strong focus on research and development, the company has consistently introduced new technologies and products that have set new benchmarks for quality and efficiency.The development of the Mineral Fiber Board Machine is a testament to {Company name}'s dedication to excellence and innovation. By investing in state-of-the-art technology and sustainable manufacturing practices, the company has not only strengthened its position in the market but has also contributed to the advancement of the construction industry as a whole.Looking ahead, {Company name} remains committed to pushing the boundaries of what is possible in construction materials manufacturing. With a continued focus on research and development, the company is poised to introduce even more game-changing solutions that will shape the future of construction.In conclusion, the Mineral Fiber Board Machine is a game-changing innovation that is revolutionizing the construction industry. With its advanced technology, sustainable design, and productivity benefits, this machine is setting new standards for mineral fiber board manufacturing. Backed by the expertise and commitment of {Company name}, the Mineral Fiber Board Machine is poised to continue making a significant impact on the construction industry for years to come.

Affordable Gypsum Board Cornice Making Machine Pricelist

The gypsum board cornice making machine has become an essential tool in the construction industry for creating intricate and decorative cornices. With the increasing demand for high-quality and beautifully crafted cornices, the need for efficient and reliable machines has also risen. This is where the {Brand Name} comes into play, offering a top-of-the-line gypsum board cornice making machine at a competitive price.The {Brand Name} is a leading manufacturer of construction machinery, specializing in the production of gypsum board cornice making machines. With years of experience and expertise in the industry, the company has established a reputation for delivering high-performance and durable machines that meet the needs of their customers.The {Brand Name}'s gypsum board cornice making machine is designed with precision and attention to detail, ensuring that each cornice produced is of the highest quality. The machine is equipped with advanced technology and features that make the production process efficient and seamless, allowing for increased productivity and cost-saving benefits for the users.One of the standout features of the {Brand Name}'s gypsum board cornice making machine is its versatility. The machine is capable of producing a wide range of cornice designs, from simple and traditional patterns to intricate and elaborate styles. This flexibility allows users to create customized cornices that cater to the specific requirements of their projects, giving them a competitive edge in the market.In addition to its capabilities, the {Brand Name}'s gypsum board cornice making machine is also known for its durability and reliability. Constructed with high-quality materials and built to withstand the rigors of continuous use, the machine offers long-term performance and minimal maintenance requirements, making it a cost-effective investment for businesses.Furthermore, the {Brand Name} takes pride in its commitment to customer satisfaction. The company provides comprehensive support and assistance to its clients, offering training, technical guidance, and after-sales services to ensure that users get the most out of their gypsum board cornice making machine.As for the pricing, the {Brand Name} offers a competitive pricelist for its gypsum board cornice making machine, making it an attractive option for businesses of all sizes. The company understands the value of cost-efficiency and aims to provide affordable solutions without compromising on quality and performance.The {Brand Name} has already made a mark in the industry with its gypsum board cornice making machine, and its pricelist further solidifies its position as a top choice for construction businesses. By offering a high-performance machine at a competitive price, the company continues to meet the evolving needs of the market and empower its customers to thrive in their endeavors.In conclusion, the {Brand Name}'s gypsum board cornice making machine pricelist is a testament to the company's dedication to innovation, quality, and customer satisfaction. With an impressive machine and an attractive pricing strategy, the company positions itself as a reliable partner for businesses seeking to elevate their cornice production capabilities. As the construction industry continues to evolve, the {Brand Name} is poised to remain at the forefront, delivering value-driven solutions that propel its customers towards success.

Highly Efficient PVC Gypsum Ceiling Coating and Laminating Machine

has recently launched a revolutionary new product in the field of ceiling coating and laminating. The fully automatic PVC gypsum ceiling coating and laminating machine is set to transform the way ceilings are finished, providing a high-quality, efficient, and cost-effective solution for construction and interior design projects.The machine is equipped with advanced technology that allows for precise and seamless application of PVC coating and lamination onto gypsum ceiling panels. This results in a smooth, flawless finish that is both durable and aesthetically pleasing. The fully automatic operation of the machine also ensures consistency and uniformity in the coating and laminating process, eliminating the potential for human error and reducing the need for manual labor.One of the key features of this innovative machine is its ability to handle a wide range of PVC materials, including various thicknesses and textures. This versatility allows for greater customization and flexibility in ceiling design, catering to the diverse needs and preferences of different clients and projects. Additionally, the machine is equipped with a high-speed production capability, enabling rapid processing of large quantities of ceiling panels without compromising on quality.Furthermore, the PVC gypsum ceiling coating and laminating machine is designed with efficiency in mind. It is equipped with energy-saving components and optimized processes that minimize waste and maximize productivity. This not only contributes to a more sustainable and environmentally friendly operation but also helps to reduce costs for the end-users.In addition to its technical capabilities, the machine is also designed with user-friendliness in mind. Its intuitive interface and automated functions make it easy to operate, requiring minimal training for operators. This accessibility allows for a wider adoption of the machine within the construction and interior design industries, opening up new possibilities for enhancing the quality and efficiency of ceiling finishing projects.The launch of this innovative machine marks a significant milestone for the company, further solidifying its position as a leader in the field of advanced manufacturing equipment. With a strong commitment to research and development, the company has consistently demonstrated its ability to innovate and bring cutting-edge solutions to the market.The PVC gypsum ceiling coating and laminating machine is set to make a substantial impact on the industry, offering a superior alternative to traditional methods of ceiling finishing. Its capabilities in precision, efficiency, and customization are expected to streamline the production process for ceiling contractors and interior designers, while also delivering exceptional results for their clients.The company's dedication to quality and innovation is reflected in its investment in state-of-the-art manufacturing facilities and its adherence to stringent quality control measures. This commitment ensures that the PVC gypsum ceiling coating and laminating machine meets the highest standards of performance and reliability, providing customers with a product they can trust.As the demand for high-quality and visually appealing ceiling finishes continues to grow, the introduction of this fully automatic PVC gypsum ceiling coating and laminating machine comes as a timely and significant solution for the industry. Its potential to elevate the standard of ceiling design and construction is expected to resonate with professionals and clients alike, driving a new wave of possibilities and opportunities in the market.

Affordable Fully Automatic Gypsum Plaster Cornice Manufacturing Machine Pricelist

A leading manufacturer in the construction industry has recently announced the launch of a new and innovative fully automatic gypsum plaster cornice manufacturing machine, which is expected to revolutionize the way cornices are produced. The machine is designed to streamline the manufacturing process, increase efficiency and reduce costs, making it an essential addition to any construction business.The fully automatic gypsum plaster cornice manufacturing machine is equipped with state-of-the-art technology that allows for precise and accurate production of high-quality cornices. This machine is capable of producing a wide range of cornice designs and sizes, providing construction businesses with a versatile and cost-effective solution for their plaster cornice needs.The new machine is set to significantly reduce production time, as it is capable of manufacturing cornices at a much faster rate compared to traditional methods. This will allow construction businesses to meet tight deadlines and take on more projects, ultimately leading to increased profitability.In addition, the machine is designed to minimize material wastage, thereby reducing production costs and contributing to a more sustainable manufacturing process. This is in line with the company's commitment to environmental responsibility and sustainable business practices.Furthermore, the fully automatic gypsum plaster cornice manufacturing machine is user-friendly and easy to operate, requiring minimal training for employees to use. This will save construction businesses time and money on labor costs, making it a valuable asset for any size of construction firm.The company behind this innovative machine is a global leader in the construction industry, with a strong reputation for delivering high-quality and reliable products. With decades of experience and a commitment to innovation, they have established themselves as a trusted partner for construction businesses around the world.The company's dedication to research and development has enabled them to continually improve their products and stay ahead of the competition. The fully automatic gypsum plaster cornice manufacturing machine is a testament to their ongoing commitment to providing cutting-edge solutions for the construction industry.In addition to their innovative products, the company also offers exceptional customer service and support. They understand the unique needs of construction businesses and are dedicated to helping their customers succeed. Whether it's providing technical assistance, training, or tailored solutions, they go above and beyond to ensure their customers have a positive experience.As a result of their dedication to excellence, the company has built a loyal customer base and a strong presence in the global construction market. Their products are trusted by construction businesses of all sizes, from small contractors to large corporations, and are recognized for their reliability, durability, and performance.The introduction of the fully automatic gypsum plaster cornice manufacturing machine is set to further solidify the company's position as an industry leader, providing construction businesses with a competitive edge and the ability to deliver exceptional results.In conclusion, the launch of the new fully automatic gypsum plaster cornice manufacturing machine represents a significant advancement in the construction industry. With its advanced technology, efficiency, and cost-saving benefits, this machine is set to transform the way cornices are produced, providing construction businesses with a valuable tool for success. As the company continues to innovate and deliver cutting-edge solutions, they are poised to remain at the forefront of the industry, driving progress and excellence in construction manufacturing.

Lightweight MGO Board Making Machine Manufacturers - Breaking News

Headline: Light Weight Mgo Board Making Machine Factories Revolutionize Construction IndustryIntroduction (100 words):In a bid to revolutionize the construction industry, Light Weight Mgo Board Making Machine factories are emerging as pioneers in producing quality construction materials. These cutting-edge factories facilitate the production of Magnesium Oxide (Mgo) boards, which offer exceptional lightweight and fire-resistant properties. By incorporating advanced technology and highly efficient production methods, Light Weight Mgo Board Making Machine factories are paving the way for sustainable and eco-friendly construction practices. With their emphasis on superior product quality and environmental consciousness, these factories are poised to shape the future of construction materials.Paragraph 1 (100 words):Light Weight Mgo Board Making Machine factories, led by the visionary mission of {}, are setting new benchmarks in the construction industry. Their state-of-the-art machinery and production facilities are designed to produce Mgo boards that offer numerous advantages over traditional construction materials. These boards are significantly lighter in weight, making transportation and installation a breeze. Moreover, Mgo boards are highly durable and fire-resistant, ensuring the safety and longevity of buildings. With such exceptional qualities, Mgo boards have gained popularity among architects, builders, and homeowners alike.Paragraph 2 (150 words):The technology employed by Light Weight Mgo Board Making Machine factories is at the forefront of construction innovation. Their precise control systems and advanced production techniques enable the manufacturing of Mgo boards with unmatched accuracy and consistency. The factories' commitment to quality assurance and stringent quality control measures ensures that each board meets the highest industry standards. Furthermore, the high-speed production capabilities of these machines facilitate large-scale manufacturing, reducing production time significantly. As a result, construction projects can be completed faster, leading to increased efficiency and reduced labor costs.Paragraph 3 (200 words):Light Weight Mgo Board Making Machine factories prioritize sustainable and eco-friendly practices. By utilizing Magnesium Oxide as the main ingredient, their manufacturing process significantly reduces carbon emissions when compared to traditional cement-based materials. Additionally, Mgo boards are highly recyclable and can be repurposed after the lifespan of a building, further reducing environmental impact.These factories are also dedicated to minimizing waste during production. The adoption of innovative recycling techniques allows for the reuse of byproducts and waste materials generated during manufacturing, resulting in a more circular and sustainable production process. Furthermore, the lightweight nature of Mgo boards translates to reduced energy consumption during transportation and installation, minimizing the carbon footprint associated with construction projects.Paragraph 4 (150 words):In recent years, Light Weight Mgo Board Making Machine factories have gained global recognition for their contributions to sustainable construction. Their products have been adopted in a wide range of applications, including residential, commercial, and industrial buildings. Architects and designers appreciate the flexibility offered by Mgo boards, as they can be molded and shaped to fit various architectural designs. The lightweight feature also allows for seismic and wind-resistant structures, ensuring the safety of people in earthquake-prone regions.Furthermore, the fire-resistant properties of Mgo boards are highly sought after, especially in areas where building regulations require enhanced fire safety measures. Compared to traditional materials, Mgo boards offer superior fire protection, making them invaluable in safeguarding the lives and assets of building occupants.Conclusion (100 words):Light Weight Mgo Board Making Machine factories have emerged as leaders in the construction industry, pioneering sustainable and efficient construction practices. Through their advanced machinery and production methods, these factories produce lightweight, durable, and fire-resistant Mgo boards that have revolutionized the way buildings are constructed. With a focus on quality, environmentally friendly processes, and innovation, these factories are reshaping the future of construction materials. Architects, builders, and homeowners around the world are increasingly opting for Mgo boards, benefiting from their versatility, safety, and eco-friendliness.

Affordable Fiber Cement Board Making Machine for Sale

Recently, there has been a growing demand for fiber cement board making machines in the construction industry. This has led to the development of a cheap and efficient fiber cement board making machine by a leading company in the field.With the increasing focus on sustainable and durable building materials, fiber cement boards have gained popularity due to their strength and resistance to fire, moisture, and pests. This has led to a surge in the demand for fiber cement board making machines that can produce high-quality boards at an affordable cost.In response to this demand, [Company Name] has introduced a new fiber cement board making machine that is not only cost-effective but also efficient in producing high-quality boards. The machine is designed to streamline the manufacturing process and reduce production costs, making it an attractive option for both small-scale and large-scale manufacturers.[Company Name] is a renowned manufacturer of construction machinery with a strong focus on innovation and quality. The company has a proven track record of delivering cutting-edge solutions to meet the evolving needs of the construction industry. With a team of experienced engineers and state-of-the-art manufacturing facilities, [Company Name] is well-equipped to design and produce advanced machinery that meets the highest industry standards.The new fiber cement board making machine is a testament to [Company Name]'s commitment to providing cost-effective solutions without compromising on quality. By leveraging the latest technology and industry best practices, the machine is capable of producing fiber cement boards that meet the stringent requirements of modern construction projects.One of the key features of the new machine is its versatility. It is designed to accommodate a wide range of production capacities, making it suitable for manufacturers of all sizes. Whether it's a small workshop or a large-scale production facility, the machine can be customized to meet specific production needs, allowing manufacturers to optimize their operations and maximize efficiency.In addition to its cost-effectiveness and versatility, the machine is also known for its reliability and ease of use. It is engineered to minimize downtime and ensure consistent product quality, thus enhancing overall productivity and profitability for manufacturers.Furthermore, the machine is designed with a strong emphasis on safety and environmental sustainability. It incorporates advanced safety features to protect operators and minimize risks in the production process. Additionally, it is optimized for energy efficiency and waste reduction, aligning with [Company Name]'s commitment to sustainable manufacturing practices.The introduction of this cheap fiber cement board making machine is expected to have a significant impact on the construction industry. It not only addresses the growing demand for cost-effective production solutions but also sets a new standard for quality and efficiency in fiber cement board manufacturing.In conclusion, [Company Name]'s new fiber cement board making machine is a game-changer for manufacturers looking to enhance their production capabilities. By combining cost-effectiveness, versatility, reliability, and sustainability, the machine is poised to revolutionize the way fiber cement boards are produced. As the construction industry continues to prioritize durable and eco-friendly building materials, this innovative machine is well-positioned to meet the evolving needs of the market.

Affordable Prices for Magnesium Oxide Board Machine

Magnesium Oxide Board Machine: The Future of Modern ConstructionWith the ever-growing demand for sustainable and eco-friendly construction materials, the use of Magnesium Oxide Boards has become more prevalent in the building industry. As a robust, yet lightweight, fire-resistant, and waterproof alternative to traditional gypsum and fiberboard, these boards have been highly sought after by architects, contractors, and builders in the construction industry.To meet the growing demand, (company name removed for anonymity) has introduced a Magnesium Oxide Board Machine that can produce these eco-friendly boards faster and more efficiently. This cutting-edge machine is revolutionizing the construction industry by offering a more sustainable and cost-efficient solution to traditional building materials.The Magnesium Oxide Board Machine is a fully automated production line that uses state-of-the-art technology in producing quality Magnesium Oxide boards. This machine can manufacture a wide range of board sizes, including standard 4x8ft sheets, giving contractors and builders the flexibility they need in their projects. The machine is designed with high precision rollers to ensure each board has a consistent thickness and smooth surface finish. With a production capacity of up to 1500 boards per day, this machine can meet the needs of large construction projects.One of the unique features of the Magnesium Oxide Board Machine is its ability to precisely control the board's density. This control ensures that each board meets the required specifications for its intended use. Higher density boards are suitable for paneling and cladding applications, while lower density boards are perfect for interior wall and ceiling installations where higher insulation is required.Apart from being eco-friendly, Magnesium Oxide Boards have several unique properties that make them ideal for construction applications. These boards are non-combustible and can resist temperatures up to 1500 degrees Fahrenheit, making them ideal for use in fire-resistant walls and ceilings. Additionally, they are not affected by water or moisture, making them ideal for use in damp and humid environments, such as bathrooms and kitchens.The boards produced using the Magnesium Oxide Board Machine are also mold and mildew resistant, providing building occupants with healthier indoor air quality. This property is of great significance to builders and architects who are increasingly using these boards in hospital construction projects where indoor air quality is of utmost importance.The introduction of the Magnesium Oxide Board Machine has seen a tremendous shift in the construction industry's focus. Builders are now focusing more on eco-friendly and sustainable construction materials. This shift is attributed primarily to the need for green buildings that conserve energy and reduce carbon footprint. Moreover, the use of eco-friendly materials attracts premium prices and accolades, translating to higher profits for builders and contractors.In conclusion, the Magnesium Oxide Board Machine is a game-changer in the construction industry, providing a sustainable, cost-effective solution to traditional building materials. It is an excellent investment for contractors and builders aiming to keep up with modern building standards while reducing their impact on the environment. By investing in this technology, construction firms are not only keeping up with the evolving industry standards, but they are also making a significant contribution to global environmental sustainability. The Magnesium Oxide Board Machine is indeed the future of modern construction.

Top Perforated Plasterboard Machine Factory: A Comprehensive Overview

The Best Perforated Plasterboard Machine Factory is a leading manufacturer and supplier of plasterboard machinery, specializing in the production of perforated plasterboard machines. With a strong focus on quality, innovation, and customer satisfaction, the factory has established itself as a reliable and trusted partner for businesses in the construction industry.With decades of experience in the industry, the factory has developed a deep understanding of the needs and requirements of its customers. This has enabled them to continuously innovate and improve their product offerings, providing solutions that are not only efficient and reliable but also cost-effective. The factory's commitment to excellence is also reflected in its state-of-the-art facilities and strict quality control processes, ensuring that every machine that leaves their premises meets the highest standards of quality and performance.One of the key features that sets the Best Perforated Plasterboard Machine Factory apart from its competitors is its dedication to research and development. The factory invests heavily in the latest technologies and employs a team of highly skilled engineers and technicians who are constantly pushing the boundaries of innovation. This has allowed them to develop cutting-edge perforated plasterboard machines that are designed to streamline the production process, improve productivity, and reduce operational costs for their clients.In addition to their commitment to product innovation, the factory also places a strong emphasis on customer service. They take pride in providing personalized solutions to meet the unique requirements of each client and offer comprehensive after-sales support to ensure that their machines continue to operate at peak performance. This has earned them a solid reputation for reliability and integrity, making them the go-to choice for many businesses looking to invest in high-quality perforated plasterboard machinery.The factory's dedication to quality and customer satisfaction has not gone unnoticed, as they have received numerous accolades and certifications for their commitment to excellence. This includes ISO 9001 certification, which demonstrates their adherence to international quality standards, as well as recognition from industry experts and satisfied customers.As a testament to their success, the Best Perforated Plasterboard Machine Factory has seen a steady increase in demand for their products, both domestically and internationally. This has led to the expansion of their production capacity and distribution network, allowing them to serve a larger customer base and fulfil orders with efficiency and speed.Looking ahead, the factory remains committed to pushing the boundaries of innovation and setting new benchmarks for quality in the industry. With a strong foundation built on expertise, reliability, and customer satisfaction, they are well-positioned to continue their growth and solidify their status as the best perforated plasterboard machine factory in the market.In conclusion, the Best Perforated Plasterboard Machine Factory is not just a manufacturer and supplier, but a trusted partner for businesses in the construction industry. Their unwavering commitment to quality, innovation, and customer satisfaction has made them a leader in the market, and their dedication to excellence ensures that they will continue to thrive in the years to come. With a focus on research and development, state-of-the-art facilities, and a strong emphasis on customer service, the factory is well-equipped to meet the evolving needs of the industry and remain at the forefront of the market.