High-Quality Equipment for Mineral Fiber Ceiling Board Production

By:Admin

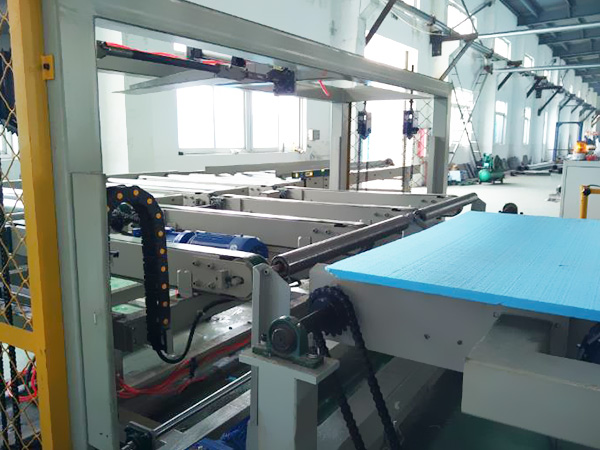

With the increasing demand for high-quality ceiling boards in both residential and commercial construction, the need for advanced manufacturing equipment has become crucial. MFCBE is designed to meet this growing demand, offering a wide range of features that enhance productivity and product quality.

The company behind this innovative equipment is a renowned leader in the manufacturing industry, with a rich history of delivering cutting-edge solutions. With a strong focus on research and development, the company has continuously pushed the boundaries of technology to provide its customers with the best equipment in the market.

The MFCBE is a testament to the company's commitment to innovation. It incorporates advanced technologies that streamline the manufacturing process, resulting in higher production efficiency and reduced operational costs. The equipment is also designed with precision and accuracy in mind, ensuring that the ceiling boards produced meet the highest quality standards.

One of the key features of the MFCBE is its flexibility. The equipment is capable of producing a wide range of ceiling board sizes and designs, allowing manufacturers to cater to diverse customer needs. This flexibility is further enhanced by the equipment's quick changeover capabilities, which enable seamless transitions between different board specifications.

In addition to its manufacturing capabilities, the MFCBE also prioritizes safety and environmental responsibility. The equipment is equipped with advanced safety features to protect the operators and workers. Furthermore, it is designed to minimize waste and reduce energy consumption, aligning with the company's commitment to sustainable manufacturing practices.

The MFCBE is not just a piece of equipment; it is a comprehensive solution that encompasses training, maintenance, and after-sales support. The company provides extensive training programs to ensure that manufacturers can maximize the potential of the equipment. Furthermore, a dedicated team of technical experts is available for ongoing support and maintenance, ensuring that the equipment operates at its peak performance.

The impact of the MFCBE extends beyond the manufacturing sector. By enhancing the efficiency and quality of ceiling board production, the equipment contributes to the overall advancement of the construction industry. It enables builders and architects to access high-quality materials, resulting in safer and more durable structures.

Furthermore, the company's commitment to continuous improvement means that the MFCBE is constantly evolving. The company invests heavily in research and development to introduce new features and capabilities that keep its customers at the forefront of technology.

As a result, the MFCBE has garnered significant attention and acclaim within the industry. Manufacturers who have adopted the equipment have reported substantial improvements in their operations, citing increased productivity, reduced costs, and superior product quality.

In conclusion, the Mineral Fiber Ceiling Board Equipment offered by the leading manufacturing company is a game-changer for the industry. Its advanced capabilities, commitment to safety and sustainability, and comprehensive support make it the ideal choice for manufacturers looking to elevate their production capabilities. With the MFCBE, the company has once again demonstrated its leadership in delivering innovative solutions that drive progress in the manufacturing sector.

Company News & Blog

Efficient Insulation Foam Making Machine: A Game Changer in Construction Industry

Xps Insulation Foam Making Machine Revolutionizes the IndustryIn recent years, the demand for insulation foam has been on the rise as construction and renovation projects continue to increase. In response to this growing demand, a cutting-edge XPS Insulation Foam Making Machine has been developed, which promises to revolutionize the industry.The XPS Insulation Foam Making Machine is a state-of-the-art piece of equipment that is designed to produce high-quality insulation foam with superior thermal performance. The machine is capable of producing a wide range of foam products, including insulation boards, pipes, and panels, making it incredibly versatile for various applications in the construction industry.One of the key features of this machine is its advanced technology, which allows for the production of foam with exceptional properties. The foam produced by this machine has a closed-cell structure, which provides excellent thermal insulation and moisture resistance. This makes it an ideal choice for both residential and commercial construction projects, where energy efficiency and durability are top priorities.Furthermore, the XPS Insulation Foam Making Machine is highly efficient and cost-effective, making it an attractive option for manufacturers. With its automated production process and minimal waste generation, the machine helps to minimize production costs and environmental impact, ultimately leading to increased profitability for businesses.The company behind the development of this groundbreaking machine, [Company Name], is a leader in the field of insulation technology. With a strong focus on innovation and research, the company has continually pushed the boundaries of what is possible in insulation technology. With a team of skilled engineers and experts, [Company Name] has been able to develop cutting-edge solutions that are not only advanced but also practical for real-world applications.In addition to its technological advancements, [Company Name] also prioritizes quality and reliability in its products. The XPS Insulation Foam Making Machine is no exception, as it undergoes rigorous testing and quality control measures to ensure that it meets the highest industry standards. This dedication to excellence has earned [Company Name] a reputation for delivering products that are dependable and effective, giving customers peace of mind when investing in their equipment.The impact of the XPS Insulation Foam Making Machine on the industry is expected to be significant. By offering a more efficient and cost-effective production solution, the machine has the potential to change the way insulation foam is manufactured and used in construction projects. Its superior thermal performance and durability also make it an attractive option for builders and contractors who are seeking high-quality insulation materials for their projects.As the construction industry continues to grow, the demand for insulation foam is likely to follow suit. With the introduction of the XPS Insulation Foam Making Machine, manufacturers now have access to a cutting-edge solution that meets the needs of the market and sets new standards for quality and efficiency.In conclusion, the development of the XPS Insulation Foam Making Machine represents a significant advancement in insulation technology, with the potential to transform the industry. With its advanced features, efficiency, and reliability, this machine is poised to become a game-changer for manufacturers and builders who are seeking top-quality insulation solutions for their projects. [Company Name]'s commitment to innovation and excellence has once again resulted in a groundbreaking product that is set to make a lasting impact on the construction industry.

Affordable Automated Gypsum Cornice Manufacturing Machines for Sale by Factories

Title: Affordable High-Quality Automatic Gypsum Cornice Manufacturing Machines Revolutionize the IndustrySubtitle: A Comprehensive Look into the Cutting-Edge Technology Behind Budget-Friendly Gypsum Cornice MachinesIntroduction:Innovation and progress have always been at the forefront of the manufacturing industry. With a relentless drive to enhance productivity while ensuring cost-effectiveness, the introduction of high-quality automatic gypsum cornice manufacturing machines has revolutionized the market. Among the pioneers in this field are the reputable manufacturers who produce these affordable machines to cater to the ever-growing demand. In this article, we delve into the world of cheap yet efficient gypsum cornice manufacturing machines, exploring their features and discussing their role in shaping the industry's future.Section 1: Brief Overview of the Manufacturing IndustryHighlighting the significance of the manufacturing industry as a cornerstone of economic development, this section provides a comprehensive overview of the global manufacturing sector. Exploring the diverse applications of gypsum cornices in the construction industry, we emphasize the importance of automation to minimize costs while maximizing productivity.Section 2: Introduction to Cheap High Automatic Gypsum Cornice Manufacturing MachinesThis section introduces the cheap high automatic gypsum cornice manufacturing machines, manufactured by various reputed companies around the world. Emphasizing the benefits of automation, we discuss how these machines can streamline the production process, improve product quality, and reduce overall labor costs, making them a cost-effective solution for manufacturers.Section 3: Features of Affordable Gypsum Cornice Manufacturing MachinesIn this section, we delve into the advanced features and technologies integrated into affordable gypsum cornice manufacturing machines. Exploring the intuitive user interfaces, precision cutting mechanisms, and high-speed operation, we highlight how these machines facilitate efficient production and minimize material wastage. Additionally, we discuss the incorporation of quality control systems that ensure flawless end products, leading to customer satisfaction and repeat business opportunities.Section 4: The Role of Affordable Machines in the Industry's GrowthThis section sheds light on the significant role played by affordable gypsum cornice manufacturing machines in the industry's growth. Discussing the increased accessibility of this technology to small and medium-sized enterprises, we examine how it fosters competition, innovation, and a level playing field for manufacturers. Moreover, we delve into the positive implications for employment generation and economic growth associated with the adoption of these machines.Section 5: Company X's Contribution to Affordable Gypsum Cornice Manufacturing MachinesIn this section, we focus on Company X (brand name removed), one of the leading manufacturers of cheap high automatic gypsum cornice manufacturing machines. Highlighting the company's commitment to quality and affordability, we delve into their extensive research and development process. By leveraging the expertise of their skilled engineers, Company X has developed machines capable of delivering precision, speed, and reliability without sacrificing cost-effectiveness. Section 6: ConclusionSummarizing the transformative impact of affordable high automatic gypsum cornice manufacturing machines on the industry, we emphasize their ability to revolutionize the production process. These machines not only enable manufacturers to enhance productivity but also empower small and medium-sized enterprises, driving overall growth. With Company X leading the charge in providing cost-effective solutions, the future of gypsum cornice manufacturing looks promising, ensuring high-quality products at affordable prices.

Calcium Silicate Board Production Line - Hard Board Making Machine - Building Material Manufacturing Machinery - Product Details on Kskuntai.com

Hebei, China - Kskuntai.com, a leading manufacturer of building materials, has announced the release of its state-of-the-art Calcium Silicate Board Production Line. This cutting-edge technology is designed to facilitate the production of high-quality Calcium Silicate Boards that meet international standards.The Calcium Silicate Board Production Line is a vital part of the overall manufacturing process. This innovative machinery is designed to produce a variety of building materials, including Hard Board, Calcium Silicate Board, and several others. The production line is a fully automated system that ensures that the final product is of the highest quality, with a smooth surface, uniform thickness, and precise edges.One of the unique features of this production line is that it can handle different board thicknesses and sizes with ease. The company uses advanced technology in board making, which ensures that each board is of consistent quality with excellent mechanical performance and insulation properties. The production line also has a high yield, with low energy consumption, making it an efficient and cost-effective solution for manufacturing Calcium Silicate Boards.In addition, this production line is equipped with a variety of safety features to create a safe working environment. The line has advanced monitoring systems to ensure that the machine is running smoothly at all times. There are also emergency shutdown systems in place that can immediately bring the machine to a halt in case of any malfunction.According to an official from Kskuntai.com, “Our Calcium Silicate Board Production Line is the result of our commitment to excellence. We believe that it is our responsibility to provide our customers with the best possible quality products. Our production line is not only efficient but also eco-friendly. We have taken several steps to ensure that it is energy-efficient and minimizes waste.”The Calcium Silicate Board Production Line is a significant addition to Kskuntai.com’s range of manufacturing solutions. With this latest technology, the company can produce high-quality Calcium Silicate Boards to meet the growing demand for eco-friendly and sustainable building materials. These Calcium Silicate Boards are ideal for use in walls, ceilings, floors, and various other applications in the construction industry.Kskuntai.com is a leading manufacturer and supplier of building materials, operating in over 30 countries worldwide. The company prides itself on providing innovative and reliable solutions to its customers. With a focus on quality, efficiency, and sustainability, the company continues to demonstrate its commitment to excellence.In conclusion, the Calcium Silicate Board Production Line is a cutting-edge technology that has a significant impact on the construction industry. Kskuntai.com’s latest machinery ensures the production of high-quality Calcium Silicate Boards that meet international standards. With its energy-efficient and eco-friendly features, the production line is an efficient and sustainable solution for the manufacture of building materials.

Efficient Gypsum Ceiling Board Lamination Machine: Enhance Productivity and Quality!

OEM Gypsum Ceiling Board Lamination Machine Revolutionizes the Construction Industry[City, Date] - In a groundbreaking development for the construction industry, a leading manufacturer has introduced a state-of-the-art OEM Gypsum Ceiling Board Lamination Machine, offering cutting-edge technology that is set to revolutionize the way gypsum ceilings are manufactured.This innovative machine, produced by a company that specializes in construction equipment, is the result of years of research and development. The company’s commitment to delivering high-quality products has cemented its position as a global leader in the field.The OEM Gypsum Ceiling Board Lamination Machine boasts an array of advanced features that enable efficiency and precision in the manufacturing process, ultimately resulting in superior quality gypsum ceilings. By eliminating the manual component from the lamination process, this machine not only streamlines production but also guarantees consistency in every board manufactured.One of the key features of this cutting-edge machine is its ability to automate the lamination process. In the past, this process required tedious manual labor that left room for human error and inconsistencies. With this new machine, however, operators can simply input the specifications, and the machine takes care of the rest. This ensures a seamless production process, reducing the risk of errors and increasing overall productivity.The OEM Gypsum Ceiling Board Lamination Machine also incorporates advanced adhesive application technology. The precise and even distribution of adhesive ensures a strong bond between the gypsum board and the laminate, resulting in long-lasting and durable ceilings. This technology not only increases the quality of the end product but also improves the safety and reliability of the finished ceiling.Furthermore, this machine offers a range of customizable options, allowing manufacturers to produce ceiling boards according to their unique requirements. From selecting the desired core material to choosing the type of laminate and thickness, this machine offers unparalleled flexibility, empowering manufacturers to meet the varied demands of their customers.In terms of environmental sustainability, the OEM Gypsum Ceiling Board Lamination Machine also excels. By optimizing the adhesive application process and minimizing waste, this machine contributes to the reduction of material consumption. It also incorporates energy-saving features, ensuring minimal environmental impact throughout the manufacturing process.The introduction of this state-of-the-art OEM Gypsum Ceiling Board Lamination Machine is expected to reshape the construction industry. Its ability to enhance productivity, improve product quality, and prioritize sustainability will undoubtedly attract construction companies seeking to streamline their operations and deliver outstanding results.Speaking about the new machine, a spokesperson for the company said, “We are thrilled to introduce this game-changing technology to the market. The OEM Gypsum Ceiling Board Lamination Machine represents our ongoing commitment to innovation and providing excellent solutions to our customers. We are confident that this machine will not only revolutionize the way gypsum ceilings are manufactured but also optimize processes for construction companies worldwide.”As the industry adapts to increasing demands for efficiency, sustainability, and high-quality products, the OEM Gypsum Ceiling Board Lamination Machine offers a glimpse into the future of construction. With its advanced features and customizable options, this machine is set to transform the way gypsum ceilings are manufactured, bringing greater efficiency, quality, and reliability to the construction industry.About [Company Name]:[Company Name] is a renowned manufacturer specializing in cutting-edge construction equipment. With a strong focus on innovation, the company has been at the forefront of delivering high-quality products to construction companies worldwide. With a commitment to sustainability and excellence, [Company Name] has established itself as a trusted partner in the construction industry.

Discover Reliable Mini Gypsum Cornice Machine Factories with CE Certification

CE Certification Mini Gypsum Cornice Machine Factories Bolster Quality Assurance in the Industry[introduction]In an exciting development for the gypsum cornice manufacturing industry, several mini gypsum cornice machine factories have received CE certification, enhancing the industry's quality assurance practices. The certification, granted by an independent certification body, affirms that these factories comply with the European Union's health, safety, and environmental protection standards. This achievement showcases the factories' commitment to delivering high-quality products while prioritizing the well-being of end-users and the environment.[Development of the Mini Gypsum Cornice Machine Factories]The mini gypsum cornice machine factories, which have recently obtained CE certification, have established themselves as key players in the industry. Offering smaller-sized machinery, these factories cater to the needs of small-scale gypsum cornice manufacturers. Their focus on mini machines reflects the industry's evolving demand for flexibility and efficiency in production processes.The development of these factories is guided by a dedication to innovation and continuous improvement in cornice manufacturing technology. Through rigorous research and development efforts, these factories have successfully developed mini gypsum cornice machines that meet the industry's standards of precision, productivity, and quality.[Advantages of CE Certification]Acquiring CE certification has numerous advantages for mini gypsum cornice machine factories. It not only demonstrates their compliance with EU regulations but also increases their competitiveness in the market. CE certification serves as a credible endorsement of these factories' commitment to providing safe and reliable miniature machines, bolstering their reputation as industry leaders.Furthermore, CE certification enables manufacturers to enter new markets and cater to a wider range of customers, domestically and internationally. Exporting machinery with CE certification removes potential barriers to trade, as many countries now require such certification for imported goods. This certification goes a long way in instilling confidence in potential buyers and strengthens business relationships across borders.[Quality Assurance and Consumer Satisfaction]CE certification plays a vital role in ensuring the quality and safety of mini gypsum cornice machines. It verifies that these machines adhere to strict manufacturing standards, including materials used, construction, and electrical safety. Through rigorous testing and inspections, accredited certification bodies assess and confirm compliance with these standards, guaranteeing that the machines do not pose any health or safety risks.This commitment to quality assurance extends to the end-users of these mini gypsum cornice machines as well. By obtaining CE certification, these factories prioritize delivering machinery that meets the highest standards of functionality, durability, and performance. Customers can rest assured knowing that their investment in these certified machines will result in efficient gypsum cornice production, minimizing downtime and maximizing productivity.[The Way Forward]The attainment of CE certification by mini gypsum cornice machine factories marks a significant milestone for the industry. It elevates the level of quality assurance within the manufacturing processes and underscores the commitment of these factories to delivering top-notch products. With increased market competitiveness and enhanced consumer satisfaction, these certified factories are poised to contribute to the continued growth and advancement of the gypsum cornice industry.In conclusion, the recent achievement of CE certification by several mini gypsum cornice machine factories reinforces the industry's commitment to excellence. This certification not only ensures compliance with EU regulations but also boosts market competitiveness. With a focus on quality assurance and customer satisfaction, these certified factories are set to drive innovation and advancement in the gypsum cornice manufacturing sector, fostering a future of sustainable growth and success.

Get the Latest Updates on Certified Plasterboard Ceiling Machines

CE Certification Plasterboard Ceiling Machine Ensuring Quality and Efficiency in Construction Industry[City, Date] – In an era where technological advancements play a significant role in improving efficiency and quality, the introduction of the CE Certification Plasterboard Ceiling Machine by [Company Name] is revolutionizing the construction industry. This state-of-the-art machine is equipped with cutting-edge features, granting construction companies easy access to high-quality plasterboard ceiling production.The CE certification is testament to the machine's adherence to European safety, health, and environmental protection standards. With this certification, [Company Name] demonstrates their commitment to providing reliable and safe equipment, ensuring the utmost satisfaction for their customers.The plasterboard ceiling machine allows construction companies to streamline their production processes, significantly reducing time and labor costs. With its advanced automation capabilities, this machine eliminates the need for manual intervention, resulting in enhanced efficiency and precision. [Company Name], a renowned manufacturer with expertise in construction machinery, has developed this machine to meet the diverse needs of the construction sector.Key Features of the CE Certification Plasterboard Ceiling MachineThe innovative and intelligent design of the plasterboard ceiling machine offers numerous features that make it a standout product in the market. These features include:1. High-Speed Production: The advanced automation system allows the machine to produce plasterboard ceilings at an impressive speed, significantly increasing overall productivity.2. Accurate Measurements: Equipped with precise measurement mechanisms, the machine ensures the outputted plasterboard ceilings meet the required specifications, eliminating rework and wastage.3. Easy Operation: The user-friendly interface of the machine enables effortless operation, reducing the need for specialized training and facilitating the smooth integration of the machine into existing production lines.4. Enhanced Durability: The plasterboard ceiling machine is designed and manufactured with robust and durable materials, providing longevity and reliability for years, reinforcing its status as a wise investment for construction companies.5. Customization Options: [Company Name] acknowledges the diverse needs of their customers. To cater to these requirements, the machine offers customization options, allowing construction companies to produce plasterboard ceilings of various sizes, shapes, and designs.[Company Name] – Industry Leader in Construction MachineryWith a strong presence in the construction machinery sector, [Company Name] has been consistently delivering high-quality and reliable equipment to customers worldwide. The introduction of the CE Certification Plasterboard Ceiling Machine further solidifies their position as an industry leader.[Company Name] values customer satisfaction and ensures that their machines go through rigorous quality checks at every stage of production. By adhering to international standards and cultivating an environment of constant innovation, [Company Name] excels at providing cutting-edge solutions that meet the evolving needs of the construction industry.The company's commitment to research and development, coupled with its extensive expertise, has allowed them to introduce an array of construction machinery that caters to various construction needs. These products have gained recognition for their reliability, efficiency, and cost-effectiveness.ConclusionThe CE Certification Plasterboard Ceiling Machine by [Company Name] is set to bring a wave of transformation to the construction industry. With its advanced features, commitment to quality, and compliance with international standards, construction companies can guarantee enhanced productivity and efficiency in plasterboard ceiling production.[Company Name] continues to be a frontrunner in providing construction machinery that meets the highest industry standards. Embracing innovation and quality, they reaffirm their dedication to assisting companies in achieving excellence in construction projects.

High-Quality Gypsum Decorative Tile Machine Factory: A Great Option for Your Business

Gypsum Decorative Tile Machine Factory is a leading manufacturer of gypsum decorative tile machines in the industry. The company has been in operation for over 20 years and has established a strong reputation for providing high-quality machines and excellent customer service. The factory is equipped with advanced production technology and a team of skilled engineers and technicians who are dedicated to delivering innovative and reliable products to their global customers. The company's product range includes a variety of gypsum decorative tile machines, designed to meet the diverse needs of their clients.In recent news, Gypsum Decorative Tile Machine Factory has announced the launch of their latest model, the GDTM-800, which is set to revolutionize the gypsum decorative tile manufacturing process. The new machine boasts a range of advanced features and capabilities, including improved efficiency, durability, and cost-effectiveness.The GDTM-800 has been designed with the latest technology in mind, incorporating state-of-the-art components and intelligent control systems to ensure optimal performance and precision. The machine also offers a high degree of flexibility, allowing for the production of a wide range of gypsum decorative tiles in various sizes, shapes, and designs.In addition to its advanced technical capabilities, the GDTM-800 is also highly user-friendly, with a simple and intuitive interface that enables operators to easily program and control the machine. This ensures a smooth and efficient production process, and minimizes the need for extensive training or technical expertise.The launch of the GDTM-800 represents a significant milestone for Gypsum Decorative Tile Machine Factory, further cementing their position as a leader in the industry. The company's ongoing commitment to research and development has allowed them to continually push the boundaries of innovation and deliver cutting-edge solutions to their customers."We are thrilled to introduce the GDTM-800 to the market," said the company's CEO. "This new machine represents the culmination of years of hard work and dedication from our team, and we believe it will significantly enhance the capabilities of our customers and enable them to take their decorative tile manufacturing to the next level."The GDTM-800 has already garnered significant interest from industry professionals and is expected to generate strong demand in the coming months. Gypsum Decorative Tile Machine Factory has already begun taking orders for the new machine and is ramping up production to meet the anticipated demand.In addition to the launch of the GDTM-800, Gypsum Decorative Tile Machine Factory is also expanding its global reach, with a growing network of distributors and partners around the world. The company's commitment to customer satisfaction and after-sales support has earned them a loyal customer base, and they are continually seeking to strengthen their presence in new markets.With its unrivaled expertise in gypsum decorative tile machines and a steadfast dedication to innovation, Gypsum Decorative Tile Machine Factory is poised to remain at the forefront of the industry for years to come. The launch of the GDTM-800 is just the latest example of the company's commitment to pushing the boundaries of what is possible in decorative tile manufacturing, and customers can expect even more groundbreaking developments in the future.

Quality Wood Plastic Door Production Line for Board, Profile, and Frame Manufacturing in China

Wood Plastic Door Production Line (Board/Profile/Frame) China ManufacturerAs people become more aware of environmental issues and sustainable resources, there has been a growing demand for innovation in the construction industry. One of the latest trends taking the industry by storm is the wood plastic door production line. This technology combines the benefits of wood and plastic to create a durable and eco-friendly material that's perfect for doors, frames, and profiles. In this article, we'll explore the benefits of this technology and the leading China manufacturer of wood plastic door production line.What is a Wood Plastic Door Production Line?A wood plastic door production line is a modern manufacturing technology that combines natural wood fibers with plastic to create a composite material that's durable, lightweight, and eco-friendly. The wood fibers come from sustainable sources like sawdust, wood chips, or agricultural waste, which are then mixed with thermoplastic materials like PVC, PE, or PP. The resulting composite material has a higher strength-to-weight ratio than traditional wood and is resistant to water, decay, and insects.The wood plastic door production line can produce a range of products, including boards, profiles, and frames. These products can be used for different applications, such as doors, windows, decking, fencing, and more. The wood plastic composite products have a natural wood-like appearance and can be painted or stained to match any design requirement.Benefits of a Wood Plastic Door Production Line1. Eco-Friendly: One of the main benefits of a wood plastic door production line is that it's eco-friendly. The use of sustainable materials like wood fibers and recycled plastics reduces the carbon footprint of the production process and helps preserve natural resources. Moreover, the wood plastic composite products are recyclable, which further enhances their sustainability.2. Durability: Another benefit of a wood plastic door production line is that it produces products that are durable and long-lasting. The composite material is resistant to water, decay, and insects, which makes it ideal for outdoor applications. The products have a longer lifespan than traditional wood and require less maintenance, which saves time and money in the long run.3. Design Versatility: Wood plastic door production line can produce a wide range of designs and color options. The natural wood-like appearance of the products gives them a warm and inviting look, and they can be painted or stained to match any design requirement. The products can be molded into different shapes and sizes, which gives designers more flexibility in their projects.China Manufacturer of Wood Plastic Door Production LineIf you're looking for a reliable manufacturer of wood plastic door production line in China, then look no further than (need remove brand name). As a leading manufacturer and supplier of composite machinery, they have years of experience in the industry and are committed to providing high-quality products and services to customers worldwide.Their wood plastic door production line is designed to produce fireproof, waterproof, and eco-friendly products that meet international standards. The production line can manufacture a wide range of products, including boards, profiles, and frames, that are suitable for indoor and outdoor applications.Their wood plastic door production line is equipped with advanced machinery, such as twin-screw extruders, cooling baths, and cutting machines. The production process is fully automated, which ensures quality control and reduces the risk of errors.ConclusionIn conclusion, the wood plastic door production line is a modern technology that combines the benefits of wood and plastic to create a durable and eco-friendly material that's perfect for doors, frames, and profiles. The products produced by this line are eco-friendly, durable, and versatile, making them an ideal choice for designers and builders. If you're looking for a reliable manufacturer of wood plastic door production line in China, then (need remove brand name) is your go-to source. Their products are designed to meet international standards, and they're committed to providing high-quality products and services to customers worldwide.

High Quality Sheet Metal Perforating Machine for Gypsum Plasterboard Manufacturing

In today's fast-paced industrial sector, automated technologies have become the norm. Automated machinery is widely used in various industries to increase productivity, efficiency and reduce production costs. Sheet metal perforation machines are one such automated technology that has gained immense popularity in recent times.Sheet metal perforation machines are primarily used in the manufacturing industry to punch holes or shapes in sheets of metal. The process of sheet metal perforation involves the use of precision-engineered tools that punch holes in a carefully controlled pattern. This process allows manufacturers to create various designs, sizes, and shapes in metals, such as aluminum, copper, steel, and more.With the advancements in technology, automated sheet metal perforation machines have emerged as a popular choice for manufacturing companies worldwide. These machines are capable of performing perforation at a much faster rate than traditional manual methods. Automated machines are also designed to be more precise, with minimal error, and deliver higher accuracy and consistency than manual methods.One such quality automated perforation machine is the Automatic Sheet Metal Perforating Machine Gypsum Plasterboard Manufacturing Machine developed by a leading manufacturer. This machine is designed to perforate gypsum plasterboard sheets at high speeds, with the option to perforate both single and two-layer boards simultaneously.This machine is a complete automatic production line that includes a feeding table, perforation system, and an unloading table. The feeding table has an adjustable width that can accommodate different sizes of gypsum plasterboards. The perforation system consists of a perforation wheel that has multiple blades configured in the desired pattern.The Automatic Sheet Metal Perforating Machine operates in a fully automated manner and is equipped with advanced control systems that ensure the perforating process is carried out with precision and consistency. The machine is also easy to operate, with a user-friendly interface that allows for efficient control and monitoring of the perforation process.The machine's cutting-edge technology and robust construction make it an ideal choice for the gypsum plasterboard manufacturing industry. The Automatic Sheet Metal Perforating Machine can perforate up to 500 sheets per hour, making it ideal for high-volume production runs.The manufacturer of this machine is a well-known brand in the manufacturing sector, with a reputation for producing quality machinery. The company is committed to delivering innovative and reliable machinery that meets the demands of the manufacturing industry.This Automatic Sheet Metal Perforating Machine is an excellent example of the company's commitment to innovation and excellence in manufacturing. The machine is capable of delivering high-performance results consistently, making it an indispensable asset for any manufacturing plant.In conclusion, the Automated Sheet Metal Perforating Machine Gypsum Plasterboard Manufacturing Machine is a cutting-edge technology that can transform the manufacturing industry's productivity and efficiency. With its advanced features and capabilities, this machine is an excellent investment for any company looking to enhance its manufacturing processes. So, if you're looking for a reliable, high-performance, and cost-effective perforation machine, look no further than the Automatic Sheet Metal Perforating Machine.