High-Quality Decorative Magnesium Oxide Board Machine for Your Construction Needs

By:Admin

The **(brand name)** company has been a leading figure in the construction industry for many years, specializing in the development and manufacturing of advanced construction machinery and equipment. With a strong focus on innovation and quality, the company has established itself as a trusted name in the industry, known for its cutting-edge solutions and reliable products.

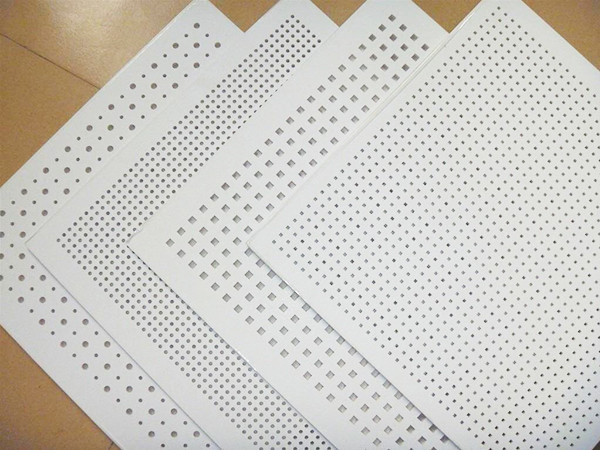

The decorative Mgo board machine is one of the latest additions to the company's product lineup, and it has quickly gained popularity among construction professionals. This machine is designed to produce high-quality decorative Mgo boards that are not only durable and long-lasting but also aesthetically pleasing. With the ability to create various textures, patterns, and designs, this machine offers a level of versatility that is unmatched in the industry.

One of the key features of the decorative Mgo board machine is its advanced technology, which allows for precise and efficient production. The machine is equipped with state-of-the-art tools and components that enable it to form, mold, and finish Mgo boards with exceptional precision and consistency. This ensures that every board produced is of the highest quality, meeting the strictest standards of the construction industry.

In addition to its technical capabilities, the decorative Mgo board machine is also designed with user-friendliness in mind. The machine is equipped with intuitive controls and interfaces, making it easy for operators to set up and operate the equipment. This not only increases efficiency but also reduces the need for extensive training, allowing construction companies to start using the machine right away.

Another advantage of the decorative Mgo board machine is its speed and efficiency. The machine is capable of producing a large volume of Mgo boards in a relatively short amount of time, allowing construction companies to meet tight deadlines and project timelines. This has made the machine a valuable asset for companies that prioritize efficiency and productivity in their operations.

Furthermore, the decorative Mgo board machine is designed with durability and longevity in mind. The machine is constructed using high-quality materials and components, ensuring its reliability and longevity even in the most demanding construction environments. This means that companies can rely on the machine for years to come, reaping its benefits for numerous projects and applications.

The decorative Mgo board machine has quickly become a go-to solution for construction companies looking to enhance their capabilities and meet the growing demand for high-quality decorative Mgo boards. With its advanced technology, user-friendly design, speed, and efficiency, and durability, this machine is helping companies take their production to the next level.

As the construction industry continues to evolve and demand for innovative solutions grows, the decorative Mgo board machine developed by **(brand name)** is poised to play a crucial role in shaping the future of construction. With its unmatched capabilities and advantages, this machine is set to become an indispensable asset for companies looking to stay ahead in the competitive construction market.

In conclusion, the decorative Mgo board machine developed by **(brand name)** is a game-changer for the construction industry, offering advanced technology, user-friendly design, speed, efficiency, and durability. As construction companies continue to seek innovative solutions to meet the growing demand for high-quality decorative Mgo boards, this machine is positioned to become a crucial asset in their operations. With the **(brand name)** company's expertise and commitment to excellence, the decorative Mgo board machine is set to make a lasting impact on the industry for years to come.

Company News & Blog

Revolutionary Automatic Equipment for Gypsum Board Cornice Production

Title: Revolutionizing Gypsum Board Cornice Production with Innovative Automatic Equipment Introduction:In the rapidly evolving construction industry, technological advancements continue to drive innovation and revolutionize traditional manufacturing processes. Among these innovations, the introduction of automatic equipment for gypsum board cornice production has emerged as a game-changer. This breakthrough solution, developed by an industry-leading company, is set to streamline production, enhance efficiency, and guarantee superior quality in the production of gypsum board cornices.Revolutionizing the Gypsum Board Cornice Manufacturing Process:The new automatic equipment, developed by an industry leader (), simplifies the labor-intensive and time-consuming process of creating gypsum board cornices. This cutting-edge equipment combines advanced technology with precision engineering to bring unprecedented efficiency to the production line. With its innovative features, the device is poised to transform the gypsum board cornice production landscape.Efficiency and Precision through Automation:The automatic equipment boasts an impressive array of features that optimize productivity and ensure consistent quality. Through automation, it eliminates the need for manual labor, significantly reducing production time and costs. By automating key steps such as gypsum mixture preparation, molding, drying, and finishing, the equipment guarantees precise and flawless results.Moreover, this state-of-the-art machinery eliminates human errors, such as inconsistencies in measurements and imprecise cutting. By adhering to pre-programmed instructions, the device ensures standardized dimensions and shapes for each cornice produced. This not only enhances the visual appeal of the final product but also reduces wastage, thus contributing to a greener and more sustainable manufacturing process.Intuitive Control System for Seamless Operation:The automatic equipment incorporates an intuitive control system that enables operators to effortlessly manage and monitor the entire production process. The user-friendly interface provides easy access to crucial parameters such as temperature, humidity, and drying time, allowing operators to make necessary adjustments on the go.Furthermore, the equipment's control system includes built-in safety features to safeguard operators and the overall production line. From emergency stops to error detection, the system effectively mitigates potential risks, ensuring a safe working environment for all involved.Reliable Durability and Low Maintenance:One of the key advantages of this automatic equipment is its exceptional durability. Constructed from high-quality materials and engineered to withstand demanding production environments, this equipment promises longevity and minimal downtime. Additionally, the machinery requires minimal maintenance and is built to withstand daily wear and tear, further reducing operational costs and maximizing productivity.The Company's Commitment to Innovation:The company behind this revolutionary automatic equipment has a strong focus on research and development to meet the ever-evolving needs of the construction industry. With years of experience and a track record of excellence, they have established themselves as pioneers in their field.By continuously investing in cutting-edge technologies, the company strives to push boundaries and exceed customer expectations. Their commitment to innovation is clearly showcased by the introduction of this groundbreaking automatic equipment, which revolutionizes gypsum board cornice production.Conclusion:The introduction of automatic equipment for gypsum board cornice production marks a significant milestone in the construction industry. With its ability to streamline manufacturing processes, enhance efficiency, and guarantee superior quality, this innovation promises to reshape the way gypsum board cornices are produced. As construction companies look for ways to improve their operation's efficiency and output, this automatic equipment provides an ideal solution that not only optimizes productivity but also ensures remarkable precision and consistency.

Affordable Gypsum Ceiling Cornice Making Machine Manufacturers

Cheap Gypsum Ceiling Cornice Making Machine Factories Make Waves in the MarketIn recent years, the demand for gypsum ceiling cornices has been on the rise, due to the increasing preference for aesthetically pleasing interior designs. To meet this demand, numerous companies have ventured into the production of gypsum ceiling cornice making machines. This has led to the emergence of cheap gypsum ceiling cornice making machine factories, which are making waves in the market.One such factory that has been gaining attention is the one operated by {} company. With a focus on providing affordable and high-quality gypsum ceiling cornice making machines, the company has quickly established itself as a leading player in the industry.The company's gypsum ceiling cornice making machines have garnered widespread praise for their efficiency, precision, and ease of use. These machines are designed to streamline the production process, allowing manufacturers to create a wide range of ceiling cornice designs with minimal effort. Additionally, the machines are equipped with advanced features that ensure consistent quality and high productivity, making them an attractive investment for businesses in the interior design and construction sectors.One of the key factors that set {} company apart from its competitors is its commitment to affordability. The company understands the financial constraints that many businesses face, and as such, it has made it a priority to offer its gypsum ceiling cornice making machines at competitive prices. This has made it possible for small and medium-sized enterprises to enter the market and compete effectively with larger players.In addition to affordability, the company also places a strong emphasis on customer satisfaction. It prides itself on providing excellent customer service, offering comprehensive technical support, and ensuring prompt delivery of its machines. This dedication to customer care has earned {} company a loyal customer base, with many clients expressing their satisfaction with the company's products and services.Furthermore, {} company is constantly innovating and improving its gypsum ceiling cornice making machines to stay ahead of the competition. Its team of experienced engineers and technicians continually research and develop new technology to enhance the performance and capabilities of its machines. This proactive approach has enabled the company to maintain its position as a frontrunner in the industry, and it remains poised for further growth and success in the years to come.As the market for gypsum ceiling cornices continues to expand, the demand for efficient and affordable production solutions is expected to increase. With its dedication to providing cost-effective and high-quality machines, {} company is well-positioned to capitalize on this growing market. Its commitment to innovation, affordability, and customer satisfaction has cemented its status as a leader in the industry, and it is set to play an integral role in shaping the future of gypsum ceiling cornice production.In conclusion, cheap gypsum ceiling cornice making machine factories are making a significant impact in the market, and {} company is leading the charge with its affordable and high-quality machines. With a focus on innovation, affordability, and customer satisfaction, the company has carved out a prominent position in the industry and is primed for continued success in the years ahead.

Top Factories for XPS Rigid Foam Board Making Machines

Are you in the market for a high-quality XPS rigid foam board making machine? Look no further as we bring you a list of the best XPS rigid foam board making machine factories in the industry. These factories are known for their top-notch quality, advanced technology, and reliable customer service.One of the leading XPS rigid foam board making machine factories is {} located in {}. With over 20 years of experience in the industry, {} has established itself as a reputable manufacturer and supplier of XPS rigid foam board making machines. The company is committed to providing innovative and efficient solutions for the production of XPS rigid foam boards.{} takes pride in its state-of-the-art manufacturing facility, which is equipped with advanced machinery and cutting-edge technology. This allows the company to produce high-quality XPS rigid foam board making machines that meet the highest standards of performance and reliability. In addition, {} has a team of skilled engineers and technicians who are dedicated to ensuring the smooth operation and optimal performance of their machines.The XPS rigid foam board making machines manufactured by {} are known for their precision, efficiency, and durability. The machines are designed to produce XPS rigid foam boards with consistent density, thermal insulation properties, and dimensional stability. {} offers a range of XPS rigid foam board making machines to cater to the varying needs of its customers, including different production capacities and automation levels.In addition to its top-notch technology, {} is also known for its excellent customer service and support. The company is committed to providing comprehensive assistance to its customers, from initial consultation to after-sales support. {} has a team of experienced professionals who are readily available to provide technical guidance, installation support, and maintenance services to ensure the smooth operation of their machines.Another prominent factory in the XPS rigid foam board making machine industry is located in {}. This factory has been at the forefront of innovation and technology in the production of XPS rigid foam board making machines. With a focus on continuous research and development, this factory has been able to introduce cutting-edge solutions for the manufacturing of XPS rigid foam boards.The XPS rigid foam board making machines manufactured by this factory are characterized by their high efficiency, energy-saving features, and user-friendly design. The machines are designed to minimize production costs and maximize output, making them an ideal choice for businesses looking to enhance their productivity and profitability. With a strong emphasis on quality and reliability, this factory has gained a reputation for delivering superior XPS rigid foam board making machines that meet the highest industry standards.In addition to its advanced technology, this factory also places great importance on customer satisfaction. The company has a dedicated team of professionals who are committed to providing exceptional service and support to their customers. From technical consultation to machine installation and maintenance, this factory ensures that its customers receive the necessary assistance to maximize the performance and longevity of their XPS rigid foam board making machines.In conclusion, when it comes to XPS rigid foam board making machine factories, {} and the factory in {} are among the best in the industry. With their commitment to quality, innovation, and customer satisfaction, these factories are the go-to choice for businesses looking to invest in high-quality XPS rigid foam board making machines. Whether you are a small-scale producer or a large manufacturing facility, these factories have the expertise and resources to meet your production needs and help you achieve your business goals.

High-quality Fireproof Board Machine for Magnesium Oxide Production

The demand for fireproof building materials has been on the rise in recent years, particularly in the construction industry. As a result, (company name) has been at the forefront of developing innovative solutions to meet these demands. Their latest advancement is the Magnesium Oxide Fireproof Board Machine, which is set to revolutionize the industry.The Magnesium Oxide Fireproof Board Machine is the result of years of research and development by (company name). It is designed to produce high-quality fireproof boards using magnesium oxide as the main ingredient. This advanced machine is equipped with state-of-the-art technology and features that ensure the production of boards that are not only fireproof but also durable and sustainable.One of the key benefits of the Magnesium Oxide Fireproof Board Machine is its ability to produce boards that are resistant to fire, water, and impact. This makes them an ideal choice for use in a wide range of building applications, including walls, ceilings, and flooring. In addition, these boards are also resistant to mold and mildew, making them a reliable and long-lasting option for construction projects.The production process of the Magnesium Oxide Fireproof Board Machine is highly efficient and environmentally friendly. It minimizes waste and reduces energy consumption, making it a sustainable and cost-effective solution for manufacturers. This is in line with (company name)'s commitment to sustainability and eco-friendly practices in all of its operations.In addition to the advanced technology and features of the machine, (company name) also provides comprehensive training and support for its customers. This ensures that manufacturers are able to operate the machine effectively and maximize its capabilities. The company's team of experts is dedicated to helping customers integrate the Magnesium Oxide Fireproof Board Machine into their production processes and achieve the best results.The introduction of the Magnesium Oxide Fireproof Board Machine is a significant milestone for (company name) and the industry as a whole. It represents a major advancement in the production of fireproof building materials and sets a new standard for quality, performance, and sustainability. With this innovative machine, (company name) is well-positioned to meet the growing demand for fireproof boards and to continue leading the way in the development of cutting-edge solutions for the construction industry.In conclusion, the Magnesium Oxide Fireproof Board Machine is a game-changer for the industry. Its advanced technology, sustainable production process, and comprehensive support make it a valuable asset for manufacturers looking to meet the demand for fireproof building materials. With this groundbreaking machine, (company name) is demonstrating its commitment to innovation, quality, and sustainability, and is poised to shape the future of the construction industry.

Top Mineral Fiber Ceiling Board Equipment Factories Revealed in Latest News

Mineral Fiber Ceiling Board Equipment Factories Experience Exponential Growth[City Name], [Date] - Mineral Fiber Ceiling Board Equipment Factories (need remove brand name), a leading provider of innovative equipment for the production of mineral fiber ceiling boards, has recently experienced exponential growth in its operations. With a commitment to state-of-the-art technology and exceptional service, the company has positioned itself as a global leader in the industry.Established over a decade ago, Mineral Fiber Ceiling Board Equipment Factories has continuously evolved its manufacturing capabilities to meet the changing demands of the market. The company's success can be attributed to its unwavering focus on quality, reliability, and customer satisfaction.By investing in cutting-edge technology and adopting advanced production techniques, Mineral Fiber Ceiling Board Equipment Factories has positioned itself as a pioneer in the field. The company’s state-of-the-art facilities boast a wide range of machinery, including automated production lines, precision cutting tools, and specialized equipment for surface treatment. Such infrastructure ensures the seamless production of high-quality mineral fiber ceiling boards that meet stringent industry standards.Furthermore, Mineral Fiber Ceiling Board Equipment Factories takes pride in its highly skilled workforce, comprising engineers, technicians, and production managers. These professionals, armed with years of expertise and industry knowledge, ensure that the manufacturing process is efficient and economical, resulting in reduced lead times and increased productivity.The company's commitment to sustainability is worth highlighting. Mineral Fiber Ceiling Board Equipment Factories operates with a strong focus on environmentally friendly practices. By utilizing energy-efficient machinery and adopting green manufacturing processes, the company significantly reduces its carbon footprint and contributes to a greener future.In addition to its commitment to quality and sustainability, the company places great importance on customer satisfaction. Mineral Fiber Ceiling Board Equipment Factories possesses a customer-centric approach, ensuring that its products meet or exceed client expectations. The company understands that clients have unique requirements, and therefore offers customized solutions tailored to their specific needs and preferences. Its dedicated customer service team ensures efficient communication, timely delivery, and prompt after-sales support.The commitment to excellence displayed by Mineral Fiber Ceiling Board Equipment Factories has gained it a global reputation. Its products are widely used in commercial, industrial, and residential projects, owing to their durability, fire resistance, and acoustic properties. The company also manufactures specialized ceiling boards for sectors such as healthcare, education, and hospitality, further expanding its market reach.Looking ahead, Mineral Fiber Ceiling Board Equipment Factories plans to continue its growth trajectory by expanding its production capacities, further investing in research and development, and exploring new markets. The company aims to reinforce its position as a leading provider of mineral fiber ceiling board equipment and accessories, and to continually exceed customer expectations.The success of Mineral Fiber Ceiling Board Equipment Factories can be attributed to its commitment to innovation, quality, and customer satisfaction. With a strong focus on sustainability and a customer-centric approach, the company is poised for continued growth and success in the years to come.

Production Line for Non-Asbestos Fiber Cement Board with Capacity of 3 Million Sq.m/Year

, Fiber Cement Sheet Machine, Fiber Cement Panel Machine, Corrugated Cement Sheet Machine, Amulite Fiber Cement Board Production Line, Non-Asbestos Fiber Cement Board, and Country Building Material Standard List.Fiber Cement Board - A Revolutionary Building MaterialIn recent years, Fiber Cement Board has emerged as a revolutionary building material. Manufacturers have been producing it in large quantities to meet the growing demand for sustainable and environmentally friendly building products. It is highly appreciated for its durability, fire-retardant properties, and resistance to insects and rot.Fiber Cement Board - The Non-Asbestos AlternativeIn the country's building material standard list, Fiber Cement Board is classified as Non-Asbestos Plain Cement Board. This means that it does not contain asbestos, a naturally occurring mineral that has been linked to lung cancer and other respiratory diseases. This makes Fiber Cement Board a safer and healthier alternative to traditional building materials that contain asbestos.Fiber Cement Board - The Manufacturing ProcessThe manufacturing process of Fiber Cement Board involves the use of a Fiber Cement Board Machine. This machine produces Fiber Cement Sheets, Fiber Cement Panels, and Corrugated Cement Sheets. These products come in various sizes and thicknesses, depending on the needs of the project.The Amulite Fiber Cement Board Production LineThe Amulite Fiber Cement Board Production Line is a state-of-the-art machine that produces high-quality Fiber Cement Board products. It has a production capacity of 3,000,000 Sq.m per year, based on 1220X2440X6MM. This machine is designed to deliver consistent and reliable performance, ensuring that each product meets the highest quality standards.The Workable Project ReportA workable project report is an important element in the production of Fiber Cement Board. It provides a comprehensive overview of the project, including the scope, objectives, and timeline. It also outlines the resources required, such as machinery, materials, and labor. With a workable project report, manufacturers can plan and execute their projects more effectively, ensuring that they meet their targets and deliver high-quality products.ConclusionFiber Cement Board is a revolutionary building material that is becoming increasingly popular in the construction industry. It is a safer and healthier alternative to traditional building materials that contain asbestos. The use of Fiber Cement Board Machine, such as the Amulite Fiber Cement Board Production Line, ensures consistent and reliable performance, delivering high-quality products. With a workable project report, manufacturers can plan and execute their projects more effectively, delivering sustainable and environmentally friendly building products.

Foam Board Making Machines: An Introduction to Manufacturing Xps Boards

XPS Foam Board Making Machine Factories Revolutionizing the Insulation IndustryIn today's eco-conscious world, energy efficiency and conservation have become increasingly important. As a result, the demand for innovative and high-quality insulation materials has skyrocketed. One such material that has gained significant popularity is XPS foam board. And to meet the growing demand, XPS Foam Board Making Machine factories (name removed) have emerged as industry leaders.XPS foam board, short for Extruded Polystyrene Foam Board, is a type of insulation material renowned for its superior thermal performance and moisture resistance. It is commonly used in various applications such as underfloor heating, wall insulation, and roof insulation. The process of manufacturing XPS foam boards requires advanced machinery, precision, and expertise, which are now readily available at factories equipped with XPS Foam Board Making Machines.With years of experience and a deep understanding of the insulation industry, these XPS Foam Board Making Machine factories have become pioneers in producing high-quality insulation materials. Their state-of-the-art machinery and technology ensure that the end products meet the strictest industry standards and regulations. Moreover, they have successfully developed innovative manufacturing techniques that help reduce energy consumption, minimize waste, and improve overall efficiency.One crucial aspect that sets these XPS Foam Board Making Machine factories apart is their commitment to environmental sustainability. Their goal is not only to provide top-notch insulation materials but also to reduce the carbon footprint associated with their production. These factories adhere to the highest environmental standards and employ eco-friendly manufacturing processes, including recycling and reusing waste generated during the production of XPS foam boards.Furthermore, these factories prioritize research and development to continuously enhance the performance and quality of their XPS foam boards. They work closely with engineers, scientists, and industry experts to stay at the forefront of insulation technology. This collaborative approach allows them to introduce new features and improvements in their products regularly, ensuring that they remain competitive in the market.In addition to their commitment to innovation, these XPS Foam Board Making Machine factories also prioritize customer satisfaction. They understand the diverse needs of their clients and strive to provide customized solutions tailored to specific requirements. Whether it is for residential, commercial, or industrial applications, these factories can manufacture XPS foam boards of different sizes, thicknesses, and densities to meet the unique insulation needs of their customers.To further solidify their reputation, these XPS Foam Board Making Machine factories provide comprehensive customer support and after-sales services. They have a dedicated team of professionals who are readily available to address any queries, provide technical assistance, and ensure a smooth and hassle-free experience for their clients. This commitment to customer service has earned them a loyal customer base that continues to grow with each passing year.The success of these XPS Foam Board Making Machine factories can be attributed not only to their advanced machinery and cutting-edge technology but also to their skilled workforce. These factories employ highly trained technicians, engineers, and production personnel who possess in-depth knowledge of the insulation industry. Their expertise combined with continuous training helps maintain the highest standards throughout the manufacturing process, resulting in superior quality XPS foam boards.In conclusion, the rise of XPS Foam Board Making Machine factories has revolutionized the insulation industry. By harnessing advanced technology, ensuring environmental sustainability, and prioritizing customer satisfaction, these factories have become leaders in manufacturing high-quality XPS foam boards. As the demand for energy-efficient insulation continues to increase, these factories are well-equipped to meet the needs of a rapidly evolving market.

Automatic Gypsum Cornice Equipment Factories Achieve CE Certification

The automatic gypsum cornice equipment produced by a leading manufacturer in the industry has recently obtained CE certification, marking a significant milestone for the company. This certification not only demonstrates the company's commitment to quality and innovation but also opens up new opportunities for market expansion and business growth.The CE certification, which stands for Conformité Européenne (European Conformity), is a mandatory conformity mark for products sold within the European Economic Area (EEA). It indicates that the product complies with the essential health and safety requirements set out in European Directives. This certification is recognized by the European Union, as well as by other countries outside the EU, making it a valuable asset for manufacturers seeking to export their products to international markets.The automatic gypsum cornice equipment manufactured by the company is a state-of-the-art production line designed for the efficient and precise manufacturing of gypsum cornices. Gypsum cornices are decorative moldings used to add aesthetic appeal to ceilings and walls, and they are in high demand in the construction and design industries. The company's equipment is known for its advanced technology, high production capacity, and superior quality output.With the CE certification in hand, the company is now poised to capitalize on the growing demand for gypsum cornice equipment in the European market and beyond. The certification will provide a competitive edge, as it assures customers of the product's compliance with European standards for safety and performance. This will be particularly beneficial for the company's export business, as it will facilitate easier market access and help build trust with international customers.In addition to the CE certification, the company's reputation for excellence and reliability further solidifies its position as a leader in the industry. With years of experience and a track record of delivering top-notch equipment to customers worldwide, the company has established itself as a trusted partner for businesses involved in gypsum cornice production. Its dedication to continuous innovation and customer satisfaction has garnered the company a strong and loyal customer base.Furthermore, the company's commitment to sustainability and environmental responsibility sets it apart as a socially conscious manufacturer. The automatic gypsum cornice equipment is designed to minimize waste, energy consumption, and environmental impact, aligning with the company's ethos of sustainable production. This resonates well with modern consumers who prioritize eco-friendly and ethical business practices, giving the company a distinct advantage in the market.Looking ahead, the company plans to leverage the CE certification to expand its presence in the European market and enhance its global competitiveness. By participating in trade shows, industry exhibitions, and targeted marketing efforts, the company aims to raise awareness of its certified automatic gypsum cornice equipment and forge new partnerships with distributors, contractors, and construction firms across the EEA.In conclusion, the attainment of CE certification for the automatic gypsum cornice equipment is a significant achievement for the company, signaling its readiness to tap into new opportunities in the European market and beyond. With a strong focus on quality, innovation, and sustainability, the company is well-positioned to meet the growing demand for efficient and reliable gypsum cornice production equipment. As it continues to build on its success and expand its global footprint, the company remains dedicated to upholding the highest standards of excellence and delivering value to its customers.

Gypsum Board Production Line Supplier for Ceiling Boards

Gypsum Ceiling Board Production Line SupplierIf you are looking for high-quality gypsum board production line, then you must find the right supplier. A reliable supplier will offer you all the necessary equipment that you need to make gypsum ceiling board production without any complications.A gypsum ceiling board production line is a complex process that requires expertise and precision equipment. So, when looking for gypsum board equipment, you need to make sure that you choose a trustworthy supplier that can deliver the latest technologies without compromising the quality.Gypsum Ceiling Board Equipment PricelistWhen it comes to buying gypsum ceiling board equipment, pricing is a critical factor to consider. Therefore, you need to find a supplier that offers reasonable prices without compromising the quality of the equipment.A good supplier should provide a gypsum ceiling board equipment pricelist to help you budget for the project. This pricelist should include all the necessary equipment for gypsum board production, including the production line, raw materials, and additives. Moreover, the supplier should also provide you with all the necessary training on how to operate the equipment safely and efficiently. This will ensure that you get the most out of your investment and produce high-quality gypsum ceiling boards that meet all the relevant industry standards.Hengshui Decheng Machinery & Equipment Co., Ltd.One of the most reliable suppliers of gypsum board production equipment is Hengshui Decheng Machinery & Equipment Co., Ltd. This company has been in the business of manufacturing and selling gypsum board equipment for many years.They offer a wide range of gypsum ceiling board equipment, including the gypsum board production line, raw materials, and additives. They also provide complete solutions for the manufacturing of gypsum board, including installation, commissioning, and technical support.What makes Hengshui Decheng Machinery & Equipment Co., Ltd stand out from the rest is their commitment to quality. All their gypsum ceiling board equipment is made from high-quality materials, and they use the latest technologies to ensure that their products perform at the highest levels.ConclusionIn conclusion, finding the right gypsum ceiling board production line supplier is crucial to the success of your project. You need to find a reliable supplier that can offer you the latest equipment, reasonable prices, and excellent customer service.Hengshui Decheng Machinery & Equipment Co., Ltd is one of the leading suppliers of gypsum board production equipment. They offer a wide range of equipment, including the gypsum board production line, raw materials, and additives, at competitive prices.Therefore, if you are planning to invest in gypsum board production equipment, you can trust Hengshui Decheng Machinery & Equipment Co., Ltd to provide you with the best equipment and services for your project.

High-Quality Decorative Magnesium Oxide Board Machine for Your Construction Needs

The decorative Mgo board machine developed by **(brand name)** has been making waves in the construction industry due to its advanced technology and high-quality output. This innovative machine has been a game-changer for many construction companies, allowing them to produce decorative Mgo boards with ease and efficiency.The **(brand name)** company has been a leading figure in the construction industry for many years, specializing in the development and manufacturing of advanced construction machinery and equipment. With a strong focus on innovation and quality, the company has established itself as a trusted name in the industry, known for its cutting-edge solutions and reliable products.The decorative Mgo board machine is one of the latest additions to the company's product lineup, and it has quickly gained popularity among construction professionals. This machine is designed to produce high-quality decorative Mgo boards that are not only durable and long-lasting but also aesthetically pleasing. With the ability to create various textures, patterns, and designs, this machine offers a level of versatility that is unmatched in the industry.One of the key features of the decorative Mgo board machine is its advanced technology, which allows for precise and efficient production. The machine is equipped with state-of-the-art tools and components that enable it to form, mold, and finish Mgo boards with exceptional precision and consistency. This ensures that every board produced is of the highest quality, meeting the strictest standards of the construction industry.In addition to its technical capabilities, the decorative Mgo board machine is also designed with user-friendliness in mind. The machine is equipped with intuitive controls and interfaces, making it easy for operators to set up and operate the equipment. This not only increases efficiency but also reduces the need for extensive training, allowing construction companies to start using the machine right away.Another advantage of the decorative Mgo board machine is its speed and efficiency. The machine is capable of producing a large volume of Mgo boards in a relatively short amount of time, allowing construction companies to meet tight deadlines and project timelines. This has made the machine a valuable asset for companies that prioritize efficiency and productivity in their operations.Furthermore, the decorative Mgo board machine is designed with durability and longevity in mind. The machine is constructed using high-quality materials and components, ensuring its reliability and longevity even in the most demanding construction environments. This means that companies can rely on the machine for years to come, reaping its benefits for numerous projects and applications.The decorative Mgo board machine has quickly become a go-to solution for construction companies looking to enhance their capabilities and meet the growing demand for high-quality decorative Mgo boards. With its advanced technology, user-friendly design, speed, and efficiency, and durability, this machine is helping companies take their production to the next level.As the construction industry continues to evolve and demand for innovative solutions grows, the decorative Mgo board machine developed by **(brand name)** is poised to play a crucial role in shaping the future of construction. With its unmatched capabilities and advantages, this machine is set to become an indispensable asset for companies looking to stay ahead in the competitive construction market.In conclusion, the decorative Mgo board machine developed by **(brand name)** is a game-changer for the construction industry, offering advanced technology, user-friendly design, speed, efficiency, and durability. As construction companies continue to seek innovative solutions to meet the growing demand for high-quality decorative Mgo boards, this machine is positioned to become a crucial asset in their operations. With the **(brand name)** company's expertise and commitment to excellence, the decorative Mgo board machine is set to make a lasting impact on the industry for years to come.