Durable Gypsum Cornice Making Machine for Moisture-Proof House Decoration

By:Admin

{} is a leading manufacturer and supplier of machinery and equipment for the construction and decoration industry. With years of experience and a commitment to innovation, the company has earned a reputation for excellence and reliability in the market. Their Gypsum Cornice Making Machine is the latest addition to their product line, and it promises to revolutionize the way moisture-proof house decoration is done.

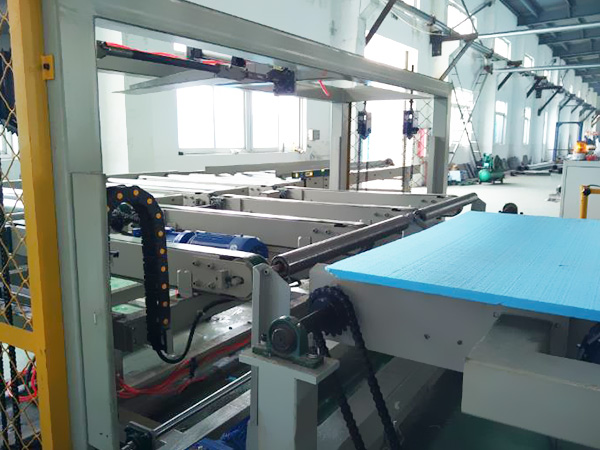

The machine is designed to produce gypsum cornices that are not only visually appealing but also highly resistant to moisture, making them an ideal choice for house decoration. The use of high-quality materials and advanced technology ensures that the cornices are durable and long-lasting, providing homeowners with a cost-effective solution for protecting their homes from water damage.

One of the key features of the Gypsum Cornice Making Machine is its ability to produce a wide range of designs and patterns, allowing for greater flexibility and customization in house decoration. Whether it's a simple, classic design or a more intricate and ornate pattern, the machine can accommodate various styles and preferences, catering to the diverse needs of homeowners and decorators.

Moreover, the machine is equipped with advanced moisture-proofing technology, ensuring that the gypsum cornices are able to withstand high humidity levels and resist mold and mildew growth. This not only enhances the longevity of the cornices but also contributes to a healthier indoor environment for the residents of the house.

In addition to its technical capabilities, the Gypsum Cornice Making Machine is designed for easy operation and maintenance, making it an accessible and user-friendly option for businesses and professionals in the construction and decoration industry. Its efficient production process and low energy consumption also contribute to its cost-effectiveness, providing a valuable asset for companies looking to enhance their product offerings and expand their market reach.

With the launch of the Gypsum Cornice Making Machine, {} has once again demonstrated its commitment to delivering superior quality and innovative solutions to the construction and decoration industry. The machine is set to raise the standards for moisture-proof house decoration, offering a reliable and efficient means of producing high-quality gypsum cornices that meet the demands of modern homeowners and businesses.

As the demand for moisture-proof house decoration continues to grow, {} is well-positioned to capitalize on this trend and provide industry-leading solutions that set new benchmarks for excellence and performance. With its Gypsum Cornice Making Machine, the company is paving the way for a new era of house decoration, where quality, durability, and aesthetics converge to create spaces that are not only visually stunning but also resilient to the challenges of moisture and humidity.

In conclusion, by introducing the Gypsum Cornice Making Machine, {} is reaffirming its status as a pioneer and innovator in the construction and decoration industry. The machine's advanced capabilities and superior performance make it a valuable asset for businesses and professionals looking to stay ahead of the curve and meet the evolving needs of the market. With {} at the forefront, the future of moisture-proof house decoration looks brighter than ever.

Company News & Blog

Affordable Mgo Board Making Machine Price: Unlocking Cost-effective Solutions

Title: Mgo Board Making Machine: An Affordable Solution for Efficient Construction Board ProductionIntroduction:In recent years, the construction industry has witnessed a surge in demand for innovative building materials that offer durability, sustainability, and cost-effectiveness. Magnesium Oxide (MgO) boards have emerged as a superior alternative to traditional drywall, cement boards, and wood-based panels due to their fire resistance, moisture resistance, and mold resistance properties. To meet the rising demand for MgO boards, various companies have introduced Mgo Board Making Machines, enabling efficient and cost-effective production. In this article, we explore the benefits of Mgo Board Making Machines and delve into their price range, facilitating the adoption of this groundbreaking technology in the construction industry.Benefits of Mgo Board Making Machines:1. Enhanced Efficiency:Mgo Board Making Machines utilize advanced manufacturing processes to ensure fast and consistent production of high-quality MgO boards. These machines automate the entire production process, from raw material mixing to board formation, resulting in a significant increase in overall efficiency. Manual labor requirements are reduced, leading to reduced costs and enhanced productivity.2. Precise and Customizable Production:Mgo Board Making Machines provide precise control over the thickness, density, and dimensions of the MgO boards being produced. Manufacturers can easily customize these settings according to specific project requirements, ensuring that the boards meet the desired specifications. This flexibility enables construction companies to create tailored solutions for different applications within the industry.3. High-Quality End Products:With automated production processes, Mgo Board Making Machines maintain consistent quality standards in every batch produced. The machines ensure uniform distribution of raw materials, resulting in boards with excellent strength, durability, and dimensional stability. The robust quality of MgO boards makes them an ideal choice for various construction applications, including wall partitions, ceilings, flooring, and furniture production.4. Environmentally Sustainable:One of the key advantages of MgO boards is their eco-friendly composition, which makes them an environmentally sustainable alternative to other construction materials. Mgo Board Making Machines promote sustainable practices by utilizing low-energy production methods and reducing waste generation. Additionally, the recyclable nature of MgO boards contributes to a greener construction industry, reducing the overall environmental impact of building projects.Mgo Board Making Machine Price:Considering the growing demand for high-quality MgO boards, the market offers numerous options for Mgo Board Making Machines. Prices may vary depending on factors such as production capacity, automation level, raw material compatibility, and added features. On average, Mgo Board Making Machines are available in the price range of $XX,XXX to $XX,XXX. It is important to note that investing in a reliable machine is crucial to ensure long-term productivity and minimal maintenance costs.Company XYZ - Striving for Excellence:One prominent player in the Mgo Board Making Machine industry is Company XYZ. As a leading manufacturer, Company XYZ has been at the forefront of developing innovative machinery for MgO board production. With a strong focus on research and development, they offer cutting-edge solutions that cater to the evolving needs of the construction market.Company XYZ's Mgo Board Making Machines are known for their precision, durability, and user-friendly operation. These machines are equipped with state-of-the-art technology, allowing for efficient production, uniform board quality, and reduced downtime. The company prides itself on providing excellent technical support, assisting customers at every stage of the machine purchase and implementation process.Conclusion:Mgo Board Making Machines have revolutionized the production of MgO boards in the construction industry. Their ability to enhance efficiency, provide precise manufacturing, ensure high-quality products, and promote environmental sustainability has made them an attractive investment for construction companies worldwide. With competitive prices and innovative solutions offered by companies like Company XYZ, the adoption of Mgo Board Making Machines is likely to soar, leading to faster and more sustainable construction practices.

Gypsum Cornice Production Line Prices in China

China has emerged as a global leader in the production of gypsum cornice, a key component in the construction industry. With the increasing demand for high-quality gypsum cornice, manufacturers in China have been at the forefront of developing innovative production lines to meet the growing needs of the market. As a result, China's gypsum cornice production line has become a popular choice for builders and contractors around the world.One of the leading companies in China's gypsum cornice production industry is {}, a well-established manufacturer with a strong reputation for delivering top-notch products. The company has recently introduced its latest gypsum cornice production line, which has garnered considerable attention from industry professionals and observers. With its advanced technology and high production capacity, the new production line is expected to set a new standard in the industry.The company's gypsum cornice production line is designed to maximize efficiency and productivity while maintaining the highest standards of quality. The production line is equipped with state-of-the-art machinery and equipment, ensuring that each piece of gypsum cornice is precisely manufactured to meet the exact specifications and requirements of customers. Additionally, the production line incorporates the latest automation and control systems, allowing for seamless operation and minimal human intervention, further enhancing the overall efficiency of the manufacturing process.In addition to its exceptional technical capabilities, the company's gypsum cornice production line is also notable for its environmental sustainability. The production line is designed to minimize waste and energy consumption, incorporating eco-friendly practices to reduce its environmental impact. As sustainability becomes an increasingly important consideration in the construction industry, the company's commitment to environmentally conscious production methods is viewed as a significant advantage in the market.The introduction of the new gypsum cornice production line has generated significant interest among industry professionals and potential customers. With its impressive technical specifications and commitment to quality and sustainability, the production line is poised to make a significant impact on the global gypsum cornice market. Builders and contractors around the world are expected to benefit from the availability of high-quality gypsum cornice produced by the company's advanced production line.In a statement, a spokesperson for the company highlighted the significance of the new gypsum cornice production line, emphasizing its potential to meet the evolving needs of the construction industry. The spokesperson noted that the company is dedicated to delivering the highest quality products to its customers, and the new production line represents a significant step forward in achieving that goal. The company's investment in advanced technology and sustainable manufacturing practices is a reflection of its commitment to innovation and excellence.Industry analysts have also taken note of the company's new gypsum cornice production line, recognizing it as a game-changing development in the industry. The advanced capabilities of the production line and its potential to drive efficiency and quality in gypsum cornice manufacturing have positioned the company as a leading player in the global market. As the demand for high-quality gypsum cornice continues to rise, the company's new production line is anticipated to play a key role in meeting that demand and solidifying China's position as a dominant force in the industry.Overall, the introduction of the new gypsum cornice production line by {} represents a significant milestone in the construction industry. With its advanced technology, commitment to quality and sustainability, and potential to meet the evolving needs of the market, the production line is set to make a lasting impact on the global gypsum cornice industry. Builders, contractors, and industry professionals can look forward to accessing high-quality gypsum cornice products manufactured by the company's state-of-the-art production line, contributing to the advancement of construction practices and standards around the world.

Calcium Silicate Board Production Line - Hard Board Making Machine - Building Material Manufacturing Machinery - Product Details on Kskuntai.com

Hebei, China - Kskuntai.com, a leading manufacturer of building materials, has announced the release of its state-of-the-art Calcium Silicate Board Production Line. This cutting-edge technology is designed to facilitate the production of high-quality Calcium Silicate Boards that meet international standards.The Calcium Silicate Board Production Line is a vital part of the overall manufacturing process. This innovative machinery is designed to produce a variety of building materials, including Hard Board, Calcium Silicate Board, and several others. The production line is a fully automated system that ensures that the final product is of the highest quality, with a smooth surface, uniform thickness, and precise edges.One of the unique features of this production line is that it can handle different board thicknesses and sizes with ease. The company uses advanced technology in board making, which ensures that each board is of consistent quality with excellent mechanical performance and insulation properties. The production line also has a high yield, with low energy consumption, making it an efficient and cost-effective solution for manufacturing Calcium Silicate Boards.In addition, this production line is equipped with a variety of safety features to create a safe working environment. The line has advanced monitoring systems to ensure that the machine is running smoothly at all times. There are also emergency shutdown systems in place that can immediately bring the machine to a halt in case of any malfunction.According to an official from Kskuntai.com, “Our Calcium Silicate Board Production Line is the result of our commitment to excellence. We believe that it is our responsibility to provide our customers with the best possible quality products. Our production line is not only efficient but also eco-friendly. We have taken several steps to ensure that it is energy-efficient and minimizes waste.”The Calcium Silicate Board Production Line is a significant addition to Kskuntai.com’s range of manufacturing solutions. With this latest technology, the company can produce high-quality Calcium Silicate Boards to meet the growing demand for eco-friendly and sustainable building materials. These Calcium Silicate Boards are ideal for use in walls, ceilings, floors, and various other applications in the construction industry.Kskuntai.com is a leading manufacturer and supplier of building materials, operating in over 30 countries worldwide. The company prides itself on providing innovative and reliable solutions to its customers. With a focus on quality, efficiency, and sustainability, the company continues to demonstrate its commitment to excellence.In conclusion, the Calcium Silicate Board Production Line is a cutting-edge technology that has a significant impact on the construction industry. Kskuntai.com’s latest machinery ensures the production of high-quality Calcium Silicate Boards that meet international standards. With its energy-efficient and eco-friendly features, the production line is an efficient and sustainable solution for the manufacture of building materials.

High-Quality Mineral Fiber Tiles Production Line in China

China's mineral fiber tiles production line has seen a significant boost in activity in recent times. The production line, provided by a company that specializes in the manufacturing and exporting of mineral fiber tiles, has been instrumental in meeting the growing demand for these products.The company, with its state-of-the-art production line, has been at the forefront of supplying high-quality mineral fiber tiles to various construction projects in China and abroad. With a strong focus on innovation and product development, the company has been able to establish itself as a leading player in the mineral fiber tiles industry.The mineral fiber tiles production line is designed to meet the diverse needs of customers, offering a wide range of products that cater to different design preferences and functional requirements. The production line is equipped with advanced machinery and technology, allowing for efficient and precise manufacturing processes.One of the key features of the production line is its ability to produce mineral fiber tiles in a variety of sizes, shapes, and patterns. This flexibility has enabled the company to meet the specific requirements of each project, while also offering a high level of customization to its customers.In addition to its focus on product quality and customization, the company has also prioritized sustainability and environmental responsibility in its production processes. The mineral fiber tiles production line has been designed to minimize waste and energy consumption, ensuring that the company's operations are as eco-friendly as possible.Furthermore, the company has implemented rigorous quality control measures throughout the production process, ensuring that each mineral fiber tile that leaves the production line meets the highest standards of quality and durability. This dedication to quality has earned the company a strong reputation among its customers and stakeholders.The company's commitment to excellence extends beyond its products, as it also provides exceptional customer service and support. With a team of experienced professionals, the company is able to offer technical assistance, design consultation, and project management expertise to its clients, ensuring that their needs are met at every step of the process.The success of the mineral fiber tiles production line can be attributed to the company's relentless pursuit of excellence and its ability to adapt to the ever-changing needs of the market. By staying ahead of industry trends and investing in cutting-edge technology, the company has been able to maintain its competitive edge and continue to grow its market share.Looking ahead, the company plans to further expand its production capacity and capabilities, in order to meet the increasing demand for mineral fiber tiles both domestically and internationally. With a strong track record of success and a commitment to innovation, the company is well-positioned to play a leading role in the global mineral fiber tiles industry.In conclusion, the mineral fiber tiles production line provided by the company has been a game-changer for the industry, offering high-quality, customizable products that meet the diverse needs of customers. With a focus on sustainability, quality, and customer satisfaction, the company has established itself as a trusted partner for construction projects around the world. As the company continues to grow and innovate, it is poised to remain a dominant force in the mineral fiber tiles market for years to come.

Affordable Automatic Gypsum Cornice Equipment Manufacturers: Enhance Search Engine Optimization

Title: Leading Automatic Gypsum Cornice Equipment Factories Revolutionize Manufacturing ProcessIntroduction:Gypsum cornices are an integral part of interior design, adding a touch of elegance and sophistication to any space. In an exciting development, a leading automatic gypsum cornice equipment factory is transforming the manufacturing process, propelling the industry forward. This groundbreaking technology, combined with the company's commitment to innovation, is revolutionizing the production of gypsum cornices. With unmatched precision and efficiency, these state-of-the-art equipment factories are shaping the future of interior decor.Body:1. The Rise of Automatic Gypsum Cornice Equipment Manufacturing:Over the past decade, there has been a considerable increase in the demand for high-quality gypsum cornices. To meet this growing demand, automatic gypsum cornice equipment factories have emerged, catering to the needs of interior designers, architects, and construction companies. These factories utilize cutting-edge technology to streamline production processes, ensuring increased efficiency and reduced costs.2. Cutting-Edge Technology and Manufacturing Process:The automatic gypsum cornice equipment factories incorporate advanced machinery and automation systems to optimize the manufacturing process. By utilizing computer numerical control (CNC) and robotics, these factories can produce gypsum cornices with unparalleled precision, consistency, and intricate designs. This groundbreaking technology not only enhances the overall quality but also significantly reduces manual labor.3. Benefits of Automatic Gypsum Cornice Equipment:a. Improved Efficiency: The use of automatic equipment has revolutionized gypsum cornice manufacturing, enabling factories to produce a larger quantity of products in a shorter period. This efficiency boost results in an enhanced customer experience and increased satisfaction levels.b. Consistent Quality: The precision offered by automatic machinery ensures consistent quality across all gypsum cornices produced by these factories. Each product adheres to the highest standards, showcasing fine details and impeccable craftsmanship.c. Cost-Effective: By combining automation with precise material usage, these factories can minimize material waste, thereby reducing costs. This cost-effectiveness translates to competitive pricing for customers, attracting a broader range of clients and promoting widespread adoption of gypsum cornices.4. Focus on Innovation:The leading automatic gypsum cornice equipment factories are driven by a relentless focus on innovation and research. They continuously strive to improve their manufacturing processes, developing new techniques and machinery to push the boundaries of what is possible within the industry. By investing in research and development, these companies ensure that their customers have access to the latest advancements in gypsum cornice manufacturing.5. Sustainability and Environmental Responsibility:In addition to technological advancements, automatic gypsum cornice equipment factories also prioritize sustainable production methods. By adhering to environmentally friendly practices, these factories minimize waste, reduce energy consumption, and utilize recyclable materials wherever possible. This commitment to sustainability aligns with contemporary demands for eco-friendly construction materials and contributes to the preservation of our planet.Conclusion:The automatic gypsum cornice equipment factories have ushered in a new era of manufacturing, bringing innovation, precision, and efficiency to the production of gypsum cornices. By embracing cutting-edge technology and focusing on sustainability, these factories provide a competitive advantage while meeting customer demands. With their commitment to innovation, these industry leaders are undoubtedly shaping the future of interior decor, transforming spaces with bespoke gypsum cornice designs that reflect a perfect combination of artistry and automation.

Affordable Pvc Laminated Gypsum Ceiling Board Making Machine Manufacturers

Cheap PVC Laminated Gypsum Ceiling Board Making Machine Factories are on the rise as demand for affordable and durable ceiling materials continues to grow. These factories are providing an efficient and cost-effective solution for producing high-quality PVC laminated gypsum ceiling boards that are in high demand in the construction industry.One such factory that has been making a significant impact in this industry is a leading manufacturer with years of experience in the production of PVC laminated gypsum ceiling board making machines. Their commitment to quality and innovation has made them a preferred choice for many construction companies and contractors.With the increasing demand for PVC laminated gypsum ceiling boards, these factories have been able to meet the needs of their customers by providing cutting-edge machinery that is designed for maximum efficiency and productivity. By utilizing advanced technology and precision engineering, these factories are able to produce high-quality ceiling boards that meet the highest industry standards.Furthermore, the use of PVC laminated gypsum ceiling boards offers numerous advantages such as durability, fire resistance, sound insulation, and easy installation. These boards are also cost-effective and environmentally friendly, making them an ideal choice for a wide range of construction projects.The company behind these innovative PVC laminated gypsum ceiling board making machines has a strong commitment to customer satisfaction and has built a solid reputation for delivering top-quality products and exceptional customer service. Their team of experienced engineers and technicians work tirelessly to develop and improve their machinery, ensuring that their customers have access to the latest and most efficient equipment on the market.In addition to their commitment to quality, the company also prides itself on its dedication to sustainability and environmental responsibility. They have implemented strict measures to ensure that their manufacturing processes are eco-friendly and that their products comply with all relevant environmental regulations.The factory's state-of-the-art facilities are equipped with the latest machinery and technology, allowing them to produce PVC laminated gypsum ceiling board making machines that are both reliable and efficient. Their production line is capable of meeting the demands of large-scale projects while still maintaining the highest level of quality control.Furthermore, the factory's dedication to research and development has enabled them to stay ahead of the competition by continuously introducing new and improved machinery that meets the evolving needs of the industry. This commitment to innovation has allowed them to maintain their position as a leader in the PVC laminated gypsum ceiling board making machine manufacturing sector.Moreover, the company has made it a priority to provide comprehensive training and technical support to their customers, ensuring that they are able to operate their machinery with ease and confidence. This level of support has helped the company build long-lasting relationships with their clients and has contributed to their continued success in the industry.As the demand for PVC laminated gypsum ceiling boards continues to grow, these factories are playing a crucial role in meeting the needs of the construction industry. Their dedication to quality, innovation, and customer satisfaction has positioned them as key players in the manufacturing of PVC laminated gypsum ceiling board making machines.In conclusion, the rise of cheap PVC laminated gypsum ceiling board making machine factories has been a game-changer for the construction industry. With their commitment to quality, innovation, and sustainability, these factories are providing efficient and cost-effective solutions for producing high-quality PVC laminated gypsum ceiling boards. Their impact on the industry is undeniable, and they are set to play an even bigger role in the future of construction materials.

Affordable Gypsum Ceiling Cornice Making Machine Manufacturers

Cheap Gypsum Ceiling Cornice Making Machine Factories Make Waves in the MarketIn recent years, the demand for gypsum ceiling cornices has been on the rise, due to the increasing preference for aesthetically pleasing interior designs. To meet this demand, numerous companies have ventured into the production of gypsum ceiling cornice making machines. This has led to the emergence of cheap gypsum ceiling cornice making machine factories, which are making waves in the market.One such factory that has been gaining attention is the one operated by {} company. With a focus on providing affordable and high-quality gypsum ceiling cornice making machines, the company has quickly established itself as a leading player in the industry.The company's gypsum ceiling cornice making machines have garnered widespread praise for their efficiency, precision, and ease of use. These machines are designed to streamline the production process, allowing manufacturers to create a wide range of ceiling cornice designs with minimal effort. Additionally, the machines are equipped with advanced features that ensure consistent quality and high productivity, making them an attractive investment for businesses in the interior design and construction sectors.One of the key factors that set {} company apart from its competitors is its commitment to affordability. The company understands the financial constraints that many businesses face, and as such, it has made it a priority to offer its gypsum ceiling cornice making machines at competitive prices. This has made it possible for small and medium-sized enterprises to enter the market and compete effectively with larger players.In addition to affordability, the company also places a strong emphasis on customer satisfaction. It prides itself on providing excellent customer service, offering comprehensive technical support, and ensuring prompt delivery of its machines. This dedication to customer care has earned {} company a loyal customer base, with many clients expressing their satisfaction with the company's products and services.Furthermore, {} company is constantly innovating and improving its gypsum ceiling cornice making machines to stay ahead of the competition. Its team of experienced engineers and technicians continually research and develop new technology to enhance the performance and capabilities of its machines. This proactive approach has enabled the company to maintain its position as a frontrunner in the industry, and it remains poised for further growth and success in the years to come.As the market for gypsum ceiling cornices continues to expand, the demand for efficient and affordable production solutions is expected to increase. With its dedication to providing cost-effective and high-quality machines, {} company is well-positioned to capitalize on this growing market. Its commitment to innovation, affordability, and customer satisfaction has cemented its status as a leader in the industry, and it is set to play an integral role in shaping the future of gypsum ceiling cornice production.In conclusion, cheap gypsum ceiling cornice making machine factories are making a significant impact in the market, and {} company is leading the charge with its affordable and high-quality machines. With a focus on innovation, affordability, and customer satisfaction, the company has carved out a prominent position in the industry and is primed for continued success in the years ahead.

Efficient Drywall Board Making Machine: An Overview

Title: Revolutionary Mgo Drywall Board Making Machine Revolutionizing the Construction IndustryIntroduction:In today's fast-paced world, the construction industry is constantly seeking innovative solutions that enhance efficiency, durability, and sustainability. Keeping up with this demand, a leading international manufacturing company has introduced an advanced Mgo drywall board making machine. With superior technology and commendable features, this groundbreaking machine is set to revolutionize the way traditional drywall boards are produced, propelling the construction sector to new heights of excellence.1. Background and Features:The new Mgo drywall board making machine leverages advanced technology to manufacture high-quality magnesium oxide (Mgo) boards, revolutionizing the construction sector. Unlike traditional drywall boards that are made using gypsum, Mgo boards boast superior fire resistance, moisture resistance, mold resistance, and environmental friendliness. These exceptional characteristics make Mgo boards ideal for a wide range of construction applications, such as walls, ceilings, partitioning, and fire-rated assemblies.2. The Working Principle:The Mgo drywall board making machine operates on a fully automated system, ensuring accuracy, precision, and rapid production. By combining magnesium oxide, magnesium chloride, and several optional additives, the machine forms a homogeneous mixture that is then poured onto a moving belt. A continuous process of molding and cutting ensures the creation of standardized, high-quality Mgo boards of various sizes and thicknesses.3. Eco-Friendliness and Sustainability:With a growing concern for sustainability and environmental protection, the introduction of the Mgo drywall board making machine addresses these crucial aspects of construction materials. The machine uses raw materials that are non-toxic, renewable, and readily available, reducing associated environmental harm. Moreover, Mgo boards have a long lifespan, reducing maintenance requirements and minimizing waste throughout their lifecycle.4. Efficiency and Productivity:The Mgo drywall board making machine boasts significant advantages in terms of efficiency and productivity. Compared to traditional drywall board manufacturing processes that involve multiple steps and long drying periods, the new machine streamlines the entire production process. Its continuous production line ensures efficient handling, rapid drying, and consistent quality, resulting in increased output and reduced costs.5. Improved Quality and Durability:By utilizing the Mgo drywall board making machine, construction companies can be assured of superior quality and durability. The advanced manufacturing technology guarantees precise board thickness, smooth surfaces, and excellent dimensional stability. Mgo boards offer exceptional resistance to fire, moisture, and mold, thus ensuring a longer lifespan and reducing the need for frequent board replacements.6. Expansion Opportunities and Market Outlook:The introduction of the Mgo drywall board making machine opens up new avenues for the construction industry, allowing companies to meet the growing demand for sustainable and high-quality building materials. The global market for drywall boards is projected to witness substantial growth, driven by urbanization, infrastructure development, and the need for greener constructions. With its exceptional features and benefits, the Mgo drywall board making machine positions companies for success in this expanding market.Conclusion:The innovative Mgo drywall board making machine is set to transform the construction industry by offering an eco-friendly, highly efficient, and superior alternative to traditional gypsum-based drywall boards. By capitalizing on advanced technology and sustainable materials, this revolutionary machine allows construction companies to deliver projects with enhanced durability and safety. With the continual advancements in construction materials, the Mgo drywall board making machine represents a remarkable step towards building a greener and more sustainable future.

Affordable Foam Board Making Machine Factories for XPS

Cheap XPS Foam Board Making Machine FactoriesIn recent years, the demand for XPS foam board has been on the rise due to its versatile applications in the construction industry. In order to meet the increasing demand, several factories have been established to manufacture XPS foam board making machines. These factories have been playing a crucial role in the production and distribution of affordable and high-quality XPS foam board making machines.One of the leading XPS foam board making machine factories is located in China, where the company has gained a reputation for providing top-notch machines at competitive prices. The company has been at the forefront of technological advancements in the field of XPS foam board making machines and has been serving customers worldwide.The XPS foam board making machines produced by the company are known for their efficiency, durability, and precision. The machines are designed to produce XPS foam boards of various sizes and densities, catering to the diverse needs of the construction industry. In addition, the company offers customization options, allowing customers to tailor the machines according to their specific requirements.The XPS foam board making machine factories have been instrumental in the advancement of the construction industry, as they have made it possible for contractors and builders to access high-quality XPS foam board making machines at affordable prices. This has not only contributed to the growth of the construction industry but has also led to the development of eco-friendly and energy-efficient buildings.The XPS foam board making machine factories are committed to providing exceptional customer service, offering technical support, and maintenance services to ensure the smooth operation of their machines. Furthermore, the factories have a strong focus on continuous research and development, aiming to improve the efficiency and performance of their machines.In addition to manufacturing XPS foam board making machines, the factories also offer training and consultation services to their customers, equipping them with the necessary knowledge and skills to maximize the potential of the machines. This level of support and dedication sets the XPS foam board making machine factories apart from the competition, making them the go-to choice for construction companies and contractors.With the increasing demand for XPS foam board, the XPS foam board making machine factories are poised to play a significant role in the construction industry. Their commitment to innovation, quality, and affordability has made them indispensable partners for construction companies looking to enhance their production capabilities.In conclusion, the XPS foam board making machine factories have emerged as key players in the advancement of the construction industry. With their dedication to providing affordable and high-quality machines, they have become crucial enablers for the production of XPS foam board. As the demand for eco-friendly and energy-efficient construction materials continues to grow, the XPS foam board making machine factories are expected to play an even more prominent role in shaping the future of the industry. Their commitment to excellence and customer satisfaction makes them the preferred choice for construction companies and contractors worldwide.For more information on the XPS foam board making machine factories, please visit their website {} for details on their products and services.

High-Quality Mgo Board Equipment Pricing Guide

Mgo Board Equipment Pricelist Revealed by Leading ManufacturerAs a leading manufacturer in the construction materials industry, our company has recently announced the release of the pricelist for our state-of-the-art Mgo board equipment. This news has generated tremendous excitement within the industry, as the Mgo board equipment is known for its high quality and efficiency in production.The Mgo board, also known as magnesium oxide board, is a type of building material that has been gaining popularity due to its impressive fire resistance, mold resistance, and strength. As the demand for Mgo board continues to rise, our company has been at the forefront of providing advanced equipment for the manufacturing process.Our Mgo board equipment pricelist includes a range of machinery and tools that are essential for the production of high-quality Mgo boards. This includes the Mgo board production line, which is designed to efficiently mix raw materials, form the boards, and complete the curing process. Additionally, our pricelist also features cutting-edge equipment for surface finishing, edge sealing, and board stacking, ensuring that manufacturers have everything they need to produce superior Mgo boards.One of the key highlights of our Mgo board equipment pricelist is the competitive pricing. Our company is committed to providing cost-effective solutions for manufacturers looking to invest in Mgo board production. By offering a comprehensive range of equipment at competitive prices, we aim to support the growth of businesses within the construction materials industry.Furthermore, our company takes pride in the quality and reliability of our Mgo board equipment. Each piece of machinery is carefully engineered and tested to ensure optimal performance and durability. With our advanced equipment, manufacturers can enhance their production capabilities and meet the increasing demand for Mgo boards in the market.In addition to the release of the pricelist, our company also wishes to highlight our dedication to superior customer service. We understand that investing in new equipment is a significant decision for any business, which is why we strive to provide exceptional support to our customers. Whether it is technical assistance, training, or maintenance, our team is committed to helping manufacturers maximize the potential of their Mgo board equipment.Overall, the release of the Mgo board equipment pricelist marks an important milestone for our company as we continue to lead the way in providing innovative solutions for the construction materials industry. With our high-quality equipment, competitive pricing, and commitment to customer satisfaction, we are confident that manufacturers will find value in investing in our Mgo board production machinery.In conclusion, the unveiling of the Mgo board equipment pricelist by our company represents a significant opportunity for manufacturers to enhance their production capabilities and meet the growing demand for high-quality Mgo boards. We are excited to offer our advanced machinery and tools at competitive prices, further solidifying our position as a trusted provider of Mgo board equipment in the industry. As the construction materials market continues to evolve, our company remains dedicated to empowering manufacturers with the best solutions for Mgo board production.