Automatic Waterproof Mgo Board Production Line at Wholesale Prices

By:Admin

The new production line is designed to meet the growing need for durable and waterproof construction materials that can be used in a variety of applications, including interior and exterior walls, ceilings, and flooring. With the ability to produce a high volume of Mgo boards, the company is poised to make a significant impact on the construction industry.

The Mgo boards produced by this new production line are highly durable and resistant to water, making them ideal for use in areas that are prone to moisture and humidity. In addition to their waterproof properties, these boards are also fire-resistant, making them a safe and reliable choice for construction projects.

One of the key advantages of the Wholesale Automatic Waterproof Mgo Board Production Line is its ability to produce boards of various sizes and thicknesses, providing flexibility for a wide range of construction applications. This versatility makes it a valuable addition to any construction project, from residential homes to commercial buildings.

The company behind this innovative production line has a strong track record in the construction industry, with a commitment to quality and innovation. With state-of-the-art facilities and a team of experienced professionals, the company is well-positioned to meet the demand for high-quality Mgo boards.

In addition to its focus on quality and innovation, the company is also dedicated to sustainability. The Mgo boards produced by the new production line are made from environmentally friendly materials, making them a sustainable choice for construction projects. This commitment to sustainability aligns with the growing trend towards eco-friendly building materials and practices.

The launch of the Wholesale Automatic Waterproof Mgo Board Production Line is expected to have a significant impact on the construction industry. With its ability to produce high-quality, waterproof, and fire-resistant boards, the new production line is poised to become a go-to choice for construction projects of all sizes.

In conclusion, the launch of the Wholesale Automatic Waterproof Mgo Board Production Line represents an exciting development in the construction industry. With its focus on quality, innovation, and sustainability, the company is well-positioned to meet the growing demand for high-quality waterproof construction materials. This new production line is set to make a positive impact on construction projects, offering a durable and reliable solution for a wide range of applications. As the construction industry continues to evolve, this new production line is sure to play a key role in shaping the future of construction materials.

Company News & Blog

High-Quality Lightweight Wall Panel MGO Board Door Manufacturing Machinery for Magnesium Oxide Main Material

How to Get Quotes for an Automatic Gypsum Cornice Making Machine

Today, the demand for home decoration and renovation is on the rise, leading to an increased need for high-quality construction materials and machinery. In response to this growing market, {Company Name} is proud to introduce its state-of-the-art Automatic Gypsum Cornice Making Machine.The Automatic Gypsum Cornice Making Machine incorporates the latest technology and innovative design to provide a reliable and efficient solution for producing gypsum cornices. This machine is capable of producing a wide range of exquisite and intricate designs, catering to the diverse needs of customers in the construction and interior design industries.With a focus on precision and accuracy, the machine ensures that each gypsum cornice is manufactured to the highest standards, meeting the stringent requirements of modern architectural and decorative designs. Whether it is for residential, commercial, or industrial projects, the Automatic Gypsum Cornice Making Machine is equipped to handle various production demands, delivering consistent results with impressive speed and efficiency.The machine is designed to streamline the manufacturing process, reducing labor costs and increasing productivity for businesses. Its user-friendly interface and intuitive controls make it easy to operate, minimizing the need for extensive training and technical expertise. This accessibility and convenience make the Automatic Gypsum Cornice Making Machine an attractive investment for both established manufacturers and startup businesses.In addition to its advanced features, the machine is also engineered for durability and reliability, ensuring minimal downtime and maintenance costs. Its robust construction and high-quality components make it a long-lasting asset for any production facility, providing a solid return on investment for years to come.As a leading manufacturer of construction machinery, {Company Name} is committed to delivering cutting-edge solutions that meet the evolving needs of the industry. The introduction of the Automatic Gypsum Cornice Making Machine is a testament to this commitment, as the company continues to push the boundaries of innovation and excellence in the construction equipment market.With a strong emphasis on research and development, {Company Name} has invested significant resources in bringing this advanced technology to the market. By collaborating with industry experts and leveraging its manufacturing expertise, the company has developed a machine that sets new standards for gypsum cornice production, offering unparalleled precision, efficiency, and versatility.In line with its dedication to customer satisfaction, {Company Name} also offers comprehensive technical support and aftersales services for the Automatic Gypsum Cornice Making Machine. This includes onsite installation, training, and ongoing assistance to ensure that customers maximize the full potential of the machine and achieve optimal results in their production operations.Looking ahead, {Company Name} is poised to further expand its product offerings and technological capabilities, catering to the diverse needs of the construction and interior design sectors. The company remains committed to embracing digital transformation and industry 4.0 principles, as it continues to develop innovative solutions that empower businesses to thrive in a competitive and dynamic market environment.In conclusion, the introduction of the Automatic Gypsum Cornice Making Machine represents a significant milestone for {Company Name}, as it reinforces the company's position as a leading provider of cutting-edge machinery for the construction industry. With its advanced features, exceptional performance, and unwavering commitment to customer satisfaction, the machine is set to revolutionize gypsum cornice production and drive the industry towards new heights of efficiency and quality. As demand for high-quality construction materials continues to grow, {Company Name} is well-positioned to meet these needs with its innovative solutions, setting a new standard for excellence in the market.

High-quality XPS Foam Extrusion Line for Sale

Introducing the Latest XPS Foam Extrusion Line at [Company Name][Location], [Date] – [Company Name], a leading provider of innovative plastic extrusion solutions, is thrilled to announce the introduction of the latest XPS Foam Extrusion Line to their manufacturing facility. This state-of-the-art extrusion line represents a significant advancement in the company’s capabilities and further solidifies their position as a pioneer in the industry.The new XPS Foam Extrusion Line is equipped with cutting-edge technology and features, designed to enhance productivity, efficiency, and product quality. With increased automation and precision control, this extrusion line is capable of producing high-quality XPS foam with superior thermal insulation properties, making it ideal for a wide range of applications in construction and packaging.[Company Name] has always been at the forefront of innovation, and the addition of the XPS Foam Extrusion Line is a testament to their commitment to delivering cutting-edge solutions to their customers. With the ability to produce XPS foam in various thicknesses and densities, the new extrusion line enables [Company Name] to meet the diverse needs of their clients and offer customized solutions tailored to specific requirements.In addition to the technological advancements, the new XPS Foam Extrusion Line is also designed with sustainability in mind. It incorporates energy-efficient processes and environmentally friendly materials, aligning with [Company Name]’s dedication to sustainable manufacturing practices. By prioritizing sustainability, the company aims to minimize its environmental impact and contribute to a more sustainable future.The introduction of the XPS Foam Extrusion Line reaffirms [Company Name]’s position as an industry leader and sets a new standard for excellence in foam extrusion technology. With a focus on innovation, quality, and sustainability, the company continues to push the boundaries of what is possible in the field of plastic extrusion, delivering exceptional products and solutions to their customers.As a global supplier, [Company Name] serves a diverse customer base across various industries, providing them with high-performance extrusion solutions tailored to their specific needs. With the addition of the new XPS Foam Extrusion Line, the company is poised to expand its reach and offer enhanced capabilities to their clients, enabling them to achieve their goals with greater efficiency and reliability.[Company Name]’s dedication to innovation and continuous improvement is reflected in the investments they make in their manufacturing capabilities. The introduction of the XPS Foam Extrusion Line is a testament to the company’s ongoing commitment to delivering value-driven solutions that empower their customers and drive progress across the industry.In conclusion, the introduction of the latest XPS Foam Extrusion Line at [Company Name] represents a significant milestone in the company’s journey towards excellence. Equipped with cutting-edge technology, sustainability features, and a focus on quality, this extrusion line sets a new standard for foam production and reaffirms [Company Name]’s position as a leader in the industry. With a strong focus on innovation, customer satisfaction, and sustainability, [Company Name] continues to pave the way for the future of plastic extrusion, delivering exceptional products and solutions to their global customer base.

Top Gypsum Board Cornice Automatic Equipment Manufacturers

[Company Name] has become a leading manufacturer of gypsum board cornice automatic equipment, establishing itself as one of the top factories in the industry. With a state-of-the-art production facility and a strong commitment to innovation, the company has been able to consistently deliver high-quality equipment that meets the needs of their customers.The factory, located in [Location], is equipped with cutting-edge technology and advanced machinery, allowing [Company Name] to produce a wide range of gypsum board cornice automatic equipment. This includes everything from cutting and shaping machines to automatic installation and finishing equipment. The company's production process is highly efficient, ensuring that they are able to meet the growing demand for their products while maintaining the highest standards of quality.One of the key factors that sets [Company Name] apart from other factories is their dedication to research and development. The company has a team of experienced engineers and designers who are constantly working to improve their equipment and develop new technologies. This has allowed [Company Name] to stay ahead of the curve in the industry, introducing innovative products that are not only more efficient, but also more environmentally friendly.In addition to their focus on technology and innovation, [Company Name] is also committed to sustainability and responsible manufacturing practices. The factory is designed to minimize waste and energy consumption, and the company is constantly looking for ways to reduce their environmental impact. This commitment to sustainability has earned [Company Name] recognition as a leader in the industry, and has helped them build a strong reputation among their customers and partners.Despite their success, [Company Name] remains focused on providing excellent customer service and support. The company works closely with their clients to understand their specific needs and requirements, and they are able to provide customized solutions that meet these needs. This level of support has helped [Company Name] build long-lasting relationships with their customers, and has contributed to their strong reputation in the industry.Looking to the future, [Company Name] is committed to continuing their growth and development. The company is constantly looking for new opportunities to expand their product line and reach new markets. They are also committed to staying at the forefront of technological advancements, ensuring that they are able to provide their customers with the most innovative and efficient equipment on the market.In conclusion, [Company Name] has established itself as one of the top factories in the industry for gypsum board cornice automatic equipment. With a focus on technology, innovation, and sustainability, the company has been able to deliver high-quality products that meet the needs of their customers. Their commitment to customer service and support has helped them build strong relationships with their clients, and their dedication to growth and development ensures that they will continue to be a leader in the industry for years to come.

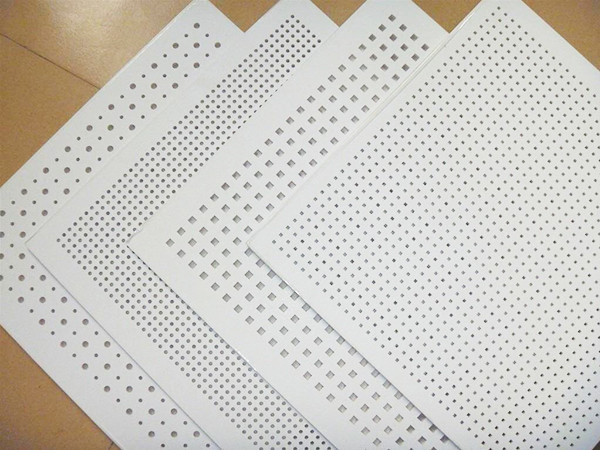

Wholesale Perforated Plasterboard Manufacturing Machine: Your Ultimate Guide

[Company Name] Introduces New Wholesale Perforated Plasterboard Machine[City, Date] - [Company Name], a leading manufacturer of construction machinery, has recently introduced a new wholesale perforated plasterboard machine, aimed at meeting the growing demand for high-quality plasterboard in the construction industry. The new machine is expected to revolutionize the production process of plasterboard, making it more efficient and cost-effective for construction companies and contractors.The new wholesale perforated plasterboard machine is equipped with advanced technology and features innovative design, making it a game-changer in the industry. With its high-speed perforation capabilities, the machine can produce perforated plasterboards at a faster rate, increasing productivity and reducing production time. Additionally, the machine is designed to produce high-quality perforated plasterboards with precision, ensuring uniform perforations and smooth finishing.[Company Name] is committed to delivering the highest quality products to its customers, and the new wholesale perforated plasterboard machine is no exception. The company prides itself on using the latest manufacturing techniques and superior materials to ensure the durability and reliability of its machinery. The new machine is built to withstand heavy-duty use, making it an ideal investment for construction businesses looking to enhance their production capabilities.In addition to its impressive functionality, the new wholesale perforated plasterboard machine is also designed with user-friendly features, making it easy to operate and maintain. The intuitive controls and ergonomic design of the machine ensure that operators can work efficiently and safely, minimizing downtime and maximizing productivity. The machine also comes with built-in safety mechanisms to protect workers and prevent accidents in the workplace.[Company Name] has a long-standing reputation for delivering exceptional products and providing outstanding customer service. With the introduction of the new wholesale perforated plasterboard machine, the company aims to further solidify its position as a trusted supplier in the construction industry. The company is dedicated to offering comprehensive support to its customers, including installation, training, and after-sales service, to ensure that they get the most out of their investment.The new wholesale perforated plasterboard machine is expected to be a game-changer in the construction industry, providing construction businesses with a competitive edge in the market. With its advanced technology, high-quality production, and user-friendly design, the machine is set to streamline the production process of perforated plasterboards, helping businesses meet the growing demand for construction materials.Construction companies and contractors looking to enhance their production capabilities and improve efficiency can now benefit from the cutting-edge wholesale perforated plasterboard machine offered by [Company Name]. With its advanced features and superior performance, the machine is poised to set a new standard in the industry, revolutionizing the way perforated plasterboards are produced.For more information about the new wholesale perforated plasterboard machine and other construction machinery offered by [Company Name], please visit their website at [website] or contact their sales team at [contact information].

Fiberboard Plant in Diboll Shut Down, Resulting in Job Loss for 90 Workers

The recent closure of a fiberboard plant in Diboll, Texas has caused a major impact on its 90 employees. While the reasons for the plant's shutdown may not be clear, it highlights the complexity of the manufacturing industry. As businesses grow and expand, they are likely to face challenges along the way, which may include fluctuations in demand, regulatory changes, and financial pressures.Despite this, there continues to be a demand for fiberboard products that are used in construction, furniture making, and other industries. Fortunately, there are many mineral fiber board machine factories that provide high-quality products for these sectors.If you are in the market for fiberboard products or are looking to start a manufacturing business, it is essential to partner with a reliable and reputable mineral fiber board machine factory. With that in mind, here are some of the best mineral fiber board machine factories to consider.1. Hebei Lvjoe Machinery Manufacturing Co., Ltd.Hebei Lvjoe Machinery Manufacturing Co., Ltd. is a professional manufacturer of mineral fiber board machines, gypsum board production lines, and other building material machinery. The factory has over 20 years of experience in the industry and has exported its products to more than 50 countries around the world.One of the things that make Hebei Lvjoe exceptional is its commitment to quality control. The factory uses advanced equipment and tools to ensure that the products that they produce meet the highest standards. Additionally, they have an experienced team of engineers and technicians who provide technical support to their clients.2. Shandong Chuangxin Building Materials Complete Equipment Co., Ltd.Shandong Chuangxin Building Materials Complete Equipment Co., Ltd. is another top mineral fiber board machine factory that specializes in the production of gypsum board equipment and mineral wool board equipment. The factory's products are used in the construction and decoration industries.The factory has a modern production facility that houses advanced equipment, including CNC machines, press brakes, and welding machines. They also have a team of highly skilled professionals who are dedicated to providing the best services to their clients.3. Wuxi Suhang Machinery Manufacturing Co., Ltd.Wuxi Suhang Machinery Manufacturing Co., Ltd. is a leading manufacturer of mineral fiber board machines, metal roll forming machines, and other construction machinery. The factory has a strong focus on research and development and has invested heavily in new technology to improve its production processes.The factory's products are known for their quality and durability, and they come with a one-year warranty. They also offer excellent after-sales support, including technical assistance and spare parts supply.In conclusion, the recent closure of the fiberboard plant in Diboll serves as a reminder of the importance of partnering with reputable mineral fiber board machine factories. By doing so, you can be confident that you are getting high-quality products that meet your needs and standards. Hebei Lvjoe Machinery Manufacturing Co., Ltd., Shandong Chuangxin Building Materials Complete Equipment Co., Ltd., and Wuxi Suhang Machinery Manufacturing Co., Ltd. are some of the best factories that you can consider for your requirements.

Affordable Mineral Fiber Ceiling Board Equipment Manufacturers

Cheap Mineral Fiber Ceiling Board Equipment Factories in High DemandIn recent years, there has been a surge in the demand for mineral fiber ceiling board equipment, particularly those that are affordable without compromising on quality. This has led to the rise of numerous equipment factories across the globe, with many companies striving to meet the growing needs of the construction industry. One such company that has been making waves in the market is {Company Name}, a leading provider of high-quality and cost-effective mineral fiber ceiling board equipment.Founded with the vision of revolutionizing the manufacturing process of mineral fiber ceiling boards, {Company Name} has successfully established itself as a prominent player in the industry. With a strong focus on innovation and advanced technology, the company has been able to develop state-of-the-art equipment that not only delivers exceptional performance but also comes at a fraction of the cost compared to their competitors.The mineral fiber ceiling board equipment offered by {Company Name} is designed to meet the diverse needs of construction projects, ranging from residential buildings to commercial spaces. With a commitment to sustainability, the company has also incorporated eco-friendly features into their equipment, making it an ideal choice for environmentally conscious builders and developers.One of the key factors that set {Company Name} apart from its counterparts is its dedication to customer satisfaction. The company not only ensures that their equipment meets the highest standards of quality but also provides comprehensive support and after-sales services. This has earned them a loyal customer base and has solidified their reputation as a trusted and reliable supplier in the market.The rising demand for cheap mineral fiber ceiling board equipment has been attributed to the increasing focus on cost-effective and efficient building materials. As the construction industry continues to expand, there is a growing need for equipment that can streamline the manufacturing process while keeping expenses at a minimum. This is where companies like {Company Name} have been able to fill the gap, offering affordable solutions without compromising on performance.Moreover, the versatility of mineral fiber ceiling board equipment makes it an attractive choice for builders and contractors. From its ease of installation to its fire-resistant and acoustic properties, mineral fiber ceiling boards have become a popular choice for various construction projects. This has further fueled the demand for cost-effective equipment that can produce high-quality ceiling boards at a rapid pace.As the industry continues to evolve, {Company Name} remains at the forefront, continuously innovating and expanding its product line to cater to the changing needs of the market. With a strong emphasis on research and development, the company is committed to staying ahead of the curve and delivering cutting-edge solutions that meet the evolving demands of the construction industry.In conclusion, the demand for cheap mineral fiber ceiling board equipment continues to rise as the construction industry seeks cost-effective and efficient solutions. {Company Name} has emerged as a key player in meeting this demand, offering high-quality equipment at a competitive price point. With a focus on innovation, sustainability, and customer satisfaction, the company is set to further solidify its position as a leading provider of mineral fiber ceiling board equipment in the global market.

Affordable PVC Laminated Gypsum Board Machine Price List Unveiled in Recent News

PVC Laminated Gypsum Board Machine Aims to Reinforce Efficiency and Quality in Manufacturing ProcessIn recent industry news, a leading company in the manufacturing and distribution of gypsum board machinery, known for their commitment to innovative technology and exceptional quality, announced the introduction of a new PVC laminated gypsum board machine. This advanced machinery aims to provide a solution for enhancing efficiency and elevating the quality of gypsum board production.The machinery, which leverages cutting-edge technology and industry expertise, offers numerous advantages to manufacturers in the gypsum board industry. With a focus on increasing productivity, this machine can significantly reduce the production time required for manufacturing gypsum boards while maintaining high-quality standards. By streamlining the entire manufacturing process, companies can optimize their production output, allowing for greater profitability and customer satisfaction.One of the key features of this PVC laminated gypsum board machine is its ability to integrate the lamination process directly into the manufacturing line, eliminating the need for a separate lamination process. This integration not only saves time and labor but also ensures consistent and superior adhesion between the PVC layer and the gypsum board. By eliminating the risk of delamination, manufacturers can guarantee a longer lifespan for their gypsum boards, making them more reliable for various construction applications.Furthermore, this state-of-the-art machinery incorporates advanced control systems that enable real-time monitoring and adjustment of production parameters. This ensures precision in the manufacturing process, resulting in consistently high-quality boards with accurate dimensions and smooth surfaces. Manufacturers can also benefit from the machine's versatility, as it offers customizable settings to meet specific industry requirements or produce various board sizes and designs.With sustainability being a significant concern in today's manufacturing industry, this PVC laminated gypsum board machine incorporates eco-friendly features to reduce its environmental impact. The machinery optimizes energy consumption through efficient power management systems, minimizing energy waste during production. Additionally, it utilizes low-emission technology, reducing harmful emissions and promoting cleaner air quality in the workplace.Alongside the introduction of this new machinery, the company aims to provide comprehensive technical support and after-sales service to their clients. Their team of highly skilled engineers and technicians will be available to assist manufacturers with machine installation, training, and troubleshooting, ensuring a seamless transition into the new production process. By offering ongoing support, the company establishes a strong partnership with their clients, strengthening their reputation as a reliable and customer-oriented provider.As global demand for gypsum board continues to rise, driven by the booming construction industry, manufacturers must invest in advanced machinery to remain competitive. This new PVC laminated gypsum board machine addresses the industry's need for improved efficiency, productivity, and quality standards. By adopting this innovative solution, manufacturers can enhance their production capabilities, streamline their operations, and deliver superior gypsum board products to meet market demands.In conclusion, the introduction of the PVC laminated gypsum board machine represents a significant milestone for the manufacturing industry. With its advanced technology, integration of lamination processes, precise control systems, and eco-friendly features, this machinery aims to revolutionize the gypsum board manufacturing process. The company's commitment to providing technical support and after-sales service further demonstrates their dedication to customer satisfaction. As manufacturers embrace this groundbreaking solution, they will be well-equipped to meet the growing demand for high-quality gypsum boards in construction projects worldwide.

Efficient Drywall Board Making Machine: An Overview

Title: Revolutionary Mgo Drywall Board Making Machine Revolutionizing the Construction IndustryIntroduction:In today's fast-paced world, the construction industry is constantly seeking innovative solutions that enhance efficiency, durability, and sustainability. Keeping up with this demand, a leading international manufacturing company has introduced an advanced Mgo drywall board making machine. With superior technology and commendable features, this groundbreaking machine is set to revolutionize the way traditional drywall boards are produced, propelling the construction sector to new heights of excellence.1. Background and Features:The new Mgo drywall board making machine leverages advanced technology to manufacture high-quality magnesium oxide (Mgo) boards, revolutionizing the construction sector. Unlike traditional drywall boards that are made using gypsum, Mgo boards boast superior fire resistance, moisture resistance, mold resistance, and environmental friendliness. These exceptional characteristics make Mgo boards ideal for a wide range of construction applications, such as walls, ceilings, partitioning, and fire-rated assemblies.2. The Working Principle:The Mgo drywall board making machine operates on a fully automated system, ensuring accuracy, precision, and rapid production. By combining magnesium oxide, magnesium chloride, and several optional additives, the machine forms a homogeneous mixture that is then poured onto a moving belt. A continuous process of molding and cutting ensures the creation of standardized, high-quality Mgo boards of various sizes and thicknesses.3. Eco-Friendliness and Sustainability:With a growing concern for sustainability and environmental protection, the introduction of the Mgo drywall board making machine addresses these crucial aspects of construction materials. The machine uses raw materials that are non-toxic, renewable, and readily available, reducing associated environmental harm. Moreover, Mgo boards have a long lifespan, reducing maintenance requirements and minimizing waste throughout their lifecycle.4. Efficiency and Productivity:The Mgo drywall board making machine boasts significant advantages in terms of efficiency and productivity. Compared to traditional drywall board manufacturing processes that involve multiple steps and long drying periods, the new machine streamlines the entire production process. Its continuous production line ensures efficient handling, rapid drying, and consistent quality, resulting in increased output and reduced costs.5. Improved Quality and Durability:By utilizing the Mgo drywall board making machine, construction companies can be assured of superior quality and durability. The advanced manufacturing technology guarantees precise board thickness, smooth surfaces, and excellent dimensional stability. Mgo boards offer exceptional resistance to fire, moisture, and mold, thus ensuring a longer lifespan and reducing the need for frequent board replacements.6. Expansion Opportunities and Market Outlook:The introduction of the Mgo drywall board making machine opens up new avenues for the construction industry, allowing companies to meet the growing demand for sustainable and high-quality building materials. The global market for drywall boards is projected to witness substantial growth, driven by urbanization, infrastructure development, and the need for greener constructions. With its exceptional features and benefits, the Mgo drywall board making machine positions companies for success in this expanding market.Conclusion:The innovative Mgo drywall board making machine is set to transform the construction industry by offering an eco-friendly, highly efficient, and superior alternative to traditional gypsum-based drywall boards. By capitalizing on advanced technology and sustainable materials, this revolutionary machine allows construction companies to deliver projects with enhanced durability and safety. With the continual advancements in construction materials, the Mgo drywall board making machine represents a remarkable step towards building a greener and more sustainable future.

High-Quality 12mm Calcium Silicate Board Production Line for Sale

12mm Calcium Silicate Board Production Line Now in Operation at {}{}, a leading manufacturer of construction materials, is proud to announce the successful installation and operation of their new 12mm Calcium Silicate Board Production Line. This state-of-the-art production line is set to revolutionize the production process for calcium silicate boards, offering improved efficiency, increased output, and higher quality products.The new production line is a result of {}'s commitment to innovation and delivering top-of-the-line products to their customers. With the increasing demand for high-quality construction materials, especially in the rapidly growing infrastructure and building construction sectors, {} recognized the need for a more advanced and efficient production process for calcium silicate boards.The 12mm Calcium Silicate Board Production Line is equipped with the latest technology and machinery, allowing for a seamless and automated production process. This not only ensures a higher level of precision and consistency in the production of calcium silicate boards but also significantly increases the production capacity, allowing {} to meet the growing demand from their customers.With the new production line now in operation, {} is poised to take a leading position in the market for calcium silicate boards. The company is committed to maintaining the highest standards of quality in their products, and the new production line is a testament to this commitment.One of the key features of the new production line is its ability to produce 12mm calcium silicate boards, which are widely used in various construction applications. These boards are known for their high strength, durability, and resistance to fire and moisture, making them an ideal choice for a wide range of construction projects. With the new production line, {} will be able to produce these boards in larger quantities without compromising on quality.The installation of the 12mm Calcium Silicate Board Production Line also represents {}'s contribution to promoting sustainable and environmentally friendly construction practices. The production line is designed to minimize waste and optimize energy usage, reducing the environmental impact of the manufacturing process.In addition to the new production line, {} is also investing in research and development to further improve the quality and performance of their calcium silicate boards. The company is committed to staying ahead of the curve and meeting the evolving needs of the construction industry.The successful installation and operation of the 12mm Calcium Silicate Board Production Line marks a significant milestone for {}. It not only showcases their dedication to innovation and excellence but also positions them as a key player in the market for construction materials.With the new production line now fully operational, {} is ready to meet the increasing demand for high-quality calcium silicate boards and continue to serve their customers with the best products on the market. As the construction industry continues to grow, {} is well-positioned to meet the needs of the market and contribute to the development of sustainable and resilient infrastructure.