Artistic Gypsum Cornice Production Line Price List: A Complete Guide

By:Admin

The artistic gypsum cornice production line pricelist has been unveiled by a renowned company specializing in the manufacturing and distribution of gypsum products. The company, with its commitment to quality and innovation, has introduced a comprehensive range of gypsum cornice production line that is set to revolutionize the industry.

The artistic gypsum cornice production line pricelist offers a wide range of products that cater to the diverse needs of customers. From traditional to contemporary designs, the pricelist includes a variety of cornice profiles, each exuding elegance and sophistication. The company's dedication to providing high-quality products is evident in the meticulous attention to detail and craftsmanship that goes into each piece.

With the artistic gypsum cornice production line pricelist, customers can easily find the perfect cornice to complement their interior design vision. Whether it's for a residential, commercial, or hospitality project, the pricelist offers a multitude of options that can elevate the aesthetic appeal of any space. Additionally, the competitive pricing of the products makes them accessible to a wide range of customers without compromising on quality.

In addition to the pricelist, the company's extensive experience and knowledge in the industry make them a trusted partner for customers seeking expert advice and guidance. With a team of skilled professionals, the company is committed to providing personalized service to ensure that customers find the right products that meet their specific requirements.

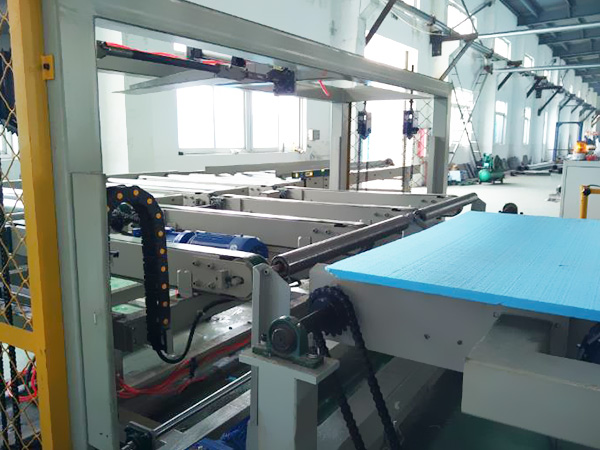

The production line is equipped with state-of-the-art machinery and technology, allowing for efficient and precise manufacturing processes. This ensures that each gypsum cornice produced is of the highest standard and meets the company's stringent quality control measures. Moreover, the company's commitment to sustainability and environmental responsibility is reflected in their use of eco-friendly materials and production methods.

As a leading player in the industry, the company has established a strong reputation for delivering superior products and exceptional customer service. Their dedication to continuous improvement and innovation has enabled them to stay ahead of industry trends and anticipate the evolving needs of their customers.

The unveiling of the artistic gypsum cornice production line pricelist is a testament to the company's unwavering commitment to providing top-notch products and services to their customers. By offering a diverse range of high-quality gypsum cornice products at competitive prices, the company aims to set new standards of excellence in the industry and contribute to the enhancement of interior spaces worldwide.

With the artistic gypsum cornice production line pricelist now available, customers have the opportunity to explore the diverse range of products and make informed decisions based on their specific requirements. The company's dedication to quality, innovation, and customer satisfaction makes them the preferred choice for customers seeking premium gypsum cornice products.

In conclusion, the unveiling of the artistic gypsum cornice production line pricelist signifies a new era of excellence and innovation in the industry. Customers can expect nothing less than superior products, exceptional service, and a commitment to sustainability from the esteemed company.

Company News & Blog

Top Gypsum Board Cornice Automatic Equipment Manufacturers

[Company Name] has become a leading manufacturer of gypsum board cornice automatic equipment, establishing itself as one of the top factories in the industry. With a state-of-the-art production facility and a strong commitment to innovation, the company has been able to consistently deliver high-quality equipment that meets the needs of their customers.The factory, located in [Location], is equipped with cutting-edge technology and advanced machinery, allowing [Company Name] to produce a wide range of gypsum board cornice automatic equipment. This includes everything from cutting and shaping machines to automatic installation and finishing equipment. The company's production process is highly efficient, ensuring that they are able to meet the growing demand for their products while maintaining the highest standards of quality.One of the key factors that sets [Company Name] apart from other factories is their dedication to research and development. The company has a team of experienced engineers and designers who are constantly working to improve their equipment and develop new technologies. This has allowed [Company Name] to stay ahead of the curve in the industry, introducing innovative products that are not only more efficient, but also more environmentally friendly.In addition to their focus on technology and innovation, [Company Name] is also committed to sustainability and responsible manufacturing practices. The factory is designed to minimize waste and energy consumption, and the company is constantly looking for ways to reduce their environmental impact. This commitment to sustainability has earned [Company Name] recognition as a leader in the industry, and has helped them build a strong reputation among their customers and partners.Despite their success, [Company Name] remains focused on providing excellent customer service and support. The company works closely with their clients to understand their specific needs and requirements, and they are able to provide customized solutions that meet these needs. This level of support has helped [Company Name] build long-lasting relationships with their customers, and has contributed to their strong reputation in the industry.Looking to the future, [Company Name] is committed to continuing their growth and development. The company is constantly looking for new opportunities to expand their product line and reach new markets. They are also committed to staying at the forefront of technological advancements, ensuring that they are able to provide their customers with the most innovative and efficient equipment on the market.In conclusion, [Company Name] has established itself as one of the top factories in the industry for gypsum board cornice automatic equipment. With a focus on technology, innovation, and sustainability, the company has been able to deliver high-quality products that meet the needs of their customers. Their commitment to customer service and support has helped them build strong relationships with their clients, and their dedication to growth and development ensures that they will continue to be a leader in the industry for years to come.

Mineral Fiber Suspended Ceiling Tiles for Your Space: All You Need to Know

Suspended ceilings, also known as drop ceilings or false ceilings, have been a popular option for commercial and residential spaces for many years. These ceilings are installed on a metal grid system and can be easily accessed for repairs and maintenance. Suspended ceilings are not only functional, but they are also aesthetically pleasing and offer a wide range of design options.One of the most popular materials for suspended ceiling tiles is mineral fiber. Mineral fiber tiles are made from a blend of natural and synthetic materials, including mineral wool, clay, perlite, and cellulose. These ingredients are mixed together to create a durable, fire-resistant material that is ideal for use in buildings of all kinds.Mineral fiber tiles offer many benefits over other materials. They are highly absorbent, making them ideal for use in acoustically sensitive areas such as conference rooms, lecture halls, and theaters. They also provide excellent thermal insulation, helping to reduce heating and cooling costs.In addition to their functional qualities, mineral fiber tiles are also available in a wide range of designs and finishes to suit any aesthetic preference. They can be painted, printed, embossed, or textured to create a unique and personalized look.When installing suspended ceilings, it is essential to choose the best mineral fiber ceiling tiles machine. This machine is responsible for producing high-quality tiles that meet the required industry standards. A good mineral fiber ceiling tiles machine should be efficient, reliable, and easy to use.There are several factors to consider when selecting a mineral fiber ceiling tiles machine. One of the most critical factors to consider is the production capacity. The machine should be capable of producing a sufficient number of tiles to meet the project's needs.Another important consideration is the level of automation. Automated machines can offer improved efficiency, minimize waste, and reduce labor costs. They may also provide more consistent quality control than manual machines.Ease of use is another vital factor when selecting a mineral fiber ceiling tiles machine. The machine should be easy to operate and maintain, with clear instructions and minimal downtime.In conclusion, mineral fiber suspended ceiling tiles offer many benefits, including durability, insulation, and an aesthetically pleasing appearance. When selecting a mineral fiber ceiling tiles machine, it is crucial to consider factors such as production capacity, automation, and ease of use, to ensure that the machine meets the project's needs and delivers high-quality tiles.

High-Quality Gypsum Ceiling Tiles Machine Prices And Pricelist

In today's competitive market, the demand for efficient and high-quality construction materials is constantly on the rise. This is especially true for materials such as gypsum ceiling tiles, which are an essential component of modern interior design and architecture. As a result, the need for advanced and reliable production machinery, capable of meeting the industry's demands, has never been greater.Enter {}, a leading manufacturer of gypsum ceiling tiles machines. With a solid reputation for innovative technology and superior quality, {} has been at the forefront of the industry for over a decade. The company takes pride in its commitment to excellence, and its products are widely recognized for their durability, precision, and efficiency.One of the key factors that sets {} apart from its competitors is its focus on continuous research and development. The company invests heavily in the latest technologies and production methods, ensuring that its machines are always at the cutting edge of innovation. This dedication to improvement has allowed {} to stay ahead of the curve and provide customers with state-of-the-art solutions that meet and exceed their expectations.In line with its commitment to customer satisfaction, {} offers a comprehensive range of gypsum ceiling tiles machines, tailored to suit different production needs. From small-scale equipment for start-ups and SMEs to large-scale, fully automated production lines for established enterprises, {} has the capacity to cater to a wide spectrum of requirements. This flexibility has made the company a preferred choice for businesses of all sizes, looking to invest in reliable and cost-effective solutions for their manufacturing needs.Moreover, {}'s machines are designed with efficiency and cost-effectiveness in mind. By utilizing the latest technological advancements, the company's equipment is able to optimize production processes, minimize wastage, and reduce overall operational costs. This not only benefits the end-users in terms of savings but also contributes to the sustainable use of resources, making {} a responsible and environmentally conscious partner.To further enhance its customer service, {} provides comprehensive after-sales support, including installation, training, and maintenance services. This ensures that clients can maximize the performance and longevity of their equipment, while also having access to technical assistance whenever needed. In addition, the company's commitment to quality is reflected in its adherence to international standards and certifications, giving customers the reassurance that they are investing in products that meet the highest industry benchmarks.However, one of the most compelling aspects of {}'s offerings is its competitive pricing. The company understands the importance of cost-efficiency in today's business landscape and strives to provide its machines at competitive price points. In fact, {} recently released an updated pricelist for its gypsum ceiling tiles machines, making its products even more accessible to a wider range of customers.The pricelist encompasses the entire range of {}'s machines, catering to different budgets and requirements. Whether it's a manual production line for small-scale operations or a fully automated system for large-scale manufacturing, customers can find a solution that fits their needs without compromising on quality or performance. With {}'s transparent pricing, businesses can make informed decisions and plan their investments with confidence, knowing that they are getting the best value for their money.In conclusion, {}'s gypsum ceiling tiles machines pricelist is a testament to the company's dedication to providing top-tier solutions at affordable rates. Coupled with its reputation for excellence, innovation, and customer-centric approach, {} continues to be a driving force in the industry, empowering businesses to thrive in the competitive market. As the demand for high-quality construction materials continues to grow, {} stands ready to meet the needs of its customers and support their success for years to come.

China-based Manufacturer Offers PVC Imitation Marble Decorative Sheet Making Machine

Kingshine Plastic Machinery: A Leading Manufacturer in ChinaKingshine Plastic Machinery is a leading manufacturer and supplier of high-quality plastic machinery and equipment. The company is based in China and has over 10 years of experience in the field of plastic machinery. Kingshine Plastic Machinery is committed to providing innovative and cost-effective solutions to customers across the world. In this article, we will focus on one of the company's flagship products, the PVC Imitation Marble Decorative sheet Making Machine.PVC Imitation Marble Decorative sheet Making MachineKingshine Plastic Machinery has introduced its latest product, the PVC Imitation Marble Decorative sheet Making Machine. As per their website, “PVC Imitation Marble Decorative sheet Making Machine is a highly automated manufacturing solution for MS and PC sheets used in various industries.” It is designed to produce sheets with a marble-like finish, which can be used to create decorative panels for a wide range of applications such as flooring, walls, furniture, and more.Features of PVC Imitation Marble Decorative sheet Making MachineThe PVC Imitation Marble Decorative sheet Making Machine is built with the latest technology and state-of-the-art equipment. Some of the features of this machine include:1. High Production Efficiency: The PVC Imitation Marble Decorative sheet Making Machine is capable of producing up to 800 Kg of sheets per hour, making it ideal for large-scale production.2. Versatility: With this machine, users can produce sheets of different sizes and thicknesses depending on their specific needs.3. Easy Operation: The machine is designed for ease of use and requires minimal technical knowledge to operate. It also comes with a user-friendly interface that makes it easier for operators to monitor the production process.4. Energy Efficient: The PVC Imitation Marble Decorative sheet Making Machine is engineered to optimize energy consumption, resulting in significant savings in electricity costs.5. High-Quality Output: The sheets produced by this machine have a marble-like finish, high gloss, and excellent physical properties.Why Choose Kingshine Plastic Machinery?Kingshine Plastic Machinery is a respected name in the plastic machinery industry. The company has been in business for over a decade and has built a reputation for providing high-quality machinery and excellent customer service. Some of the reasons to choose Kingshine Plastic Machinery include:1. Exceptional Quality: All Kingshine Plastic Machinery products are made with high-quality materials and are designed to meet or exceed industry standards.2. Custom Solutions: Kingshine Plastic Machinery understands that every customer has unique needs. As such, the company offers customized machinery solutions tailored to individual customer requirements.3. Competitive Prices: Kingshine Plastic Machinery offers high-quality products at competitive prices, making them an affordable option for businesses of all sizes.4. Excellent Customer Support: The company has a team of knowledgeable and experienced professionals who provide excellent customer support to clients, from initial inquiries to after-sales support.ConclusionThe PVC Imitation Marble Decorative sheet Making Machine is one of the latest offerings from Kingshine Plastic Machinery. With its high production efficiency, versatility, and ease of use, this machine is an excellent investment for businesses seeking to manufacture high-quality sheets for various decorative applications. As a leading manufacturer of plastic machinery, Kingshine Plastic Machinery provides innovative and cost-effective solutions to clients across the world. To learn more about the PVC Imitation Marble Decorative sheet Making Machine and Kingshine Plastic Machinery, visit their website.

Efficient T-Ceiling Roll Forming Machine for Gypsum Board Panel Production

If you are planning to renovate or build a new home or office, you are probably wondering how to choose the best type of ceiling for your space. One of the most popular choices for ceilings is gypsum board, also known as drywall or plasterboard. It is a versatile and affordable material that can be shaped into many styles and patterns to suit any interior design scheme.If you are looking for a reliable and efficient way to produce gypsum board ceilings, you should consider investing in a gypsum board frame T-grid roll forming machine. This type of machine is specially designed to produce high-quality and precise gypsum board T-grids, which are the supporting elements that hold the gypsum panels in place.Gypsum board frame T-grid roll forming machines are widely used in decoration gypsum ceiling board machine factories, as they offer many advantages over traditional manufacturing methods. One of the main benefits of using a roll forming machine is that it allows for continuous production, which means higher output and faster delivery times.Moreover, T-grids produced by a gypsum board frame T-grid roll forming machine are extremely accurate and consistent in size and shape, which ensures a perfect fit between the grid and the gypsum panels. This is especially important for large-scale projects where minor deviations can make a big difference in the overall appearance and stability of the ceilings.Another advantage of using a gypsum board frame T-grid roll forming machine is that it offers a high level of flexibility and customization. The machine can be easily adjusted to produce T-grids of different dimensions, shapes, and patterns, depending on the specific requirements of the project. This means that you can create unique and creative ceiling designs that are tailored to your clients' needs and preferences.When choosing a gypsum board frame T-grid roll forming machine, it is important to look for a reliable and experienced manufacturer that can provide you with the best quality equipment and technical support. A good manufacturer should have a team of skilled engineers and technicians who can help you with installation, training, and maintenance services, as well as offer customized solutions to meet your specific production needs.In conclusion, a gypsum board frame T-grid roll forming machine is an essential tool for any decoration gypsum ceiling board machine factory that produces gypsum board ceilings. With its high efficiency, accuracy, and flexibility, it can help you achieve excellent results and meet your clients' expectations. If you want to take your business to the next level, investing in a roll forming machine could be the best decision you ever make.

Highly Efficient Gypsum Ceiling Board Production Line for Manufacturing

Gypsum Ceiling Board Production Line Revolutionizes Manufacturing ProcessIn the world of manufacturing, innovation is key to staying ahead of the competition. This is especially true in the production of gypsum ceiling boards, where efficiency and quality are paramount. As such, the introduction of the Gypsum Ceiling Board Production Line by [Company Name] has caused a significant stir in the industry.[Company Name] is a leading manufacturer of gypsum board production equipment, with a strong reputation for quality and innovation. The company has been at the forefront of the industry for many years, and their latest offering, the Gypsum Ceiling Board Production Line, is yet another example of their commitment to advancing the manufacturing process.The Gypsum Ceiling Board Production Line is a state-of-the-art system that is designed to automate and streamline the production of gypsum ceiling boards. It is capable of producing a wide range of board sizes and thicknesses, and can also be customized to meet the specific needs of different manufacturers. This level of flexibility is a key feature of the production line, as it allows manufacturers to tailor their production process to their exact requirements.One of the most impressive aspects of the Gypsum Ceiling Board Production Line is its efficiency. The system is capable of producing a large volume of boards in a relatively short amount of time, without sacrificing on quality. This is achieved through the use of advanced technology and precision engineering, which ensures that each board is of the highest standard.In addition to its efficiency, the Gypsum Ceiling Board Production Line also offers a number of environmental benefits. The system is designed to minimize waste and reduce energy consumption, making it a sustainable choice for manufacturers who are looking to reduce their environmental impact. This is in line with [Company Name]'s commitment to sustainability, and is a key selling point for the production line.Another advantage of the Gypsum Ceiling Board Production Line is its ease of use. The system is designed to be user-friendly, with a simple and intuitive interface that makes it easy for operators to control and monitor the production process. This not only increases productivity, but also reduces the need for extensive training, making it an accessible option for manufacturers of all sizes.The introduction of the Gypsum Ceiling Board Production Line is a significant development for the industry, and one that is sure to have a lasting impact. By combining advanced technology, efficiency, and sustainability, [Company Name] has once again proven itself to be a leader in the field of gypsum board production equipment. With this latest offering, manufacturers can expect to see improvements in their production processes, as well as their bottom line.Overall, the Gypsum Ceiling Board Production Line by [Company Name] represents a new era in manufacturing, one that is characterized by innovation, efficiency, and sustainability. This is a system that has the potential to revolutionize the industry, and one that is sure to be welcomed by manufacturers around the world. As the demand for high-quality gypsum ceiling boards continues to grow, the introduction of this advanced production line could not have come at a better time.

Latest Technology for Producing Fireproof Magnesium Oxide Board

Fireproof Magnesium Oxide Board Machine: Revolutionizing Construction IndustryIn recent years, the demand for fireproof building materials has been on the rise, and one company at the forefront of meeting this demand is {Company Name}. Their innovative Fireproof Magnesium Oxide Board Machine is revolutionizing the construction industry by providing a reliable and sustainable solution for building safer and more durable structures.{Company Name} is a leading manufacturer of construction machinery and equipment. With years of experience and a commitment to innovation, they have developed a state-of-the-art Fireproof Magnesium Oxide Board Machine that is changing the way buildings are constructed. The machine is designed to produce fireproof magnesium oxide boards, which are becoming increasingly popular in the construction industry due to their superior fire resistance and durability.The Fireproof Magnesium Oxide Board Machine is a result of extensive research and development by {Company Name}’s team of engineers and experts in the field of construction materials. The machine is equipped with advanced technology and automation, allowing for efficient and precise production of fireproof magnesium oxide boards. This not only ensures high-quality output but also increases productivity and reduces production costs.The use of fireproof magnesium oxide boards in construction offers numerous benefits. Unlike traditional building materials such as wood or drywall, magnesium oxide boards are non-combustible and can withstand high temperatures, making them an ideal choice for fire-resistant construction. Additionally, these boards are highly durable and resistant to water, mold, and impact, making them suitable for a wide range of applications in both residential and commercial buildings.The Fireproof Magnesium Oxide Board Machine from {Company Name} is also environmentally friendly, as it utilizes sustainable and recyclable materials in the production process. This aligns with the growing trend towards sustainable and eco-friendly construction practices, making the machine a preferred choice for environmentally conscious builders and developers.Furthermore, {Company Name} offers comprehensive customer support and training for the Fireproof Magnesium Oxide Board Machine, ensuring that their clients are equipped with the necessary knowledge and expertise to operate the machine efficiently. This commitment to customer satisfaction has made {Company Name} a trusted partner for construction companies and developers worldwide.As the demand for fireproof building materials continues to grow, the Fireproof Magnesium Oxide Board Machine from {Company Name} is well-positioned to meet this demand and make a significant impact on the construction industry. With its cutting-edge technology, sustainable approach, and exceptional performance, the machine is set to revolutionize the way buildings are constructed, offering a safer and more sustainable alternative to traditional building materials.In conclusion, the Fireproof Magnesium Oxide Board Machine from {Company Name} represents a significant advancement in construction technology, offering a reliable and sustainable solution for the growing demand for fireproof building materials. With its innovative design, advanced features, and commitment to customer satisfaction, the machine is poised to make a lasting impact on the construction industry, paving the way for safer and more durable buildings in the future.

High Quality PVC Laminated Gypsum Ceiling Board - 595*595 603*603mm

On May 15, 2021, a new product was launched by a renowned construction materials company, a PVC laminated gypsum board that has gained significant attention in the market. This new product promises to revolutionize the construction industry and serve as an answer to the demand for innovative and quality materials.The PVC laminated gypsum board, available in two standard sizes- 595*595mm and 603*603mm, is designed to meet the needs of builders and architects looking to create an exquisite and elegant interior design for their projects. This gypsum ceiling tile is made from high-quality paper-faced gypsum board and then laminated with PVC materials.The PVC laminate on the board provides a smooth and uniform surface while no dust will be generated during the installation process, which makes it a clean and simple installation option. This feature saves time and allows the builders to achieve excellent coverage with low costs, making the PVC laminated gypsum board more reasonable in pricing than other similar products available in the market.The PVC laminated gypsum board offers a durable finish with excellent finish coordination for the entire design scheme. Its waterproof and fire resistance properties make it suitable to install in areas with a high risk of moisture and fire, such as kitchens and bathrooms, medical facilities, and laboratories.Additionally, it is designed to provide insulation, which limits the spread of noise throughout the building, making it ideal for commercial and residential buildings. Its unique surface characteristic reduces the effect of impact sounds and eliminates any problems of sound reverberation providing a comfortable interior space for customers.This new building material solution is also highly customizable, and therefore ideal for creative and artistic designs, which open up new possibilities for building interiors. This means that it is possible to achieve any desired appearance, whether traditional or modern, bright or subtle, matt or glossy, by choosing from a wide range of colors, patterns, and finishes. As a result, it is perfect for use in a range of environments, including luxurious hotel rooms, sport centers, offices, shopping malls, and government buildings. The PVC laminated gypsum board has passed numerous environmental tests, and has been certified as a green material, meaning that it is safe for both builders and customers. It is made from natural resources, which make it a sustainable option for future generations while also meeting the LEED requirements for green building construction standard.The launch of the PVC laminated gypsum board is a significant milestone for the building construction industry. The availability of such a high-quality material that meets all the needs and functions required of today's modern interior design has to come as a welcome development. The advance technology and creativity that went into developing this building material are evident in its outstanding features and design quality, which makes it suitable for a wide range of applications.In conclusion, the PVC laminated gypsum board is a game-changer not only for interior design but also for sustainable building construction. It offers impressive benefits with its durability, waterproofing properties, insulations, and ability to reduce noise and fire hazards making it a perfect choice for builders, architects, and homeowners alike. If you want a building material for your project that combines affordability, superior quality, and sustainability, then the PVC laminated gypsum board is the right choice for you.

High-Quality Lamination Machines for Gypsum Board Glue Spreading and mgo Board Lamination Production in China

China's industrial landscape is constantly evolving, with a host of manufacturers and suppliers emerging in different sectors of the industry. In recent years, the Chinese manufacturing industry has seen a significant surge in demand for high-quality laminating equipment and machinery.Amid this market growth, China is emerging as a frontrunner in the laminating machinery and equipment space. In particular, the creation of high-quality Gypsum Board Glue Spreading Board and MgO Board Lamination Machines is a testament to the country's manufacturing prowess.The Gypsum Board Glue Spreading Board and MgO Board Lamination Machines are being manufactured using advanced technology and innovative techniques that are highly efficient, reliable, and durable. These machines are designed to be easy to operate and maintain, making them ideal for businesses that need to increase their production capacity. Additionally, the machines are also very versatile, meaning they can be used in a wide range of industrial settings. This flexibility has made them popular with entrepreneurs looking to start manufacturing businesses in various sectors.The Gypsum Board Glue Spreading Board and MgO Board Lamination Machines are also designed to ensure that they operate safely and securely on the production floor. Each machine is fitted with modern safety features that guarantee protection to operators and other employees working in the production system. These safety features include automatic shut-offs, alarms, and other safety measures that prevent accidents and reduce the risk of injury.Companies producing these laminating machines adhere to strict quality control guidelines to ensure they comply with international safety and quality standards. Each machine is tested comprehensively to guarantee that they meet the required standards before they are released to the market.The manufacturers of Gypsum Board Glue Spreading Board and MgO Board Lamination Machines in China take pride in their products. With a keen focus on innovative technology and high-quality standards, these manufacturers provide businesses with reliable and long-lasting machines to enhance their production capabilities.The success of these machines in the global market has led to a significant increase in demand. As a result, manufacturers have been optimizing their production capacity to keep up with the ever-growing demand for these machines. Many businesses from around the world are sourcing their laminating machinery from China to benefit from high-quality machines.The Chinese producer of the laminating machines, which earned significant success in recent years, has been producing some of the most cutting-edge industrial machinery through advanced manufacturing procedures and techniques. Their Gypsum Board Glue Spreading Board and MgO Board Lamination Machines are some of the most advanced and reliable products on the market.These machines are designed to offer exceptional versatility, safety, and reliability, making them ideal for businesses of all sizes. Whether it is a small startup or a large conglomerate, these lamination machines can optimize productivity and enhance manufacturing operations.In conclusion, the Gypsum Board Glue Spreading Board and MgO Board Lamination Machines from China are an excellent testimony to the country’s continued excellence in the manufacturing industry. These laminating machines deliver exceptional quality and performance, guaranteeing long-lasting reliability and ease of operation. With surging demand for these machines globally, China is set to continue its dominance in the machinery and equipment manufacturing industry for the foreseeable future.

Top-Performing Laminated Gypsum Board Machine for PVC Production

Title: Leading Manufacturer Introduces Cutting-Edge PVC Laminated Gypsum Board MachineIntroduction:As the construction industry continues to evolve, innovative technologies and machinery are paramount to meet the demands of modern architecture. One such breakthrough is the introduction of the best PVC laminated gypsum board machine by a renowned industry leader. With a strong reputation for excellence and expertise, this company is set to revolutionize the manufacturing process of gypsum boards.I. Overview of the CompanyWith decades of experience, the company has become a prominent player in the construction machinery industry. Their commitment to high-quality products, advanced research, and customer satisfaction has earned them a global reputation. The company's state-of-the-art manufacturing facilities, coupled with their vast knowledge pool, have allowed them to consistently produce cutting-edge machinery solutions.II. The Need for PVC Laminated Gypsum Board MachineGypsum boards are widely used in interior construction due to their excellent fire resistance, acoustic properties, and ease of installation. However, traditional gypsum boards often required additional surface treatments, such as painting or wallpapering. To overcome these shortcomings and provide enhanced aesthetic options, the introduction of PVC laminated gypsum board machine was necessary.III. Features and AdvantagesThe newly introduced PVC laminated gypsum board machine offers a host of innovative features, making it an indispensable solution in the construction industry. Some key features and advantages include:1. Enhanced Efficiency: The machine incorporates cutting-edge technology that ensures high-speed production without compromising quality. This enables manufacturers to meet customer demands promptly and stay competitive in the market.2. Precision and Accuracy: With advanced automation and intelligent control systems, the machine guarantees precise cutting, laminating, and edge banding, resulting in perfectly finished gypsum boards.3. Wide Range of Designs: The machine allows for the lamination of various PVC designs, giving manufacturers the flexibility to cater to a diverse range of architectural styles and preferences. This enables customization options to meet the unique requirements of each project.4. Cost-effective Solution: By eliminating the need for additional surface treatments like painting or wallpapering, the PVC laminated gypsum board machine significantly reduces labor and material costs. This cost-effectiveness benefits both manufacturers and end-users in the long run.IV. Commitment to SustainabilityIn an era where environmental consciousness is paramount, the company takes sustainability seriously. The PVC laminated gypsum board machine is designed with energy-efficient mechanisms, reducing both energy consumption and carbon emissions during the manufacturing process. Additionally, the machine supports the use of eco-friendly materials, contributing to a more sustainable construction industry.V. Advancements in Research and DevelopmentThe company prioritizes research and development to continuously improve their machinery. Regular investment in cutting-edge technologies and continuous feedback from industry professionals help them stay ahead in the market. This commitment to innovation ensures that customers receive the latest and most efficient solutions for their manufacturing needs.VI. Global Market ReachRecognizing the importance of international expansion, the company has established a strong global network, making their products easily accessible to manufacturers worldwide. With a dedicated after-sales support team and comprehensive training programs, the company ensures efficient installation and smooth operation of the PVC laminated gypsum board machine for all its customers.Conclusion:As construction projects become increasingly sophisticated, the introduction of the best PVC laminated gypsum board machine by this renowned company is a game-changer. Its advanced features, efficiency, and commitment to sustainability are set to reshape the manufacturing process, providing manufacturers with the tools they need to meet the evolving demands of the construction industry. With their extensive global reach and unwavering focus on customer satisfaction, this leading manufacturer is cementing their position as an industry innovator.