Aluminum Punching Ceiling Panel Suppliers in China: Find the Best Deals

By:Admin

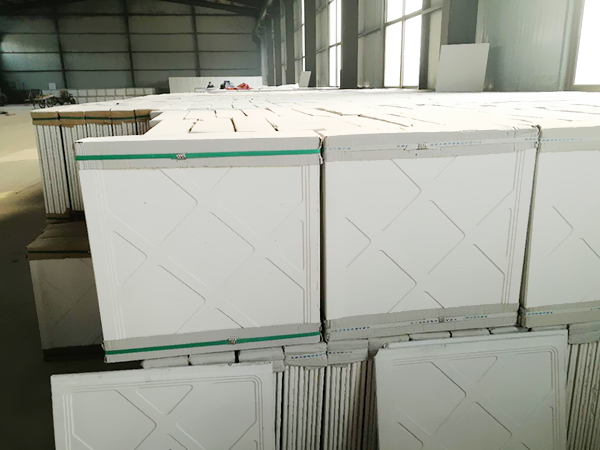

The company's manufacturing facility is equipped with state-of-the-art technology and machinery, allowing them to produce a wide range of aluminum punching ceiling panels that meet the highest standards of quality and reliability. Their team of skilled engineers and technicians work tirelessly to ensure that each panel meets the specific requirements and preferences of their customers.

The aluminum punching ceiling panels offered by China Aluminum Punching Ceiling Panel Suppliers are available in a variety of sizes, designs, and finishes, making them suitable for a wide range of applications. Whether it's for commercial, residential, or industrial use, the company has the capability to fulfill the diverse needs of its clients.

One of the key features of the aluminum punching ceiling panels manufactured by China Aluminum Punching Ceiling Panel Suppliers is their exceptional durability and longevity. Made from high-grade aluminum, these panels are corrosion-resistant and can withstand harsh environmental conditions, making them ideal for both indoor and outdoor use.

In addition to their durability, the ceiling panels are also known for their aesthetic appeal. The punching patterns and designs on the panels are meticulously crafted to enhance the visual appeal of any space. Whether it's for a modern office environment, a stylish retail outlet, or a contemporary residential setting, the panels can add a touch of elegance and sophistication to the interior.

Furthermore, the aluminum punching ceiling panels offered by China Aluminum Punching Ceiling Panel Suppliers are easy to install and maintain. With their lightweight construction and simple installation process, they can be quickly and efficiently installed, saving time and labor costs. Additionally, the panels are easy to clean and maintain, ensuring that they retain their pristine appearance for years to come.

The company prides itself on its commitment to customer satisfaction. They work closely with their clients to understand their specific needs and preferences, providing tailored solutions that meet their exact requirements. By maintaining open communication and a collaborative approach, China Aluminum Punching Ceiling Panel Suppliers has built long-lasting relationships with their clients, earning their trust and loyalty.

In terms of quality assurance, the company adheres to strict quality control measures throughout the production process. From the selection of raw materials to the final inspection of finished products, every step is carefully monitored to ensure that the aluminum punching ceiling panels meet the highest standards of quality and performance.

Moreover, China Aluminum Punching Ceiling Panel Suppliers places a strong emphasis on environmental sustainability. Their manufacturing processes are designed to minimize waste and reduce energy consumption, aligning with their commitment to eco-friendly practices. By choosing their products, customers can contribute to a greener future while benefiting from the superior quality of the aluminum punching ceiling panels.

With a strong focus on innovation and continuous improvement, China Aluminum Punching Ceiling Panel Suppliers strives to stay ahead of the competition and set new industry standards. They invest in research and development to explore new technologies and design concepts, allowing them to introduce cutting-edge products that cater to the evolving needs of the market.

In conclusion, China Aluminum Punching Ceiling Panel Suppliers stands as a reliable and reputable provider of aluminum punching ceiling panels. With a dedication to excellence, a focus on customer satisfaction, and a commitment to innovation, the company continues to elevate the standard of ceiling solutions in the industry. Whether for commercial, residential, or industrial applications, customers can trust that they will receive top-quality products and exceptional service from China Aluminum Punching Ceiling Panel Suppliers.

Company News & Blog

Top Automatic Factories Producing the Best Gypsum Cornice Designs

Gypsum cornices have been used as a decorative element for centuries. They add elegance and character to any interior space. However, manually producing these ornate designs is a time-consuming and difficult process. To overcome this challenge, several automatic equipment factories have been established. Among these, one of the best gypsum cornice design automatic equipment factories is located in China.This factory, which shall remain unnamed for confidentiality reasons, specializes in the manufacture of gypsum cornice molding machines. With its highly advanced technology, this factory has gained popularity among its customers for its efficiency and quality. The automatic equipment produced by this factory is used in the production of gypsum cornices, which are widely used in interior decoration.The gypsum cornice molding machine produced by this factory is fully automatic and operates with high precision. This equipment eliminates the manual labor and production errors that often occur in traditional methods. In addition, the machine has a high production capacity which means that it can produce a large number of gypsum cornices in a shorter time without sacrificing quality.The factory uses high-quality raw materials to manufacture its machinery. The machines are made of sturdy materials that ensure the long life span of the production equipment. The factory also has strict quality control measures in place during the production process. This quality control ensures that the machinery produced is of the highest standard.The gypsum cornice molding machine produced by this factory can produce various designs and sizes of gypsum cornices. The machine can produce classic, contemporary, and customized designs. This production flexibility makes it an ideal solution for contractors and designers seeking a customizable finishing touch to their projects.The factory also provides training and after-sales services to its clients. This support ensures that clients can use the equipment properly and efficiently. It also provides assistance if there are any issues with the equipment.The gypsum cornices produced using the automatic equipment from this factory are in high demand across the world. The cornices produced are of superior quality and are used in various settings, including commercial, residential, and public spaces. The gypsum cornice design automatic equipment factory is known for its commitment to excellence and innovation. The use of technology to produce gypsum cornices has revolutionized the industry, and this factory is leading the way in this expansion of the industry.The factory's commitment to quality and innovation has made it a leader in the industry. The use of automatic equipment has made the production process efficient and cost-effective. The factory has been able to provide quality products to the market at competitive prices. This commitment to quality has earned the factory a strong reputation and a loyal customer base.The use of gypsum cornices in interior design is growing, and this factory is poised to take advantage of this upward trend. With its state-of-the-art technology and commitment to quality, this factory is positioned to remain as a leader in the industry for many years to come.In conclusion, the best gypsum cornice design automatic equipment factory, located in China, is using advanced technology to produce high-quality gypsum cornices. Their commitment to excellence and innovation has made them a leader in the industry. Their machines are efficient, cost-effective, and produce superior quality gypsum cornices. Their dedication to quality and service has earned them a loyal customer base. They have positioned themselves to remain at the forefront of the industry, contributing to the growth of the gypsum cornice industry.

High-Quality Mineral Fiber Sheet Board Manufacturing Machine Ready for Market Launch

Mineral Fiber Sheet Board Machine Introduced by Leading ManufacturerThe recent launch of the Mineral Fiber Sheet Board Machine by one of the leading manufacturing companies has drawn attention from different industries. The new machine is designed to produce high-quality mineral fiber sheet boards that can be used in various applications.The Mineral Fiber Sheet Board Machine is the latest addition to the company's line of reliable and efficient equipment for the construction and building industries. This new machine is expected to revolutionize the production process for mineral fiber sheet boards, making it faster, more cost-effective, and more environmentally friendly.According to the manufacturer, the Mineral Fiber Sheet Board Machine is a state-of-the-art piece of machinery that combines advanced technology and superior design to produce high-quality material. The machine is equipped with the latest control systems, ensuring precise and consistent manufacturing of the products.The company spokesperson mentioned that the Mineral Fiber Sheet Board Machine uses natural and eco-friendly raw materials, making it a sustainable and environment-friendly solution for the construction industry. The manufacturing process involves the use of wool, clay, and other natural materials, which are mixed and formed into sheets to make the final product. This innovative process significantly reduces the carbon footprint of the manufacturing process.With the Mineral Fiber Sheet Board Machine, the company is committed to providing its customers with a reliable and efficient solution for their mineral fiber board needs. The machine is designed to cater to the needs of all sizes of businesses, from small workshops to large-scale manufacturing plants.The spokesperson also mentioned that the new machine is an ideal investment for businesses looking to upgrade their production processes and take advantage of the growing demand for high-quality mineral fiber sheet boards. The machine's advanced features and intuitive design make it easy to operate and maintain, reducing downtime and increasing productivity.The Mineral Fiber Sheet Board Machine's launch is timely, considering the ever-increasing demand for eco-friendly and sustainable building materials, driven by the need to reduce carbon emissions and protect the environment. This new product demonstrates the company's commitment to innovation and sustainability, helping its customers meet the expectations of their clients while reducing their environmental impact.The manufacturer is dedicated to providing its clients with excellent customer service, including after-sales support, training, and maintenance. They understand that investing in new equipment can be challenging, and therefore they ensure that their clients receive the necessary support to operate the machines efficiently.In conclusion, the Mineral Fiber Sheet Board Machine by the leading manufacturing company is a game-changer in the production of eco-friendly and sustainable building materials. With its advanced features and intuitive design, the machine is a reliable and efficient solution for businesses looking to upgrade their production process. The innovative manufacturing process reduces the carbon footprint while delivering high-quality products that meet the expectations of clients across different industries. The Mineral Fiber Sheet Board Machine is an excellent investment for businesses, providing long-term benefits and contributing to a more sustainable future.

High-Quality Fiber Optic Star Ceiling Panels for Moon Shooting - FCC Approved, 15W Power, 600*600mm Size

China is known for its phenomenal innovation and technological advancements. In recent times, it has been making immense strides with the production of high-quality PMMA 15W Fiber Optic Star Ceiling Panels 600*600mm FCC for moon shooting. These products are second to none with their excellent quality and strict quality control.Leading Fiber Optic Star Ceiling Panels factories have been working tirelessly to ensure that their products meet the high standards of tech enthusiasts and professionals in the industry. With this, they have been producing highly efficient and reliable PMMA 15W Fiber Optic Star Ceiling Panels, designed specifically for moon shooting.The star ceiling panels are rated 15W and are made from Polymethyl methacrylate (PMMA), a highly durable and versatile material that is commonly used to produce high-tech products. The panels are excellent for providing accurate and reliable fiber optic lighting without the need for electricity, making them an eco-friendly lighting solution.The PMMA 15W Fiber Optic Star Ceiling Panels have been particularly successful in moon shooting projects, where the clarity and accuracy of the lighting are critical. They produce a stunning starlight effect that is ideal for creating the illusion of a starry sky, perfect for filming and photography.One of the greatest advantages of using these star ceiling panels is the fact that they do not emit any heat, making them an ideal solution for sensitive lighting projects, such as those required in the filming or photography industry. In addition, the PMMA material used in their production ensures that they are highly durable and long-lasting.China's leading Fiber Optic Star Ceiling Panels product market has been at the forefront of innovating and producing top-quality star ceiling panels, among other high-tech products. With their neck for excellence and their focus on maintaining strict quality control, they have managed to establish themselves as market leaders, providing clients with reliable and efficient products for their lighting needs.In conclusion, PMMA 15W Fiber Optic Star Ceiling Panels 600*600mm FCC for moon shooting from China are some of the most innovative and reliable lighting solutions on the market today. Their high-quality production and strict quality control ensure that they are long-lasting and efficient, making them the perfect fit for any sensitive lighting project. Well done, China, for yet another remarkable achievement in the technological world.

Find Quality Mineral Fiber Sheet Board Machine at Competitive Prices

Mineral Fiber Sheet Board Machine Pricelist Unveiled by Leading Manufacturer{Company Name}, a renowned manufacturer of industrial machinery and equipment, has recently announced the release of its latest mineral fiber sheet board machine pricelist. This new addition to the company's product lineup is set to provide customers with a high-quality and efficient solution for producing mineral fiber sheet boards.{Company Name} has a strong reputation in the industry for delivering cutting-edge machines that offer superior performance and reliability. With an extensive experience in the manufacturing of industrial equipment, the company has solidified its position as a trusted and innovative supplier to various sectors including construction, building materials, and manufacturing.The mineral fiber sheet board machine pricelist release comes as a response to the increasing demand for advanced machinery in the production of mineral fiber sheet boards. As the construction and building materials market continues to expand, there is a growing need for efficient and cost-effective solutions to meet the demands of this thriving industry.The new mineral fiber sheet board machine from {Company Name} is designed to meet the specific requirements of manufacturers looking to enhance their production capabilities. The machine boasts advanced features and cutting-edge technology that ensure the production of high-quality mineral fiber sheet boards with consistent results.One of the key highlights of the mineral fiber sheet board machine is its efficient production process, which allows for increased output while maintaining high levels of precision and quality. This is made possible through the integration of state-of-the-art automation and control systems, as well as durable and reliable components that are designed to withstand the rigors of continuous operation.In addition to its superior performance, the mineral fiber sheet board machine also offers a user-friendly interface and intuitive operation, making it easy for operators to set up and manage the production process. This streamlined operation not only enhances productivity but also minimizes the need for manual intervention, thereby reducing the risk of errors and ensuring consistent output.Furthermore, {Company Name} has emphasized the importance of affordability and cost-effectiveness in the development of the mineral fiber sheet board machine. By optimizing the design and engineering of the machine, the company has successfully managed to offer a competitive pricing structure without compromising on the quality and performance of the equipment.The unveiling of the mineral fiber sheet board machine pricelist demonstrates {Company Name}'s commitment to meeting the evolving needs of its customers and the market. By providing a comprehensive solution for mineral fiber sheet board production, the company aims to support manufacturers in achieving their production goals while maintaining high standards of quality and efficiency.The release of the mineral fiber sheet board machine pricelist is expected to generate significant interest from companies operating in the construction, building materials, and manufacturing sectors. With its proven track record of delivering reliable and innovative machinery, {Company Name} is poised to strengthen its position as a leading supplier of industrial equipment in the global market.In summary, {Company Name} has introduced its latest mineral fiber sheet board machine pricelist, catering to the increasing demand for advanced production solutions in the construction and building materials industry. With its focus on performance, reliability, and affordability, the company is set to provide customers with a competitive edge in their production operations, solidifying its position as a trusted and innovative supplier of industrial machinery.

Get the Latest Updates on Certified Plasterboard Ceiling Machines

CE Certification Plasterboard Ceiling Machine Ensuring Quality and Efficiency in Construction Industry[City, Date] – In an era where technological advancements play a significant role in improving efficiency and quality, the introduction of the CE Certification Plasterboard Ceiling Machine by [Company Name] is revolutionizing the construction industry. This state-of-the-art machine is equipped with cutting-edge features, granting construction companies easy access to high-quality plasterboard ceiling production.The CE certification is testament to the machine's adherence to European safety, health, and environmental protection standards. With this certification, [Company Name] demonstrates their commitment to providing reliable and safe equipment, ensuring the utmost satisfaction for their customers.The plasterboard ceiling machine allows construction companies to streamline their production processes, significantly reducing time and labor costs. With its advanced automation capabilities, this machine eliminates the need for manual intervention, resulting in enhanced efficiency and precision. [Company Name], a renowned manufacturer with expertise in construction machinery, has developed this machine to meet the diverse needs of the construction sector.Key Features of the CE Certification Plasterboard Ceiling MachineThe innovative and intelligent design of the plasterboard ceiling machine offers numerous features that make it a standout product in the market. These features include:1. High-Speed Production: The advanced automation system allows the machine to produce plasterboard ceilings at an impressive speed, significantly increasing overall productivity.2. Accurate Measurements: Equipped with precise measurement mechanisms, the machine ensures the outputted plasterboard ceilings meet the required specifications, eliminating rework and wastage.3. Easy Operation: The user-friendly interface of the machine enables effortless operation, reducing the need for specialized training and facilitating the smooth integration of the machine into existing production lines.4. Enhanced Durability: The plasterboard ceiling machine is designed and manufactured with robust and durable materials, providing longevity and reliability for years, reinforcing its status as a wise investment for construction companies.5. Customization Options: [Company Name] acknowledges the diverse needs of their customers. To cater to these requirements, the machine offers customization options, allowing construction companies to produce plasterboard ceilings of various sizes, shapes, and designs.[Company Name] – Industry Leader in Construction MachineryWith a strong presence in the construction machinery sector, [Company Name] has been consistently delivering high-quality and reliable equipment to customers worldwide. The introduction of the CE Certification Plasterboard Ceiling Machine further solidifies their position as an industry leader.[Company Name] values customer satisfaction and ensures that their machines go through rigorous quality checks at every stage of production. By adhering to international standards and cultivating an environment of constant innovation, [Company Name] excels at providing cutting-edge solutions that meet the evolving needs of the construction industry.The company's commitment to research and development, coupled with its extensive expertise, has allowed them to introduce an array of construction machinery that caters to various construction needs. These products have gained recognition for their reliability, efficiency, and cost-effectiveness.ConclusionThe CE Certification Plasterboard Ceiling Machine by [Company Name] is set to bring a wave of transformation to the construction industry. With its advanced features, commitment to quality, and compliance with international standards, construction companies can guarantee enhanced productivity and efficiency in plasterboard ceiling production.[Company Name] continues to be a frontrunner in providing construction machinery that meets the highest industry standards. Embracing innovation and quality, they reaffirm their dedication to assisting companies in achieving excellence in construction projects.

High-Quality Lightweight Wall Panel MGO Board Door Manufacturing Machinery for Magnesium Oxide Main Material

High-Volume Gypsum Ceiling Board Pvc Laminating Machine for Sale - 6 Million Sqm Capacity

6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine to be Unveiled by Leading Manufacturer[Manufacturer’s Name], a renowned leader in the manufacturing of advanced machinery for the construction industry, is set to unveil its latest innovation – the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine. This cutting-edge equipment is poised to revolutionize the production of gypsum ceiling boards, offering unprecedented efficiency and quality.The new machine, boasting an impressive 6 million square meter capacity, is designed to meet the growing demand for high-quality gypsum ceiling boards in the construction sector. It is equipped with state-of-the-art technology that enables precise lamination of PVC onto gypsum boards, ensuring a flawless finish and enhanced durability.[Manufacturer’s Name] has always been at the forefront of innovation in the construction machinery industry, and the introduction of the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine is a testament to the company's commitment to delivering advanced solutions to its customers. With a focus on automation and efficiency, this new machine is set to streamline the production process for manufacturers of gypsum ceiling boards, allowing them to meet market demands with ease.In addition to its impressive capacity, the new machine is also equipped with advanced features that ensure optimal performance. An intelligent control system allows for precise adjustment of lamination parameters, ensuring consistent quality across all products. The machine is also designed for easy maintenance, minimizing downtime and maximizing productivity for the end user.Moreover, [Manufacturer’s Name] takes pride in its dedication to sustainability, and the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine is no exception. The equipment is designed to minimize energy consumption and waste generation, aligning with the company's commitment to environmentally-friendly manufacturing practices.The unveiling of this new machine comes at a time when the construction industry is experiencing rapid growth, with increasing demand for high-quality building materials. With the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine, [Manufacturer’s Name] aims to empower manufacturers to meet this demand effectively, without compromising on quality or efficiency.In anticipation of the launch, [Manufacturer’s Name] is set to showcase the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine at several upcoming industry events, offering potential customers the opportunity to experience its capabilities firsthand. The company is confident that the new machine will garner significant interest from construction businesses looking to enhance their production capabilities.As a leading manufacturer of construction machinery, [Manufacturer’s Name] continues to set the standard for innovation and quality in the industry. The introduction of the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine is yet another demonstration of the company's commitment to pushing the boundaries of what is possible in construction technology.In conclusion, the unveiling of the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine marks a significant milestone for [Manufacturer’s Name] and the construction industry as a whole. With its advanced capabilities and commitment to sustainability, the new machine is set to redefine the production of gypsum ceiling boards, setting a new standard for efficiency and quality in the market. [Manufacturer’s Name] looks forward to the opportunities and advancements this innovation will bring to the construction industry.

Top Perforated Plasterboard Machine Factory: A Comprehensive Overview

The Best Perforated Plasterboard Machine Factory is a leading manufacturer and supplier of plasterboard machinery, specializing in the production of perforated plasterboard machines. With a strong focus on quality, innovation, and customer satisfaction, the factory has established itself as a reliable and trusted partner for businesses in the construction industry.With decades of experience in the industry, the factory has developed a deep understanding of the needs and requirements of its customers. This has enabled them to continuously innovate and improve their product offerings, providing solutions that are not only efficient and reliable but also cost-effective. The factory's commitment to excellence is also reflected in its state-of-the-art facilities and strict quality control processes, ensuring that every machine that leaves their premises meets the highest standards of quality and performance.One of the key features that sets the Best Perforated Plasterboard Machine Factory apart from its competitors is its dedication to research and development. The factory invests heavily in the latest technologies and employs a team of highly skilled engineers and technicians who are constantly pushing the boundaries of innovation. This has allowed them to develop cutting-edge perforated plasterboard machines that are designed to streamline the production process, improve productivity, and reduce operational costs for their clients.In addition to their commitment to product innovation, the factory also places a strong emphasis on customer service. They take pride in providing personalized solutions to meet the unique requirements of each client and offer comprehensive after-sales support to ensure that their machines continue to operate at peak performance. This has earned them a solid reputation for reliability and integrity, making them the go-to choice for many businesses looking to invest in high-quality perforated plasterboard machinery.The factory's dedication to quality and customer satisfaction has not gone unnoticed, as they have received numerous accolades and certifications for their commitment to excellence. This includes ISO 9001 certification, which demonstrates their adherence to international quality standards, as well as recognition from industry experts and satisfied customers.As a testament to their success, the Best Perforated Plasterboard Machine Factory has seen a steady increase in demand for their products, both domestically and internationally. This has led to the expansion of their production capacity and distribution network, allowing them to serve a larger customer base and fulfil orders with efficiency and speed.Looking ahead, the factory remains committed to pushing the boundaries of innovation and setting new benchmarks for quality in the industry. With a strong foundation built on expertise, reliability, and customer satisfaction, they are well-positioned to continue their growth and solidify their status as the best perforated plasterboard machine factory in the market.In conclusion, the Best Perforated Plasterboard Machine Factory is not just a manufacturer and supplier, but a trusted partner for businesses in the construction industry. Their unwavering commitment to quality, innovation, and customer satisfaction has made them a leader in the market, and their dedication to excellence ensures that they will continue to thrive in the years to come. With a focus on research and development, state-of-the-art facilities, and a strong emphasis on customer service, the factory is well-equipped to meet the evolving needs of the industry and remain at the forefront of the market.

Affordable Full Automatic Laminating Machine for PVC Aluminum Foil Gypsum-Board

Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine - Revolutionizing the IndustryIn recent years, the construction industry has witnessed a growing demand for high-quality gypsum-board laminating machines that can efficiently produce laminated panels for various applications. Meeting this demand, [Company Name]'s state-of-the-art Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine has revolutionized the industry with its advanced technology and superior performance.This innovative machine is designed to streamline the production process, offering a cost-effective and efficient solution for laminating gypsum boards with PVC aluminum foil. With its fully automatic operation, it can significantly increase productivity and reduce labor costs, making it an ideal choice for manufacturers looking to enhance their production capabilities.One of the standout features of this machine is its precision and accuracy in laminating PVC aluminum foil onto gypsum boards. The advanced technology incorporated in the machine ensures uniform lamination, resulting in high-quality panels that meet the industry's stringent standards. This is crucial for applications where the aesthetics and durability of the laminated panels play a vital role, such as in residential and commercial construction projects.In addition to its superior lamination capabilities, the Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine is also designed for ease of use and maintenance. Its user-friendly interface and intuitive controls make operation simple and hassle-free, while its robust construction and durable components ensure long-lasting performance with minimal downtime.Furthermore, this cutting-edge machine is equipped with safety features to protect operators and maintain a safe working environment. From emergency stop mechanisms to protective guards, [Company Name] has prioritized the well-being of its users while ensuring optimal productivity.The Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine aligns with [Company Name]'s commitment to delivering innovative solutions that cater to the evolving needs of the construction industry. With a focus on research and development, the company has continuously strived to push the boundaries of technology, resulting in game-changing products that elevate the industry standards.[Company Name] has established itself as a leader in the manufacturing of advanced machinery for the construction sector, with a reputation for excellence and reliability. The Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine is a testament to the company's dedication to engineering cutting-edge solutions that address the challenges faced by manufacturers in the industry.By investing in this groundbreaking machine, manufacturers can expect to enhance their production capabilities, improve the quality of their laminated panels, and ultimately gain a competitive edge in the market. The Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine is a game-changer for the construction industry, setting new benchmarks for efficiency, quality, and performance.In conclusion, [Company Name]'s Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine represents a significant advancement in the field of construction machinery. With its advanced technology, precision lamination capabilities, and user-friendly design, this machine is poised to transform the way gypsum boards are laminated, offering manufacturers a reliable and efficient solution to meet the demands of the industry. As the construction sector continues to evolve, [Company Name] remains at the forefront of innovation, driving progress and delivering solutions that shape the future of the industry.

Revolutionary Automatic Equipment for Gypsum Board Cornice Production

Title: Revolutionizing Gypsum Board Cornice Production with Innovative Automatic Equipment Introduction:In the rapidly evolving construction industry, technological advancements continue to drive innovation and revolutionize traditional manufacturing processes. Among these innovations, the introduction of automatic equipment for gypsum board cornice production has emerged as a game-changer. This breakthrough solution, developed by an industry-leading company, is set to streamline production, enhance efficiency, and guarantee superior quality in the production of gypsum board cornices.Revolutionizing the Gypsum Board Cornice Manufacturing Process:The new automatic equipment, developed by an industry leader (), simplifies the labor-intensive and time-consuming process of creating gypsum board cornices. This cutting-edge equipment combines advanced technology with precision engineering to bring unprecedented efficiency to the production line. With its innovative features, the device is poised to transform the gypsum board cornice production landscape.Efficiency and Precision through Automation:The automatic equipment boasts an impressive array of features that optimize productivity and ensure consistent quality. Through automation, it eliminates the need for manual labor, significantly reducing production time and costs. By automating key steps such as gypsum mixture preparation, molding, drying, and finishing, the equipment guarantees precise and flawless results.Moreover, this state-of-the-art machinery eliminates human errors, such as inconsistencies in measurements and imprecise cutting. By adhering to pre-programmed instructions, the device ensures standardized dimensions and shapes for each cornice produced. This not only enhances the visual appeal of the final product but also reduces wastage, thus contributing to a greener and more sustainable manufacturing process.Intuitive Control System for Seamless Operation:The automatic equipment incorporates an intuitive control system that enables operators to effortlessly manage and monitor the entire production process. The user-friendly interface provides easy access to crucial parameters such as temperature, humidity, and drying time, allowing operators to make necessary adjustments on the go.Furthermore, the equipment's control system includes built-in safety features to safeguard operators and the overall production line. From emergency stops to error detection, the system effectively mitigates potential risks, ensuring a safe working environment for all involved.Reliable Durability and Low Maintenance:One of the key advantages of this automatic equipment is its exceptional durability. Constructed from high-quality materials and engineered to withstand demanding production environments, this equipment promises longevity and minimal downtime. Additionally, the machinery requires minimal maintenance and is built to withstand daily wear and tear, further reducing operational costs and maximizing productivity.The Company's Commitment to Innovation:The company behind this revolutionary automatic equipment has a strong focus on research and development to meet the ever-evolving needs of the construction industry. With years of experience and a track record of excellence, they have established themselves as pioneers in their field.By continuously investing in cutting-edge technologies, the company strives to push boundaries and exceed customer expectations. Their commitment to innovation is clearly showcased by the introduction of this groundbreaking automatic equipment, which revolutionizes gypsum board cornice production.Conclusion:The introduction of automatic equipment for gypsum board cornice production marks a significant milestone in the construction industry. With its ability to streamline manufacturing processes, enhance efficiency, and guarantee superior quality, this innovation promises to reshape the way gypsum board cornices are produced. As construction companies look for ways to improve their operation's efficiency and output, this automatic equipment provides an ideal solution that not only optimizes productivity but also ensures remarkable precision and consistency.