Affordable Mineral Fiber Sheet Equipment Manufacturers

By:Admin

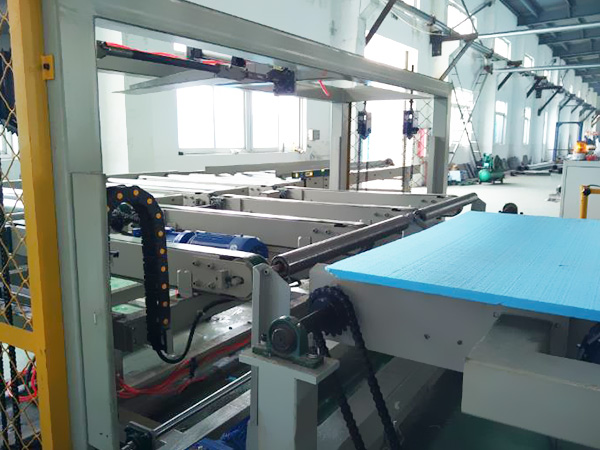

As the demand for mineral fiber sheet equipment continues to rise, the cheap mineral fiber sheet equipment factories, including the renowned company {}, have expanded their production capacity to meet the growing market needs. With a significant increase in the construction and automotive industries, the demand for high-quality mineral fiber sheet equipment has soared, prompting these factories to ramp up their production capabilities.

The factories, including the leading company {}, specialize in producing cost-effective mineral fiber sheet equipment that is utilized in various applications such as insulation, acoustics, and fire protection. As a key player in the industry, {} has established itself as a trusted supplier of mineral fiber sheet equipment, catering to the needs of clients both domestically and internationally.

With the recent surge in demand for mineral fiber sheet equipment, these factories have recognized the need to expand their production facilities to ensure a steady supply of products to the market. By increasing their manufacturing capacity, the factories are better equipped to meet the growing needs of their customers and capitalize on the opportunities presented by the booming construction and automotive sectors.

{} is known for its state-of-the-art production facilities and commitment to delivering high-quality mineral fiber sheet equipment at competitive prices. The company's advanced manufacturing capabilities enable it to produce a wide range of mineral fiber sheet equipment, including ceiling tiles, acoustic panels, and thermal insulation products. By expanding its production capacity, {} aims to further strengthen its position as a leading supplier of mineral fiber sheet equipment in the global market.

The expansion of production capabilities by these cheap mineral fiber sheet equipment factories not only addresses the immediate demand for their products but also demonstrates their long-term commitment to meeting the evolving needs of the industry. By investing in new technologies, equipment, and processes, these factories are positioning themselves for sustained growth and success in the highly competitive market for mineral fiber sheet equipment.

In addition to increasing their production capacity, these factories are also focusing on enhancing the efficiency and sustainability of their manufacturing processes. By implementing measures to reduce energy consumption, minimize waste, and optimize resource utilization, the factories are aligning their operations with the principles of environmental responsibility. This holistic approach to production reflects their dedication to delivering high-quality mineral fiber sheet equipment in an environmentally friendly and socially responsible manner.

Furthermore, the expansion of production facilities is expected to create new employment opportunities and contribute to the economic development of the regions where these factories are located. By hiring additional staff and supporting local businesses and suppliers, the factories are making a positive impact on the communities in which they operate.

With the demand for mineral fiber sheet equipment showing no signs of slowing down, the decision of these factories to expand their production capacity comes at a crucial time. By anticipating and responding to market trends, {} and other cheap mineral fiber sheet equipment factories are securing their position as reliable suppliers of essential products in the construction and automotive industries.

As the global economy continues to recover and grow, the expansion of production capabilities by these factories is poised to meet the increasing demand for mineral fiber sheet equipment, driving innovation, and progress in the industry. With their unwavering commitment to quality, affordability, and sustainability, these cheap mineral fiber sheet equipment factories are well-positioned to play a pivotal role in shaping the future of the industry and meeting the diverse needs of their customers worldwide.

Company News & Blog

Discover Reliable Mini Gypsum Cornice Machine Factories with CE Certification

CE Certification Mini Gypsum Cornice Machine Factories Bolster Quality Assurance in the Industry[introduction]In an exciting development for the gypsum cornice manufacturing industry, several mini gypsum cornice machine factories have received CE certification, enhancing the industry's quality assurance practices. The certification, granted by an independent certification body, affirms that these factories comply with the European Union's health, safety, and environmental protection standards. This achievement showcases the factories' commitment to delivering high-quality products while prioritizing the well-being of end-users and the environment.[Development of the Mini Gypsum Cornice Machine Factories]The mini gypsum cornice machine factories, which have recently obtained CE certification, have established themselves as key players in the industry. Offering smaller-sized machinery, these factories cater to the needs of small-scale gypsum cornice manufacturers. Their focus on mini machines reflects the industry's evolving demand for flexibility and efficiency in production processes.The development of these factories is guided by a dedication to innovation and continuous improvement in cornice manufacturing technology. Through rigorous research and development efforts, these factories have successfully developed mini gypsum cornice machines that meet the industry's standards of precision, productivity, and quality.[Advantages of CE Certification]Acquiring CE certification has numerous advantages for mini gypsum cornice machine factories. It not only demonstrates their compliance with EU regulations but also increases their competitiveness in the market. CE certification serves as a credible endorsement of these factories' commitment to providing safe and reliable miniature machines, bolstering their reputation as industry leaders.Furthermore, CE certification enables manufacturers to enter new markets and cater to a wider range of customers, domestically and internationally. Exporting machinery with CE certification removes potential barriers to trade, as many countries now require such certification for imported goods. This certification goes a long way in instilling confidence in potential buyers and strengthens business relationships across borders.[Quality Assurance and Consumer Satisfaction]CE certification plays a vital role in ensuring the quality and safety of mini gypsum cornice machines. It verifies that these machines adhere to strict manufacturing standards, including materials used, construction, and electrical safety. Through rigorous testing and inspections, accredited certification bodies assess and confirm compliance with these standards, guaranteeing that the machines do not pose any health or safety risks.This commitment to quality assurance extends to the end-users of these mini gypsum cornice machines as well. By obtaining CE certification, these factories prioritize delivering machinery that meets the highest standards of functionality, durability, and performance. Customers can rest assured knowing that their investment in these certified machines will result in efficient gypsum cornice production, minimizing downtime and maximizing productivity.[The Way Forward]The attainment of CE certification by mini gypsum cornice machine factories marks a significant milestone for the industry. It elevates the level of quality assurance within the manufacturing processes and underscores the commitment of these factories to delivering top-notch products. With increased market competitiveness and enhanced consumer satisfaction, these certified factories are poised to contribute to the continued growth and advancement of the gypsum cornice industry.In conclusion, the recent achievement of CE certification by several mini gypsum cornice machine factories reinforces the industry's commitment to excellence. This certification not only ensures compliance with EU regulations but also boosts market competitiveness. With a focus on quality assurance and customer satisfaction, these certified factories are set to drive innovation and advancement in the gypsum cornice manufacturing sector, fostering a future of sustainable growth and success.

Pricelist for Affordable Mineral Fiber Board Making Machines Unveiled

Title: Cutting-Edge Mineral Fiber Board Making Machine Revolutionizes Affordable Construction SolutionsIntroductionIn a recent move spearheading technological innovation in the construction industry, a leading company has unveiled an advanced Mineral Fiber Board Making Machine capable of manufacturing high-quality yet affordable mineral fiber boards. The state-of-the-art machine aims to address the growing demand for cost-effective building materials without compromising on quality and performance. With its cutting-edge features and seamless production capabilities, this groundbreaking solution is set to transform the construction landscape.I. Overview of the Mineral Fiber Board Making MachineThe Mineral Fiber Board Making Machine is designed to automate the production process of mineral fiber boards, providing a cost-effective, efficient, and sustainable solution to meet the rising demand in the construction industry. The equipment is equipped with the latest technology to ensure optimal performance, precision, and high production capacity.1. Advanced Features:a. High-efficiency Cutter: The machine incorporates a high-precision cutter that ensures accurate board dimensions, resulting in uniform thickness and precise sizing for enhanced structural integrity.b. Automatic Feed System: The automated feed system boosts productivity by seamless integration with the cutter, enabling continuous processing of raw materials without interruptions.c. Digital Control Panel: The intuitive digital control panel allows operators to monitor production parameters, adjust settings, and track overall manufacturing progress in real-time.d. Environmentally Sustainable Operation: The machine is designed to minimize energy consumption and reduce waste generation, aligning with global sustainability goals.2. Production Capabilities:The Mineral Fiber Board Making Machine stands out due to its ability to manufacture a wide range of mineral fiber boards, leveraging both common and specialized raw materials. These boards find applications in ceiling panels, wall linings, insulation boards, acoustic products, and fire-resistant materials, among others.II. Advantages and Impact on the Construction Industry1. Cost-Effectiveness:The Mineral Fiber Board Making Machine's introduction represents a major breakthrough in affordability within the construction industry. By streamlining the manufacturing process and eliminating costly manual labor, the machine significantly reduces production costs, making mineral fiber boards accessible to a larger consumer base.2. Enhanced Quality Control:With its precise cutting mechanism and advanced control panel, the machine ensures consistent product quality across the board, meeting strict industry standards. This reliability reduces the need for replacements or repairs, leading to long-term cost savings for both manufacturers and end-users.3. Improved Efficiency:Automation eliminates human errors and enhances production efficiency. The machine's ability to operate without interruptions and sustain high production speeds enables manufacturers to meet deadlines and scale up their output to meet growing market demands.4. Sustainability:The Mineral Fiber Board Making Machine promotes sustainability in the construction sector. Its energy-efficient operation reduces carbon emissions, while optimized material usage minimizes waste. By offering an eco-friendly solution, manufacturers and consumers can contribute to a greener future.III. Forward-Looking ImplicationsThe launch of the innovative Mineral Fiber Board Making Machine may revolutionize the construction industry in several ways.1. Market Expansion:Affordable mineral fiber boards will enable builders, contractors, and developers to explore new possibilities for cost-effective and sustainable construction. This expansion will cater to a wider spectrum of customers, encouraging growth in commercial, residential, and infrastructure projects.2. Economic Development:By reducing production costs and enhancing manufacturing capabilities, companies utilizing the Mineral Fiber Board Making Machine can become more competitive and financially viable. This, in turn, leads to increased employment opportunities and economic growth in the construction sector.3. Environmental Protection:The machine's sustainable operation aligns with global efforts to reduce carbon footprints and promote environmental protection. By implementing this state-of-the-art solution, construction practices can become more eco-conscious, mitigating the industry's impact on the planet.ConclusionThe Mineral Fiber Board Making Machine represents a significant milestone in the construction industry's pursuit of cost-effectiveness, efficiency, and sustainability. The advent of this innovative technology promises to reshape the market landscape, making quality mineral fiber boards more accessible, versatile, and environmentally friendly. With its consistent product quality, enhanced production capabilities, and positive socio-economic impact, this cutting-edge solution is poised to revolutionize affordable construction solutions worldwide.

Affordable Roof Panel Roll Forming Machine Manufacturers and Suppliers in China with Stock Availability

If you're searching for affordable, high-quality roof panel roll forming machines, look no further than Xinhonghua. As a leading manufacturer and supplier of roll forming machines in China, we offer a comprehensive range of machines specifically designed to meet the needs of roofing contractors and others working in the construction industry. With our cheap prices and extensive inventory of machines, you're sure to find the perfect roll forming machine for your application.Our roof panel roll forming machines are meticulously designed and crafted to ensure high-quality, precision performance. We use only the best materials and components, and our machines are engineered to provide long-lasting, reliable service. Whether you're looking for a machine to produce metal roofing panels, corrugated panels, or other types of roofing panels, we have the perfect machine to meet your needs.In addition to roof panel roll forming machines, we also offer a range of other roll forming machines, including Cheap Mgo Board Forming Machine Pricelist. Our MGO board forming machines are designed to produce high-quality, fire-resistant MGO boards that are perfect for use in construction, interior finishing, and other applications. With our MGO board forming machines, you can easily produce high-volume quantities of boards quickly and efficiently.At Xinhonghua, we pride ourselves on our dedication to quality, reliability, and customer service. We understand that our success depends on the satisfaction of our customers, and we work tirelessly to ensure that our machines are up to the highest standards of excellence. Whether you're a small contractor or a large construction firm, we have the expertise and experience to provide you with the products and services you need to succeed.So if you're in the market for a new roof panel roll forming machine or Cheap Mgo Board Forming Machine Pricelist, be sure to contact us today. Our friendly and knowledgeable staff are always on hand to answer any questions you may have, and we're committed to providing you with the best possible service and support. Let us help you transform your construction business with high-quality, affordable rolling forming machines from Xinhonghua.

Affordable Automatic Gypsum Cornice Equipment Manufacturers: Enhance Search Engine Optimization

Title: Leading Automatic Gypsum Cornice Equipment Factories Revolutionize Manufacturing ProcessIntroduction:Gypsum cornices are an integral part of interior design, adding a touch of elegance and sophistication to any space. In an exciting development, a leading automatic gypsum cornice equipment factory is transforming the manufacturing process, propelling the industry forward. This groundbreaking technology, combined with the company's commitment to innovation, is revolutionizing the production of gypsum cornices. With unmatched precision and efficiency, these state-of-the-art equipment factories are shaping the future of interior decor.Body:1. The Rise of Automatic Gypsum Cornice Equipment Manufacturing:Over the past decade, there has been a considerable increase in the demand for high-quality gypsum cornices. To meet this growing demand, automatic gypsum cornice equipment factories have emerged, catering to the needs of interior designers, architects, and construction companies. These factories utilize cutting-edge technology to streamline production processes, ensuring increased efficiency and reduced costs.2. Cutting-Edge Technology and Manufacturing Process:The automatic gypsum cornice equipment factories incorporate advanced machinery and automation systems to optimize the manufacturing process. By utilizing computer numerical control (CNC) and robotics, these factories can produce gypsum cornices with unparalleled precision, consistency, and intricate designs. This groundbreaking technology not only enhances the overall quality but also significantly reduces manual labor.3. Benefits of Automatic Gypsum Cornice Equipment:a. Improved Efficiency: The use of automatic equipment has revolutionized gypsum cornice manufacturing, enabling factories to produce a larger quantity of products in a shorter period. This efficiency boost results in an enhanced customer experience and increased satisfaction levels.b. Consistent Quality: The precision offered by automatic machinery ensures consistent quality across all gypsum cornices produced by these factories. Each product adheres to the highest standards, showcasing fine details and impeccable craftsmanship.c. Cost-Effective: By combining automation with precise material usage, these factories can minimize material waste, thereby reducing costs. This cost-effectiveness translates to competitive pricing for customers, attracting a broader range of clients and promoting widespread adoption of gypsum cornices.4. Focus on Innovation:The leading automatic gypsum cornice equipment factories are driven by a relentless focus on innovation and research. They continuously strive to improve their manufacturing processes, developing new techniques and machinery to push the boundaries of what is possible within the industry. By investing in research and development, these companies ensure that their customers have access to the latest advancements in gypsum cornice manufacturing.5. Sustainability and Environmental Responsibility:In addition to technological advancements, automatic gypsum cornice equipment factories also prioritize sustainable production methods. By adhering to environmentally friendly practices, these factories minimize waste, reduce energy consumption, and utilize recyclable materials wherever possible. This commitment to sustainability aligns with contemporary demands for eco-friendly construction materials and contributes to the preservation of our planet.Conclusion:The automatic gypsum cornice equipment factories have ushered in a new era of manufacturing, bringing innovation, precision, and efficiency to the production of gypsum cornices. By embracing cutting-edge technology and focusing on sustainability, these factories provide a competitive advantage while meeting customer demands. With their commitment to innovation, these industry leaders are undoubtedly shaping the future of interior decor, transforming spaces with bespoke gypsum cornice designs that reflect a perfect combination of artistry and automation.

PVC Foam Board Extrusion Line Machine with CE and ISO Certification: A Comprehensive Introduction

Qingdao Suke Machinery Co., Ltd., a well-known manufacturer of plastic extrusion machinery, has recently introduced a PVC foam board extruder machine with CE and ISO, aimed at catering to the growing demand for quality foam board products across the world. The PVC foam board extrusion line machine is equipped with advanced features that ensure high efficiency and quality output, making it the ideal choice for beginners looking to produce foam board products.The Foam Board Production Line is equipped with SJSZ 45/90 extruder, which has a maximum output of 180kg/h, making it suitable for small to medium scale production. The machine is made using high-quality materials and adheres to international standards, ensuring durability and reliability. The production line is also equipped with a variety of components such as a feeder, calibration table, tractor, and cutting unit, which work in unison to produce high-quality foam board products.The machine is easy to use, making it a popular choice for beginners. It has a user-friendly touch screen interface that allows operators to control all aspects of the production process, from raw material feeding to final product cutting. The machine also has an automatic cutting system, which helps to save time and reduce wastage.The Foam Board Production Line is suitable for producing a wide range of foam board products, including advertising boards, furniture boards, and building materials. The end products have a smooth surface, high density, good strength and rigidity, making them ideal for versatile applications.Talking about the company, Qingdao Suke Machinery Co., Ltd. is a leading manufacturer of plastic extrusion machinery, catering to a wide range of industries such as packaging, construction, automobiles, and more. The company has been in business for over a decade, and its machines are known for their premium quality, innovative designs, and high-level automation. Qingdao Suke Machinery Co., Ltd. has built a global reputation for its commitment to customer satisfaction, providing reliable service and support to each of its clients.With the introduction of the PVC foam board extruder machine, Qingdao Suke Machinery Co., Ltd. is further expanding its range of plastic extrusion machinery, catering to a growing demand for foam board products. The company's commitment to quality, reliability, and innovation makes it the ideal partner for businesses looking to invest in plastic extrusion machinery.In conclusion, the PVC foam board extruder machine with CE and ISO introduced by Qingdao Suke Machinery Co., Ltd. is a high-quality production line that offers a reliable and efficient solution for foam board production. The machine is easy to use, making it a popular choice for beginners, and is suitable for producing a wide range of foam board products. With its commitment to customer satisfaction, Qingdao Suke Machinery Co., Ltd. is the ideal partner for businesses looking to invest in plastic extrusion machinery.

Affordable Gypsum Ceiling Pressing Machine Emerges as a Game-changer

Cheap Gypsum Ceiling Pressing Machine Revolutionizes the Construction IndustryIn an era where technological advancements are transforming every sector, the construction industry is no exception. Gone are the days when workers had to rely solely on manual labor, as innovative machinery now takes center stage. The introduction of the Cheap Gypsum Ceiling Pressing Machine by an esteemed company marks a significant leap forward in construction technology. With its efficient design, superior performance, and affordable price, this cutting-edge machine is revolutionizing gypsum ceiling installation techniques.The Cheap Gypsum Ceiling Pressing Machine, developed by a forward-thinking industry leader, has quickly gained traction due to its outstanding features and unrivaled capabilities. By incorporating state-of-the-art technology, this machine provides a seamless and efficient solution to the tedious process of gypsum ceiling installation. The company, known for its expertise in engineering solutions, has designed this machine to cater to the needs of construction professionals in a cost-effective manner.One of the most notable advantages of the Cheap Gypsum Ceiling Pressing Machine is its easy operation. With user-friendly controls, even workers with limited experience can operate the machine without complications. This allows construction companies to save both time and money by reducing the training required for their workforce. The machine's intuitive interface ensures that it can be operated efficiently, leading to increased productivity.Furthermore, this groundbreaking machine boasts exceptional performance capabilities, surpassing those of its competitors. The innovative design allows the Cheap Gypsum Ceiling Pressing Machine to press gypsum boards quickly and accurately onto the ceiling framework, resulting in seamless installations. The machine's precision guarantees a smooth finish, eliminating the need for further touch-ups, and ensuring customer satisfaction.The affordability of the Cheap Gypsum Ceiling Pressing Machine is another key factor that sets it apart from other machines in the market. With its competitive price range, this machine offers construction companies an opportunity to enhance their productivity without breaking the bank. The lower initial investment required for this machine makes it an attractive option, particularly for small and medium-sized enterprises looking to expand their capabilities.The company behind the Cheap Gypsum Ceiling Pressing Machine has a rich history of engineering excellence. With years of experience in the construction industry, they have fine-tuned their machinery to meet the evolving needs of professionals in the field. Recognized for their commitment to quality and customer satisfaction, the company ensures that their products are built to withstand the rigorous demands of the construction sector.In addition to the Cheap Gypsum Ceiling Pressing Machine, the company offers a wide range of other construction machinery and equipment. From versatile tools to cutting-edge technology, their product catalog caters to various construction needs. With a well-established global presence and a network of trusted distributors, the company has positioned itself as a go-to source for reliable and high-performing machinery.As the construction industry progresses towards automation and efficiency, the Cheap Gypsum Ceiling Pressing Machine emerges as a game-changer. Its groundbreaking features, user-friendly operation, exceptional performance, and affordable price make it an invaluable asset to construction professionals worldwide. This technological advancement not only simplifies the installation process but also elevates the overall quality of gypsum ceiling projects.In conclusion, the introduction of the Cheap Gypsum Ceiling Pressing Machine by a renowned company brings a new era of innovation to the construction industry. With its remarkable features, this machine surpasses its competitors in terms of performance, ease of use, and affordability. As construction professionals continue to seek efficient and cost-effective solutions, the Cheap Gypsum Ceiling Pressing Machine stands out as an invaluable addition to their arsenal of tools.

Fully Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine

The cutting-edge technology and innovative design of the Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine have been making waves in the industry. This state-of-the-art machine features advanced automatic functions that streamline the laminating process, making it more efficient and cost-effective for manufacturers.The Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine has been designed to meet the growing demand for high-quality laminated gypsum boards in the construction and interior design industries. With its fully automatic operation, this machine is capable of laminating PVC film and aluminum foil onto gypsum boards with precision and consistency, ensuring a flawless finish every time.The advanced features of this machine include automatic feeding, gluing, laminating, cutting, and stacking, reducing the need for manual labor and significantly increasing production capacity. This makes it an ideal investment for manufacturers looking to improve their productivity and meet the increasing demand for laminated gypsum boards.The Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine also offers a high degree of customization, allowing manufacturers to adjust the settings and parameters to meet their specific production requirements. This flexibility makes it suitable for a wide range of applications, from small-scale operations to large manufacturing facilities.In addition to its advanced technological capabilities, this machine is also designed with efficiency and sustainability in mind. It features energy-saving components and a streamlined production process, reducing waste and minimizing environmental impact. This aligns with the company's commitment to sustainable manufacturing practices and reducing its carbon footprint.The cutting-edge technology and innovative design of the Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine have positioned the company as a leader in the industry. With a focus on research and development, the company has consistently introduced new and improved products to meet the evolving needs of its customers.As a leading manufacturer of laminating equipment, the company has established a strong reputation for delivering high-quality, reliable machines that streamline the production process and improve overall efficiency. Its dedication to innovation and customer satisfaction has earned it the trust and loyalty of customers around the world.With a global presence and a diverse portfolio of products, the company continues to expand its reach and strengthen its position as a market leader. Its commitment to excellence and investment in cutting-edge technology have allowed it to stay ahead of the competition and anticipate the needs of the industry.In conclusion, the Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine represents a significant advancement in the manufacturing process for laminated gypsum boards. Its innovative design, advanced automatic functions, and commitment to efficiency and sustainability make it an ideal investment for manufacturers seeking to improve their production capabilities and meet the growing demand for high-quality laminated products.As the industry continues to evolve, the company remains at the forefront of innovation, driving progress and setting new standards for excellence. With its dedication to research and development, commitment to customer satisfaction, and a strong global presence, the company is well-positioned to lead the way in the laminating equipment market for years to come.

Effective Slurry Distribution for Multiple Screens: PU Dewatering Screen with Vibrating Motor

As the demand for high-quality mineral fiber ceiling board increases, so does the need for efficient and reliable production equipment. Fortunately, there are now several top-grade Mineral Fiber Ceiling Board Machine factories that offer state-of-the-art production machinery and systems designed to meet the demands of modern manufacturing.One of the best ways to achieve high-quality ceiling boards is by using mineral fiber materials, which are known for their sound absorption, fire resistance, and thermal insulation properties. These materials are derived from naturally occurring minerals, such as basalt, perlite, and volcanic rock, which are then processed and combined with various binders, such as starch or resin.To produce mineral fiber ceiling boards, a Mineral Fiber Ceiling Board Machine is used to mix and form the materials into panels or tiles of varying sizes and densities. These machines utilize advanced technologies, such as heating and pressing, to create a strong and durable product that meets the required specifications.When selecting a Mineral Fiber Ceiling Board Machine factory, it is essential to consider some critical factors that will ensure optimal performance, reliability, and cost-effectiveness. Some of these factors include:Quality of the MachinesA high-quality Mineral Fiber Ceiling Board Machine should be durable, reliable, and easy to operate. The quality of the materials used in the manufacturing process is also critical, as low-quality materials can lead to frequent breakdowns and maintenance issues.Production CapacityThe production capacity of the Mineral Fiber Ceiling Board Machine should meet the needs of your manufacturing facility. It is essential to choose a machine that can handle your desired output without compromising on quality or efficiency.Maintenance and SupportChoosing a reputable Mineral Fiber Ceiling Board Machine factory that offers reliable maintenance and technical support ensures minimal downtime and maximum productivity. It is essential to choose a factory that provides regular maintenance and repair services and offers quick response times in case of any technical issues.Cost-effectivenessThe cost of the equipment and its maintenance should be within your budget. Choosing a Mineral Fiber Ceiling Board Machine factory that offers affordable solutions without compromising on quality or efficiency is critical to the success of your manufacturing plant.ConclusionMineral fiber ceiling board production has come a long way in recent years, thanks to advanced Mineral Fiber Ceiling Board Machine technology. By selecting a quality Mineral Fiber Ceiling Board Machine factory, you can ensure that your manufacturing plant produces high-quality, cost-effective, and efficient mineral fiber ceiling boards. Contact a reputable factory today to get the best mineral fiber ceiling board production machinery for your facility.

High-Quality Mineral Fiber and Mineral Wool Boards for Ceilings

TNT Quality Mineral Fiber Ceilings and Boards: Meeting the Demand for Quality and Aesthetics in Commercial ConstructionFor over a decade, TNT Quality Mineral Fiber Ceilings and Boards have been satisfying the needs of architects, designers, contractors, and building owners for high-performance, aesthetically pleasing, and sustainable ceiling solutions. The company, based in China, has established itself as a leader in the production and marketing of mineral fiber ceiling tiles, mineral wool ceiling panels, and related accessories.TNT Quality Mineral Fiber Ceilings and Boards offers a wide range of products, including acoustic, fire-resistant, moisture-resistant, and thermal insulation ceiling panels, as well as ceiling grids, suspension systems, and accessories. Their products have been widely used in commercial, institutional, industrial, and residential buildings, such as airports, hospitals, hotels, offices, schools, shopping malls, and airports.The company's commitment to quality and innovation is reflected in its modern manufacturing facilities, cutting-edge equipment, ISO 9001 and ISO 14001 certifications, and rigorous quality control measures. They source their raw materials from reliable suppliers and use advanced processes to produce consistent, durable, and cost-effective ceiling solutions.Some of the key features and benefits of TNT Quality Mineral Fiber Ceilings and Boards' products are:- Excellent acoustic performance: mineral fiber and wool are natural sound absorbers that reduce noise and create a comfortable and productive environment.- Fire resistance: mineral fiber and wool are non-combustible and can withstand high temperatures, ensuring safety and compliance with building codes and regulations.- Moisture resistance: mineral fiber and wool can resist humidity, condensation, and sagging, preventing mold, mildew, and deterioration.- Thermal insulation: mineral fiber and wool can conserve energy and reduce heating and cooling costs by providing effective insulation against heat transfer.- Aesthetics: TNT Quality Mineral Fiber Ceilings and Boards' products come in a variety of colors, patterns, textures, and sizes, allowing for creative and customized design options that enhance the visual appeal and functionality of any space.- Sustainability: mineral fiber and wool are eco-friendly, recyclable, and contribute to LEED certification points.TNT Quality Mineral Fiber Ceilings and Boards' commitment to customer satisfaction is evident in its personalized service, fast delivery, competitive pricing, and responsive technical support. They work closely with their clients to understand their needs, provide recommendations, and offer solutions that meet their specific requirements and budget.The company's success is also due to its emphasis on innovation and adaptation to market changes. They continuously invest in research and development to improve their products' performance, quality, and durability. They also keep abreast of emerging trends and technologies, such as digital printing, LED lighting, and acoustic testing, to offer the latest and most advanced ceiling solutions.In conclusion, TNT Quality Mineral Fiber Ceilings and Boards' products have proven themselves to be reliable, versatile, and attractive solutions for all types of commercial construction projects. Their commitment to quality, sustainability, innovation, and customer service sets them apart from their competitors and positions them to meet the growing demand for high-performance ceilings that enhance the built environment and the well-being of its occupants.