- Home

- Calcium Silicate Board Manufacturing Process

Optimizing Calcium Silicate Board Manufacturing Process by a Trusted Exporter from China

Hebei Greens Building Material Technology Development Co., Ltd. is a reliable and experienced manufacturer, supplier, and factory of Calcium Silicate Board. Our company is located in China and we specialize in the production of these high-quality boards that are known for their excellent physical and mechanical properties.

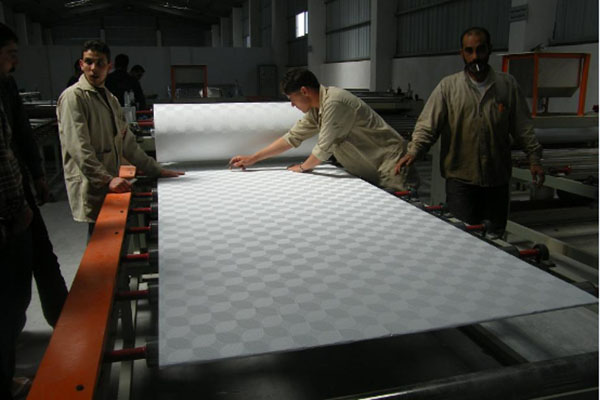

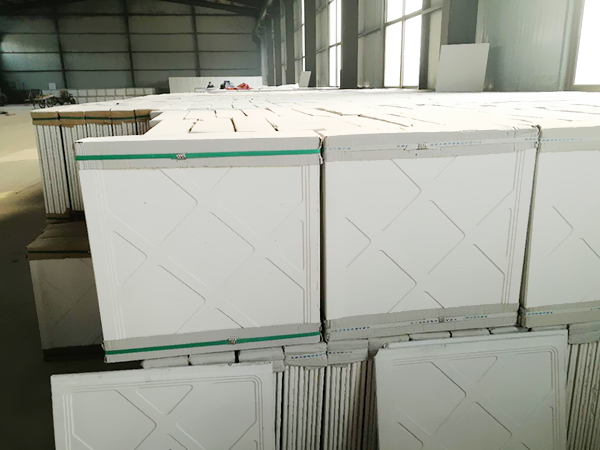

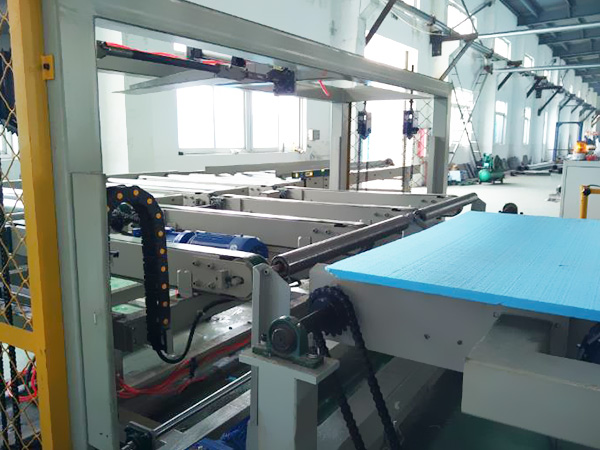

Our Calcium Silicate Boards are made using a state-of-the-art manufacturing process that ensures superior quality, durability, and strength. We use selected raw materials that are carefully combined and mixed to create a homogeneous mixture that is then shaped into boards using a hydraulic press.

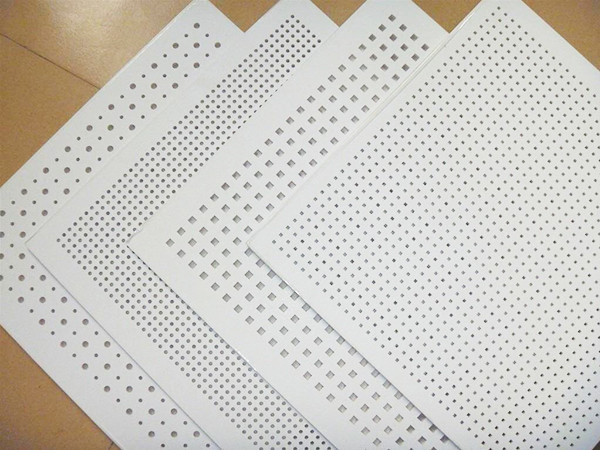

Our manufacturing process ensures that the boards are not only easy to install but also resistant to cracking, water, fire, and heat. They also offer good sound absorption and insulation properties, making them ideal for use in construction and building projects.

If you're looking for a reliable supplier of quality Calcium Silicate Boards, Hebei Greens Building Material Technology Development Co., Ltd. is the perfect choice. We are committed to ensuring customer satisfaction by providing top-quality products at competitive prices. Contact us today to place your order.

HEBEI GREENS BUILDING MATERIAL TECHNOLOGY DEVELOPMENT CO., LTD.

Company News

Related News

Gypsum Cornice Production Line

Looking for high-quality, durable Gypsum Cornice Production Line? Look no further! Our factory specializes in manufacturing top-of-the-line gypsum cornice production equipment. Buy today!

PVC Vinyl Film

Looking for high-quality PVC Vinyl Film? Look no further than our factory! We produce top-quality film for a range of applications, with superior durability and performance. Contact us today to learn more!

Mineral Fiber Ceiling Board Production Line

Looking for a reliable Mineral Fiber Ceiling Board Production Line? Look no further than our factory! We specialize in producing high-quality, durable products that meet your needs.

Gypsum Decorative Tile Machine

Looking for high-quality gypsum decorative tile machines? Look no further than our factory! We offer top-of-the-line products at competitive prices. Contact us today for more information.

Fiber Cement Board Making Machine

Looking for a quality Fiber Cement Board Making Machine? Look no further than our factory. We manufacture durable and reliable machines designed to meet your every need. Contact us today for more information.

XPS Foam Board Production Line

Looking for high-quality XPS foam board production line? Look no further! Our factory produces top-of-the-line equipment that will help you get the job done right. Contact us today to learn more.

Gypsum Board Perforationg Machine

As a factory specializing in gypsum board perforating machines, we offer high-quality and efficient equipment for your perforation needs. Trust us to provide excellent service. #SEO #GypsumBoardPerforatingMachine

Calcium Silicate Board Production Line

Looking for top-quality calcium silicate board production line? Look no further! We are a leading factory that offers reliable and efficient calcium silicate board production line solutions. Our products are designed to meet the highest industry standards. Get in touch to learn more!

Mgo Board Production Line

Looking for a reliable Mgo Board Production Line supplier? Look no further! We're a factory that offers quality production for all your construction needs.

Gypsum Board Lamination Machine

Looking for a reliable Gypsum Board Lamination Machine? Look no further! Our factory produces high-quality machines at competitive prices. Contact us today for more information.

- Calcium Silicate Board Manufacturing Process: Leading Manufacturer for Wholesale Supply

- Reviews

- Related Videos

Calcium silicate board is a popular construction material that is widely used in building and construction projects. It is made using a unique manufacturing process that combines calcium oxide and silica, which are then reinforced with cellulose fibers and other chemical additives. This results in a strong, durable, and heat-resistant product that is ideal for use in a variety of applications. The manufacturing process of calcium silicate board involves several steps, including mixing the raw materials, forming the board, and curing. The raw materials are first mixed together to form a slurry, which is poured into a mold and pressed into shape. The board is then cured at high temperatures and pressures, which helps to solidify the material and ensure its strength and durability. Calcium silicate board is highly resistant to fire, moisture, and termites, making it an ideal choice for use as a building material. It is also lightweight and easy to cut and shape, allowing for easy installation and customization. Additionally, it offers excellent insulation properties, which can help to reduce energy costs and increase comfort for building occupants. Overall, the calcium silicate board manufacturing process produces a high-quality product that is suitable for use in a variety of construction projects. Its unique properties and versatility make it an ideal choice for builders, architects, and contractors looking for a high-performance material that can stand up to the demands of even the toughest applications.

Calcium silicate board is a vital insulation material used in construction. The manufacturing process starts by mixing calcium silicate, cellulose, sand, and other additives. The mixture is then poured and pressed into a board shape, followed by the heating process, where it's baked at high temperatures, which results in a strong, durable, and heat resistant board. The finished product is perfect for use in walls, ceilings, roofs, and floors. It's easy to work with, lightweight, and doesn't require any added specialized tools, making it a homeowner or contractor's favorite insulation choice. Overall, the calcium silicate board is an excellent addition to any building project.

If you're looking for a durable, fire-resistant and moisture-resistant building material, Calcium Silicate Board is an excellent choice. The manufacturing process involves mixing calcium oxide, silica, and other materials to create a slurry. This slurry is then spread onto a conveyor belt and compressed under high pressure and temperature to produce a hard and dense board. Calcium Silicate Boards are light in weight, strong, and easy to work with. They have great thermal and acoustic insulation properties and can be used for fireproof walls, ceilings, and floors. It's a dependable and cost-effective option for both residential and commercial construction.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours