Top Perforated Plasterboard Machine for Improved Production

By:Admin

The construction industry is one of the largest sectors in the world, with the global construction market projected to grow to a value of 8 trillion dollars by 2030. With such rapid expansion, the demand for innovative and efficient construction solutions is at an all-time high. One company that is leading the charge in providing cutting-edge technology for the construction industry is {Company Name}.

{Company Name} has been a pioneer in the development of advanced machinery for the construction industry for over two decades. They have continuously pushed the boundaries of innovation, producing state-of-the-art equipment that has redefined construction processes. Their commitment to quality and excellence has earned them a reputation as a trusted and reliable partner in the construction industry.

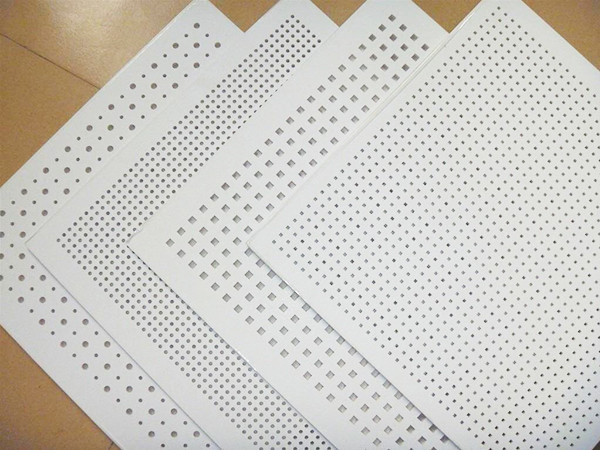

In keeping with their tradition of excellence, {Company Name} has recently unveiled their latest breakthrough in construction technology – the {Model Name} Perforated Plasterboard Machine. This revolutionary machine is set to transform the way plasterboard is manufactured and used in the construction industry.

The {Model Name} Perforated Plasterboard Machine is designed to produce high-quality perforated plasterboard with unparalleled precision and efficiency. The machine is equipped with advanced features that allow for custom perforation patterns, giving builders and designers the flexibility to create unique and innovative architectural designs. Additionally, the machine is capable of producing plasterboard in various thicknesses, further expanding its versatility and usability in a wide range of construction projects.

One of the key advantages of the {Model Name} Perforated Plasterboard Machine is its speed and efficiency. The machine is capable of producing large quantities of perforated plasterboard in a fraction of the time it takes with traditional methods. This not only increases productivity but also reduces production costs, making it an economical and practical choice for construction companies.

Moreover, the {Model Name} Perforated Plasterboard Machine is equipped with cutting-edge technology that ensures the quality and consistency of the produced plasterboard. This level of precision and reliability is crucial in ensuring that construction projects meet the highest standards of safety and durability.

The introduction of the {Model Name} Perforated Plasterboard Machine has already garnered significant attention and praise from industry experts and construction professionals. Many have hailed it as a game-changer in the construction industry, citing its potential to streamline construction processes and improve overall project outcomes.

In addition to the impressive features of the {Model Name} Perforated Plasterboard Machine, {Company Name} also offers comprehensive customer support and maintenance services. Their team of highly skilled technicians and engineers provide expert guidance and assistance, ensuring that clients get the most out of their investment in the machine.

As the global construction industry continues to grow and evolve, the need for innovative and efficient construction solutions becomes increasingly important. With the introduction of the {Model Name} Perforated Plasterboard Machine, {Company Name} has once again demonstrated their commitment to driving innovation and providing superior technology for the construction industry.

With their track record of success and dedication to excellence, {Company Name} is poised to set new standards in the construction industry with their groundbreaking {Model Name} Perforated Plasterboard Machine. As the demand for advanced construction technology continues to rise, {Company Name} remains at the forefront, delivering cutting-edge solutions that will shape the future of construction.

Company News & Blog

Mineral Fiber Suspended Ceiling Tiles for Your Space: All You Need to Know

Suspended ceilings, also known as drop ceilings or false ceilings, have been a popular option for commercial and residential spaces for many years. These ceilings are installed on a metal grid system and can be easily accessed for repairs and maintenance. Suspended ceilings are not only functional, but they are also aesthetically pleasing and offer a wide range of design options.One of the most popular materials for suspended ceiling tiles is mineral fiber. Mineral fiber tiles are made from a blend of natural and synthetic materials, including mineral wool, clay, perlite, and cellulose. These ingredients are mixed together to create a durable, fire-resistant material that is ideal for use in buildings of all kinds.Mineral fiber tiles offer many benefits over other materials. They are highly absorbent, making them ideal for use in acoustically sensitive areas such as conference rooms, lecture halls, and theaters. They also provide excellent thermal insulation, helping to reduce heating and cooling costs.In addition to their functional qualities, mineral fiber tiles are also available in a wide range of designs and finishes to suit any aesthetic preference. They can be painted, printed, embossed, or textured to create a unique and personalized look.When installing suspended ceilings, it is essential to choose the best mineral fiber ceiling tiles machine. This machine is responsible for producing high-quality tiles that meet the required industry standards. A good mineral fiber ceiling tiles machine should be efficient, reliable, and easy to use.There are several factors to consider when selecting a mineral fiber ceiling tiles machine. One of the most critical factors to consider is the production capacity. The machine should be capable of producing a sufficient number of tiles to meet the project's needs.Another important consideration is the level of automation. Automated machines can offer improved efficiency, minimize waste, and reduce labor costs. They may also provide more consistent quality control than manual machines.Ease of use is another vital factor when selecting a mineral fiber ceiling tiles machine. The machine should be easy to operate and maintain, with clear instructions and minimal downtime.In conclusion, mineral fiber suspended ceiling tiles offer many benefits, including durability, insulation, and an aesthetically pleasing appearance. When selecting a mineral fiber ceiling tiles machine, it is crucial to consider factors such as production capacity, automation, and ease of use, to ensure that the machine meets the project's needs and delivers high-quality tiles.

High-quality Wall Board Machine Manufacturer for Mgo Boards

Mgo Wall Board Machine Manufacturer, a leading manufacturer of construction machinery, recently announced the launch of their new state-of-the-art Mgo Wall Board Machine. The company has been known for its high-quality construction equipment and this latest addition to their product line is no exception.The Mgo Wall Board Machine is designed to produce high-quality Magnesium Oxide Wall Boards, which are widely used in the construction industry for their fire resistance, water resistance, and durability. The machine is equipped with the latest technology and is capable of producing a large volume of Mgo Wall Boards with a high degree of precision and efficiency.The company has invested heavily in research and development to ensure that the Mgo Wall Board Machine meets the highest industry standards. The machine is equipped with advanced features such as automatic feeding, mixing, and molding, as well as precise control of temperature and pressure during the production process. This ensures that the Mgo Wall Boards produced are of consistent quality and meet all the necessary specifications for construction applications.In addition to its advanced technology, the Mgo Wall Board Machine is also designed with user-friendly features that make it easy to operate and maintain. The machine is equipped with a user-friendly interface and is designed for minimal downtime, allowing for continuous production without interruptions.The launch of the Mgo Wall Board Machine is a significant milestone for the company, as it further strengthens their position as a leading manufacturer of construction machinery. With the increasing demand for high-quality construction materials, the company is confident that the Mgo Wall Board Machine will be well-received in the market.The company has a strong focus on customer satisfaction and has a dedicated team of professionals who are committed to providing excellent service and support to their customers. With a global network of sales and service partners, the company is well-equipped to meet the needs of customers around the world.The Mgo Wall Board Machine is the latest addition to the company's comprehensive product line, which includes a wide range of construction machinery such as drywall machines, plasterboard production lines, and other building materials production equipment. The company takes pride in offering a complete solution for the construction industry, providing customers with everything they need to meet their production needs.With a strong track record of delivering high-quality products and exceptional customer service, the company has established itself as a trusted partner for construction companies worldwide. The launch of the Mgo Wall Board Machine is a testament to the company's commitment to innovation and excellence in manufacturing.The company's dedication to quality and innovation has earned them a solid reputation in the industry, and they are continuously striving to stay ahead of the competition by investing in new technologies and expanding their product offerings.In conclusion, the launch of the Mgo Wall Board Machine by Mgo Wall Board Machine Manufacturer is a significant development that further solidifies the company's position as a leading manufacturer of construction machinery. With its advanced technology, user-friendly features, and commitment to customer satisfaction, the Mgo Wall Board Machine is set to make a lasting impact in the construction industry.

High-Quality XPS Foam Board Making Equipment Manufacturing Factories

Xps Foam Board Making Equipment Factories(Xps Foam Board Making Equipment Factories), a leading manufacturer of XPS foam board making equipment, has continued to emerge as a key player in the global manufacturing industry. With a strong commitment to providing high-quality equipment and machinery, the company has cemented its reputation as a reliable and innovative supplier in the market.Established in (year), (Xps Foam Board Making Equipment Factories) has rapidly grown to become a prominent name in the industry. The company specializes in the design, production, and distribution of XPS foam board making equipment, offering a comprehensive range of machinery and solutions for manufacturers worldwide.One of the key factors that sets (Xps Foam Board Making Equipment Factories) apart from its competitors is its cutting-edge technology and state-of-the-art manufacturing facilities. The company has made significant investments in research and development, enabling it to develop advanced equipment that meets the highest industry standards. By leveraging the latest innovations and engineering expertise, (Xps Foam Board Making Equipment Factories) is able to deliver efficient, reliable, and cost-effective solutions to its customers.Furthermore, (Xps Foam Board Making Equipment Factories) prides itself on its strict adherence to quality control and production standards. The company has implemented rigorous inspection processes at every stage of manufacturing to ensure that its equipment meets the most demanding requirements. As a result, customers can trust in the durability, performance, and safety of (Xps Foam Board Making Equipment Factories)’s products, providing them with peace of mind and confidence in their manufacturing operations.In addition to its commitment to quality, (Xps Foam Board Making Equipment Factories) also places a strong emphasis on customer satisfaction. The company has a dedicated team of professionals who work closely with clients to understand their specific needs and provide tailored solutions that align with their production requirements. This customer-centric approach has earned (Xps Foam Board Making Equipment Factories) a loyal and satisfied customer base, further solidifying its position as a trusted partner in the industry.With a solid track record of success and a steadfast commitment to excellence, (Xps Foam Board Making Equipment Factories) has not only established a strong presence in its domestic market but has also expanded its reach to serve customers globally. The company has built a network of distribution and support channels in key regions around the world, enabling it to effectively serve a diverse range of customers and industries.Looking ahead, (Xps Foam Board Making Equipment Factories) is poised for continued growth and success as it remains dedicated to driving innovation, delivering superior products, and exceeding customer expectations. The company’s relentless pursuit of excellence and its focus on continuous improvement have positioned it as a significant player in the XPS foam board making equipment industry, and it is well-positioned to capitalize on the growing demand for high-performance machinery in the global manufacturing sector.In conclusion, (Xps Foam Board Making Equipment Factories) has solidified its position as a leading manufacturer of XPS foam board making equipment, thanks to its commitment to quality, innovation, and customer satisfaction. With a focus on delivering cutting-edge solutions and exceeding industry standards, the company continues to set itself apart as a trusted and preferred partner for manufacturers seeking reliable and efficient equipment. As (Xps Foam Board Making Equipment Factories) looks toward the future, its dedication to excellence and its ability to anticipate and respond to market needs will undoubtedly fuel its ongoing success in the industry.

Highly Efficient and Innovative Fiber Cement Board Manufacturing Machine

Fiber Cement Board Making Machine revolutionizes the construction industry with its efficiency and high-quality outputs. Developed and manufactured by a leading construction machinery company, this innovative machine offers a game-changing solution to the traditional ways of creating fiber cement boards.Fiber cement boards have been prevalent in the construction industry for decades, mainly due to their durability, versatility, and fire resistance. However, production processes involved in creating these boards require extensive labor and time, making it a tedious and costly process. This is where the Fiber Cement Board Making Machine comes in.The machine's operation is simple and straightforward. First, the raw materials are mixed and combined into a slurry that is poured onto a mesh on the machine's conveyor belt. The slurry is then compressed by a roller before passing through a vacuum system for water drainage. The machine's automated cutting system then splits the board into the desired length.An added advantage of this machine is its adaptability to produce different types of fiber cement boards, such as siding, roofing, and flooring. This versatility makes it an attractive option for builders and construction companies looking to diversify their product range.The company behind this innovation is a prominent construction machinery manufacturer with a rich history of over a decade. The company's mission is to provide quality, solutions-driven machinery to construction companies worldwide, ensuring they achieve maximum productivity and profitability.In line with that mission, the Fiber Cement Board Making Machine boasts of several features that make it a top-quality product. These include its heavy-duty steel frame, precision electronic control system, and adjustable speed motor for better control. The machine is also energy-efficient, with a low carbon emissions footprint, contributing to the company's commitment to sustainable manufacturing practices.The Fiber Cement Board Making Machine has already gained traction in markets worldwide, with construction companies in Europe, Asia, and America choosing it for its ease of use, reliability, and high-quality output.One company in the United States reported significant results after acquiring the machine. "We had always used traditional board-making processes that required a lot of labor and time to create our fiber cement boards. But since we acquired the Fiber Cement Board Making Machine, we have seen a tremendous improvement in productivity, and our products have also improved in quality," said the company's CEO.The Fiber Cement Board Making Machine has also stirred interest in emerging markets, where the demand for quality and affordable building materials is high. The company's commitment to providing after-sales support and training in operating and maintaining the machine has made it an ideal solution for businesses seeking to invest in sustainable and profitable machinery.In conclusion, the Fiber Cement Board Making Machine is a game-changer in the construction industry, providing a cost-effective, efficient, and sustainable solution for creating fiber cement boards. The machine's adaptability and quality output make it an attractive option for builders and construction companies worldwide looking to diversify their product range and maximize their profitability.

Europe Style for XPS Foam Board Production Line - XPS Foam Sheet Extrusion Line

article about Europe style Xps Foam Board Production Line.In recent years, the demand for Xps Foam Board has rapidly increased due to its excellent thermal insulation properties. Xps Foam Board is a type of insulation material that is widely used in construction industry to reduce energy consumption and keep the buildings warm. To meet the growing demand for Xps Foam Board, JEEBO Machinery has developed a state-of-the-art Xps Foam Board Production Line that is specifically designed to produce high quality and durable Xps Foam Boards.JEEBO Machinery, based in Qingdao, China, is a renowned manufacturer of plastic extrusion machines. With years of experience in the industry, JEEBO Machinery has built a reputation for producing cost-effective and reliable plastic extrusion machines that meet the needs of a wide range of industries. The company's Xps Foam Sheet Extrusion Line is a result of extensive research and development, and is designed to meet the specific production requirements of Xps Foam Board.The Xps Foam Board Production Line by JEEBO Machinery is fully automatic and computerized, ensuring high precision and consistency in the production process. The machine is equipped with advanced technology that allows for the production of multilayer Xps Foam Boards in a variety of thicknesses and densities. The machine is also equipped with a high-performance cooling system that ensures the Xps Foam Boards are cooled quickly and evenly, resulting in a smooth and uniform surface.One of the notable features of JEEBO Machinery's Xps Foam Board Production Line is its ability to produce Xps Foam Boards in the Europe style. The Europe style Xps Foam Board is characterized by its narrow ribs that run parallel to the long edge of the board. This design enables the Xps Foam Board to interlock with each other, creating a tight and secure seal that prevents heat loss. The Europe style Xps Foam Board is also known for its high compression strength, making it suitable for use in high-load applications.The Xps Foam Board Production Line by JEEBO Machinery is fully certified by CE and SGS, ensuring that the equipment meets the highest quality standards. The company's commitment to quality is reflected in its use of high-quality raw materials and components, as well as its rigorous testing and quality control processes.JEEBO Machinery's Xps Foam Board Production Line has received high praise from customers around the world. The machine is known for its efficiency, reliability, and ease of operation, making it a popular choice among manufacturers of Xps Foam Board. The company's after-sales service is also highly regarded, with a team of experienced technicians available to provide technical support and maintenance services.In conclusion, JEEBO Machinery's Xps Foam Board Production Line is a highly advanced and efficient machine that is designed to produce high-quality Xps Foam Boards in the Europe style. The machine's advanced technology, high precision, and consistency in the production process ensure that customers receive Xps Foam Boards that meet the highest quality standards. With its commitment to quality and customer satisfaction, JEEBO Machinery is a leading manufacturer of Xps Foam Board Production Line, and is set to play a key role in the construction industry's transition towards energy-efficient buildings.

High-Quality Panels Making Machine for Making Mgo Panels

Mgo Panels Making Machine Revolutionizing the Construction IndustryWith the increasing demand for eco-friendly and sustainable materials in the construction industry, the need for efficient and innovative manufacturing processes has become more apparent than ever. In response to this demand, a leading manufacturing company has introduced a cutting-edge Mgo panels making machine, which is revolutionizing the way Mgo panels are produced.Mgo panels, also known as magnesium oxide panels, are a popular choice in the construction industry due to their fire resistance, water resistance, and durability. These panels are used for a variety of applications, including wall and ceiling systems, furniture, and decorative elements. The traditional method of producing Mgo panels involves a labor-intensive and time-consuming process, which often results in inconsistencies and inefficiencies in the final product.However, the introduction of this advanced Mgo panels making machine has completely transformed the manufacturing process. This state-of-the-art machine is equipped with advanced technology and features that streamline the production of Mgo panels, resulting in higher quality, precision, and efficiency. The automated system ensures a consistent and uniform production process, eliminating the potential for human error and delivering a superior end product.The Mgo panels making machine is designed to handle various sizes and thicknesses of Mgo panels, providing versatility and flexibility for different construction needs. Its advanced software and control system allow for precise customization and adjustment of panel specifications, ensuring that the final product meets the exact requirements of the project.In addition to its advanced manufacturing capabilities, the Mgo panels making machine is also designed with environmental sustainability in mind. It utilizes eco-friendly materials and processes, minimizing waste and energy consumption. This aligns with the company's commitment to promoting sustainability and reducing the environmental impact of construction materials.Furthermore, the company behind this innovative Mgo panels making machine has a proven track record of excellence in the manufacturing industry. With decades of experience and expertise, the company has established itself as a leader in providing cutting-edge solutions for the construction sector. Its dedication to research and development has led to the creation of groundbreaking technologies that are reshaping the industry.The introduction of the Mgo panels making machine is a testament to the company's commitment to innovation and its ongoing efforts to meet the evolving needs of the construction industry. By offering a more efficient and sustainable solution for Mgo panel production, the company is helping to drive positive change and progress in the construction sector.The impact of this new technology is not only limited to the manufacturing process but also extends to the overall quality and performance of Mgo panels in construction projects. With the consistent and precise production facilitated by the machine, construction professionals can expect enhanced functionality, durability, and aesthetics in their projects.As the construction industry continues to embrace sustainable and high-quality materials, the Mgo panels making machine is set to play a pivotal role in shaping the future of construction. Its ability to deliver superior Mgo panels in an efficient and environmentally responsible manner is a significant step forward for the industry.In conclusion, the introduction of the Mgo panels making machine represents a major advancement in construction technology. By combining state-of-the-art manufacturing capabilities with a commitment to sustainability, the company is driving positive change and innovation in the industry. As the demand for eco-friendly and durable construction materials continues to grow, this groundbreaking machine is poised to make a lasting impact on the way Mgo panels are produced and utilized in construction projects.

Efficient Drywall Board Making Machine: An Overview

Title: Revolutionary Mgo Drywall Board Making Machine Revolutionizing the Construction IndustryIntroduction:In today's fast-paced world, the construction industry is constantly seeking innovative solutions that enhance efficiency, durability, and sustainability. Keeping up with this demand, a leading international manufacturing company has introduced an advanced Mgo drywall board making machine. With superior technology and commendable features, this groundbreaking machine is set to revolutionize the way traditional drywall boards are produced, propelling the construction sector to new heights of excellence.1. Background and Features:The new Mgo drywall board making machine leverages advanced technology to manufacture high-quality magnesium oxide (Mgo) boards, revolutionizing the construction sector. Unlike traditional drywall boards that are made using gypsum, Mgo boards boast superior fire resistance, moisture resistance, mold resistance, and environmental friendliness. These exceptional characteristics make Mgo boards ideal for a wide range of construction applications, such as walls, ceilings, partitioning, and fire-rated assemblies.2. The Working Principle:The Mgo drywall board making machine operates on a fully automated system, ensuring accuracy, precision, and rapid production. By combining magnesium oxide, magnesium chloride, and several optional additives, the machine forms a homogeneous mixture that is then poured onto a moving belt. A continuous process of molding and cutting ensures the creation of standardized, high-quality Mgo boards of various sizes and thicknesses.3. Eco-Friendliness and Sustainability:With a growing concern for sustainability and environmental protection, the introduction of the Mgo drywall board making machine addresses these crucial aspects of construction materials. The machine uses raw materials that are non-toxic, renewable, and readily available, reducing associated environmental harm. Moreover, Mgo boards have a long lifespan, reducing maintenance requirements and minimizing waste throughout their lifecycle.4. Efficiency and Productivity:The Mgo drywall board making machine boasts significant advantages in terms of efficiency and productivity. Compared to traditional drywall board manufacturing processes that involve multiple steps and long drying periods, the new machine streamlines the entire production process. Its continuous production line ensures efficient handling, rapid drying, and consistent quality, resulting in increased output and reduced costs.5. Improved Quality and Durability:By utilizing the Mgo drywall board making machine, construction companies can be assured of superior quality and durability. The advanced manufacturing technology guarantees precise board thickness, smooth surfaces, and excellent dimensional stability. Mgo boards offer exceptional resistance to fire, moisture, and mold, thus ensuring a longer lifespan and reducing the need for frequent board replacements.6. Expansion Opportunities and Market Outlook:The introduction of the Mgo drywall board making machine opens up new avenues for the construction industry, allowing companies to meet the growing demand for sustainable and high-quality building materials. The global market for drywall boards is projected to witness substantial growth, driven by urbanization, infrastructure development, and the need for greener constructions. With its exceptional features and benefits, the Mgo drywall board making machine positions companies for success in this expanding market.Conclusion:The innovative Mgo drywall board making machine is set to transform the construction industry by offering an eco-friendly, highly efficient, and superior alternative to traditional gypsum-based drywall boards. By capitalizing on advanced technology and sustainable materials, this revolutionary machine allows construction companies to deliver projects with enhanced durability and safety. With the continual advancements in construction materials, the Mgo drywall board making machine represents a remarkable step towards building a greener and more sustainable future.

PVC Foam Board Extrusion Line Machine with CE and ISO Certification: A Comprehensive Introduction

Qingdao Suke Machinery Co., Ltd., a well-known manufacturer of plastic extrusion machinery, has recently introduced a PVC foam board extruder machine with CE and ISO, aimed at catering to the growing demand for quality foam board products across the world. The PVC foam board extrusion line machine is equipped with advanced features that ensure high efficiency and quality output, making it the ideal choice for beginners looking to produce foam board products.The Foam Board Production Line is equipped with SJSZ 45/90 extruder, which has a maximum output of 180kg/h, making it suitable for small to medium scale production. The machine is made using high-quality materials and adheres to international standards, ensuring durability and reliability. The production line is also equipped with a variety of components such as a feeder, calibration table, tractor, and cutting unit, which work in unison to produce high-quality foam board products.The machine is easy to use, making it a popular choice for beginners. It has a user-friendly touch screen interface that allows operators to control all aspects of the production process, from raw material feeding to final product cutting. The machine also has an automatic cutting system, which helps to save time and reduce wastage.The Foam Board Production Line is suitable for producing a wide range of foam board products, including advertising boards, furniture boards, and building materials. The end products have a smooth surface, high density, good strength and rigidity, making them ideal for versatile applications.Talking about the company, Qingdao Suke Machinery Co., Ltd. is a leading manufacturer of plastic extrusion machinery, catering to a wide range of industries such as packaging, construction, automobiles, and more. The company has been in business for over a decade, and its machines are known for their premium quality, innovative designs, and high-level automation. Qingdao Suke Machinery Co., Ltd. has built a global reputation for its commitment to customer satisfaction, providing reliable service and support to each of its clients.With the introduction of the PVC foam board extruder machine, Qingdao Suke Machinery Co., Ltd. is further expanding its range of plastic extrusion machinery, catering to a growing demand for foam board products. The company's commitment to quality, reliability, and innovation makes it the ideal partner for businesses looking to invest in plastic extrusion machinery.In conclusion, the PVC foam board extruder machine with CE and ISO introduced by Qingdao Suke Machinery Co., Ltd. is a high-quality production line that offers a reliable and efficient solution for foam board production. The machine is easy to use, making it a popular choice for beginners, and is suitable for producing a wide range of foam board products. With its commitment to customer satisfaction, Qingdao Suke Machinery Co., Ltd. is the ideal partner for businesses looking to invest in plastic extrusion machinery.

Affordable Roof Panel Roll Forming Machine Manufacturers and Suppliers in China with Stock Availability

If you're searching for affordable, high-quality roof panel roll forming machines, look no further than Xinhonghua. As a leading manufacturer and supplier of roll forming machines in China, we offer a comprehensive range of machines specifically designed to meet the needs of roofing contractors and others working in the construction industry. With our cheap prices and extensive inventory of machines, you're sure to find the perfect roll forming machine for your application.Our roof panel roll forming machines are meticulously designed and crafted to ensure high-quality, precision performance. We use only the best materials and components, and our machines are engineered to provide long-lasting, reliable service. Whether you're looking for a machine to produce metal roofing panels, corrugated panels, or other types of roofing panels, we have the perfect machine to meet your needs.In addition to roof panel roll forming machines, we also offer a range of other roll forming machines, including Cheap Mgo Board Forming Machine Pricelist. Our MGO board forming machines are designed to produce high-quality, fire-resistant MGO boards that are perfect for use in construction, interior finishing, and other applications. With our MGO board forming machines, you can easily produce high-volume quantities of boards quickly and efficiently.At Xinhonghua, we pride ourselves on our dedication to quality, reliability, and customer service. We understand that our success depends on the satisfaction of our customers, and we work tirelessly to ensure that our machines are up to the highest standards of excellence. Whether you're a small contractor or a large construction firm, we have the expertise and experience to provide you with the products and services you need to succeed.So if you're in the market for a new roof panel roll forming machine or Cheap Mgo Board Forming Machine Pricelist, be sure to contact us today. Our friendly and knowledgeable staff are always on hand to answer any questions you may have, and we're committed to providing you with the best possible service and support. Let us help you transform your construction business with high-quality, affordable rolling forming machines from Xinhonghua.

High-Quality Gypsum Ceiling Tiles Machine Prices And Pricelist

In today's competitive market, the demand for efficient and high-quality construction materials is constantly on the rise. This is especially true for materials such as gypsum ceiling tiles, which are an essential component of modern interior design and architecture. As a result, the need for advanced and reliable production machinery, capable of meeting the industry's demands, has never been greater.Enter {}, a leading manufacturer of gypsum ceiling tiles machines. With a solid reputation for innovative technology and superior quality, {} has been at the forefront of the industry for over a decade. The company takes pride in its commitment to excellence, and its products are widely recognized for their durability, precision, and efficiency.One of the key factors that sets {} apart from its competitors is its focus on continuous research and development. The company invests heavily in the latest technologies and production methods, ensuring that its machines are always at the cutting edge of innovation. This dedication to improvement has allowed {} to stay ahead of the curve and provide customers with state-of-the-art solutions that meet and exceed their expectations.In line with its commitment to customer satisfaction, {} offers a comprehensive range of gypsum ceiling tiles machines, tailored to suit different production needs. From small-scale equipment for start-ups and SMEs to large-scale, fully automated production lines for established enterprises, {} has the capacity to cater to a wide spectrum of requirements. This flexibility has made the company a preferred choice for businesses of all sizes, looking to invest in reliable and cost-effective solutions for their manufacturing needs.Moreover, {}'s machines are designed with efficiency and cost-effectiveness in mind. By utilizing the latest technological advancements, the company's equipment is able to optimize production processes, minimize wastage, and reduce overall operational costs. This not only benefits the end-users in terms of savings but also contributes to the sustainable use of resources, making {} a responsible and environmentally conscious partner.To further enhance its customer service, {} provides comprehensive after-sales support, including installation, training, and maintenance services. This ensures that clients can maximize the performance and longevity of their equipment, while also having access to technical assistance whenever needed. In addition, the company's commitment to quality is reflected in its adherence to international standards and certifications, giving customers the reassurance that they are investing in products that meet the highest industry benchmarks.However, one of the most compelling aspects of {}'s offerings is its competitive pricing. The company understands the importance of cost-efficiency in today's business landscape and strives to provide its machines at competitive price points. In fact, {} recently released an updated pricelist for its gypsum ceiling tiles machines, making its products even more accessible to a wider range of customers.The pricelist encompasses the entire range of {}'s machines, catering to different budgets and requirements. Whether it's a manual production line for small-scale operations or a fully automated system for large-scale manufacturing, customers can find a solution that fits their needs without compromising on quality or performance. With {}'s transparent pricing, businesses can make informed decisions and plan their investments with confidence, knowing that they are getting the best value for their money.In conclusion, {}'s gypsum ceiling tiles machines pricelist is a testament to the company's dedication to providing top-tier solutions at affordable rates. Coupled with its reputation for excellence, innovation, and customer-centric approach, {} continues to be a driving force in the industry, empowering businesses to thrive in the competitive market. As the demand for high-quality construction materials continues to grow, {} stands ready to meet the needs of its customers and support their success for years to come.