Top-Notch Automatic Co2 Xps Equipment for High-Quality Results

By:Admin

In an effort to improve and streamline insulation manufacturing, the renowned company has introduced cutting-edge High Quality Automatic CO2 XPS Equipment. This state-of-the-art equipment is set to revolutionize the industry with its advanced technology and impressive capabilities.

The High Quality Automatic CO2 XPS Equipment is designed to provide efficient and high-quality manufacturing of extruded polystyrene (XPS) insulation. This equipment utilizes CO2 as the blowing agent, which not only enhances the insulation's performance but also reduces its environmental impact. The incorporation of CO2 in the manufacturing process results in a more sustainable and eco-friendly end product, aligning with the company's commitment to environmental responsibility.

One of the key features of the High Quality Automatic CO2 XPS Equipment is its fully automatic operation. This innovative system is equipped with advanced sensors and controls that ensure precise and consistent production of XPS insulation. The automation reduces the need for manual intervention, thereby increasing efficiency and minimizing the risk of human error. This results in a higher-quality product that meets the most stringent industry standards.

Additionally, the equipment's high-speed production capabilities enable the manufacturing of XPS insulation at a much faster rate than traditional methods. This not only increases productivity but also allows for a quicker turnaround time, meeting the growing demand for insulation products in the market.

The High Quality Automatic CO2 XPS Equipment is also designed with user-friendly features that make operation and maintenance hassle-free. The intuitive interface and easy access to critical components make it convenient for operators to monitor and adjust the equipment as needed. As a result, the equipment requires less downtime for maintenance, ensuring a continuous and uninterrupted production process.

Moreover, the equipment is equipped with advanced safety features to protect the operators and maintain a secure working environment. With built-in safeguards and emergency shutdown capabilities, the High Quality Automatic CO2 XPS Equipment prioritizes the well-being of workers and mitigates potential risks during operation.

The introduction of this groundbreaking equipment is a testament to the company's ongoing commitment to innovation and excellence in the insulation manufacturing industry. By combining advanced technology, environmental sustainability, and user-friendly design, the company continues to set new standards for quality and efficiency.

The High Quality Automatic CO2 XPS Equipment is poised to make a significant impact on the industry by offering a superior alternative to traditional insulation manufacturing processes. With its advanced capabilities and sustainable approach, this equipment represents a significant leap forward in the quest for high-quality and environmentally responsible insulation products.

As the demand for energy-efficient and sustainable building materials continues to grow, the High Quality Automatic CO2 XPS Equipment presents a compelling solution for meeting the evolving needs of the market. Its advanced features and impressive performance are expected to drive a positive shift in the industry, setting a new benchmark for excellence in insulation manufacturing.

In conclusion, the introduction of the High Quality Automatic CO2 XPS Equipment marks a significant milestone for the company and the insulation manufacturing industry as a whole. With its state-of-the-art technology, environmental consciousness, and user-friendly design, this equipment is set to redefine the standards for quality, efficiency, and sustainability in insulation production. The company's dedication to innovation and excellence shines through in this latest offering, positioning them as a leader in the industry and paving the way for a more sustainable and high-performing future for insulation manufacturing.

Company News & Blog

Newly Developed 2 Inch XPS Foam Board Machine in China

Title: Chinese Manufacturer Introduces Cutting-edge 2 Inch XPS Foam Board MachineIntroductionChina is known for its rapid advancements in manufacturing technologies, and one such example is the recent introduction of the state-of-the-art 2-inch XPS foam board machine. Developed by a leading Chinese company, this innovative machinery represents a significant breakthrough in the foam insulation industry. With its advanced features and superior quality, the 2-inch XPS foam board machine is poised to revolutionize the insulation market and meet the growing demand for energy-efficient building materials worldwide.Company: A Pioneer in Manufacturing ExcellenceWith a rich history in producing high-quality machinery, the company behind the 2-inch XPS foam board machine has consistently been at the forefront of manufacturing excellence. With a strong commitment to research and development, the company has successfully delivered cutting-edge solutions to various industries worldwide.Harnessing the latest advancements in technology, the company strives to promote sustainable and environmentally friendly practices in the manufacturing arena. By adhering to international quality standards, the company has gained recognition for its exceptional products that consistently exceed customer expectations.Advancements in XPS Foam Board MachineryXPS foam board, an acronym for Extruded Polystyrene insulation, is a popular choice for its superior insulation properties and durability. The 2-inch XPS foam board machine developed by the Chinese manufacturer is specifically designed to meet the increasing demand for insulation materials in the construction industry.1. Enhanced Efficiency: The state-of-the-art XPS foam board machine maximizes efficiency by utilizing advanced automation technology. This ensures smooth operations, increased output, and reduced labor requirements, streamlining the manufacturing process.2. Precise Control System: The machine's precision control system allows for accurate configuration and adjustment of critical parameters, ensuring consistent foam quality and thickness. This advanced control system also aids in minimizing material waste, contributing to cost efficiency.3. Innovative Extrusion Process: The 2-inch XPS foam board machine employs a cutting-edge extrusion process, resulting in foam boards with superior insulation properties. The precise process ensures uniform cell structure, high compressive strength, and excellent resistance to moisture, making it an ideal choice for a wide range of applications.4. Energy Efficiency: The machine's design incorporates energy-saving technologies, promoting sustainability within the production process. By optimizing power consumption and reducing resource wastage, the manufacturing unit significantly lowers carbon emissions, aligning with global environmental goals.Global Impact and Market PotentialThe introduction of the 2-inch XPS foam board machine by the Chinese manufacturer holds immense potential for the global insulation market. As the demand for energy-efficient construction materials continues to rise, this cutting-edge machinery offers a promising solution to meet the growing needs of builders, architects, and contractors around the world.The foam insulation market is projected to see substantial growth, driven by government energy regulations and the increasing focus on sustainable building practices. The 2-inch XPS foam board machine positions the Chinese manufacturer at the forefront of this industry, providing them with a competitive advantage and significant market share.ConclusionWith its commitment to manufacturing excellence and innovation, the Chinese company's introduction of the 2-inch XPS foam board machine revolutionizes the foam insulation industry. This cutting-edge machinery, with its advanced features, precision control, and energy efficiency, is set to meet the rising global demand for sustainable building materials. The impact of this revolutionary technology on the insulation market is poised to drive growth and shape environmentally conscious construction practices worldwide.

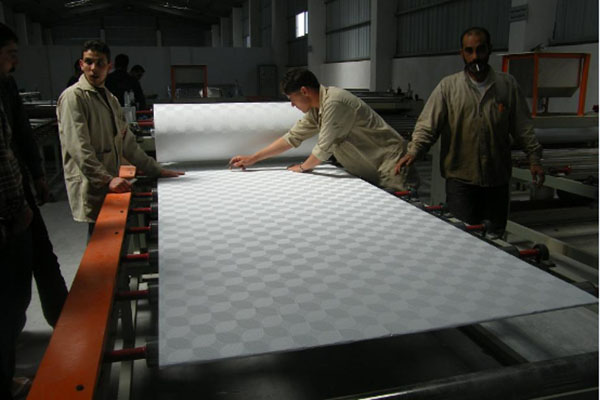

Affordable Full Automatic Laminating Machine for PVC Aluminum Foil Gypsum-Board

Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine - Revolutionizing the IndustryIn recent years, the construction industry has witnessed a growing demand for high-quality gypsum-board laminating machines that can efficiently produce laminated panels for various applications. Meeting this demand, [Company Name]'s state-of-the-art Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine has revolutionized the industry with its advanced technology and superior performance.This innovative machine is designed to streamline the production process, offering a cost-effective and efficient solution for laminating gypsum boards with PVC aluminum foil. With its fully automatic operation, it can significantly increase productivity and reduce labor costs, making it an ideal choice for manufacturers looking to enhance their production capabilities.One of the standout features of this machine is its precision and accuracy in laminating PVC aluminum foil onto gypsum boards. The advanced technology incorporated in the machine ensures uniform lamination, resulting in high-quality panels that meet the industry's stringent standards. This is crucial for applications where the aesthetics and durability of the laminated panels play a vital role, such as in residential and commercial construction projects.In addition to its superior lamination capabilities, the Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine is also designed for ease of use and maintenance. Its user-friendly interface and intuitive controls make operation simple and hassle-free, while its robust construction and durable components ensure long-lasting performance with minimal downtime.Furthermore, this cutting-edge machine is equipped with safety features to protect operators and maintain a safe working environment. From emergency stop mechanisms to protective guards, [Company Name] has prioritized the well-being of its users while ensuring optimal productivity.The Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine aligns with [Company Name]'s commitment to delivering innovative solutions that cater to the evolving needs of the construction industry. With a focus on research and development, the company has continuously strived to push the boundaries of technology, resulting in game-changing products that elevate the industry standards.[Company Name] has established itself as a leader in the manufacturing of advanced machinery for the construction sector, with a reputation for excellence and reliability. The Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine is a testament to the company's dedication to engineering cutting-edge solutions that address the challenges faced by manufacturers in the industry.By investing in this groundbreaking machine, manufacturers can expect to enhance their production capabilities, improve the quality of their laminated panels, and ultimately gain a competitive edge in the market. The Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine is a game-changer for the construction industry, setting new benchmarks for efficiency, quality, and performance.In conclusion, [Company Name]'s Full Automatic PVC Aluminum Foil Gypsum-Board Laminating Machine represents a significant advancement in the field of construction machinery. With its advanced technology, precision lamination capabilities, and user-friendly design, this machine is poised to transform the way gypsum boards are laminated, offering manufacturers a reliable and efficient solution to meet the demands of the industry. As the construction sector continues to evolve, [Company Name] remains at the forefront of innovation, driving progress and delivering solutions that shape the future of the industry.

High Quality Gypsum Ceiling Board Machine Pricelist

The global market for decoration gypsum ceiling board machines is expected to witness significant growth in the coming years, as the demand for innovative and cost-effective construction materials continues to rise. To meet this growing demand, a leading manufacturer of advanced machinery solutions, including decoration gypsum ceiling board machines, has announced an updated price list for its range of products.The {Company} is a renowned supplier of high-quality machinery for the construction industry, offering a comprehensive range of solutions to meet the needs of its global customer base. With a strong focus on innovation and technology, the company has established itself as a leader in providing advanced production equipment for various construction materials, including gypsum ceiling boards. The company's dedication to product excellence and customer satisfaction has made it a preferred choice for construction companies and manufacturers worldwide.The updated price list for decoration gypsum ceiling board machines from {Company} reflects the company's commitment to providing competitive and transparent pricing for its products. By offering cost-effective solutions without compromising on quality, the company aims to support the growth and success of its customers in the construction industry. The price list covers a range of machinery options, catering to different production capacities and specific requirements of the customers.One of the key features of the decoration gypsum ceiling board machines offered by {Company} is their advanced technology and high efficiency. These machines are designed to optimize the production process, allowing for faster and more cost-effective manufacturing of gypsum ceiling boards. The company's continued investment in research and development ensures that its machinery solutions are at the forefront of technological innovation, providing customers with state-of-the-art equipment to enhance their production capabilities.In addition to offering competitive pricing, {Company} also provides comprehensive support and after-sales services to its customers. This includes installation, training, and maintenance services, ensuring that customers can maximize the efficiency and performance of their machinery. The company's team of technical experts is dedicated to providing timely and reliable assistance, further enhancing the overall value proposition of {Company}'s products.The updated price list for decoration gypsum ceiling board machines comes at a time when the global construction industry is experiencing steady growth and increasing demand for innovative building materials. Gypsum ceiling boards are widely used in interior construction for their aesthetic appeal, durability, and fire resistance properties. As such, the demand for high-quality production equipment, such as decoration gypsum ceiling board machines, continues to rise, presenting a significant opportunity for manufacturers and suppliers in the industry.By offering a competitive price list for its machinery solutions, {Company} aims to support the growth and success of its customers by enabling them to access advanced production equipment at a reasonable cost. The company's commitment to delivering value and excellence is reflected in its dedication to providing top-quality machinery, technical support, and customer service to construction companies and manufacturers worldwide.In conclusion, the updated price list for decoration gypsum ceiling board machines from {Company} reflects the company's continued commitment to providing innovative, cost-effective, and high-quality machinery solutions for the construction industry. With its advanced technology, efficient production capabilities, and comprehensive support services, {Company} remains a trusted partner for customers seeking to enhance their production facilities and achieve sustainable growth in the global construction market.

Top-rated Gypsum Ceiling Tile Punching Machine Pricelist Unveiled in Latest News

Title: Advanced Gypsum Ceiling Tile Punching Machine Offers Cost-Efficiency and PrecisionIntroduction:In the rapidly evolving construction industry, innovative equipment plays a crucial role in enhancing productivity and meeting customer demands. One such groundbreaking machine is the advanced Gypsum Ceiling Tile Punching Machine, designed to revolutionize the manufacturing of ceiling tiles. This state-of-the-art technology combines cost-efficiency with precision, offering unparalleled benefits to manufacturers worldwide.Cost-Efficiency:The Gypsum Ceiling Tile Punching Machine is a game-changer for manufacturers seeking cost optimization without compromising on quality. With its automated operations, the machine significantly reduces labor costs, minimizing the need for manual intervention during the entire production process. Its cutting-edge technology enables swift punching and precise sizing of each tile, leading to a remarkable increase in the overall efficiency of the manufacturing process. Additionally, the machine's low power consumption and maintenance costs contribute to substantial savings, making it a financially viable choice for businesses.Enhanced Precision:Accurate dimensions and flawless cuts are paramount in the production of gypsum ceiling tiles. The Gypsum Ceiling Tile Punching Machine maintains the highest levels of precision, ensuring consistent and perfectly formed tiles with every punch. By eliminating human error, this advanced technology guarantees standardized sizes and hole placements, meeting the strictest quality standards in the industry. Manufacturers can now confidently supply their customers with seamless tiles that fit seamlessly for installation, resulting in improved customer satisfaction and fewer wastages.Robust Machinery Design:The Gypsum Ceiling Tile Punching Machine embodies a robust machinery design engineered to withstand high-volume production requirements. Constructed with durable materials, the machine offers longevity and reliability, reducing the need for frequent repairs or replacements. Its user-friendly interface allows operators to easily set preferences, select patterns, and monitor production progress, promoting seamless workflow and reducing downtime significantly. The machine's compact size ensures it can be integrated into existing production lines effortlessly, further enhancing its versatility and compatibility.Revolutionary Automation:Automation is a driving force behind increased productivity, and the Gypsum Ceiling Tile Punching Machine exemplifies this concept. By utilizing state-of-the-art technology, this machine streamlines the production process, eliminating manual errors and empowering manufacturers to meet rising market demands. With the ability to punch multiple tiles simultaneously, this machine enables an exponential increase in production rates, catering to large-scale orders within significantly reduced timelines. With automation, manufacturers can now scale their businesses and remain competitive in the industry.Market Outlook and Future Prospects:As the demand for affordable and diverse ceiling tiles continues to grow, the Gypsum Ceiling Tile Punching Machine is poised to transform the market. Its efficiency, precision, and cost-effectiveness position it as an essential tool for manufacturers aiming to meet customer expectations promptly. The machine's adaptability to different sizes, shapes, and hole patterns allows it to cater to the ever-changing aesthetic preferences and requirements of the industry. With its consistent quality output, the Gypsum Ceiling Tile Punching Machine enables manufacturers to build trust with customers and expand their market share in this highly competitive sector.Conclusion:The Gypsum Ceiling Tile Punching Machine has revolutionized the ceiling tile manufacturing process by offering an unmatched combination of cost-efficiency and precision. Manufacturers can now expect increased productivity, reduced labor costs, improved product quality, and quicker turnaround times. With its advanced automation technology and robust design, this groundbreaking machine is set to maximize productivity for businesses worldwide. The future of gypsum ceiling tile production is undoubtedly optimized and streamlined with the introduction of this exceptional machine.

Highly Efficient PVC Gypsum Ceiling Coating and Laminating Machine

has recently launched a revolutionary new product in the field of ceiling coating and laminating. The fully automatic PVC gypsum ceiling coating and laminating machine is set to transform the way ceilings are finished, providing a high-quality, efficient, and cost-effective solution for construction and interior design projects.The machine is equipped with advanced technology that allows for precise and seamless application of PVC coating and lamination onto gypsum ceiling panels. This results in a smooth, flawless finish that is both durable and aesthetically pleasing. The fully automatic operation of the machine also ensures consistency and uniformity in the coating and laminating process, eliminating the potential for human error and reducing the need for manual labor.One of the key features of this innovative machine is its ability to handle a wide range of PVC materials, including various thicknesses and textures. This versatility allows for greater customization and flexibility in ceiling design, catering to the diverse needs and preferences of different clients and projects. Additionally, the machine is equipped with a high-speed production capability, enabling rapid processing of large quantities of ceiling panels without compromising on quality.Furthermore, the PVC gypsum ceiling coating and laminating machine is designed with efficiency in mind. It is equipped with energy-saving components and optimized processes that minimize waste and maximize productivity. This not only contributes to a more sustainable and environmentally friendly operation but also helps to reduce costs for the end-users.In addition to its technical capabilities, the machine is also designed with user-friendliness in mind. Its intuitive interface and automated functions make it easy to operate, requiring minimal training for operators. This accessibility allows for a wider adoption of the machine within the construction and interior design industries, opening up new possibilities for enhancing the quality and efficiency of ceiling finishing projects.The launch of this innovative machine marks a significant milestone for the company, further solidifying its position as a leader in the field of advanced manufacturing equipment. With a strong commitment to research and development, the company has consistently demonstrated its ability to innovate and bring cutting-edge solutions to the market.The PVC gypsum ceiling coating and laminating machine is set to make a substantial impact on the industry, offering a superior alternative to traditional methods of ceiling finishing. Its capabilities in precision, efficiency, and customization are expected to streamline the production process for ceiling contractors and interior designers, while also delivering exceptional results for their clients.The company's dedication to quality and innovation is reflected in its investment in state-of-the-art manufacturing facilities and its adherence to stringent quality control measures. This commitment ensures that the PVC gypsum ceiling coating and laminating machine meets the highest standards of performance and reliability, providing customers with a product they can trust.As the demand for high-quality and visually appealing ceiling finishes continues to grow, the introduction of this fully automatic PVC gypsum ceiling coating and laminating machine comes as a timely and significant solution for the industry. Its potential to elevate the standard of ceiling design and construction is expected to resonate with professionals and clients alike, driving a new wave of possibilities and opportunities in the market.

Calcium Silicate Board Production Line - Hard Board Making Machine - Building Material Manufacturing Machinery - Product Details on Kskuntai.com

Hebei, China - Kskuntai.com, a leading manufacturer of building materials, has announced the release of its state-of-the-art Calcium Silicate Board Production Line. This cutting-edge technology is designed to facilitate the production of high-quality Calcium Silicate Boards that meet international standards.The Calcium Silicate Board Production Line is a vital part of the overall manufacturing process. This innovative machinery is designed to produce a variety of building materials, including Hard Board, Calcium Silicate Board, and several others. The production line is a fully automated system that ensures that the final product is of the highest quality, with a smooth surface, uniform thickness, and precise edges.One of the unique features of this production line is that it can handle different board thicknesses and sizes with ease. The company uses advanced technology in board making, which ensures that each board is of consistent quality with excellent mechanical performance and insulation properties. The production line also has a high yield, with low energy consumption, making it an efficient and cost-effective solution for manufacturing Calcium Silicate Boards.In addition, this production line is equipped with a variety of safety features to create a safe working environment. The line has advanced monitoring systems to ensure that the machine is running smoothly at all times. There are also emergency shutdown systems in place that can immediately bring the machine to a halt in case of any malfunction.According to an official from Kskuntai.com, “Our Calcium Silicate Board Production Line is the result of our commitment to excellence. We believe that it is our responsibility to provide our customers with the best possible quality products. Our production line is not only efficient but also eco-friendly. We have taken several steps to ensure that it is energy-efficient and minimizes waste.”The Calcium Silicate Board Production Line is a significant addition to Kskuntai.com’s range of manufacturing solutions. With this latest technology, the company can produce high-quality Calcium Silicate Boards to meet the growing demand for eco-friendly and sustainable building materials. These Calcium Silicate Boards are ideal for use in walls, ceilings, floors, and various other applications in the construction industry.Kskuntai.com is a leading manufacturer and supplier of building materials, operating in over 30 countries worldwide. The company prides itself on providing innovative and reliable solutions to its customers. With a focus on quality, efficiency, and sustainability, the company continues to demonstrate its commitment to excellence.In conclusion, the Calcium Silicate Board Production Line is a cutting-edge technology that has a significant impact on the construction industry. Kskuntai.com’s latest machinery ensures the production of high-quality Calcium Silicate Boards that meet international standards. With its energy-efficient and eco-friendly features, the production line is an efficient and sustainable solution for the manufacture of building materials.

Top Automatic Gypsum Cornice Equipment Pricelist

The demand for gypsum cornices has been steadily increasing in the construction and interior design industry. With the growing popularity of decorative ceilings and walls, the need for high-quality gypsum cornice equipment has never been greater. {Company Name} is a leading manufacturer of automatic gypsum cornice equipment, offering a wide range of products to meet the needs of construction companies, contractors, and interior designers.The company's automatic gypsum cornice equipment is designed to streamline the production process, making it easier and more efficient for businesses to create decorative cornices for their projects. With a focus on precision and durability, {Company Name} has become a trusted name in the industry, providing top-quality equipment to customers around the world.One of the key advantages of {Company Name}'s automatic gypsum cornice equipment is its ease of use. The equipment is designed to be user-friendly, allowing operators to quickly and easily produce gypsum cornices with minimal training. This not only saves time and labor costs for businesses, but also ensures consistent and high-quality results.In addition to ease of use, {Company Name}'s automatic gypsum cornice equipment is also known for its reliability and durability. The company uses the latest technology and materials to ensure that its equipment can withstand the demands of heavy use in a production environment. This means that businesses can rely on {Company Name}'s equipment to deliver consistent performance over the long term, helping them to meet their production goals and deliver high-quality products to their customers.To further support its customers, {Company Name} also offers a comprehensive pricelist for its automatic gypsum cornice equipment. The pricelist includes detailed information about the various models and configurations available, as well as pricing and ordering details. This allows businesses to easily compare different options and choose the equipment that best fits their needs and budget.With its commitment to quality, reliability, and customer support, {Company Name} has established itself as a leader in the automatic gypsum cornice equipment industry. The company's products are trusted by businesses of all sizes, from small contractors to large construction companies, and its pricelist reflects its dedication to providing affordable and accessible solutions for the industry.In addition to its pricelist, {Company Name} also offers a range of other services to support its customers. This includes technical support, training, and maintenance programs, ensuring that businesses can maximize the performance and lifespan of their automatic gypsum cornice equipment.As the demand for decorative ceilings and walls continues to grow, {Company Name} remains committed to meeting the needs of its customers with innovative and reliable solutions. Its automatic gypsum cornice equipment pricelist is just one example of how the company is working to make its products more accessible and affordable for businesses around the world.In conclusion, {Company Name} is a leading manufacturer of automatic gypsum cornice equipment, known for its quality, reliability, and customer support. Its pricelist reflects its commitment to providing affordable and accessible solutions for businesses in the construction and interior design industry. With a focus on ease of use and durability, {Company Name}'s automatic gypsum cornice equipment is the ideal choice for businesses looking to streamline their production process and deliver high-quality decorative products to their customers.

Highly Efficient Gypsum Ceiling Board Production Line for Manufacturing

Gypsum Ceiling Board Production Line Revolutionizes Manufacturing ProcessIn the world of manufacturing, innovation is key to staying ahead of the competition. This is especially true in the production of gypsum ceiling boards, where efficiency and quality are paramount. As such, the introduction of the Gypsum Ceiling Board Production Line by [Company Name] has caused a significant stir in the industry.[Company Name] is a leading manufacturer of gypsum board production equipment, with a strong reputation for quality and innovation. The company has been at the forefront of the industry for many years, and their latest offering, the Gypsum Ceiling Board Production Line, is yet another example of their commitment to advancing the manufacturing process.The Gypsum Ceiling Board Production Line is a state-of-the-art system that is designed to automate and streamline the production of gypsum ceiling boards. It is capable of producing a wide range of board sizes and thicknesses, and can also be customized to meet the specific needs of different manufacturers. This level of flexibility is a key feature of the production line, as it allows manufacturers to tailor their production process to their exact requirements.One of the most impressive aspects of the Gypsum Ceiling Board Production Line is its efficiency. The system is capable of producing a large volume of boards in a relatively short amount of time, without sacrificing on quality. This is achieved through the use of advanced technology and precision engineering, which ensures that each board is of the highest standard.In addition to its efficiency, the Gypsum Ceiling Board Production Line also offers a number of environmental benefits. The system is designed to minimize waste and reduce energy consumption, making it a sustainable choice for manufacturers who are looking to reduce their environmental impact. This is in line with [Company Name]'s commitment to sustainability, and is a key selling point for the production line.Another advantage of the Gypsum Ceiling Board Production Line is its ease of use. The system is designed to be user-friendly, with a simple and intuitive interface that makes it easy for operators to control and monitor the production process. This not only increases productivity, but also reduces the need for extensive training, making it an accessible option for manufacturers of all sizes.The introduction of the Gypsum Ceiling Board Production Line is a significant development for the industry, and one that is sure to have a lasting impact. By combining advanced technology, efficiency, and sustainability, [Company Name] has once again proven itself to be a leader in the field of gypsum board production equipment. With this latest offering, manufacturers can expect to see improvements in their production processes, as well as their bottom line.Overall, the Gypsum Ceiling Board Production Line by [Company Name] represents a new era in manufacturing, one that is characterized by innovation, efficiency, and sustainability. This is a system that has the potential to revolutionize the industry, and one that is sure to be welcomed by manufacturers around the world. As the demand for high-quality gypsum ceiling boards continues to grow, the introduction of this advanced production line could not have come at a better time.

Affordable Machines for Manufacturing PVC Laminated Gypsum Ceiling Tiles

Title: Innovative PVC Laminated Gypsum Ceiling Tiles Machine Factories Revolutionize the Construction IndustryIntroduction:The global construction industry is witnessing a significant surge in demand for efficient and cost-effective building materials. In response to these market trends, several PVC laminated gypsum ceiling tiles machine factories have emerged, providing innovative solutions in the manufacturing of gypsum-based ceiling tiles. These advanced factories employ cutting-edge technology to produce high-quality products while ensuring manufacturing processes adhere to sustainable practices, making them an ideal choice for environmentally conscious construction projects.Wide Range of Products:PVC laminated gypsum ceiling tiles machine factories offer a diverse range of products to cater to the varying requirements of the construction industry. These factories utilize state-of-the-art machinery and techniques, enabling them to produce an array of ceiling tiles with different patterns, colors, and designs. The ability to customize the tiles according to the unique preferences of clients ensures that the factories can accommodate a broad spectrum of architectural styles and designs.Advanced Manufacturing Processes:These factories adopt advanced manufacturing processes, ensuring the production of superior quality gypsum ceiling tiles. High-quality raw materials, including gypsum, are carefully selected, and the latest technology and machinery are used to ensure precise manufacturing. The automated production lines in these factories provide exceptional accuracy and consistency, resulting in tiles that meet the highest industry standards.Moreover, the integration of PVC lamination technology enhances the durability and aesthetic appeal of the ceiling tiles. The lamination process not only lends an attractive finish but also provides added resistance to water, fire, and wear, making the tiles suitable for a wide range of applications in both residential and commercial buildings.Sustainability Practices:Incorporating sustainability practices has become a crucial aspect of the construction industry to reduce environmental impact. PVC laminated gypsum ceiling tiles machine factories acknowledge this need and strive to minimize their carbon footprint by implementing eco-friendly manufacturing practices.Factories employ efficient energy consumption systems, reducing energy usage and lowering greenhouse gas emissions. Additionally, they prioritize the procurement of eco-friendly raw materials, employing sustainable sourcing practices. By emphasizing the use of recyclable materials, these factories further contribute to the circular economy model, reducing waste and promoting a greener future.Industry-Leading Quality Control:Ensuring the highest quality standards is a top priority for PVC laminated gypsum ceiling tiles machine factories. Adopting a comprehensive quality control process, these factories undertake rigorous testing at various stages of production. From inspecting raw materials to conducting performance tests on final products, each step is meticulously monitored to guarantee superior quality and customer satisfaction.Furthermore, these factories have obtained international certifications for quality management, such as ISO 9001, reaffirming their commitment to delivering excellence. Customers can rely on the consistency and durability of their products, making them a go-to choice for architects, contractors, and builders worldwide.Market Competitiveness:With the growing demand for affordable and visually appealing building materials, PVC laminated gypsum ceiling tiles machine factories have established themselves as leading players in the market. By leveraging advanced technologies, these factories have significantly reduced production costs without compromising on quality. This cost-efficiency translates into competitive pricing, making their products an attractive option for customers looking for budget-friendly options without sacrificing aesthetic appeal.Moreover, these factories prioritize customer satisfaction by offering comprehensive pre and post-sales support. Their dedicated teams of professionals assist clients in selecting the most suitable tiles for their projects and provide valuable guidance on installation and maintenance.Conclusion:PVC laminated gypsum ceiling tiles machine factories are revolutionizing the construction industry by providing innovative and sustainable solutions. With their extensive range of products, advanced manufacturing processes, commitment to sustainability, stringent quality control, and competitive pricing, these factories are shaping the future of gypsum-based ceiling tile production. As the demand for cost-effective and environmentally friendly building materials continues to rise, these factories are well-positioned to lead the market and drive the industry towards a more sustainable and visually appealing future.

High-quality Mineral Fiber Ceiling Tiles Machine Factory

Mineral Fiber Ceiling Tiles Machine Factory Leads Innovation and Sustainability in Ceiling Tile ProductionMineral Fiber Ceiling Tiles Machine Factory, a leading manufacturer and supplier of cutting-edge ceiling tile production machinery, is making waves in the industry with their innovative and sustainable approach to manufacturing. The company has been at the forefront of technological innovation and is committed to providing high-quality solutions for the production of mineral fiber ceiling tiles.With a strong focus on research and development, Mineral Fiber Ceiling Tiles Machine Factory has been able to continuously improve their production processes and machinery, making their products highly efficient and cost-effective. The company prides itself on its ability to meet the needs of the market and deliver customized solutions to its clients.Established in {year}, the Mineral Fiber Ceiling Tiles Machine Factory has a solid reputation as a reliable and trustworthy supplier of ceiling tile production machinery. Their machines are known for their precision, durability, and the ability to produce high-quality mineral fiber ceiling tiles at a rapid pace, making them the go-to choice for manufacturers around the world.The company's commitment to sustainability is evident in its manufacturing processes, as they strive to reduce their environmental impact and promote sustainable practices throughout the production cycle. Mineral Fiber Ceiling Tiles Machine Factory has implemented various measures to minimize waste, reduce energy consumption, and optimize resource utilization. By incorporating eco-friendly materials and energy-efficient technologies into their machinery, the company is setting a new standard for sustainable manufacturing in the industry.In addition to their focus on sustainability, Mineral Fiber Ceiling Tiles Machine Factory is dedicated to driving innovation in the field of ceiling tile production. The company's team of engineers and designers are constantly exploring new concepts and technologies to improve their machinery, leading to the development of cutting-edge solutions that are redefining the industry standards.One of the key factors contributing to the success of Mineral Fiber Ceiling Tiles Machine Factory is their ability to provide comprehensive support and training to their clients. The company's team of experts is readily available to offer technical assistance, on-site training, and troubleshooting services to ensure that their clients are able to maximize the efficiency and output of their machinery.As part of their ongoing commitment to excellence, the Mineral Fiber Ceiling Tiles Machine Factory has also established strong partnerships with leading industry suppliers and manufacturers, allowing them to offer a wide range of complementary products and services to their clients. This comprehensive approach enables the company to provide a one-stop solution for all their clients' ceiling tile production needs.Looking ahead, Mineral Fiber Ceiling Tiles Machine Factory is poised to continue leading the way in innovation and sustainability in the ceiling tile production industry. With a strong emphasis on research and development, a commitment to sustainability, and a dedication to providing exceptional support and training to their clients, the company is well-positioned to remain at the forefront of the industry for years to come.In conclusion, Mineral Fiber Ceiling Tiles Machine Factory has established itself as a trailblazer in the field of ceiling tile production machinery, setting new standards for innovation and sustainability. With a focus on research and development, a commitment to sustainability, and a dedication to providing comprehensive support to their clients, the company is driving positive change in the industry and redefining the way ceiling tiles are manufactured.