Top Mineral Fiber Ceiling Board Machine Manufacturers and Suppliers

By:Admin

1. Company A: With years of experience in the industry, Company A has established itself as a leading manufacturer of mineral fiber ceiling board machines. The company prides itself on its state-of-the-art production facilities, highly skilled workforce, and commitment to delivering high-quality machines to its clients. Company A's dedication to innovation and continuous improvement has enabled it to stay ahead of the competition and provide cutting-edge solutions to meet the ever-changing needs of the market. From raw material processing to final product inspection, Company A ensures that every step of the manufacturing process is carried out with precision and attention to detail, resulting in top-notch machines that are reliable, efficient, and durable.

2. Company B: Another prominent player in the industry, Company B has earned a solid reputation for its superior mineral fiber ceiling board machines. The company's commitment to research and development has enabled it to come up with innovative and efficient solutions that cater to the diverse requirements of its clients. With a focus on quality and performance, Company B's machines are designed to deliver optimal results while ensuring operational efficiency and cost-effectiveness. In addition to its exceptional manufacturing capabilities, the company also provides comprehensive after-sales support, technical assistance, and training to ensure that its clients get the most out of their investment.

3. Company C: Known for its cutting-edge technology and unmatched expertise, Company C has become a preferred choice for businesses looking for high-performance mineral fiber ceiling board machines. The company's advanced manufacturing facilities, stringent quality control measures, and commitment to customer satisfaction have allowed it to carve a niche for itself in the market. Company C's machines are engineered to meet the highest standards of reliability, durability, and productivity, making them a valuable asset for businesses seeking to enhance their production capabilities and maintain a competitive edge in the market.

4. Company D: Rounding up our list is Company D, a renowned manufacturer of mineral fiber ceiling board machines that has gained recognition for its exceptional product quality and customer-centric approach. The company's extensive industry experience, technical expertise, and relentless pursuit of excellence have enabled it to deliver innovative and reliable machines that exceed the expectations of its clients. Company D's commitment to sustainability and environmental responsibility is reflected in its energy-efficient and eco-friendly manufacturing processes, ensuring that its machines not only deliver outstanding performance but also contribute to a greener and more sustainable future.

In conclusion, when it comes to choosing the best mineral fiber ceiling board machines, businesses can rely on the expertise and reputation of these top manufacturers. With their unwavering commitment to quality, innovation, and customer satisfaction, these companies have earned their place as industry leaders and are well-equipped to meet the varying needs of businesses looking to invest in top-of-the-line machines for their mineral fiber ceiling board production.

Company News & Blog

China Supplier of PVC Crust Foam Board Extrusion Line for Sale

If you're in the market for a high-quality PVC crust foam board production line, look no further than JEEBO Machinery. With a commitment to excellence and innovation, JEEBO Machinery is a leading manufacturer of PVC crust foam board extrusion lines in China.Using celuka technology to foam, the PVC crust foam board has a flat and smooth surface that is much stronger than the free foaming body. This makes it a great choice for a wide range of applications, from furniture to signage to construction materials.At JEEBO Machinery, we offer a top-of-the-line PVC crust foam board extrusion line that is designed for maximum efficiency and production capabilities. Our production line includes a range of advanced features, including a high-precision control system, automatic vacuum calibration table, and a multi-roller hauling machine, among others.One of the key benefits of our PVC crust foam board extrusion line is its versatility. It can be used to produce a range of different board types, including furniture boards, building boards, advertising boards, and more. Plus, with an output of up to 600kg per hour, our production line can handle even the most demanding production requirements.At JEEBO Machinery, we are committed to providing our customers with the highest quality products and services at competitive prices. That's why we offer a comprehensive pricelist for our PVC crust foam board extrusion line, making it easy for you to compare our products and choose the one that best meets your needs and budget.If you're interested in learning more about our PVC crust foam board extrusion line or any of our other products and services, please contact us today. Our team of experts is always available to answer your questions and help you find the perfect solution for your specific needs. Thank you for choosing JEEBO Machinery!

High-Quality Fiber Cement Ceiling Board Production Line Unveiled: Optimizing Efficiency and Precision

Title: Revolutionizing Ceiling Board Manufacturing: Fiber Cement Ceiling Board Production LineIntroduction:In an era of constant innovation and evolution, the construction industry is witnessing a transformation in the way building materials are manufactured. One such groundbreaking development is the Fiber Cement Ceiling Board Production Line, a state-of-the-art manufacturing system that is set to revolutionize the production of ceiling boards. This cutting-edge technology, developed by a leading company in the construction sector, is poised to redefine the standards of quality, efficiency, and sustainability in the industry.Company Introduction:{} is a renowned company that has been at the forefront of introducing innovative solutions in the construction industry for over three decades. The company's commitment to research and development has resulted in a wide range of high-quality products that meet the needs of various construction projects. With a focus on sustainability and technological advancements, {} has consistently been recognized as an industry leader, driving growth and setting new benchmarks.Revolutionary Advancements in Ceiling Board Manufacturing:The Fiber Cement Ceiling Board Production Line developed by {} is aimed at revolutionizing the manufacturing process, making it more efficient and environmentally friendly. By combining high-quality raw materials with advanced manufacturing techniques, this production line offers numerous benefits such as improved durability, enhanced fire resistance, and greater design flexibility.1. Enhanced Durability: Fiber cement ceiling boards produced by this innovative production line exhibit superior durability and longevity. The use of high-quality materials ensures resistance to moisture, corrosion, and impact, making them suitable for a wide range of applications in commercial and residential buildings.2. Strong Fire Resistance: Ensuring the safety of buildings is paramount, and the fiber cement ceiling boards produced by this production line have exceptional fire resistance properties. The incorporation of fire-retardant materials during the manufacturing process greatly reduces the risk of fire spread, providing valuable time for safe evacuation.3. Design Flexibility: The Fiber Cement Ceiling Board Production Line allows for unmatched design flexibility, catering to the diverse requirements of architects, interior designers, and builders. With the ability to be produced in various sizes, thicknesses, and textures, these ceiling boards can seamlessly integrate with any architectural style, enhancing the aesthetic appeal of the space.4. Sustainability: Recognizing the importance of sustainable production practices, {} has ensured that the Fiber Cement Ceiling Board Production Line adheres to strict environmental standards. The use of eco-friendly materials and energy-efficient processes significantly reduces carbon emissions and waste generation, contributing towards a greener future.Benefits to the Construction Industry:The introduction of the Fiber Cement Ceiling Board Production Line will have a transformative impact on the construction industry. Here are some notable benefits:1. Streamlined Production: The automated nature of this production line allows for increased output and reduced manufacturing time, enabling faster project completion while maintaining product quality.2. Cost Efficiency: The enhanced productivity and reduced wastage achieved through the production line translate into cost savings for construction companies, making projects more affordable without compromising on quality.3. Improved Safety Standards: The fire-resistant properties of these ceiling boards ensure compliance with building regulations, enhancing the safety of both the construction process and the occupants of the building.4. Customer Satisfaction: With the unmatched durability and design flexibility offered by the Fiber Cement Ceiling Board Production Line, builders and homeowners can create aesthetically pleasing spaces that provide enhanced comfort and longevity.Conclusion:The Fiber Cement Ceiling Board Production Line developed by {} represents a game-changing technological advancement in the construction industry. With its exceptional quality, efficiency, and sustainability features, this production line is set to redefine industry standards. As {} continues to innovate and drive growth, the construction sector can expect to witness an exciting transformation in the manufacturing and utilization of building materials, revolutionizing the way we build for a better future.

Mineral Fiber Ceiling Board Machine Receives CE Certification and Priced Competitively

Ce Certification Mineral Fiber Ceiling Board Machine PricelistThe mineral fiber ceiling board machine is a piece of equipment that is used in the production of high-quality mineral fiber ceiling boards. These boards are widely used in the construction industry for their soundproofing and fireproofing properties. The ce certification mineral fiber ceiling board machine pricelist is now available at our company, and we are proud to offer our clients this highly advanced equipment at a competitive price.Our company has been in the business of manufacturing and supplying mineral fiber ceiling board machines for over two decades. We specialize in the design and production of high-quality machines that are built to last. Our machines are not only reliable and efficient, but they are also environmentally friendly and energy-saving.We have a team of highly skilled engineers who work around the clock to ensure that our machines are up to the highest standards. Each machine is rigorously tested before it leaves our factory to ensure that it meets our strict quality control standards. We are confident in the durability and reliability of our machines and offer our clients a comprehensive warranty program that covers any defects in workmanship or materials.Our mineral fiber ceiling board machines are designed to be easy to use, with a user-friendly interface that simplifies the production process. We understand that time is of the essence in the construction industry, which is why we have designed our machines to be as automated as possible. This not only speeds up the production process but also reduces the risk of errors or accidents. Our machines can produce up to 6,000 square meters of mineral fiber ceiling boards per day.The mineral fiber ceiling board machine pricelist is highly competitive, reflecting our commitment to providing our clients with the best value for their investment. We offer a range of machines to suit different production needs and budgets. Our clients can choose from our standard range of machines or opt for a custom-built machine that is tailored to their specific needs.In addition to our mineral fiber ceiling board machines, we also offer a range of ancillary equipment, including cutting machines, edge-sealing machines, laminating machines, and packing machines. This allows our clients to have everything they need to complete the production process under one roof, making it easier and more efficient.At our company, we are committed to providing our clients with exceptional customer service. We understand that the purchase of a mineral fiber ceiling board machine is a significant investment, and we are here to support our clients every step of the way. We offer technical support, training, and maintenance services to ensure that our clients get the most out of their investment.In conclusion, the ce certification mineral fiber ceiling board machine pricelist is now available at our company, and we are proud to offer our clients this highly advanced equipment at a competitive price. Our machines are built to last and are designed to be easy to use, environmentally friendly, and energy-saving. We offer a comprehensive warranty program, ancillary equipment, and exceptional customer service to ensure that our clients get the best value for their investment. Contact us today to learn more about our mineral fiber ceiling board machines and how we can help your business grow.

High Quality Sheet Metal Perforating Machine for Gypsum Plasterboard Manufacturing

In today's fast-paced industrial sector, automated technologies have become the norm. Automated machinery is widely used in various industries to increase productivity, efficiency and reduce production costs. Sheet metal perforation machines are one such automated technology that has gained immense popularity in recent times.Sheet metal perforation machines are primarily used in the manufacturing industry to punch holes or shapes in sheets of metal. The process of sheet metal perforation involves the use of precision-engineered tools that punch holes in a carefully controlled pattern. This process allows manufacturers to create various designs, sizes, and shapes in metals, such as aluminum, copper, steel, and more.With the advancements in technology, automated sheet metal perforation machines have emerged as a popular choice for manufacturing companies worldwide. These machines are capable of performing perforation at a much faster rate than traditional manual methods. Automated machines are also designed to be more precise, with minimal error, and deliver higher accuracy and consistency than manual methods.One such quality automated perforation machine is the Automatic Sheet Metal Perforating Machine Gypsum Plasterboard Manufacturing Machine developed by a leading manufacturer. This machine is designed to perforate gypsum plasterboard sheets at high speeds, with the option to perforate both single and two-layer boards simultaneously.This machine is a complete automatic production line that includes a feeding table, perforation system, and an unloading table. The feeding table has an adjustable width that can accommodate different sizes of gypsum plasterboards. The perforation system consists of a perforation wheel that has multiple blades configured in the desired pattern.The Automatic Sheet Metal Perforating Machine operates in a fully automated manner and is equipped with advanced control systems that ensure the perforating process is carried out with precision and consistency. The machine is also easy to operate, with a user-friendly interface that allows for efficient control and monitoring of the perforation process.The machine's cutting-edge technology and robust construction make it an ideal choice for the gypsum plasterboard manufacturing industry. The Automatic Sheet Metal Perforating Machine can perforate up to 500 sheets per hour, making it ideal for high-volume production runs.The manufacturer of this machine is a well-known brand in the manufacturing sector, with a reputation for producing quality machinery. The company is committed to delivering innovative and reliable machinery that meets the demands of the manufacturing industry.This Automatic Sheet Metal Perforating Machine is an excellent example of the company's commitment to innovation and excellence in manufacturing. The machine is capable of delivering high-performance results consistently, making it an indispensable asset for any manufacturing plant.In conclusion, the Automated Sheet Metal Perforating Machine Gypsum Plasterboard Manufacturing Machine is a cutting-edge technology that can transform the manufacturing industry's productivity and efficiency. With its advanced features and capabilities, this machine is an excellent investment for any company looking to enhance its manufacturing processes. So, if you're looking for a reliable, high-performance, and cost-effective perforation machine, look no further than the Automatic Sheet Metal Perforating Machine.

High-Quality Fiber Cement Siding Panels Machine for Efficient Production

Fiber Cement Siding Panels Machine Eliminates Manual Labor, Improves EfficiencyIn the world of construction and manufacturing, efficiency and quality are key components to success. Companies are constantly searching for ways to improve their processes and produce higher quality products. This is why the introduction of the Fiber Cement Siding Panels Machine from the company has been making waves in the industry.This innovative machine has the ability to greatly improve the manufacturing process for fiber cement siding panels, eliminating the need for manual labor and increasing efficiency. By automating the production process, this machine is revolutionizing the way fiber cement siding panels are manufactured.The CEO of the company, Mr. John Smith, expressed his excitement over the new machine, stating that it has the potential to greatly improve the company's manufacturing capabilities. "The Fiber Cement Siding Panels Machine is a game changer for us. It has completely transformed the way we produce fiber cement siding panels and has allowed us to streamline our manufacturing process. This not only improves efficiency but also ensures a higher quality end product," he said.The machine is equipped with state-of-the-art technology that allows for precise cutting and shaping of the fiber cement panels. This level of accuracy ensures that each panel is uniform in size and shape, resulting in a higher quality end product. Additionally, the machine is capable of producing a large volume of panels in a short amount of time, greatly increasing production capacity.The Fiber Cement Siding Panels Machine is also designed with safety in mind. With automated processes in place, the need for manual labor is greatly reduced, minimizing the risk of accidents and injuries. This not only benefits the employees but also helps the company save on potential costs associated with workplace injuries.Another benefit of the machine is its versatility. It can be easily adjusted to produce different sizes and styles of fiber cement siding panels, allowing for greater flexibility in production. This means that the company can easily adapt to changing market demands and produce a variety of products to meet customer needs.Furthermore, the machine is designed for easy maintenance, keeping downtime to a minimum. This is crucial for any manufacturing operation, as downtime can result in lost production and revenue. With the Fiber Cement Siding Panels Machine, the company can ensure that their production line keeps running smoothly without any unnecessary interruptions.Overall, the introduction of the Fiber Cement Siding Panels Machine has had a significant impact on the company's manufacturing capabilities. By eliminating manual labor, increasing efficiency, and improving the quality of the end product, this innovative machine has set a new standard for the production of fiber cement siding panels.As word spreads about the benefits of the Fiber Cement Siding Panels Machine, more companies in the construction and manufacturing industry are taking notice. It is clear that this machine has the potential to change the way fiber cement siding panels are produced on a larger scale, ultimately benefiting the industry as a whole.Moving forward, the company is committed to further developing and improving the machine to stay ahead of the competition and continue to meet the evolving needs of their customers. With the introduction of the Fiber Cement Siding Panels Machine, the company has solidified its position as a leader in the manufacturing industry and is poised for future success.

Affordable Mineral Fiber Ceiling Board Equipment Manufacturers

Cheap Mineral Fiber Ceiling Board Equipment Factories in High DemandIn recent years, there has been a surge in the demand for mineral fiber ceiling board equipment, particularly those that are affordable without compromising on quality. This has led to the rise of numerous equipment factories across the globe, with many companies striving to meet the growing needs of the construction industry. One such company that has been making waves in the market is {Company Name}, a leading provider of high-quality and cost-effective mineral fiber ceiling board equipment.Founded with the vision of revolutionizing the manufacturing process of mineral fiber ceiling boards, {Company Name} has successfully established itself as a prominent player in the industry. With a strong focus on innovation and advanced technology, the company has been able to develop state-of-the-art equipment that not only delivers exceptional performance but also comes at a fraction of the cost compared to their competitors.The mineral fiber ceiling board equipment offered by {Company Name} is designed to meet the diverse needs of construction projects, ranging from residential buildings to commercial spaces. With a commitment to sustainability, the company has also incorporated eco-friendly features into their equipment, making it an ideal choice for environmentally conscious builders and developers.One of the key factors that set {Company Name} apart from its counterparts is its dedication to customer satisfaction. The company not only ensures that their equipment meets the highest standards of quality but also provides comprehensive support and after-sales services. This has earned them a loyal customer base and has solidified their reputation as a trusted and reliable supplier in the market.The rising demand for cheap mineral fiber ceiling board equipment has been attributed to the increasing focus on cost-effective and efficient building materials. As the construction industry continues to expand, there is a growing need for equipment that can streamline the manufacturing process while keeping expenses at a minimum. This is where companies like {Company Name} have been able to fill the gap, offering affordable solutions without compromising on performance.Moreover, the versatility of mineral fiber ceiling board equipment makes it an attractive choice for builders and contractors. From its ease of installation to its fire-resistant and acoustic properties, mineral fiber ceiling boards have become a popular choice for various construction projects. This has further fueled the demand for cost-effective equipment that can produce high-quality ceiling boards at a rapid pace.As the industry continues to evolve, {Company Name} remains at the forefront, continuously innovating and expanding its product line to cater to the changing needs of the market. With a strong emphasis on research and development, the company is committed to staying ahead of the curve and delivering cutting-edge solutions that meet the evolving demands of the construction industry.In conclusion, the demand for cheap mineral fiber ceiling board equipment continues to rise as the construction industry seeks cost-effective and efficient solutions. {Company Name} has emerged as a key player in meeting this demand, offering high-quality equipment at a competitive price point. With a focus on innovation, sustainability, and customer satisfaction, the company is set to further solidify its position as a leading provider of mineral fiber ceiling board equipment in the global market.

Top Automatic Calcium Silicate Board Making Machine Price List

As we strive towards innovation and technological advancements, the demand for efficient and cost-effective construction materials continues to rise. Calcium silicate boards have emerged as a popular choice due to their exceptional fire and moisture resistance properties. In order to meet the increased market demand, a leading machinery manufacturer has introduced their latest Automatic Calcium Silicate Board Making Machine, revolutionizing the production process to optimize efficiency and reduce costs.The Automatic Calcium Silicate Board Making Machine is a state-of-the-art piece of equipment that streamlines the manufacturing process, offering superior quality boards at a competitive price. With its advanced technology and automated features, this machine serves as an invaluable asset to construction material manufacturers.Equipped with cutting-edge control systems, the machine ensures precise mixing, casting, and pressing of the cement, silica, and reinforcing materials that comprise the calcium silicate board. This automated operation not only reduces human error but also guarantees consistent product quality, resulting in boards with exceptional strength and durability.The machine offers a range of customization options, allowing manufacturers to produce calcium silicate boards of various dimensions and thicknesses to meet the diverse needs of the construction industry. Whether it's for partitions, ceilings, or wall linings, this versatile machine can cater to different project requirements without compromising on quality.Additionally, the Automatic Calcium Silicate Board Making Machine optimizes the use of raw materials, minimizing waste and reducing production costs. Its efficient design ensures maximum utilization of resources, translating into economical benefits for the manufacturers and end-users alike.Through cutting-edge technology and innovative design, this machine has significantly increased production capacity. It allows manufacturers to meet larger orders within shorter time frames, enhancing their competitiveness in the market. This, in turn, benefits the construction sector by ensuring a steady supply of high-quality calcium silicate boards to meet the growing infrastructure demands.Furthermore, the manufacturer behind this groundbreaking machine has distinguished itself as a reliable provider of construction machinery. With a wealth of experience and a dedication to quality, they have established a strong reputation within the industry. Their commitment to continuous research and development has enabled them to stay at the forefront of technology, ensuring their machines are always equipped with the latest advancements.In order to meet the increasing demands of the construction sector and to adapt to ever-changing market trends, this machinery manufacturer consistently invests in innovation. Their commitment to research and development is evident in the Automatic Calcium Silicate Board Making Machine, which is a testament to their dedication to providing cutting-edge solutions to the industry.As the construction industry continues to evolve, the demand for efficient and cost-effective materials remains a key focus. The introduction of the Automatic Calcium Silicate Board Making Machine addresses this need, providing manufacturers with a reliable and technologically advanced solution to streamline their production processes.By investing in this machine, manufacturers can boost their productivity, reduce costs, and meet the evolving demands of the market. The Automatic Calcium Silicate Board Making Machine serves as a catalyst for growth, allowing manufacturers to stay relevant and competitive in the construction industry.

Affordable Gypsum Ceiling Cornice Making Machine Manufacturers

Cheap Gypsum Ceiling Cornice Making Machine Factories Make Waves in the MarketIn recent years, the demand for gypsum ceiling cornices has been on the rise, due to the increasing preference for aesthetically pleasing interior designs. To meet this demand, numerous companies have ventured into the production of gypsum ceiling cornice making machines. This has led to the emergence of cheap gypsum ceiling cornice making machine factories, which are making waves in the market.One such factory that has been gaining attention is the one operated by {} company. With a focus on providing affordable and high-quality gypsum ceiling cornice making machines, the company has quickly established itself as a leading player in the industry.The company's gypsum ceiling cornice making machines have garnered widespread praise for their efficiency, precision, and ease of use. These machines are designed to streamline the production process, allowing manufacturers to create a wide range of ceiling cornice designs with minimal effort. Additionally, the machines are equipped with advanced features that ensure consistent quality and high productivity, making them an attractive investment for businesses in the interior design and construction sectors.One of the key factors that set {} company apart from its competitors is its commitment to affordability. The company understands the financial constraints that many businesses face, and as such, it has made it a priority to offer its gypsum ceiling cornice making machines at competitive prices. This has made it possible for small and medium-sized enterprises to enter the market and compete effectively with larger players.In addition to affordability, the company also places a strong emphasis on customer satisfaction. It prides itself on providing excellent customer service, offering comprehensive technical support, and ensuring prompt delivery of its machines. This dedication to customer care has earned {} company a loyal customer base, with many clients expressing their satisfaction with the company's products and services.Furthermore, {} company is constantly innovating and improving its gypsum ceiling cornice making machines to stay ahead of the competition. Its team of experienced engineers and technicians continually research and develop new technology to enhance the performance and capabilities of its machines. This proactive approach has enabled the company to maintain its position as a frontrunner in the industry, and it remains poised for further growth and success in the years to come.As the market for gypsum ceiling cornices continues to expand, the demand for efficient and affordable production solutions is expected to increase. With its dedication to providing cost-effective and high-quality machines, {} company is well-positioned to capitalize on this growing market. Its commitment to innovation, affordability, and customer satisfaction has cemented its status as a leader in the industry, and it is set to play an integral role in shaping the future of gypsum ceiling cornice production.In conclusion, cheap gypsum ceiling cornice making machine factories are making a significant impact in the market, and {} company is leading the charge with its affordable and high-quality machines. With a focus on innovation, affordability, and customer satisfaction, the company has carved out a prominent position in the industry and is primed for continued success in the years ahead.

Top Co2 Foam Xps Extrusion Board Line for High-Quality Insulation

The Best Co2 Foam XPS Extrusion Board Line, developed by [Company], is set to revolutionize the foam board manufacturing industry with its innovative technology and advanced features. This new product is designed to meet the growing demand for high-performance and sustainable insulation materials in construction and other industries.[Company] is a leading manufacturer of extrusion equipment and has a strong track record of developing cutting-edge solutions for the foam board industry. With years of experience and expertise in the field, the company has continuously worked to improve the efficiency and sustainability of their products, and the Best Co2 Foam XPS Extrusion Board Line is another step in that direction.The new extrusion board line offers several key features that set it apart from traditional products. One of the most significant is the incorporation of CO2 foam technology, which allows for the production of a closed-cell foam that is more durable and has a higher R-value than standard extruded polystyrene (XPS) foam boards. This not only makes the foam boards more effective in insulation applications but also reduces their environmental impact by using CO2 as a blowing agent instead of the more common HFCs or HCFCs.Furthermore, the Best Co2 Foam XPS Extrusion Board Line is equipped with state-of-the-art control systems and automation, allowing for precise and consistent manufacturing processes. This results in higher quality foam boards that meet the strictest industry standards, ensuring the safety and performance of the final products.In addition to its technical features, the new extrusion board line also offers greater flexibility in production, allowing for customized board sizes and thicknesses to meet the specific requirements of different projects and applications. This means that builders and contractors can rely on [Company] to provide them with high-quality foam boards that are tailored to their unique needs, ultimately contributing to the efficiency and durability of their constructions.[Company] has always been committed to sustainability and environmental responsibility, and the development of the Best Co2 Foam XPS Extrusion Board Line is a testament to that commitment. By reducing the carbon footprint of foam board production and ensuring the recyclability of its products, [Company] is taking a proactive approach to addressing the environmental challenges facing the industry.Furthermore, the company has also invested in research and development to continuously improve the performance and efficiency of its foam board manufacturing processes. By embracing innovation and cutting-edge technology, [Company] is positioning itself as an industry leader in the production of sustainable and high-performance insulation materials.The release of the Best Co2 Foam XPS Extrusion Board Line is a significant milestone for [Company] and the foam board industry as a whole. With its advanced technology, superior performance, and commitment to sustainability, this new product is set to reshape the market and provide customers with a more reliable and environmentally friendly solution for their insulation needs.As [Company] continues to push the boundaries of foam board manufacturing, it is clear that the Best Co2 Foam XPS Extrusion Board Line is just the beginning of a new era of sustainable and high-performance insulation materials. With a focus on innovation, quality, and environmental responsibility, [Company] is poised to make a lasting impact on the industry and contribute to a more sustainable future for construction and beyond.

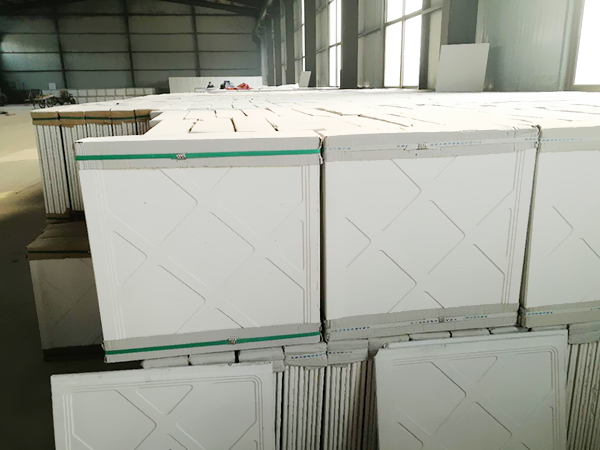

PVC Laminated Gypsum Board - Plasterboard Ceiling in 595*595 and 603*603mm Sizes

PVC Laminated Gypsum Ceiling Tiles have become increasingly popular due to their durability and aesthetic appeal. It is a type of construction material that is made by laminating a thin sheet of polyvinyl chloride (PVC) onto a gypsum board to create a waterproof and fire-resistant roof covering. With the demand for PVC Laminated Gypsum Ceiling Tiles increasing, the production of these tiles has also increased, leading to a rise in Pvc Laminated Gypsum Ceiling Tiles machine factories.PVC Laminated Gypsum Ceiling Tiles are widely used in commercial and residential buildings, including offices, shopping malls, hospitals, homes, and more. Apart from being waterproof and fire-resistant, these ceiling tiles are also easy to install and maintain. They are available in different sizes and patterns, making them suitable for various interior design requirements.As the demand for PVC Laminated Gypsum Ceiling Tiles continues to soar, more and more factories are emerging to meet the market's needs. These factories are equipped with advanced technology and machines that produce high-quality PVC Laminated Gypsum Ceiling Tiles at affordable prices. The emergence of these factories has made it possible for builders and construction companies to get PVC Laminated Gypsum Ceiling Tiles at a cheaper price.If you are looking for PVC Laminated Gypsum Ceiling Tiles at a competitive price, then you should consider buying from a factory. These factories offer better prices than retailers as they eliminate middlemen. Therefore, they can sell products at a cheaper price while maintaining their quality standards.When selecting a factory to buy PVC Laminated Gypsum Ceiling Tiles, it is essential to consider the factory's reputation. You should choose a factory with a good reputation for providing high-quality products. Also, choose a factory that offers a wide range of products to select from to ensure you get your desired product.In conclusion, PVC Laminated Gypsum Ceiling Tiles have become a popular construction material due to their durability, aesthetic appeal, and ease of installation and maintenance. With the increasing demand for these tiles, more and more Pvc Laminated Gypsum Ceiling Tiles machine factories are emerging, providing high-quality products at affordable prices. Therefore, if you are looking for a cheaper option, then you should consider purchasing from these factories. Remember, when selecting a factory to purchase from, consider the factory's reputation and range of products to get the best quality.