- Home

- Blog

- 6 Million Sqm Gypsum Ceiling Board Pvc Laminating Machine Factories - Get the Best Deals Now

6 Million Sqm Gypsum Ceiling Board Pvc Laminating Machine Factories - Get the Best Deals Now

By:Admin

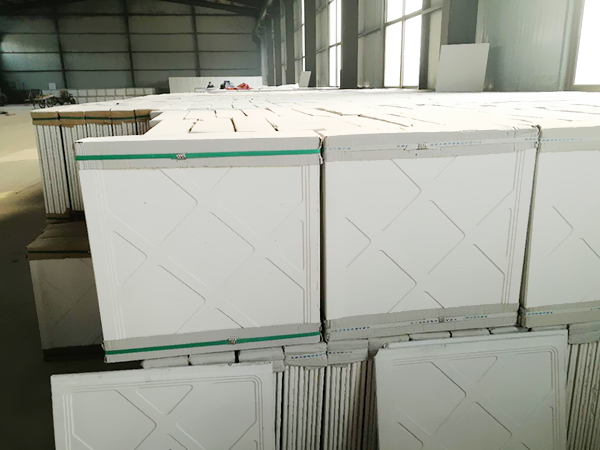

[City], [Date] - [Company Name], a leading manufacturer of industrial machinery, has recently announced plans to open a new manufacturing facility for gypsum ceiling board PVC laminating machines. The new facility, spread over an area of 6 million square meters, is expected to be a significant step forward for the company in meeting the increasing demand for its products in the global market.

The new manufacturing facility is anticipated to boost the company's production capacity and efficiency while contributing to the local economy and creating job opportunities. [Company Name] is known for its state-of-the-art machinery and equipment, and the new facility is expected to further strengthen the company's position in the industry.

The CEO of [Company Name] expressed his enthusiasm for the new manufacturing facility, stating, "We are excited to announce the opening of our new manufacturing facility for gypsum ceiling board PVC laminating machines. This expansion is a testament to our commitment to meeting the growing demand for our products while maintaining the highest standards of quality and innovation."

The company's gypsum ceiling board PVC laminating machines are widely used in the construction industry for producing high-quality ceiling boards with PVC lamination. The new facility will enable [Company Name] to streamline its manufacturing processes and meet the diverse needs of its global customer base.

With a focus on sustainability and environmental responsibility, the new manufacturing facility will incorporate the latest technologies to minimize its carbon footprint and optimize energy efficiency. This aligns with [Company Name]'s commitment to eco-friendly manufacturing practices and corporate social responsibility.

The announcement of the new manufacturing facility reflects [Company Name]'s dedication to staying at the forefront of the industry and meeting the evolving needs of its customers. The company's continued investment in research and development, coupled with its focus on customer satisfaction, has cemented its reputation as a reliable and innovative provider of industrial machinery.

In addition to the new manufacturing facility, [Company Name] also recently unveiled plans to expand its distribution network to better serve its customers across different regions. The company is working on forging strategic partnerships with distributors and suppliers to ensure seamless access to its products and services.

The establishment of the new manufacturing facility and the expansion of the distribution network are significant milestones for [Company Name] as it continues to grow and expand its presence in the global market. The company's commitment to excellence, innovation, and sustainability sets it apart as a leader in the industry.

As the demand for high-quality gypsum ceiling board PVC laminating machines continues to rise, [Company Name] is poised to meet the needs of its customers with its advanced manufacturing capabilities and dedication to customer satisfaction. The new facility is expected to be operational in the near future, and it is anticipated to have a positive impact on the company's production output and overall performance.

In conclusion, the announcement of [Company Name]'s new manufacturing facility for gypsum ceiling board PVC laminating machines underscores the company's dedication to excellence and innovation. The expansion is expected to enhance the company's manufacturing capabilities, meet the growing demand for its products, and contribute to the local economy. With a focus on sustainability and customer satisfaction, [Company Name] is well-positioned to continue its success in the industrial machinery sector.

Company News & Blog

Artistic Gypsum Cornice Production Line Price List: A Complete Guide

Artistic Gypsum Cornice Production Line Pricelist UnveiledThe artistic gypsum cornice production line pricelist has been unveiled by a renowned company specializing in the manufacturing and distribution of gypsum products. The company, with its commitment to quality and innovation, has introduced a comprehensive range of gypsum cornice production line that is set to revolutionize the industry.The artistic gypsum cornice production line pricelist offers a wide range of products that cater to the diverse needs of customers. From traditional to contemporary designs, the pricelist includes a variety of cornice profiles, each exuding elegance and sophistication. The company's dedication to providing high-quality products is evident in the meticulous attention to detail and craftsmanship that goes into each piece.With the artistic gypsum cornice production line pricelist, customers can easily find the perfect cornice to complement their interior design vision. Whether it's for a residential, commercial, or hospitality project, the pricelist offers a multitude of options that can elevate the aesthetic appeal of any space. Additionally, the competitive pricing of the products makes them accessible to a wide range of customers without compromising on quality.In addition to the pricelist, the company's extensive experience and knowledge in the industry make them a trusted partner for customers seeking expert advice and guidance. With a team of skilled professionals, the company is committed to providing personalized service to ensure that customers find the right products that meet their specific requirements.The production line is equipped with state-of-the-art machinery and technology, allowing for efficient and precise manufacturing processes. This ensures that each gypsum cornice produced is of the highest standard and meets the company's stringent quality control measures. Moreover, the company's commitment to sustainability and environmental responsibility is reflected in their use of eco-friendly materials and production methods.As a leading player in the industry, the company has established a strong reputation for delivering superior products and exceptional customer service. Their dedication to continuous improvement and innovation has enabled them to stay ahead of industry trends and anticipate the evolving needs of their customers. The unveiling of the artistic gypsum cornice production line pricelist is a testament to the company's unwavering commitment to providing top-notch products and services to their customers. By offering a diverse range of high-quality gypsum cornice products at competitive prices, the company aims to set new standards of excellence in the industry and contribute to the enhancement of interior spaces worldwide.With the artistic gypsum cornice production line pricelist now available, customers have the opportunity to explore the diverse range of products and make informed decisions based on their specific requirements. The company's dedication to quality, innovation, and customer satisfaction makes them the preferred choice for customers seeking premium gypsum cornice products.In conclusion, the unveiling of the artistic gypsum cornice production line pricelist signifies a new era of excellence and innovation in the industry. Customers can expect nothing less than superior products, exceptional service, and a commitment to sustainability from the esteemed company.

High-Quality Mgo Board Making Machine Factory: All You Need to Know

Mgo Board Making Machine Factory Leads the Way in Sustainable Construction MaterialsIn the competitive world of construction materials, the Mgo Board Making Machine Factory has emerged as a leader in providing sustainable and eco-friendly products for the building industry. With a strong commitment to innovation and quality, the company has established itself as a top choice for construction professionals looking for durable and environmentally responsible materials.The Mgo Board Making Machine Factory specializes in the production of magnesium oxide (MgO) boards, which are a popular choice for construction due to their fire resistance, water resistance, and overall durability. These boards are used in a wide range of applications, including wall panels, ceiling tiles, and flooring, making them an essential component of modern construction projects.One of the key factors that set the Mgo Board Making Machine Factory apart from its competitors is its dedication to sustainability. The company prides itself on using environmentally friendly materials and processes in the production of its MgO boards, ensuring that its products have minimal impact on the environment. This commitment to sustainability has earned the company a strong reputation among environmentally conscious builders and architects.Furthermore, the Mgo Board Making Machine Factory's state-of-the-art manufacturing facility is equipped with advanced technology and machinery, allowing for efficient and precise production of MgO boards. This ensures that the company can meet the demands of even the largest construction projects while maintaining the highest standards of quality and consistency.In addition to its dedication to sustainability and quality, the Mgo Board Making Machine Factory places a strong emphasis on customer satisfaction. The company's team of experienced professionals is committed to providing exceptional service and support to its clients, ensuring that they have all the resources they need to succeed in their construction projects.The Mgo Board Making Machine Factory's success has not gone unnoticed in the industry. The company has received numerous accolades and awards for its innovation and commitment to sustainability, further solidifying its position as a leader in the construction materials market.Looking ahead, the Mgo Board Making Machine Factory is focused on continuing to push the boundaries of sustainable construction materials. The company is constantly exploring new technologies and processes to further improve the environmental footprint of its products, with the goal of being at the forefront of the industry's shift towards more sustainable building practices.With its unwavering commitment to sustainability, quality, and innovation, the Mgo Board Making Machine Factory is poised to remain a top choice for construction professionals seeking eco-friendly and durable materials for their projects. As the demand for sustainable construction materials continues to grow, the company is well-positioned to lead the way in shaping the future of the industry.

Highly Efficient Gypsum Ceiling Board Production Line for Manufacturing

Gypsum Ceiling Board Production Line Revolutionizes Manufacturing ProcessIn the world of manufacturing, innovation is key to staying ahead of the competition. This is especially true in the production of gypsum ceiling boards, where efficiency and quality are paramount. As such, the introduction of the Gypsum Ceiling Board Production Line by [Company Name] has caused a significant stir in the industry.[Company Name] is a leading manufacturer of gypsum board production equipment, with a strong reputation for quality and innovation. The company has been at the forefront of the industry for many years, and their latest offering, the Gypsum Ceiling Board Production Line, is yet another example of their commitment to advancing the manufacturing process.The Gypsum Ceiling Board Production Line is a state-of-the-art system that is designed to automate and streamline the production of gypsum ceiling boards. It is capable of producing a wide range of board sizes and thicknesses, and can also be customized to meet the specific needs of different manufacturers. This level of flexibility is a key feature of the production line, as it allows manufacturers to tailor their production process to their exact requirements.One of the most impressive aspects of the Gypsum Ceiling Board Production Line is its efficiency. The system is capable of producing a large volume of boards in a relatively short amount of time, without sacrificing on quality. This is achieved through the use of advanced technology and precision engineering, which ensures that each board is of the highest standard.In addition to its efficiency, the Gypsum Ceiling Board Production Line also offers a number of environmental benefits. The system is designed to minimize waste and reduce energy consumption, making it a sustainable choice for manufacturers who are looking to reduce their environmental impact. This is in line with [Company Name]'s commitment to sustainability, and is a key selling point for the production line.Another advantage of the Gypsum Ceiling Board Production Line is its ease of use. The system is designed to be user-friendly, with a simple and intuitive interface that makes it easy for operators to control and monitor the production process. This not only increases productivity, but also reduces the need for extensive training, making it an accessible option for manufacturers of all sizes.The introduction of the Gypsum Ceiling Board Production Line is a significant development for the industry, and one that is sure to have a lasting impact. By combining advanced technology, efficiency, and sustainability, [Company Name] has once again proven itself to be a leader in the field of gypsum board production equipment. With this latest offering, manufacturers can expect to see improvements in their production processes, as well as their bottom line.Overall, the Gypsum Ceiling Board Production Line by [Company Name] represents a new era in manufacturing, one that is characterized by innovation, efficiency, and sustainability. This is a system that has the potential to revolutionize the industry, and one that is sure to be welcomed by manufacturers around the world. As the demand for high-quality gypsum ceiling boards continues to grow, the introduction of this advanced production line could not have come at a better time.

Affordable Insulation Foam Making Machine Factories: Find the Best Deals on XPS Equipment

Cheap XPS Insulation Foam Making Machine Factories Continue to ThriveIn recent years, the demand for XPS insulation foam making machines has been on the rise, leading to the expansion and growth of numerous factories specializing in the production of these machines. The low cost and high efficiency of these factories have made them an attractive option for business owners looking to invest in XPS insulation foam making technology.One such factory that has been making waves in the industry is {reputable factory name}. Specializing in the manufacturing of XPS insulation foam making machines, {factory name} has established itself as a leading supplier of high-quality machinery for the production of XPS insulation foam. With a focus on providing cost-effective solutions for their customers, {factory name} has been able to maintain a strong presence in the market and meet the growing demand for their products.The success of {factory name} can be attributed to a combination of factors, including their commitment to innovation, quality, and customer satisfaction. By continuously investing in research and development, {factory name} has been able to stay ahead of the competition and introduce cutting-edge technology that meets the evolving needs of the industry. This, coupled with their stringent quality control measures, ensures that every XPS insulation foam making machine that leaves their factory is of the highest standards.Furthermore, {factory name} prioritizes customer satisfaction, offering a range of services to support their clients in the setup, installation, and maintenance of their machines. With a dedicated team of technical experts, {factory name} provides comprehensive support to their customers, ensuring that their machines continue to operate at peak performance.The success of {factory name} is a testament to the growing demand for XPS insulation foam making machines, as well as the potential for growth within the industry. With more and more businesses looking to invest in XPS insulation foam technology, the need for reliable and cost-effective machinery has never been greater. This has created a wealth of opportunities for factories like {factory name} to thrive and expand their operations to meet the growing demand.As the market for XPS insulation foam making machines continues to grow, it is expected that more factories will emerge to cater to the increasing demand. This is good news for the industry as a whole, as more competition will drive innovation and push for even higher standards of quality and efficiency. Ultimately, this will benefit businesses looking to invest in XPS insulation foam making technology, as they will have more options to choose from and can expect even greater value for their investment.In conclusion, the success of {factory name} is a testament to the thriving market for XPS insulation foam making machines. With a focus on innovation, quality, and customer satisfaction, {factory name} has been able to establish itself as a leading supplier in the industry. As the demand for XPS insulation foam making machines continues to grow, it is expected that more factories will emerge to meet the increasing need for this technology. This bodes well for the industry, as it will drive further innovation and push for higher standards of quality and efficiency, ultimately benefiting businesses looking to invest in XPS insulation foam making technology.

Gypsum Board Production Line Supplier for Ceiling Boards

Gypsum Ceiling Board Production Line SupplierIf you are looking for high-quality gypsum board production line, then you must find the right supplier. A reliable supplier will offer you all the necessary equipment that you need to make gypsum ceiling board production without any complications.A gypsum ceiling board production line is a complex process that requires expertise and precision equipment. So, when looking for gypsum board equipment, you need to make sure that you choose a trustworthy supplier that can deliver the latest technologies without compromising the quality.Gypsum Ceiling Board Equipment PricelistWhen it comes to buying gypsum ceiling board equipment, pricing is a critical factor to consider. Therefore, you need to find a supplier that offers reasonable prices without compromising the quality of the equipment.A good supplier should provide a gypsum ceiling board equipment pricelist to help you budget for the project. This pricelist should include all the necessary equipment for gypsum board production, including the production line, raw materials, and additives. Moreover, the supplier should also provide you with all the necessary training on how to operate the equipment safely and efficiently. This will ensure that you get the most out of your investment and produce high-quality gypsum ceiling boards that meet all the relevant industry standards.Hengshui Decheng Machinery & Equipment Co., Ltd.One of the most reliable suppliers of gypsum board production equipment is Hengshui Decheng Machinery & Equipment Co., Ltd. This company has been in the business of manufacturing and selling gypsum board equipment for many years.They offer a wide range of gypsum ceiling board equipment, including the gypsum board production line, raw materials, and additives. They also provide complete solutions for the manufacturing of gypsum board, including installation, commissioning, and technical support.What makes Hengshui Decheng Machinery & Equipment Co., Ltd stand out from the rest is their commitment to quality. All their gypsum ceiling board equipment is made from high-quality materials, and they use the latest technologies to ensure that their products perform at the highest levels.ConclusionIn conclusion, finding the right gypsum ceiling board production line supplier is crucial to the success of your project. You need to find a reliable supplier that can offer you the latest equipment, reasonable prices, and excellent customer service.Hengshui Decheng Machinery & Equipment Co., Ltd is one of the leading suppliers of gypsum board production equipment. They offer a wide range of equipment, including the gypsum board production line, raw materials, and additives, at competitive prices.Therefore, if you are planning to invest in gypsum board production equipment, you can trust Hengshui Decheng Machinery & Equipment Co., Ltd to provide you with the best equipment and services for your project.

Efficient Production Line for Mineral Fiber Ceiling Tiles Boosts Manufacturing Process

[Company Name], a leading manufacturer in the construction industry, has recently launched their state-of-the-art Mineral Fiber Ceiling Tiles Production Line. This advanced production line is set to revolutionize the production process of mineral fiber ceiling tiles, providing customers with high-quality and cost-effective solutions for their construction and interior design needs.With years of experience in the industry, [Company Name] has become renowned for their commitment to innovation and excellence. The introduction of their new Mineral Fiber Ceiling Tiles Production Line is a testament to their dedication to providing cutting-edge solutions to their customers.The production line boasts the latest technology and machinery, allowing for efficient and streamlined manufacturing processes. This ensures that each mineral fiber ceiling tile produced is of the highest quality, meeting industry standards and regulations. By incorporating advanced automation systems, the production line also improves productivity and reduces human error, resulting in increased efficiency and reliability.Mineral fiber ceiling tiles are highly sought-after in the construction and interior design sectors due to their numerous benefits. These ceiling tiles are known for their excellent acoustic properties, providing sound insulation and improving the overall acoustics of a space. Additionally, mineral fiber ceiling tiles offer superior fire resistance, making them a safe choice for various commercial and residential applications.[Company Name]'s Mineral Fiber Ceiling Tiles Production Line is capable of producing a wide range of ceiling tiles in different sizes, designs, and finishes. This versatility allows customers to choose the perfect ceiling tiles that complement their interior aesthetics while fulfilling their functional requirements.The implementation of this advanced production line also underscores [Company Name]'s commitment to sustainability. The manufacturing process of mineral fiber ceiling tiles incorporates eco-friendly practices, minimizing waste and reducing the carbon footprint. By investing in this production line, [Company Name] further solidifies their position as an environmentally responsible industry leader.Commenting on the launch, [Spokesperson Name], the CEO of [Company Name], expressed their excitement about the new production line, stating, "We are thrilled to introduce our Mineral Fiber Ceiling Tiles Production Line to the market. This state-of-the-art facility will allow us to meet the growing demand for high-quality, sustainable ceiling tiles while maintaining our commitment to innovation and customer satisfaction."As the construction industry continues to evolve, [Company Name] remains at the forefront of advancements, continuously striving to provide innovative solutions to their customers. With the launch of their Mineral Fiber Ceiling Tiles Production Line, they are expected to further strengthen their position as a market leader in the production of high-quality construction materials.Customers can now rely on [Company Name] for premium mineral fiber ceiling tiles that offer a perfect blend of functionality, aesthetics, and sustainability. Whether it's for commercial spaces, educational institutions, healthcare facilities, or residential projects, their extensive range of ceiling tiles will meet the diverse needs of different sectors.In conclusion, [Company Name]'s introduction of the Mineral Fiber Ceiling Tiles Production Line is set to redefine the production process and quality standards of mineral fiber ceiling tiles. With their commitment to innovation, sustainability, and customer satisfaction, [Company Name] continues to play a pivotal role in shaping the future of the construction industry.

Top Automatic Factories Producing the Best Gypsum Cornice Designs

Gypsum cornices have been used as a decorative element for centuries. They add elegance and character to any interior space. However, manually producing these ornate designs is a time-consuming and difficult process. To overcome this challenge, several automatic equipment factories have been established. Among these, one of the best gypsum cornice design automatic equipment factories is located in China.This factory, which shall remain unnamed for confidentiality reasons, specializes in the manufacture of gypsum cornice molding machines. With its highly advanced technology, this factory has gained popularity among its customers for its efficiency and quality. The automatic equipment produced by this factory is used in the production of gypsum cornices, which are widely used in interior decoration.The gypsum cornice molding machine produced by this factory is fully automatic and operates with high precision. This equipment eliminates the manual labor and production errors that often occur in traditional methods. In addition, the machine has a high production capacity which means that it can produce a large number of gypsum cornices in a shorter time without sacrificing quality.The factory uses high-quality raw materials to manufacture its machinery. The machines are made of sturdy materials that ensure the long life span of the production equipment. The factory also has strict quality control measures in place during the production process. This quality control ensures that the machinery produced is of the highest standard.The gypsum cornice molding machine produced by this factory can produce various designs and sizes of gypsum cornices. The machine can produce classic, contemporary, and customized designs. This production flexibility makes it an ideal solution for contractors and designers seeking a customizable finishing touch to their projects.The factory also provides training and after-sales services to its clients. This support ensures that clients can use the equipment properly and efficiently. It also provides assistance if there are any issues with the equipment.The gypsum cornices produced using the automatic equipment from this factory are in high demand across the world. The cornices produced are of superior quality and are used in various settings, including commercial, residential, and public spaces. The gypsum cornice design automatic equipment factory is known for its commitment to excellence and innovation. The use of technology to produce gypsum cornices has revolutionized the industry, and this factory is leading the way in this expansion of the industry.The factory's commitment to quality and innovation has made it a leader in the industry. The use of automatic equipment has made the production process efficient and cost-effective. The factory has been able to provide quality products to the market at competitive prices. This commitment to quality has earned the factory a strong reputation and a loyal customer base.The use of gypsum cornices in interior design is growing, and this factory is poised to take advantage of this upward trend. With its state-of-the-art technology and commitment to quality, this factory is positioned to remain as a leader in the industry for many years to come.In conclusion, the best gypsum cornice design automatic equipment factory, located in China, is using advanced technology to produce high-quality gypsum cornices. Their commitment to excellence and innovation has made them a leader in the industry. Their machines are efficient, cost-effective, and produce superior quality gypsum cornices. Their dedication to quality and service has earned them a loyal customer base. They have positioned themselves to remain at the forefront of the industry, contributing to the growth of the gypsum cornice industry.

High-Quality Economic Gypsum Cornice Making Machine with Aluminium Alloy Mold

Economic Gypsum Cornice Making Machine With Aluminium Alloy Mold is a new product launched by a leading company in the construction industry. The company is well-known for providing high-quality construction machinery and equipment for their clients. This latest product is designed to meet the growing demand for efficient and cost-effective solutions for making gypsum cornices.The Economic Gypsum Cornice Making Machine With Aluminium Alloy Mold is a state-of-the-art machine that is designed to produce high-quality gypsum cornices with great precision and speed. The machine is equipped with advanced technology and features that make it easy to use and maintain. Its aluminium alloy mold ensures the durability and longevity of the cornices, making them suitable for various construction projects.The company behind this innovative product has a strong reputation for delivering reliable and top-notch construction solutions to its clients. With years of experience in the industry, they have established themselves as a trusted name in providing cost-effective and efficient machinery for construction purposes. Their expertise in manufacturing and supplying construction equipment makes them a preferred choice for many customers.The Economic Gypsum Cornice Making Machine With Aluminium Alloy Mold is a testament to the company's commitment to innovation and excellence. The machine is designed to meet the specific needs of construction companies and contractors, providing them with a convenient and reliable solution for producing gypsum cornices. Its economic efficiency makes it a valuable addition to any construction project, helping clients to save time and money without compromising on quality.The company's dedication to quality and customer satisfaction is evident in the design and performance of the Economic Gypsum Cornice Making Machine With Aluminium Alloy Mold. The machine is built to deliver consistent and reliable results, ensuring that clients can meet their construction deadlines and quality standards. Its high-speed production capabilities make it a valuable asset for any construction project, allowing clients to increase their productivity and efficiency.In addition to its high-performance capabilities, the Economic Gypsum Cornice Making Machine With Aluminium Alloy Mold is also designed with user convenience in mind. The machine is easy to operate and maintain, allowing clients to maximize their investment and minimize downtime. Its sturdy construction and durable components make it a reliable and long-lasting solution for producing gypsum cornices.With the launch of the Economic Gypsum Cornice Making Machine With Aluminium Alloy Mold, the company continues to demonstrate its leadership in the construction industry. By offering innovative and cost-effective solutions, they are helping their clients to stay ahead of the competition and achieve their construction goals. This latest product is a testament to their commitment to delivering cutting-edge machinery and equipment that meets the evolving needs of the construction industry.Clients who are interested in the Economic Gypsum Cornice Making Machine With Aluminium Alloy Mold can contact the company for more information. With their proven track record of delivering top-quality construction solutions, clients can trust in the reliability and performance of this latest product. The company's dedication to customer satisfaction and product excellence makes them a valuable partner for any construction project.

Foaming Sheet Production Equipment: A Complete Guide

Xps Foaming Sheet Production Equipment is a game-changer in the manufacturing industry. This innovative equipment is designed to produce Xps foaming sheets, which are widely used in construction, insulation, and packaging applications. The equipment is a result of years of research and development, and it is set to revolutionize the way Xps foaming sheets are produced.The production equipment is equipped with advanced technology and state-of-the-art machinery, making it highly efficient and productive. It is capable of producing Xps foaming sheets of various thicknesses and dimensions, meeting the diverse needs of the market. The equipment is also designed to ensure consistent quality and high precision in the production process, resulting in superior and reliable products.The company behind Xps Foaming Sheet Production Equipment, {Company Name}, is a leading manufacturer and supplier of industrial machinery and equipment. With a strong focus on innovation and technology, the company has been at the forefront of developing cutting-edge solutions for various industries. The Xps Foaming Sheet Production Equipment is the latest addition to the company's product portfolio, and it is poised to make a significant impact in the manufacturing sector.{Company Name} has a global presence, with a strong network of customers and partners in different parts of the world. The company's commitment to quality, reliability, and customer satisfaction has earned it a strong reputation in the industry. With a team of highly skilled and experienced professionals, {Company Name} continuously strives to deliver superior products and services to its customers.The Xps Foaming Sheet Production Equipment is a testament to {Company Name}'s dedication to innovation and excellence. The equipment is designed to streamline the production process of Xps foaming sheets, making it more efficient and cost-effective. It is also equipped with advanced features that ensure safety and environmental sustainability, aligning with the company's commitment to responsible manufacturing practices.In addition to its technical capabilities, the Xps Foaming Sheet Production Equipment is also designed for ease of use and maintenance. The user-friendly interface and automated functionalities make it convenient for operators to manage and control the production process. Moreover, the equipment is built to withstand long hours of operation and maintain high performance, ensuring maximum uptime and productivity.The launch of Xps Foaming Sheet Production Equipment is expected to bring significant benefits to manufacturers in the construction, insulation, and packaging industries. By providing a reliable and efficient solution for producing Xps foaming sheets, the equipment is set to enhance the overall production capabilities of businesses, enabling them to meet the growing demand for high-quality products.With its commitment to innovation and customer satisfaction, {Company Name} is dedicated to supporting its customers in adopting the latest technologies for their manufacturing operations. The Xps Foaming Sheet Production Equipment is a reflection of the company's vision to create value-driven solutions that empower businesses to thrive in today's competitive environment.In conclusion, the launch of Xps Foaming Sheet Production Equipment by {Company Name} represents a significant milestone in the manufacturing industry. With its advanced technology, superior quality, and commitment to innovation, the equipment is poised to elevate the production of Xps foaming sheets to new heights. As businesses embrace this innovative solution, they can expect to achieve greater efficiency, reliability, and performance in their manufacturing operations, ultimately driving growth and success in their respective markets.

Affordable Mgo Board Equipment: A Cost-Effective Solution

With a strong focus on innovation and quality, [Company Name] has recently announced the launch of their new line of affordable Mgo boards, catering to the needs of the construction and building industry. The [Company Name] Mgo board equipment has been designed to meet the demands of modern construction projects, offering a cost-effective and durable solution for various building applications.Mgo boards, also known as magnesium oxide boards, are becoming increasingly popular in the construction industry due to their remarkable properties. These boards are known for their strength, fire resistance, and resistance to environmental factors such as water and mold. With the growing demand for sustainable and resilient building materials, Mgo boards have emerged as a preferred choice for architects and contractors.The [Company Name] Mgo board equipment stands out in the market due to its affordability without compromising on quality. The company has invested in state-of-the-art manufacturing technology to ensure that their Mgo boards meet the highest industry standards. This commitment to quality is reflected in the performance of the boards, making them suitable for a wide range of applications including wall and ceiling panels, exterior cladding, and fire-rated assemblies.In addition to their exceptional performance, the [Company Name] Mgo boards are also environmentally friendly. As a company that prioritizes sustainability, [Company Name] ensures that their manufacturing processes adhere to the highest environmental standards. This means that the Mgo boards are not only durable and cost-effective but also contribute to a greener building industry.Speaking about the new product line, [Spokesperson Name], the CEO of [Company Name], expressed his enthusiasm for the market introduction of their Mgo board equipment. "We are thrilled to bring our new line of Mgo boards to the market. With the increasing demand for sustainable and resilient building materials, we saw an opportunity to provide a cost-effective solution without compromising on quality. Our Mgo board equipment is a testament to our commitment to innovation and sustainability in the construction industry."The [Company Name] Mgo board equipment is set to disrupt the market by offering a budget-friendly alternative to traditional building materials. As the construction industry continues to evolve, there is a growing need for innovative solutions that meet the demands of modern architecture. The launch of the Mgo board equipment is a step in this direction, providing builders and contractors with a reliable and affordable option for their projects.Furthermore, [Company Name] has earned a reputation for delivering exceptional customer service and technical support. With a team of experienced professionals, the company is dedicated to ensuring that their clients receive the guidance and assistance they need when using the Mgo board equipment. This commitment to customer satisfaction sets [Company Name] apart from its competitors and has contributed to its success in the industry.In conclusion, the introduction of the new line of affordable Mgo board equipment from [Company Name] is a significant development in the construction industry. With a focus on quality, sustainability, and affordability, the company is poised to make a positive impact on the market. As the demand for resilient and environmentally friendly building materials continues to grow, the [Company Name] Mgo board equipment is well-positioned to meet the needs of the industry and establish itself as a preferred choice for construction projects.