Highly Efficient Insulated Panels Machine for MGO Production

By:Admin

{Company X} is a leading manufacturer and supplier of innovative construction materials and machinery. With a strong focus on research and development, the company has continually strived to revolutionize the construction industry. By leveraging advanced technology and a commitment to excellence, {Company X} has earned a reputation for providing high-quality products and machinery to its clients worldwide.

[News Content]

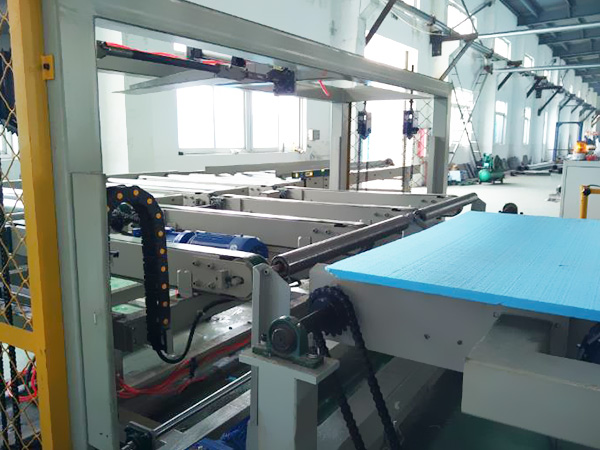

In a major breakthrough for the construction industry, {Company X} has recently unveiled its latest innovation – the Insulated Mgo Panels Machine. This cutting-edge machinery is set to revolutionize the way insulated panels are manufactured, delivering a more efficient and cost-effective solution for construction projects.

The Insulated Mgo Panels Machine is designed to produce highly insulated magnesium oxide panels, which offer exceptional thermal and fire-resistant properties. These panels are widely used in residential, commercial, and industrial construction, offering a sustainable and eco-friendly alternative to traditional building materials.

One of the key features of the Insulated Mgo Panels Machine is its advanced automation and precision engineering. The machine is equipped with state-of-the-art technology that allows for precise control over the panel manufacturing process, ensuring consistent quality and performance. This level of automation also results in higher productivity and reduced labor costs, making it an attractive option for construction companies looking to optimize their operations.

Furthermore, the Insulated Mgo Panels Machine is designed with sustainability in mind. It has been optimized to minimize waste and energy consumption, aligning with {Company X}'s commitment to environmental responsibility. By producing insulated panels with a lower environmental impact, the machine supports sustainable construction practices and helps reduce the carbon footprint of building projects.

The launch of the Insulated Mgo Panels Machine is sure to have a significant impact on the construction industry. With its ability to streamline the manufacturing process and deliver high-performance insulated panels, the machine is poised to become a game-changer for builders and developers worldwide. Its innovative features and technological advancements are set to raise the bar for construction materials and machinery, setting a new standard for efficiency and sustainability.

{Company X} remains dedicated to pushing the boundaries of what is possible in the construction industry. The Insulated Mgo Panels Machine is just the latest example of the company's commitment to innovation and excellence. With a relentless focus on research and development, {Company X} continues to lead the way in providing groundbreaking solutions that meet the evolving needs of the construction sector.

As the construction industry continues to embrace sustainable and high-performance building materials, the Insulated Mgo Panels Machine is well-positioned to meet the growing demand for advanced insulated panels. Its arrival represents a significant leap forward in the quest for more efficient, eco-friendly, and cost-effective construction solutions.

In conclusion, {Company X}'s unveiling of the Insulated Mgo Panels Machine marks a significant milestone for the construction industry. This innovative machinery promises to revolutionize the manufacturing of insulated panels, offering an efficient, sustainable, and high-performance solution for construction projects. With its advanced automation and environmental sustainability, the Insulated Mgo Panels Machine is set to redefine the standards for construction materials and machinery, setting a new benchmark for excellence in the industry.

Company News & Blog

Affordable Extrusion Line for Xps Foam Board

Cheap XPS Foam Board Extrusion Line revolutionizes the production process for insulation and construction materials. The company, a leading manufacturer in the industry, has introduced this new line of extrusion equipment with the aim of addressing the growing demand for cost-effective and high-quality XPS foam boards. This development is expected to have a significant impact on the construction and insulation market, providing a more affordable option for building materials.The introduction of the Cheap XPS Foam Board Extrusion Line comes as a response to the increasing need for insulation and construction materials that offer superior thermal performance and energy efficiency. With the rising concerns about energy consumption and environmental impact, there is a growing demand for insulation products that can effectively reduce heating and cooling costs while also minimizing the carbon footprint of buildings. XPS foam boards have long been recognized as a reliable solution for achieving these objectives. However, the high cost of production has often been a barrier to their widespread adoption.The new extrusion line is designed to address this challenge by incorporating innovative technologies that significantly reduce the cost of manufacturing XPS foam boards. With improved efficiency and productivity, the line is capable of producing high-quality insulation materials at a much lower cost, making them more accessible to a wider range of customers. This development is expected to have a positive impact on the construction industry, as builders and contractors will be able to incorporate superior insulation materials into their projects without incurring substantial expenses.In addition to cost savings, the Cheap XPS Foam Board Extrusion Line also offers advantages in terms of product quality and performance. The equipment is equipped with advanced control systems and precision engineering, ensuring that the foam boards produced meet the highest standards for insulation effectiveness and durability. This level of quality is crucial for ensuring the long-term performance of building materials, as well as the overall energy efficiency of structures. With the introduction of this new extrusion line, customers can expect to access XPS foam boards that deliver exceptional thermal performance and contribute to the sustainability of their buildings.As a leading manufacturer in the industry, {} is committed to providing innovative solutions that address the evolving needs of the market. The company has a long-standing reputation for excellence in the production of insulation and construction materials, and the introduction of the Cheap XPS Foam Board Extrusion Line is a testament to its dedication to technological advancement and customer satisfaction. By investing in the development of this new equipment, {} seeks to set new standards for the production of XPS foam boards, offering a compelling combination of affordability, quality, and performance.With the launch of the Cheap XPS Foam Board Extrusion Line, {} is poised to make a significant impact on the construction and insulation market. The company's commitment to affordability and quality, combined with its innovative approach to manufacturing, sets a new benchmark for the industry. As demand for energy-efficient and sustainable building materials continues to grow, the introduction of this new extrusion line represents a valuable opportunity for builders, contractors, and insulation professionals to access superior products that can contribute to the long-term performance and environmental impact of their projects. With the Cheap XPS Foam Board Extrusion Line, {} is redefining the possibilities for insulation and construction materials, positioning itself as a leader in the industry and a valuable partner for customers seeking reliable, cost-effective solutions.

Affordable Mineral Fiber Ceiling Machine for Acoustic Installation

Cheap Acoustic Mineral Fiber Ceiling Machine Revolutionizes Construction Industry In a path-breaking development, a leading machinery manufacturing company has introduced a new and revolutionary product, the Cheap Acoustic Mineral Fiber Ceiling Machine, that is set to transform the construction industry. With its cutting-edge technology and advanced features, this innovative machine is a game-changer in the field of construction and ceiling installation.The company has been a pioneer in the manufacturing of construction machinery for over a decade. With a strong commitment to innovation and quality, the company has consistently developed and launched products that have set new benchmarks in the industry. Their products are known for their durability, reliability, and efficiency, making them the preferred choice for construction companies and contractors worldwide.The Cheap Acoustic Mineral Fiber Ceiling Machine is the latest addition to their extensive range of machinery. It has been designed and engineered to meet the growing demand for cost-effective and efficient solutions for installing acoustic mineral fiber ceilings. The machine's state-of-the-art technology allows for quick and precise installation, saving both time and labor costs for construction projects.One of the key features of the Cheap Acoustic Mineral Fiber Ceiling Machine is its ability to handle a wide range of ceiling materials, including mineral fiber tiles, metal panels, and gypsum boards. This versatility makes it a versatile and valuable asset for construction companies as it can be used for various projects, from commercial buildings to residential properties.The machine's user-friendly interface and intuitive controls make it easy to operate, minimizing the need for specialized training or expertise. This makes it an ideal choice for both experienced professionals and new entrants in the construction industry. Additionally, the machine's compact and portable design allows for easy transportation to different job sites, further enhancing its utility and convenience.Another standout feature of the Cheap Acoustic Mineral Fiber Ceiling Machine is its cost-effectiveness. The machine is priced competitively, offering exceptional value for money compared to other similar products in the market. This makes it an attractive investment for construction companies looking to enhance their efficiency and productivity while controlling costs.The introduction of the Cheap Acoustic Mineral Fiber Ceiling Machine has already generated significant interest and excitement in the construction industry. The machine has been met with positive reviews from early adopters, who have praised its performance, reliability, and cost-saving benefits. Industry experts and analysts have also recognized its potential to drive significant improvements in the construction sector.In addition to its innovative products, the company is known for its commitment to customer satisfaction and after-sales service. They have a dedicated team of professionals who provide comprehensive support and maintenance services for all their products, ensuring smooth operations and long-term reliability for their customers.With its unmatched performance, versatility, and cost-effectiveness, the Cheap Acoustic Mineral Fiber Ceiling Machine is poised to make a significant impact on the construction industry. Its introduction is a testament to the company's ongoing dedication to developing innovative solutions that empower construction professionals and drive progress in the industry.As the construction industry continues to evolve and embrace modern technologies, the Cheap Acoustic Mineral Fiber Ceiling Machine represents a significant step forward in the quest for more efficient and sustainable building practices. It is set to become an indispensable tool for contractors and construction companies, setting new standards for excellence and productivity.In conclusion, the introduction of the Cheap Acoustic Mineral Fiber Ceiling Machine by {} demonstrates the company's unwavering commitment to innovation and excellence in the construction machinery sector. With its game-changing features and benefits, this revolutionary machine is well-positioned to revolutionize the way acoustic mineral fiber ceilings are installed, making it an essential asset for construction professionals around the world.

Efficient T-Ceiling Roll Forming Machine for Gypsum Board Panel Production

If you are planning to renovate or build a new home or office, you are probably wondering how to choose the best type of ceiling for your space. One of the most popular choices for ceilings is gypsum board, also known as drywall or plasterboard. It is a versatile and affordable material that can be shaped into many styles and patterns to suit any interior design scheme.If you are looking for a reliable and efficient way to produce gypsum board ceilings, you should consider investing in a gypsum board frame T-grid roll forming machine. This type of machine is specially designed to produce high-quality and precise gypsum board T-grids, which are the supporting elements that hold the gypsum panels in place.Gypsum board frame T-grid roll forming machines are widely used in decoration gypsum ceiling board machine factories, as they offer many advantages over traditional manufacturing methods. One of the main benefits of using a roll forming machine is that it allows for continuous production, which means higher output and faster delivery times.Moreover, T-grids produced by a gypsum board frame T-grid roll forming machine are extremely accurate and consistent in size and shape, which ensures a perfect fit between the grid and the gypsum panels. This is especially important for large-scale projects where minor deviations can make a big difference in the overall appearance and stability of the ceilings.Another advantage of using a gypsum board frame T-grid roll forming machine is that it offers a high level of flexibility and customization. The machine can be easily adjusted to produce T-grids of different dimensions, shapes, and patterns, depending on the specific requirements of the project. This means that you can create unique and creative ceiling designs that are tailored to your clients' needs and preferences.When choosing a gypsum board frame T-grid roll forming machine, it is important to look for a reliable and experienced manufacturer that can provide you with the best quality equipment and technical support. A good manufacturer should have a team of skilled engineers and technicians who can help you with installation, training, and maintenance services, as well as offer customized solutions to meet your specific production needs.In conclusion, a gypsum board frame T-grid roll forming machine is an essential tool for any decoration gypsum ceiling board machine factory that produces gypsum board ceilings. With its high efficiency, accuracy, and flexibility, it can help you achieve excellent results and meet your clients' expectations. If you want to take your business to the next level, investing in a roll forming machine could be the best decision you ever make.

High-quality Gypsum Ceiling Board Machine from China<TextView>Title 2: Superior Gypsum Ceiling Board Machine Manufactured in China

China Gypsum Ceiling Board Machine (we will refer to it as the "Machine" for the purpose of this article) has been making waves in the construction industry with its advanced technology and high-quality products. The Machine, which is manufactured by [], has established itself as a leading provider of gypsum ceiling board manufacturing equipment in the market.With its headquarters located in China, [], the company has been at the forefront of innovation in the construction sector for years. The Machine is a testament to their commitment to delivering state-of-the-art products that meet the needs of their customers.The Machine is designed to produce high-quality gypsum ceiling boards, which are commonly used in interior construction for their durability and aesthetic appeal. With its advanced technology and precise manufacturing process, the Machine has set a new standard for gypsum ceiling board production.One of the key features of the Machine is its efficiency. It is capable of producing large quantities of gypsum ceiling boards in a short amount of time, making it an ideal choice for manufacturers looking to increase their production capacity.In addition to its high-speed production capabilities, the Machine also boasts a high level of precision and accuracy. This ensures that every gypsum ceiling board produced is of the highest quality, free from defects or imperfections.Another standout feature of the Machine is its versatility. It is capable of producing a wide range of gypsum ceiling board designs, allowing manufacturers to cater to different customer preferences and market demands. This flexibility has made the Machine a popular choice among construction companies and contractors.The Machine is also known for its reliability and low maintenance requirements. Its robust design and durable components make it a long-term investment for manufacturers, offering reliable performance and minimal downtime.In addition to its impressive technical capabilities, the Machine is also backed by comprehensive customer support and after-sales service from []. This ensures that customers receive the necessary assistance and guidance to make the most of their investment in the Machine.As a result of its advanced technology, high-quality production, and exceptional customer support, the Machine has earned a strong reputation in the construction industry. It has become a preferred choice for manufacturers looking to enhance their production capabilities and deliver superior gypsum ceiling boards to their clients.The success of the Machine can also be attributed to the continuous innovation and research efforts of []. The company is dedicated to staying ahead of the curve in the construction sector, constantly developing new technologies and solutions to meet the evolving needs of the industry.Looking ahead, the Machine is expected to continue making a significant impact on the construction industry, setting new standards for gypsum ceiling board production and contributing to the advancement of interior construction. With its cutting-edge technology and unwavering commitment to quality, the Machine is well-positioned to remain a leader in its field for years to come.In conclusion, the Machine from [] is a standout example of Chinese innovation and excellence in the construction industry. Its advanced technology, high-quality production, and comprehensive support have made it a preferred choice for manufacturers looking to elevate their gypsum ceiling board production. As the construction sector continues to evolve, the Machine is poised to play a pivotal role in shaping the future of interior construction.

High-Quality Equipment for Mineral Fiber Ceiling Board Production

Mineral Fiber Ceiling Board Equipment (MFCBE) has revolutionized the manufacturing process of ceiling boards. The state-of-the-art equipment, offered by a leading company in the industry, has set a new standard for efficiency, quality, and reliability.With the increasing demand for high-quality ceiling boards in both residential and commercial construction, the need for advanced manufacturing equipment has become crucial. MFCBE is designed to meet this growing demand, offering a wide range of features that enhance productivity and product quality.The company behind this innovative equipment is a renowned leader in the manufacturing industry, with a rich history of delivering cutting-edge solutions. With a strong focus on research and development, the company has continuously pushed the boundaries of technology to provide its customers with the best equipment in the market.The MFCBE is a testament to the company's commitment to innovation. It incorporates advanced technologies that streamline the manufacturing process, resulting in higher production efficiency and reduced operational costs. The equipment is also designed with precision and accuracy in mind, ensuring that the ceiling boards produced meet the highest quality standards.One of the key features of the MFCBE is its flexibility. The equipment is capable of producing a wide range of ceiling board sizes and designs, allowing manufacturers to cater to diverse customer needs. This flexibility is further enhanced by the equipment's quick changeover capabilities, which enable seamless transitions between different board specifications.In addition to its manufacturing capabilities, the MFCBE also prioritizes safety and environmental responsibility. The equipment is equipped with advanced safety features to protect the operators and workers. Furthermore, it is designed to minimize waste and reduce energy consumption, aligning with the company's commitment to sustainable manufacturing practices.The MFCBE is not just a piece of equipment; it is a comprehensive solution that encompasses training, maintenance, and after-sales support. The company provides extensive training programs to ensure that manufacturers can maximize the potential of the equipment. Furthermore, a dedicated team of technical experts is available for ongoing support and maintenance, ensuring that the equipment operates at its peak performance.The impact of the MFCBE extends beyond the manufacturing sector. By enhancing the efficiency and quality of ceiling board production, the equipment contributes to the overall advancement of the construction industry. It enables builders and architects to access high-quality materials, resulting in safer and more durable structures.Furthermore, the company's commitment to continuous improvement means that the MFCBE is constantly evolving. The company invests heavily in research and development to introduce new features and capabilities that keep its customers at the forefront of technology.As a result, the MFCBE has garnered significant attention and acclaim within the industry. Manufacturers who have adopted the equipment have reported substantial improvements in their operations, citing increased productivity, reduced costs, and superior product quality.In conclusion, the Mineral Fiber Ceiling Board Equipment offered by the leading manufacturing company is a game-changer for the industry. Its advanced capabilities, commitment to safety and sustainability, and comprehensive support make it the ideal choice for manufacturers looking to elevate their production capabilities. With the MFCBE, the company has once again demonstrated its leadership in delivering innovative solutions that drive progress in the manufacturing sector.

Mineral Fiber Suspended Ceiling Tiles for Your Space: All You Need to Know

Suspended ceilings, also known as drop ceilings or false ceilings, have been a popular option for commercial and residential spaces for many years. These ceilings are installed on a metal grid system and can be easily accessed for repairs and maintenance. Suspended ceilings are not only functional, but they are also aesthetically pleasing and offer a wide range of design options.One of the most popular materials for suspended ceiling tiles is mineral fiber. Mineral fiber tiles are made from a blend of natural and synthetic materials, including mineral wool, clay, perlite, and cellulose. These ingredients are mixed together to create a durable, fire-resistant material that is ideal for use in buildings of all kinds.Mineral fiber tiles offer many benefits over other materials. They are highly absorbent, making them ideal for use in acoustically sensitive areas such as conference rooms, lecture halls, and theaters. They also provide excellent thermal insulation, helping to reduce heating and cooling costs.In addition to their functional qualities, mineral fiber tiles are also available in a wide range of designs and finishes to suit any aesthetic preference. They can be painted, printed, embossed, or textured to create a unique and personalized look.When installing suspended ceilings, it is essential to choose the best mineral fiber ceiling tiles machine. This machine is responsible for producing high-quality tiles that meet the required industry standards. A good mineral fiber ceiling tiles machine should be efficient, reliable, and easy to use.There are several factors to consider when selecting a mineral fiber ceiling tiles machine. One of the most critical factors to consider is the production capacity. The machine should be capable of producing a sufficient number of tiles to meet the project's needs.Another important consideration is the level of automation. Automated machines can offer improved efficiency, minimize waste, and reduce labor costs. They may also provide more consistent quality control than manual machines.Ease of use is another vital factor when selecting a mineral fiber ceiling tiles machine. The machine should be easy to operate and maintain, with clear instructions and minimal downtime.In conclusion, mineral fiber suspended ceiling tiles offer many benefits, including durability, insulation, and an aesthetically pleasing appearance. When selecting a mineral fiber ceiling tiles machine, it is crucial to consider factors such as production capacity, automation, and ease of use, to ensure that the machine meets the project's needs and delivers high-quality tiles.

Affordable Foam Board Making Machine for Sale

Cheap Xps Foam Board Making Machine Revolutionizes Insulation ManufacturingAs the demand for energy-efficient and cost-effective insulation materials continues to rise, the development of advanced production technology has become increasingly important. In response to this, the renowned machinery manufacturer, [Company Name], has introduced a groundbreaking XPS foam board making machine that is set to revolutionize the insulation manufacturing industry.The XPS foam board making machine is designed to produce high-quality extruded polystyrene (XPS) foam boards, which are widely used in construction for thermal insulation. This innovative machine boasts a range of advanced features that set it apart from traditional manufacturing equipment, making it a game-changer for insulation material production.One of the key advantages of the XPS foam board making machine is its cost-effectiveness. By utilizing state-of-the-art technology, the machine is able to significantly reduce production costs, making it an attractive investment for companies in the insulation manufacturing sector. This cost-efficient manufacturing process is expected to have a positive impact on the availability and affordability of XPS foam boards in the market.Furthermore, the XPS foam board making machine is highly efficient, with the ability to produce a large volume of insulation materials in a relatively short period of time. This increased production capacity is expected to address the growing demand for XPS foam boards in the construction industry, where energy-efficient insulation solutions are in high demand.In addition to its cost-effectiveness and efficiency, the XPS foam board making machine also boasts a high level of precision and quality control. This ensures that the produced foam boards meet the highest standards of quality and performance, providing customers with reliable and durable insulation materials for their construction projects.[Company Name] has a long-standing reputation for innovation and excellence in the manufacturing machinery industry. With a strong commitment to research and development, the company has consistently introduced cutting-edge technology to meet the evolving needs of various industries. The introduction of the XPS foam board making machine is a testament to [Company Name]'s dedication to providing state-of-the-art solutions for the insulation manufacturing sector.Furthermore, [Company Name] prides itself on its customer-centric approach, striving to deliver products and services that exceed the expectations of its clients. The XPS foam board making machine is a result of extensive market research and feedback from industry professionals, ensuring that it meets the specific requirements and demands of insulation manufacturers.With its advanced technology, cost-efficiency, and high-quality production capabilities, the XPS foam board making machine is expected to have a significant impact on the insulation manufacturing industry. As companies seek to meet the growing demand for energy-efficient construction materials, this innovative machine is poised to become a vital tool in the production of XPS foam boards.In conclusion, the introduction of the XPS foam board making machine by [Company Name] represents a major advancement in the insulation manufacturing industry. With its cost-effective production process, high efficiency, and precision quality control, the machine is set to revolutionize the production of XPS foam boards, providing a reliable and affordable solution for the construction industry's insulation needs. As [Company Name] continues to lead the way in technological innovation, the future of insulation manufacturing looks brighter than ever.

Artistic Gypsum Cornice Production Line in China: News and Updates

The art of gypsum cornice production in China has reached new heights with the introduction of the state-of-the-art production line by a leading company in the industry. This advanced production line has revolutionized the way gypsum cornices are manufactured, setting new standards for quality and efficiency in the industry.The production line, which is a result of years of research and development, combines cutting-edge technology with traditional craftsmanship to produce exquisite gypsum cornices that are unmatched in their precision and elegance. The company, with its rich history and expertise in the field, has been at the forefront of innovation and has continuously strived to improve the quality of its products.The new production line has significantly enhanced the company's production capacity, allowing it to meet the growing demand for its products both domestically and internationally. With the ability to produce a wide range of designs and patterns, the company has now positioned itself as a leader in the global market for gypsum cornices.One of the key features of the production line is its ability to produce gypsum cornices with intricate details and designs, thanks to its advanced molding and casting technology. This has enabled the company to offer a diverse range of products that cater to the varying needs and preferences of its customers.Furthermore, the production line has also incorporated environmentally sustainable practices, ensuring that the production process is eco-friendly and in line with global standards for sustainable manufacturing. This has not only reduced the company's environmental impact but has also positioned it as a responsible and ethical player in the industry.The company's commitment to quality is reflected in the materials used in the production of gypsum cornices, which are sourced from trusted suppliers and undergo stringent quality control measures. This ensures that the final products are of the highest quality, with exceptional durability and aesthetic appeal.In addition to its advanced production capabilities, the company also places a strong emphasis on research and development, constantly innovating and creating new designs and patterns that reflect the latest trends in interior design. This has enabled the company to stay ahead of the competition and consistently offer fresh and innovative products to its customers.With its new production line, the company has set a new benchmark for the industry, establishing itself as a leading manufacturer of gypsum cornices in China and beyond. Its commitment to excellence, innovation, and sustainability has earned it a strong reputation and a loyal customer base, solidifying its position as a key player in the global market.Looking ahead, the company aims to continue its legacy of excellence and innovation, further expanding its production capacity and investing in research and development to create even more impressive and environmentally friendly products. With its dedication to quality and customer satisfaction, the company is poised to make even greater strides in the industry, shaping the future of gypsum cornice production in China and around the world.

Get Affordable Quotes for Mgo Board Equipment

Company Introduction:{} is a leading manufacturer and supplier of high-quality building materials, specializing in the production of Mgo boards. With a commitment to innovation and excellence, we have been providing top-of-the-line products to our customers for over a decade. Our Mgo boards are used in various construction projects including residential, commercial, and industrial buildings, due to their durability, fire resistance, and ease of installation.News Content:In the construction industry, the choice of building materials plays a crucial role in the overall quality and safety of a structure. Mgo boards have gained popularity in recent years due to their exceptional properties, and {} is proud to offer competitive quotes on this essential construction material.Mgo boards, also known as magnesium oxide boards, are a type of building material that has gained popularity for their versatility and durability. These boards are made from a mixture of magnesium oxide, perlite, and wood fiber, and are highly regarded for their fire resistance, mold resistance, and strength. They are commonly used in a wide range of construction applications, including wall and ceiling linings, exterior cladding, and flooring.At {}, we understand the importance of high-quality building materials, and we are dedicated to providing our customers with the best products at competitive prices. Our Mgo boards are manufactured using advanced technology and strict quality control measures, ensuring that they meet the highest industry standards.To meet the growing demand for Mgo boards, we are pleased to offer competitive quotes on bulk orders of our products. Whether you are a contractor working on a large-scale construction project or a homeowner embarking on a renovation, our cost-effective quotes make it easier for you to access top-quality Mgo boards without compromising on your budget.Furthermore, our Mgo boards are easy to install, making them a practical choice for construction projects of any size. Their lightweight nature and versatile applications make them suitable for a wide range of building requirements. Additionally, our Mgo boards have a long lifespan, reducing the need for frequent replacements and maintenance, thus providing excellent value for our customers.As a customer-centric company, we also take pride in our exceptional customer service and support. Our team of experts is available to provide assistance and guidance to our clients, ensuring that they have a seamless experience from inquiry to delivery. We prioritize customer satisfaction and are committed to building lasting relationships with our clients based on trust, reliability, and superior products.In conclusion, {} is your one-stop destination for premium Mgo boards at competitive quotes. With our dedication to quality, innovation, and customer satisfaction, we are proud to be a trusted supplier of construction materials to a wide range of clients. Contact us today to learn more about our products and take advantage of our competitive quotes for your next construction project.

Automatic Waterproof Mgo Board Production Line at Wholesale Price

In recent news, the global construction industry is set to witness a significant advancement with the introduction of a new wholesale automatic waterproof Mgo board production line. This state-of-the-art production line is expected to revolutionize the way Mgo boards are manufactured, offering enhanced efficiency, precision, and cost-effectiveness.The new wholesale automatic waterproof Mgo board production line is the result of extensive research and development efforts by a leading construction materials manufacturing company. With a strong focus on innovation and technological advancement, the company has successfully developed a cutting-edge production line that is set to disrupt the traditional manufacturing processes for Mgo boards.The introduction of this new production line is expected to address several key challenges currently faced by the construction industry, particularly in relation to the production of high-quality Mgo boards. As a crucial component in modern construction, Mgo boards are widely used for their superior strength, durability, and fire resistance. However, the traditional manufacturing processes for Mgo boards are often labor-intensive, time-consuming, and cost-prohibitive.The wholesale automatic waterproof Mgo board production line is set to overcome these challenges by offering a fully automated production process that is capable of producing Mgo boards with exceptional precision and consistency. The advanced technology incorporated into the production line ensures that the Mgo boards meet the highest standards of quality and performance, making them ideal for a wide range of construction applications.One of the most noteworthy features of the new production line is its waterproof capabilities. The incorporation of advanced waterproofing technology ensures that the Mgo boards produced are highly resistant to moisture, making them suitable for use in wet and humid environments. This is a significant advantage over traditional Mgo boards, which may be susceptible to water damage over time.Furthermore, the wholesale automatic waterproof Mgo board production line is designed to be highly efficient, with a focus on minimizing waste and maximizing productivity. By streamlining the manufacturing process and reducing manual intervention, the production line is able to produce Mgo boards at a faster rate and with lower production costs. This not only benefits the company in terms of profitability but also makes the Mgo boards more cost-effective for construction projects.In addition to its technological advancements, the company behind the wholesale automatic waterproof Mgo board production line has a strong reputation for its commitment to sustainability and eco-friendly manufacturing practices. The company prioritizes the use of environmentally-friendly materials and processes, ensuring that the production of Mgo boards has minimal impact on the environment. This aligns with the growing demand for sustainable construction materials and reflects the company's dedication to responsible business practices.Overall, the introduction of the wholesale automatic waterproof Mgo board production line represents a significant milestone in the construction industry. By offering a technologically advanced and cost-effective solution for the production of high-quality Mgo boards, the production line is set to drive innovation and efficiency in construction projects around the world. With its emphasis on precision, consistency, and sustainability, the new production line sets a new standard for the manufacturing of Mgo boards and underscores the company's position as a leading player in the construction materials industry.