Highly Efficient Gypsum Ceiling Board Production Line for Manufacturing

By:Admin

In the world of manufacturing, innovation is key to staying ahead of the competition. This is especially true in the production of gypsum ceiling boards, where efficiency and quality are paramount. As such, the introduction of the Gypsum Ceiling Board Production Line by [Company Name] has caused a significant stir in the industry.

[Company Name] is a leading manufacturer of gypsum board production equipment, with a strong reputation for quality and innovation. The company has been at the forefront of the industry for many years, and their latest offering, the Gypsum Ceiling Board Production Line, is yet another example of their commitment to advancing the manufacturing process.

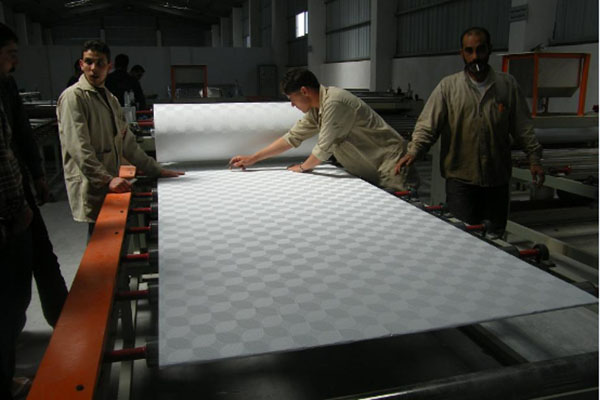

The Gypsum Ceiling Board Production Line is a state-of-the-art system that is designed to automate and streamline the production of gypsum ceiling boards. It is capable of producing a wide range of board sizes and thicknesses, and can also be customized to meet the specific needs of different manufacturers. This level of flexibility is a key feature of the production line, as it allows manufacturers to tailor their production process to their exact requirements.

One of the most impressive aspects of the Gypsum Ceiling Board Production Line is its efficiency. The system is capable of producing a large volume of boards in a relatively short amount of time, without sacrificing on quality. This is achieved through the use of advanced technology and precision engineering, which ensures that each board is of the highest standard.

In addition to its efficiency, the Gypsum Ceiling Board Production Line also offers a number of environmental benefits. The system is designed to minimize waste and reduce energy consumption, making it a sustainable choice for manufacturers who are looking to reduce their environmental impact. This is in line with [Company Name]'s commitment to sustainability, and is a key selling point for the production line.

Another advantage of the Gypsum Ceiling Board Production Line is its ease of use. The system is designed to be user-friendly, with a simple and intuitive interface that makes it easy for operators to control and monitor the production process. This not only increases productivity, but also reduces the need for extensive training, making it an accessible option for manufacturers of all sizes.

The introduction of the Gypsum Ceiling Board Production Line is a significant development for the industry, and one that is sure to have a lasting impact. By combining advanced technology, efficiency, and sustainability, [Company Name] has once again proven itself to be a leader in the field of gypsum board production equipment. With this latest offering, manufacturers can expect to see improvements in their production processes, as well as their bottom line.

Overall, the Gypsum Ceiling Board Production Line by [Company Name] represents a new era in manufacturing, one that is characterized by innovation, efficiency, and sustainability. This is a system that has the potential to revolutionize the industry, and one that is sure to be welcomed by manufacturers around the world. As the demand for high-quality gypsum ceiling boards continues to grow, the introduction of this advanced production line could not have come at a better time.

Company News & Blog

China-based Manufacturer Offers PVC Imitation Marble Decorative Sheet Making Machine

Kingshine Plastic Machinery: A Leading Manufacturer in ChinaKingshine Plastic Machinery is a leading manufacturer and supplier of high-quality plastic machinery and equipment. The company is based in China and has over 10 years of experience in the field of plastic machinery. Kingshine Plastic Machinery is committed to providing innovative and cost-effective solutions to customers across the world. In this article, we will focus on one of the company's flagship products, the PVC Imitation Marble Decorative sheet Making Machine.PVC Imitation Marble Decorative sheet Making MachineKingshine Plastic Machinery has introduced its latest product, the PVC Imitation Marble Decorative sheet Making Machine. As per their website, “PVC Imitation Marble Decorative sheet Making Machine is a highly automated manufacturing solution for MS and PC sheets used in various industries.” It is designed to produce sheets with a marble-like finish, which can be used to create decorative panels for a wide range of applications such as flooring, walls, furniture, and more.Features of PVC Imitation Marble Decorative sheet Making MachineThe PVC Imitation Marble Decorative sheet Making Machine is built with the latest technology and state-of-the-art equipment. Some of the features of this machine include:1. High Production Efficiency: The PVC Imitation Marble Decorative sheet Making Machine is capable of producing up to 800 Kg of sheets per hour, making it ideal for large-scale production.2. Versatility: With this machine, users can produce sheets of different sizes and thicknesses depending on their specific needs.3. Easy Operation: The machine is designed for ease of use and requires minimal technical knowledge to operate. It also comes with a user-friendly interface that makes it easier for operators to monitor the production process.4. Energy Efficient: The PVC Imitation Marble Decorative sheet Making Machine is engineered to optimize energy consumption, resulting in significant savings in electricity costs.5. High-Quality Output: The sheets produced by this machine have a marble-like finish, high gloss, and excellent physical properties.Why Choose Kingshine Plastic Machinery?Kingshine Plastic Machinery is a respected name in the plastic machinery industry. The company has been in business for over a decade and has built a reputation for providing high-quality machinery and excellent customer service. Some of the reasons to choose Kingshine Plastic Machinery include:1. Exceptional Quality: All Kingshine Plastic Machinery products are made with high-quality materials and are designed to meet or exceed industry standards.2. Custom Solutions: Kingshine Plastic Machinery understands that every customer has unique needs. As such, the company offers customized machinery solutions tailored to individual customer requirements.3. Competitive Prices: Kingshine Plastic Machinery offers high-quality products at competitive prices, making them an affordable option for businesses of all sizes.4. Excellent Customer Support: The company has a team of knowledgeable and experienced professionals who provide excellent customer support to clients, from initial inquiries to after-sales support.ConclusionThe PVC Imitation Marble Decorative sheet Making Machine is one of the latest offerings from Kingshine Plastic Machinery. With its high production efficiency, versatility, and ease of use, this machine is an excellent investment for businesses seeking to manufacture high-quality sheets for various decorative applications. As a leading manufacturer of plastic machinery, Kingshine Plastic Machinery provides innovative and cost-effective solutions to clients across the world. To learn more about the PVC Imitation Marble Decorative sheet Making Machine and Kingshine Plastic Machinery, visit their website.

Revolutionary Automatic Equipment for Gypsum Board Cornice Production

Title: Revolutionizing Gypsum Board Cornice Production with Innovative Automatic Equipment Introduction:In the rapidly evolving construction industry, technological advancements continue to drive innovation and revolutionize traditional manufacturing processes. Among these innovations, the introduction of automatic equipment for gypsum board cornice production has emerged as a game-changer. This breakthrough solution, developed by an industry-leading company, is set to streamline production, enhance efficiency, and guarantee superior quality in the production of gypsum board cornices.Revolutionizing the Gypsum Board Cornice Manufacturing Process:The new automatic equipment, developed by an industry leader (), simplifies the labor-intensive and time-consuming process of creating gypsum board cornices. This cutting-edge equipment combines advanced technology with precision engineering to bring unprecedented efficiency to the production line. With its innovative features, the device is poised to transform the gypsum board cornice production landscape.Efficiency and Precision through Automation:The automatic equipment boasts an impressive array of features that optimize productivity and ensure consistent quality. Through automation, it eliminates the need for manual labor, significantly reducing production time and costs. By automating key steps such as gypsum mixture preparation, molding, drying, and finishing, the equipment guarantees precise and flawless results.Moreover, this state-of-the-art machinery eliminates human errors, such as inconsistencies in measurements and imprecise cutting. By adhering to pre-programmed instructions, the device ensures standardized dimensions and shapes for each cornice produced. This not only enhances the visual appeal of the final product but also reduces wastage, thus contributing to a greener and more sustainable manufacturing process.Intuitive Control System for Seamless Operation:The automatic equipment incorporates an intuitive control system that enables operators to effortlessly manage and monitor the entire production process. The user-friendly interface provides easy access to crucial parameters such as temperature, humidity, and drying time, allowing operators to make necessary adjustments on the go.Furthermore, the equipment's control system includes built-in safety features to safeguard operators and the overall production line. From emergency stops to error detection, the system effectively mitigates potential risks, ensuring a safe working environment for all involved.Reliable Durability and Low Maintenance:One of the key advantages of this automatic equipment is its exceptional durability. Constructed from high-quality materials and engineered to withstand demanding production environments, this equipment promises longevity and minimal downtime. Additionally, the machinery requires minimal maintenance and is built to withstand daily wear and tear, further reducing operational costs and maximizing productivity.The Company's Commitment to Innovation:The company behind this revolutionary automatic equipment has a strong focus on research and development to meet the ever-evolving needs of the construction industry. With years of experience and a track record of excellence, they have established themselves as pioneers in their field.By continuously investing in cutting-edge technologies, the company strives to push boundaries and exceed customer expectations. Their commitment to innovation is clearly showcased by the introduction of this groundbreaking automatic equipment, which revolutionizes gypsum board cornice production.Conclusion:The introduction of automatic equipment for gypsum board cornice production marks a significant milestone in the construction industry. With its ability to streamline manufacturing processes, enhance efficiency, and guarantee superior quality, this innovation promises to reshape the way gypsum board cornices are produced. As construction companies look for ways to improve their operation's efficiency and output, this automatic equipment provides an ideal solution that not only optimizes productivity but also ensures remarkable precision and consistency.

Highly Efficient PVC Gypsum Ceiling Coating and Laminating Machine

has recently launched a revolutionary new product in the field of ceiling coating and laminating. The fully automatic PVC gypsum ceiling coating and laminating machine is set to transform the way ceilings are finished, providing a high-quality, efficient, and cost-effective solution for construction and interior design projects.The machine is equipped with advanced technology that allows for precise and seamless application of PVC coating and lamination onto gypsum ceiling panels. This results in a smooth, flawless finish that is both durable and aesthetically pleasing. The fully automatic operation of the machine also ensures consistency and uniformity in the coating and laminating process, eliminating the potential for human error and reducing the need for manual labor.One of the key features of this innovative machine is its ability to handle a wide range of PVC materials, including various thicknesses and textures. This versatility allows for greater customization and flexibility in ceiling design, catering to the diverse needs and preferences of different clients and projects. Additionally, the machine is equipped with a high-speed production capability, enabling rapid processing of large quantities of ceiling panels without compromising on quality.Furthermore, the PVC gypsum ceiling coating and laminating machine is designed with efficiency in mind. It is equipped with energy-saving components and optimized processes that minimize waste and maximize productivity. This not only contributes to a more sustainable and environmentally friendly operation but also helps to reduce costs for the end-users.In addition to its technical capabilities, the machine is also designed with user-friendliness in mind. Its intuitive interface and automated functions make it easy to operate, requiring minimal training for operators. This accessibility allows for a wider adoption of the machine within the construction and interior design industries, opening up new possibilities for enhancing the quality and efficiency of ceiling finishing projects.The launch of this innovative machine marks a significant milestone for the company, further solidifying its position as a leader in the field of advanced manufacturing equipment. With a strong commitment to research and development, the company has consistently demonstrated its ability to innovate and bring cutting-edge solutions to the market.The PVC gypsum ceiling coating and laminating machine is set to make a substantial impact on the industry, offering a superior alternative to traditional methods of ceiling finishing. Its capabilities in precision, efficiency, and customization are expected to streamline the production process for ceiling contractors and interior designers, while also delivering exceptional results for their clients.The company's dedication to quality and innovation is reflected in its investment in state-of-the-art manufacturing facilities and its adherence to stringent quality control measures. This commitment ensures that the PVC gypsum ceiling coating and laminating machine meets the highest standards of performance and reliability, providing customers with a product they can trust.As the demand for high-quality and visually appealing ceiling finishes continues to grow, the introduction of this fully automatic PVC gypsum ceiling coating and laminating machine comes as a timely and significant solution for the industry. Its potential to elevate the standard of ceiling design and construction is expected to resonate with professionals and clients alike, driving a new wave of possibilities and opportunities in the market.

Discover the Latest Innovations from a Leading CO2 XPS Foam Board Equipment Manufacturer

Co2 XPS Foam Board Equipment Factory Steps Up Efforts to Enhance Product Quality and Customer SatisfactionCo2 XPS Foam Board Equipment Factory announced today that it has been taking steps to improve the quality of its products and increase customer satisfaction. This move is part of the company's commitment to providing the best products and services to its customers.The company, which specializes in the production of Co2 XPS foam board equipment understands the critical importance of providing high-quality products. To this end, Co2 XPS Foam Board Equipment Factory has been focusing on enhancing its manufacturing processes by adopting advanced technologies, such as automation technology, which ensures precision and consistency in the production of its Co2 XPS foam board equipment."We recognize that our customers depend on the quality of our products to achieve their business objectives," said the company's spokesperson. "That is why we have been investing heavily in technology and processes to enhance the quality of our products."As part of its efforts to increase customer satisfaction, Co2 XPS Foam Board Equipment Factory has been improving its customer service. The company has established a customer service team that is dedicated to addressing customer inquiries and resolving issues promptly. This team has received specialized training to ensure that they can provide customers with the information they need to make informed purchases and resolve issues quickly and efficiently."Customer satisfaction is a top priority for us," said the spokesperson. "We want our customers to have the best experience possible when working with us. That is why we have invested in our customer service team to ensure that they are equipped to provide the best possible service."Co2 XPS Foam Board Equipment Factory is committed to providing its customers with products that meet the highest quality standards. The company has implemented a strict quality control system that monitors each stage of the production process to ensure that every product that leaves the factory is of the highest quality. The company also works closely with its suppliers to ensure that only high-quality raw materials are used in the production of its Co2 XPS foam board equipment."Our commitment to quality is unwavering," said the spokesperson. "We believe that quality is the key to customer satisfaction and long-term success in the market. That is why we have put in place a quality control system that ensures that all our products meet the highest standards."Co2 XPS Foam Board Equipment Factory has built a reputation for producing high-quality Co2 XPS foam board equipment that is both reliable and durable. The company's products are used in a range of industries, including construction, packaging, and insulation. The company's commitment to quality has helped it to establish a loyal customer base that values the quality of its products and the level of customer service that it provides.As part of its efforts to increase customer satisfaction, Co2 XPS Foam Board Equipment Factory has also been reviewing its pricing strategy to ensure that its products remain competitive in the market. The company has been exploring ways to reduce production costs without compromising on product quality."We understand that price is an important consideration for our customers," said the spokesperson. "That is why we have been reviewing our pricing strategy to ensure that our products remain affordable and competitive in the market."In conclusion, Co2 XPS Foam Board Equipment Factory's commitment to enhancing product quality and customer satisfaction is a positive step that will benefit both the company and its customers. By investing in technology, improving customer service, and implementing a strict quality control system, the company is positioning itself for long-term success in the market. Customers can rest assured that they are working with a reliable partner that is committed to providing high-quality products and exceptional customer service.

China Supplier of PVC Crust Foam Board Extrusion Line for Sale

If you're in the market for a high-quality PVC crust foam board production line, look no further than JEEBO Machinery. With a commitment to excellence and innovation, JEEBO Machinery is a leading manufacturer of PVC crust foam board extrusion lines in China.Using celuka technology to foam, the PVC crust foam board has a flat and smooth surface that is much stronger than the free foaming body. This makes it a great choice for a wide range of applications, from furniture to signage to construction materials.At JEEBO Machinery, we offer a top-of-the-line PVC crust foam board extrusion line that is designed for maximum efficiency and production capabilities. Our production line includes a range of advanced features, including a high-precision control system, automatic vacuum calibration table, and a multi-roller hauling machine, among others.One of the key benefits of our PVC crust foam board extrusion line is its versatility. It can be used to produce a range of different board types, including furniture boards, building boards, advertising boards, and more. Plus, with an output of up to 600kg per hour, our production line can handle even the most demanding production requirements.At JEEBO Machinery, we are committed to providing our customers with the highest quality products and services at competitive prices. That's why we offer a comprehensive pricelist for our PVC crust foam board extrusion line, making it easy for you to compare our products and choose the one that best meets your needs and budget.If you're interested in learning more about our PVC crust foam board extrusion line or any of our other products and services, please contact us today. Our team of experts is always available to answer your questions and help you find the perfect solution for your specific needs. Thank you for choosing JEEBO Machinery!

High-quality XPS Foam Extrusion Line for Sale

Introducing the Latest XPS Foam Extrusion Line at [Company Name][Location], [Date] – [Company Name], a leading provider of innovative plastic extrusion solutions, is thrilled to announce the introduction of the latest XPS Foam Extrusion Line to their manufacturing facility. This state-of-the-art extrusion line represents a significant advancement in the company’s capabilities and further solidifies their position as a pioneer in the industry.The new XPS Foam Extrusion Line is equipped with cutting-edge technology and features, designed to enhance productivity, efficiency, and product quality. With increased automation and precision control, this extrusion line is capable of producing high-quality XPS foam with superior thermal insulation properties, making it ideal for a wide range of applications in construction and packaging.[Company Name] has always been at the forefront of innovation, and the addition of the XPS Foam Extrusion Line is a testament to their commitment to delivering cutting-edge solutions to their customers. With the ability to produce XPS foam in various thicknesses and densities, the new extrusion line enables [Company Name] to meet the diverse needs of their clients and offer customized solutions tailored to specific requirements.In addition to the technological advancements, the new XPS Foam Extrusion Line is also designed with sustainability in mind. It incorporates energy-efficient processes and environmentally friendly materials, aligning with [Company Name]’s dedication to sustainable manufacturing practices. By prioritizing sustainability, the company aims to minimize its environmental impact and contribute to a more sustainable future.The introduction of the XPS Foam Extrusion Line reaffirms [Company Name]’s position as an industry leader and sets a new standard for excellence in foam extrusion technology. With a focus on innovation, quality, and sustainability, the company continues to push the boundaries of what is possible in the field of plastic extrusion, delivering exceptional products and solutions to their customers.As a global supplier, [Company Name] serves a diverse customer base across various industries, providing them with high-performance extrusion solutions tailored to their specific needs. With the addition of the new XPS Foam Extrusion Line, the company is poised to expand its reach and offer enhanced capabilities to their clients, enabling them to achieve their goals with greater efficiency and reliability.[Company Name]’s dedication to innovation and continuous improvement is reflected in the investments they make in their manufacturing capabilities. The introduction of the XPS Foam Extrusion Line is a testament to the company’s ongoing commitment to delivering value-driven solutions that empower their customers and drive progress across the industry.In conclusion, the introduction of the latest XPS Foam Extrusion Line at [Company Name] represents a significant milestone in the company’s journey towards excellence. Equipped with cutting-edge technology, sustainability features, and a focus on quality, this extrusion line sets a new standard for foam production and reaffirms [Company Name]’s position as a leader in the industry. With a strong focus on innovation, customer satisfaction, and sustainability, [Company Name] continues to pave the way for the future of plastic extrusion, delivering exceptional products and solutions to their global customer base.

New Equipment for Manufacturing MGO Board Announced

Innovative Mgo Board Equipment to Revolutionize Construction IndustryA new Mgo board equipment is poised to revolutionize the construction industry. The advanced manufacturing technology offered by this equipment is designed to deliver top-quality Mgo board products for various building applications.The equipment, whose name cannot be disclosed for competitive and legal reasons, has been developed by a leading manufacturer of Mgo board and related products. The company has been producing high-quality Mgo board for more than a decade, and has gained a solid reputation for delivering top-rated products.With a focus on innovative design and advanced technology, the company's new Mgo board equipment combines precision engineering, high-quality components, and user-friendly features that are intended to make the manufacturing process more efficient and cost-effective.The equipment features a robust workstation that is easy to operate, with a user-friendly interface that provides seamless control and precise measurement. The workstation is designed to process Mgo boards of various sizes and thickness, ensuring that the output meets the required specifications.The Mgo board equipment also features advanced mixing technology, which is essential for producing high-quality Mgo boards. The mixing process is automated and controlled, resulting in a consistent and uniform mixture that meets the required standards.In addition, the equipment is equipped with advanced cutting technology, which ensures that the Mgo boards are accurately cut to the required size and shape. The cutting process is automated and precise, providing clean and smooth edges for the finished product.One of the standout features of the new Mgo board equipment is its innovative automation capabilities. The equipment is designed to automate most of the manufacturing process, reducing the need for manual labor and minimizing the risk of human error. This results in a more efficient and cost-effective production process, while also ensuring consistently high-quality Mgo board products.Moreover, the equipment is designed to be environmentally friendly, with reduced energy consumption and minimal waste. This is achieved through advanced energy-saving technology and improved production processes that optimize material usage, while minimizing waste.The company prides itself on being committed to sustainability and environment-friendly manufacturing practices. All of its products are ISO certified, ensuring that they meet the highest standards of quality and safety.With the introduction of the new Mgo board equipment, the company aims to provide its customers with an even better experience and more high-quality products. The equipment is already in high demand, with several orders already placed by both local and international customers.The company believes that the new Mgo board equipment is poised to transform the construction industry by delivering high-quality and sustainable building materials. The company's dedication to innovation, quality, and sustainability has been one of the driving factors behind its success and continued growth in the industry.In conclusion, the new Mgo board equipment is a game-changer for the construction industry. With its advanced technology and innovative features, it promises to deliver high-quality and sustainable building materials that meet the needs of today's modern construction projects. As the demand for environmentally friendly and cost-effective building materials continues to grow, the company's new Mgo board equipment is perfectly positioned to lead the way.

Affordable 12mm Calcium Silicate Board Production Line Price List

A leading manufacturer of building materials, has recently released its new 12mm Calcium Silicate Board Production Line, offering a competitive price list for customers looking for high-quality construction materials. The company has established a strong reputation in the industry for producing reliable and durable products, and their new production line reaffirms their commitment to providing top-notch solutions for the construction sector.The 12mm Calcium Silicate Board Production Line is designed to meet the increasing demand for high-performance building materials in the market. With its advanced technology and efficient manufacturing process, the production line is capable of producing calcium silicate boards with a thickness of 12mm, which are ideal for various applications in the construction industry. These boards are known for their high strength, durability, and resistance to fire, making them a popular choice for building projects that require reliable and long-lasting materials.The company's new production line is equipped with state-of-the-art machinery and equipment, allowing for the efficient and cost-effective manufacturing of calcium silicate boards. This ensures that customers can benefit from high-quality products at a competitive price, making it an attractive option for contractors, builders, and developers looking to optimize their construction budgets without compromising on quality.In addition to offering a competitive price list for its new production line, the company also emphasizes the importance of sustainability and environmental responsibility in its manufacturing process. The 12mm Calcium Silicate Board Production Line is designed to minimize waste and maximize resource efficiency, ensuring that the production of calcium silicate boards is carried out in an environmentally friendly manner. This aligns with the company's commitment to sustainability and its efforts to reduce the environmental impact of its operations.The company's dedication to quality and customer satisfaction is reflected in its extensive experience in the industry. With a strong track record of delivering reliable and durable building materials, the company has built a solid reputation for excellence, earning the trust and loyalty of its customers. This reputation is further solidified with the introduction of the new 12mm Calcium Silicate Board Production Line, which showcases the company's continued focus on innovation and product development to meet the evolving needs of the construction industry.By offering a competitive price list for its new production line, the company aims to make high-quality calcium silicate boards more accessible to a wider range of customers. This not only benefits contractors and builders who require cost-effective solutions for their projects but also contributes to the overall advancement of the construction industry by promoting the use of reliable and durable building materials.In conclusion, the release of the new 12mm Calcium Silicate Board Production Line with a competitive price list reflects the company's ongoing commitment to excellence, innovation, and sustainability. By combining advanced technology with efficient manufacturing processes, the company is able to offer high-quality construction materials at a competitive price point, meeting the needs of a diverse customer base. With its strong reputation in the industry and dedication to customer satisfaction, the company is well-positioned to make a significant impact in the construction sector with its new production line.

Affordable Prices for Magnesium Oxide Board Machine

Magnesium Oxide Board Machine: The Future of Modern ConstructionWith the ever-growing demand for sustainable and eco-friendly construction materials, the use of Magnesium Oxide Boards has become more prevalent in the building industry. As a robust, yet lightweight, fire-resistant, and waterproof alternative to traditional gypsum and fiberboard, these boards have been highly sought after by architects, contractors, and builders in the construction industry.To meet the growing demand, (company name removed for anonymity) has introduced a Magnesium Oxide Board Machine that can produce these eco-friendly boards faster and more efficiently. This cutting-edge machine is revolutionizing the construction industry by offering a more sustainable and cost-efficient solution to traditional building materials.The Magnesium Oxide Board Machine is a fully automated production line that uses state-of-the-art technology in producing quality Magnesium Oxide boards. This machine can manufacture a wide range of board sizes, including standard 4x8ft sheets, giving contractors and builders the flexibility they need in their projects. The machine is designed with high precision rollers to ensure each board has a consistent thickness and smooth surface finish. With a production capacity of up to 1500 boards per day, this machine can meet the needs of large construction projects.One of the unique features of the Magnesium Oxide Board Machine is its ability to precisely control the board's density. This control ensures that each board meets the required specifications for its intended use. Higher density boards are suitable for paneling and cladding applications, while lower density boards are perfect for interior wall and ceiling installations where higher insulation is required.Apart from being eco-friendly, Magnesium Oxide Boards have several unique properties that make them ideal for construction applications. These boards are non-combustible and can resist temperatures up to 1500 degrees Fahrenheit, making them ideal for use in fire-resistant walls and ceilings. Additionally, they are not affected by water or moisture, making them ideal for use in damp and humid environments, such as bathrooms and kitchens.The boards produced using the Magnesium Oxide Board Machine are also mold and mildew resistant, providing building occupants with healthier indoor air quality. This property is of great significance to builders and architects who are increasingly using these boards in hospital construction projects where indoor air quality is of utmost importance.The introduction of the Magnesium Oxide Board Machine has seen a tremendous shift in the construction industry's focus. Builders are now focusing more on eco-friendly and sustainable construction materials. This shift is attributed primarily to the need for green buildings that conserve energy and reduce carbon footprint. Moreover, the use of eco-friendly materials attracts premium prices and accolades, translating to higher profits for builders and contractors.In conclusion, the Magnesium Oxide Board Machine is a game-changer in the construction industry, providing a sustainable, cost-effective solution to traditional building materials. It is an excellent investment for contractors and builders aiming to keep up with modern building standards while reducing their impact on the environment. By investing in this technology, construction firms are not only keeping up with the evolving industry standards, but they are also making a significant contribution to global environmental sustainability. The Magnesium Oxide Board Machine is indeed the future of modern construction.

Manufacturers of Gypsum Cornice Production Line and Moulds for Plaster and Fiberglass Frames

Gypsum Cornice Machine Factory: A One-Stop Solution for Your Cornice NeedsWhether you're an architect, interior designer, or homeowner, finding the right cornice design can complete the look and feel of any room. A cornice, also known as crown molding, is a decorative element that's installed on the upper edge of a wall. It can add class and elegance to any space, and make it look larger and more visually appealing.However, creating the perfect cornice design requires the right tools, skills, and materials. That's where a gypsum cornice machine factory comes in. As a specialized manufacturer of cornice-related products and equipment, they can provide the following:Gypsum Cornice Production Line / Making MachineA gypsum cornice machine factory is equipped with a production line or making machine that produces high-quality gypsum cornice molds. The production line is designed to make cornice production more efficient and less time-consuming. With the help of an automated system, the cornice molds are produced quickly, accurately, and with minimal waste.Plaster Cornice TemplateA plaster cornice template is a pre-made template or pattern that serves as a guide for creating a plaster cornice. It's used to create a precise and consistent design for the cornice. A gypsum cornice machine factory can provide a wide range of plaster cornice templates that can be customized to fit any project.Fiberglass Cornice Frame ManufacturersFiberglass cornice frames are made from fiberglass-reinforced plastic (FRP) materials that are lightweight, durable, and easy to install. Their lightweight nature makes them ideal for use in structures where weight is a factor. A gypsum cornice machine factory can provide fiberglass cornice frames that are designed to fit any size or shape of the cornice.Crown MouldingCrown molding is a decorative element that's designed to add a finishing touch to a room. It's typically installed where the ceiling meets the wall, and can be made from a variety of materials, including wood, plaster, and gypsum. A gypsum cornice machine factory can provide crown molding that's made to order and customized to fit any style or design.Plaster CastingPlaster casting is the process of creating a plaster mold from an existing object or model. It's a common technique used in the production of cornices and other decorative elements. A gypsum cornice machine factory can provide plaster casting services that can create a perfect replica of any object or model.Pop Gypsum PlasterPop gypsum plaster, also known as Plaster of Paris, is a white powder made from gypsum that hardens when mixed with water. It's commonly used in the production of cornices and other decorative elements. A gypsum cornice machine factory can provide high-quality pop gypsum plaster that's specifically designed for cornice production.Drywall Gypsum BoardDrywall gypsum board is a construction material made from gypsum plaster and a paper covering. It's commonly used in interior walls and ceilings, and can be used as a base material for the installation of cornices and other decorative elements. A gypsum cornice machine factory can provide drywall gypsum boards customized to fit any size or shape of the cornice.Fiberglass Reinforced Plastic Moulds SupplierFiberglass reinforced plastic (FRP) moulds are made from fiberglass that's reinforced with plastic materials. They're lightweight, durable, and can be used to create complex shapes and designs. A gypsum cornice machine factory can provide a wide range of FRP moulds that can be customized to fit any size or shape of the cornice.China PU/Polyurethane c (need remove brand name)PU or polyurethane c (need remove brand name) is a type of material commonly used in the production of cornices and other decorative elements. It's known for its durability, flexibility, and resistance to moisture and temperature changes. A gypsum cornice machine factory can provide PU or polyurethane c (need remove brand name) that's specifically designed for cornice production.In conclusion, a gypsum cornice machine factory can provide a one-stop solution for all your cornice needs. From production line or making machine to plaster cornice templates, fiberglass cornice frames, crown molding, plaster casting, pop gypsum plaster, drywall gypsum board, fiberglass reinforced plastic moulds supplier, and China PU/polyurethane c (need remove brand name), they have everything you need to create the perfect cornice design for your project. So, if you want to create a stunning and elegant look for your space, contact a gypsum cornice machine factory today!