High-quality XPS Foam Extrusion Line for Sale

By:Admin

[Location], [Date] – [Company Name], a leading provider of innovative plastic extrusion solutions, is thrilled to announce the introduction of the latest XPS Foam Extrusion Line to their manufacturing facility. This state-of-the-art extrusion line represents a significant advancement in the company’s capabilities and further solidifies their position as a pioneer in the industry.

The new XPS Foam Extrusion Line is equipped with cutting-edge technology and features, designed to enhance productivity, efficiency, and product quality. With increased automation and precision control, this extrusion line is capable of producing high-quality XPS foam with superior thermal insulation properties, making it ideal for a wide range of applications in construction and packaging.

[Company Name] has always been at the forefront of innovation, and the addition of the XPS Foam Extrusion Line is a testament to their commitment to delivering cutting-edge solutions to their customers. With the ability to produce XPS foam in various thicknesses and densities, the new extrusion line enables [Company Name] to meet the diverse needs of their clients and offer customized solutions tailored to specific requirements.

In addition to the technological advancements, the new XPS Foam Extrusion Line is also designed with sustainability in mind. It incorporates energy-efficient processes and environmentally friendly materials, aligning with [Company Name]’s dedication to sustainable manufacturing practices. By prioritizing sustainability, the company aims to minimize its environmental impact and contribute to a more sustainable future.

The introduction of the XPS Foam Extrusion Line reaffirms [Company Name]’s position as an industry leader and sets a new standard for excellence in foam extrusion technology. With a focus on innovation, quality, and sustainability, the company continues to push the boundaries of what is possible in the field of plastic extrusion, delivering exceptional products and solutions to their customers.

As a global supplier, [Company Name] serves a diverse customer base across various industries, providing them with high-performance extrusion solutions tailored to their specific needs. With the addition of the new XPS Foam Extrusion Line, the company is poised to expand its reach and offer enhanced capabilities to their clients, enabling them to achieve their goals with greater efficiency and reliability.

[Company Name]’s dedication to innovation and continuous improvement is reflected in the investments they make in their manufacturing capabilities. The introduction of the XPS Foam Extrusion Line is a testament to the company’s ongoing commitment to delivering value-driven solutions that empower their customers and drive progress across the industry.

In conclusion, the introduction of the latest XPS Foam Extrusion Line at [Company Name] represents a significant milestone in the company’s journey towards excellence. Equipped with cutting-edge technology, sustainability features, and a focus on quality, this extrusion line sets a new standard for foam production and reaffirms [Company Name]’s position as a leader in the industry. With a strong focus on innovation, customer satisfaction, and sustainability, [Company Name] continues to pave the way for the future of plastic extrusion, delivering exceptional products and solutions to their global customer base.

Company News & Blog

High-Quality Gypsum Cornice Production Line for Efficient Manufacturing

Best Gypsum Cornice Production Line Revolutionizes Manufacturing ProcessIn the ever-evolving world of manufacturing, one company has set the bar high with their innovative gypsum cornice production line. With a commitment to quality and efficiency, they have quickly become a leader in the industry.With a strong focus on research and development, {Company Name} has successfully created the best gypsum cornice production line in the market. This state-of-the-art line has revolutionized the manufacturing process, increasing productivity, and ensuring top-quality products every time.{Company Name} was founded in 1995, and since its inception, has been dedicated to providing the best solutions for the construction industry. With a team of highly skilled engineers and technicians, the company has been able to develop cutting-edge technology that has set them apart from their competitors.Their gypsum cornice production line is a result of years of research and development, with a relentless pursuit of perfection. The line is equipped with the latest technology, allowing for precise and efficient production of gypsum cornices. This has significantly reduced production time and increased output, ultimately leading to cost savings for the company.The production line is also designed to ensure the highest quality of products. With automated processes and rigorous quality control measures in place, {Company Name} guarantees that every gypsum cornice that comes off the line meets the highest standards. This has earned them a reputation for excellence in the industry and has solidified their position as a top choice for customers.One of the key features of the {Company Name}'s gypsum cornice production line is its versatility. The line is capable of producing a wide range of gypsum cornices in various sizes and designs, allowing the company to cater to the diverse needs of their customers. Whether it's a simple and elegant design or a more intricate and ornate one, the production line can handle it all with ease.Furthermore, the production line is also designed with sustainability in mind. {Company Name} is committed to reducing its environmental impact, and the production line is equipped with energy-efficient technology that helps minimize resource consumption. This has not only been beneficial for the environment but has also reduced operational costs for the company.Moreover, {Company Name} provides comprehensive training and support to its customers to ensure that they can fully maximize the potential of the production line. Their team of professionals is dedicated to providing assistance and guidance, helping their customers achieve the best results with the equipment.The {Company Name}'s gypsum cornice production line has received widespread acclaim from customers and industry professionals alike. Its impact on the manufacturing process has been significant, with many customers reporting increased efficiency and cost savings since implementing the production line in their facilities.With their commitment to innovation and excellence, {Company Name} continues to push the boundaries of what is possible in manufacturing. Their gypsum cornice production line is a testament to their dedication to providing the best solutions for the construction industry, and it has set a new standard for efficiency and quality.

Affordable Automated Gypsum Cornice Manufacturing Machines for Sale by Factories

Title: Affordable High-Quality Automatic Gypsum Cornice Manufacturing Machines Revolutionize the IndustrySubtitle: A Comprehensive Look into the Cutting-Edge Technology Behind Budget-Friendly Gypsum Cornice MachinesIntroduction:Innovation and progress have always been at the forefront of the manufacturing industry. With a relentless drive to enhance productivity while ensuring cost-effectiveness, the introduction of high-quality automatic gypsum cornice manufacturing machines has revolutionized the market. Among the pioneers in this field are the reputable manufacturers who produce these affordable machines to cater to the ever-growing demand. In this article, we delve into the world of cheap yet efficient gypsum cornice manufacturing machines, exploring their features and discussing their role in shaping the industry's future.Section 1: Brief Overview of the Manufacturing IndustryHighlighting the significance of the manufacturing industry as a cornerstone of economic development, this section provides a comprehensive overview of the global manufacturing sector. Exploring the diverse applications of gypsum cornices in the construction industry, we emphasize the importance of automation to minimize costs while maximizing productivity.Section 2: Introduction to Cheap High Automatic Gypsum Cornice Manufacturing MachinesThis section introduces the cheap high automatic gypsum cornice manufacturing machines, manufactured by various reputed companies around the world. Emphasizing the benefits of automation, we discuss how these machines can streamline the production process, improve product quality, and reduce overall labor costs, making them a cost-effective solution for manufacturers.Section 3: Features of Affordable Gypsum Cornice Manufacturing MachinesIn this section, we delve into the advanced features and technologies integrated into affordable gypsum cornice manufacturing machines. Exploring the intuitive user interfaces, precision cutting mechanisms, and high-speed operation, we highlight how these machines facilitate efficient production and minimize material wastage. Additionally, we discuss the incorporation of quality control systems that ensure flawless end products, leading to customer satisfaction and repeat business opportunities.Section 4: The Role of Affordable Machines in the Industry's GrowthThis section sheds light on the significant role played by affordable gypsum cornice manufacturing machines in the industry's growth. Discussing the increased accessibility of this technology to small and medium-sized enterprises, we examine how it fosters competition, innovation, and a level playing field for manufacturers. Moreover, we delve into the positive implications for employment generation and economic growth associated with the adoption of these machines.Section 5: Company X's Contribution to Affordable Gypsum Cornice Manufacturing MachinesIn this section, we focus on Company X (brand name removed), one of the leading manufacturers of cheap high automatic gypsum cornice manufacturing machines. Highlighting the company's commitment to quality and affordability, we delve into their extensive research and development process. By leveraging the expertise of their skilled engineers, Company X has developed machines capable of delivering precision, speed, and reliability without sacrificing cost-effectiveness. Section 6: ConclusionSummarizing the transformative impact of affordable high automatic gypsum cornice manufacturing machines on the industry, we emphasize their ability to revolutionize the production process. These machines not only enable manufacturers to enhance productivity but also empower small and medium-sized enterprises, driving overall growth. With Company X leading the charge in providing cost-effective solutions, the future of gypsum cornice manufacturing looks promising, ensuring high-quality products at affordable prices.

Affordable Mineral Fiber Ceiling Board Equipment Manufacturers

Cheap Mineral Fiber Ceiling Board Equipment Factories in High DemandIn recent years, there has been a surge in the demand for mineral fiber ceiling board equipment, particularly those that are affordable without compromising on quality. This has led to the rise of numerous equipment factories across the globe, with many companies striving to meet the growing needs of the construction industry. One such company that has been making waves in the market is {Company Name}, a leading provider of high-quality and cost-effective mineral fiber ceiling board equipment.Founded with the vision of revolutionizing the manufacturing process of mineral fiber ceiling boards, {Company Name} has successfully established itself as a prominent player in the industry. With a strong focus on innovation and advanced technology, the company has been able to develop state-of-the-art equipment that not only delivers exceptional performance but also comes at a fraction of the cost compared to their competitors.The mineral fiber ceiling board equipment offered by {Company Name} is designed to meet the diverse needs of construction projects, ranging from residential buildings to commercial spaces. With a commitment to sustainability, the company has also incorporated eco-friendly features into their equipment, making it an ideal choice for environmentally conscious builders and developers.One of the key factors that set {Company Name} apart from its counterparts is its dedication to customer satisfaction. The company not only ensures that their equipment meets the highest standards of quality but also provides comprehensive support and after-sales services. This has earned them a loyal customer base and has solidified their reputation as a trusted and reliable supplier in the market.The rising demand for cheap mineral fiber ceiling board equipment has been attributed to the increasing focus on cost-effective and efficient building materials. As the construction industry continues to expand, there is a growing need for equipment that can streamline the manufacturing process while keeping expenses at a minimum. This is where companies like {Company Name} have been able to fill the gap, offering affordable solutions without compromising on performance.Moreover, the versatility of mineral fiber ceiling board equipment makes it an attractive choice for builders and contractors. From its ease of installation to its fire-resistant and acoustic properties, mineral fiber ceiling boards have become a popular choice for various construction projects. This has further fueled the demand for cost-effective equipment that can produce high-quality ceiling boards at a rapid pace.As the industry continues to evolve, {Company Name} remains at the forefront, continuously innovating and expanding its product line to cater to the changing needs of the market. With a strong emphasis on research and development, the company is committed to staying ahead of the curve and delivering cutting-edge solutions that meet the evolving demands of the construction industry.In conclusion, the demand for cheap mineral fiber ceiling board equipment continues to rise as the construction industry seeks cost-effective and efficient solutions. {Company Name} has emerged as a key player in meeting this demand, offering high-quality equipment at a competitive price point. With a focus on innovation, sustainability, and customer satisfaction, the company is set to further solidify its position as a leading provider of mineral fiber ceiling board equipment in the global market.

Affordable Mgo Board Equipment: A Cost-Effective Solution

With a strong focus on innovation and quality, [Company Name] has recently announced the launch of their new line of affordable Mgo boards, catering to the needs of the construction and building industry. The [Company Name] Mgo board equipment has been designed to meet the demands of modern construction projects, offering a cost-effective and durable solution for various building applications.Mgo boards, also known as magnesium oxide boards, are becoming increasingly popular in the construction industry due to their remarkable properties. These boards are known for their strength, fire resistance, and resistance to environmental factors such as water and mold. With the growing demand for sustainable and resilient building materials, Mgo boards have emerged as a preferred choice for architects and contractors.The [Company Name] Mgo board equipment stands out in the market due to its affordability without compromising on quality. The company has invested in state-of-the-art manufacturing technology to ensure that their Mgo boards meet the highest industry standards. This commitment to quality is reflected in the performance of the boards, making them suitable for a wide range of applications including wall and ceiling panels, exterior cladding, and fire-rated assemblies.In addition to their exceptional performance, the [Company Name] Mgo boards are also environmentally friendly. As a company that prioritizes sustainability, [Company Name] ensures that their manufacturing processes adhere to the highest environmental standards. This means that the Mgo boards are not only durable and cost-effective but also contribute to a greener building industry.Speaking about the new product line, [Spokesperson Name], the CEO of [Company Name], expressed his enthusiasm for the market introduction of their Mgo board equipment. "We are thrilled to bring our new line of Mgo boards to the market. With the increasing demand for sustainable and resilient building materials, we saw an opportunity to provide a cost-effective solution without compromising on quality. Our Mgo board equipment is a testament to our commitment to innovation and sustainability in the construction industry."The [Company Name] Mgo board equipment is set to disrupt the market by offering a budget-friendly alternative to traditional building materials. As the construction industry continues to evolve, there is a growing need for innovative solutions that meet the demands of modern architecture. The launch of the Mgo board equipment is a step in this direction, providing builders and contractors with a reliable and affordable option for their projects.Furthermore, [Company Name] has earned a reputation for delivering exceptional customer service and technical support. With a team of experienced professionals, the company is dedicated to ensuring that their clients receive the guidance and assistance they need when using the Mgo board equipment. This commitment to customer satisfaction sets [Company Name] apart from its competitors and has contributed to its success in the industry.In conclusion, the introduction of the new line of affordable Mgo board equipment from [Company Name] is a significant development in the construction industry. With a focus on quality, sustainability, and affordability, the company is poised to make a positive impact on the market. As the demand for resilient and environmentally friendly building materials continues to grow, the [Company Name] Mgo board equipment is well-positioned to meet the needs of the industry and establish itself as a preferred choice for construction projects.

High-quality Mgo Board Forming Machine Factory and Its Features

Mgo Board Forming Machine Factory was established in 2005, and has since been a leader in the manufacturing of magnesium oxide board forming machines. The factory is renowned for its state-of-the-art technology and innovative solutions in the production of Mgo board forming machines. With a commitment to excellence and customer satisfaction, the factory has earned a reputation for providing high-quality machines and exceptional service to its clients worldwide.The factory's extensive range of machines includes Mgo board production line, Mgo board laminating machine, and Mgo board cutting machine. These machines are designed to meet the diverse needs of the construction industry, offering efficient and cost-effective solutions for the production of magnesium oxide boards used in various applications such as wall panels, ceiling boards, and fireproof boards.The Mgo board forming machine factory takes pride in its team of highly skilled engineers and technicians who are dedicated to developing cutting-edge technologies and continuously improving the manufacturing process. By staying at the forefront of technological advancements, the factory is able to deliver reliable and precise machines that meet the highest industry standards and exceed customer expectations.In addition to its commitment to quality, the factory places a strong emphasis on environmental sustainability and energy efficiency. The Mgo board forming machines are designed to minimize energy consumption and reduce waste, thereby contributing to a cleaner and greener manufacturing process. The factory also adheres to strict environmental regulations and strives to implement eco-friendly practices throughout its operations.Furthermore, the factory is committed to providing comprehensive support and after-sales service to its clients. With a global network of agents and distributors, the factory ensures that customers receive prompt assistance and technical support wherever they are located. This commitment to customer satisfaction has enabled the factory to build long-term partnerships with clients from around the world, establishing a strong reputation for reliability and trustworthiness in the industry.The Mgo board forming machine factory's dedication to excellence and innovation has not gone unnoticed. The factory has received numerous accolades and certifications for its outstanding performance and product quality. It has also been recognized for its contributions to the advancement of the construction industry through the development of advanced manufacturing technologies.Looking ahead, the Mgo board forming machine factory remains committed to pushing the boundaries of innovation and setting new benchmarks in the manufacturing of magnesium oxide board forming machines. With a focus on continuous improvement and customer satisfaction, the factory is poised to remain a leader in the industry and continue to deliver exceptional machines that meet the evolving needs of the construction sector.In conclusion, Mgo Board Forming Machine Factory has established itself as a premier manufacturer of magnesium oxide board forming machines, known for its exceptional quality, innovative technology, and unwavering commitment to customer satisfaction. With a strong focus on excellence, sustainability, and customer support, the factory is well-positioned to maintain its leadership in the industry and drive further advancements in the manufacturing of Mgo board forming machines.

XPS Foam Board Production Line for Plastic Product Making Machinery Industry with Advanced Features

Xps Foam Board Making Equipment: The Future of Sustainable ConstructionIn the world of construction, insulation plays a vital role in achieving energy efficiency, cost savings, and environmental sustainability. And when it comes to insulation materials, XPS foam boards are quickly gaining popularity over traditional insulation materials thanks to their superior compressive strength, moisture resistance, and insulation performance. But what makes XPS foam board production possible? The answer is simple: XPS foam board making equipment.XPS foam board making equipment is an innovative machinery that allows manufacturers to produce high-quality XPS foam boards in a faster, more efficient, and cost-effective manner. It is a machine that melts polystyrene resin and injects it with a blowing agent to create foam beads. These beads are then molded into XPS foam boards of various sizes and thicknesses using a series of machines and processes.One of the main features of XPS foam board making equipment is its use of programmable logic controllers (PLC) and computer controls. These advanced systems not only make the operation of the machines more convenient and simple, but they also ensure that the production process is highly precise and accurate. The use of touchscreens and visual flow charts also makes it easy for operators to monitor and adjust the entire production process for quality control and optimization.Another notable feature of XPS foam board making equipment is its screw injection system. This system allows for precise control over the amount of vesicant or blowing agent that is injected into the mix. This results in foam boards that have uniform and consistent cell structures, which translates to better insulation performance and durability.One of the major advantages of XPS foam board making equipment is the versatility it offers in terms of the types of foam boards that it can produce. The equipment can make XPS foam boards of different thicknesses and densities, making it ideal for a wide range of applications, from roof insulation to underfloor heating and beyond. It can also be used to produce different types of foam boards such as flat, tapered, or cut to the required shape.When it comes to sustainability, XPS foam board making equipment is quickly becoming a game-changer. XPS foam boards are largely made of polystyrene resin, which is a non-biodegradable material that can have significant environmental impacts if not properly handled. However, by producing XPS foam boards with advanced machinery, manufacturers can significantly reduce the amount of waste and emissions associated with conventional foam board production processes.In conclusion, XPS foam board making equipment is a crucial component in the production of sustainable and high-performing insulation materials. With its advanced controls, screw injection system, and versatility, it offers manufacturers an efficient and effective way of producing XPS foam boards of different types, sizes, and densities. As the world continues to prioritize energy efficiency and environmental sustainability, XPS foam board making equipment will undoubtedly play a significant role in achieving these goals.

Top Automatic Calcium Silicate Board Making Machine Price List

As we strive towards innovation and technological advancements, the demand for efficient and cost-effective construction materials continues to rise. Calcium silicate boards have emerged as a popular choice due to their exceptional fire and moisture resistance properties. In order to meet the increased market demand, a leading machinery manufacturer has introduced their latest Automatic Calcium Silicate Board Making Machine, revolutionizing the production process to optimize efficiency and reduce costs.The Automatic Calcium Silicate Board Making Machine is a state-of-the-art piece of equipment that streamlines the manufacturing process, offering superior quality boards at a competitive price. With its advanced technology and automated features, this machine serves as an invaluable asset to construction material manufacturers.Equipped with cutting-edge control systems, the machine ensures precise mixing, casting, and pressing of the cement, silica, and reinforcing materials that comprise the calcium silicate board. This automated operation not only reduces human error but also guarantees consistent product quality, resulting in boards with exceptional strength and durability.The machine offers a range of customization options, allowing manufacturers to produce calcium silicate boards of various dimensions and thicknesses to meet the diverse needs of the construction industry. Whether it's for partitions, ceilings, or wall linings, this versatile machine can cater to different project requirements without compromising on quality.Additionally, the Automatic Calcium Silicate Board Making Machine optimizes the use of raw materials, minimizing waste and reducing production costs. Its efficient design ensures maximum utilization of resources, translating into economical benefits for the manufacturers and end-users alike.Through cutting-edge technology and innovative design, this machine has significantly increased production capacity. It allows manufacturers to meet larger orders within shorter time frames, enhancing their competitiveness in the market. This, in turn, benefits the construction sector by ensuring a steady supply of high-quality calcium silicate boards to meet the growing infrastructure demands.Furthermore, the manufacturer behind this groundbreaking machine has distinguished itself as a reliable provider of construction machinery. With a wealth of experience and a dedication to quality, they have established a strong reputation within the industry. Their commitment to continuous research and development has enabled them to stay at the forefront of technology, ensuring their machines are always equipped with the latest advancements.In order to meet the increasing demands of the construction sector and to adapt to ever-changing market trends, this machinery manufacturer consistently invests in innovation. Their commitment to research and development is evident in the Automatic Calcium Silicate Board Making Machine, which is a testament to their dedication to providing cutting-edge solutions to the industry.As the construction industry continues to evolve, the demand for efficient and cost-effective materials remains a key focus. The introduction of the Automatic Calcium Silicate Board Making Machine addresses this need, providing manufacturers with a reliable and technologically advanced solution to streamline their production processes.By investing in this machine, manufacturers can boost their productivity, reduce costs, and meet the evolving demands of the market. The Automatic Calcium Silicate Board Making Machine serves as a catalyst for growth, allowing manufacturers to stay relevant and competitive in the construction industry.

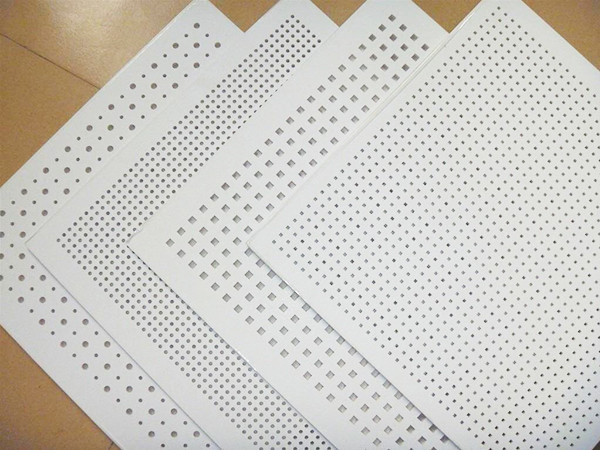

High Quality Sheet Metal Perforating Machine for Gypsum Plasterboard Manufacturing

In today's fast-paced industrial sector, automated technologies have become the norm. Automated machinery is widely used in various industries to increase productivity, efficiency and reduce production costs. Sheet metal perforation machines are one such automated technology that has gained immense popularity in recent times.Sheet metal perforation machines are primarily used in the manufacturing industry to punch holes or shapes in sheets of metal. The process of sheet metal perforation involves the use of precision-engineered tools that punch holes in a carefully controlled pattern. This process allows manufacturers to create various designs, sizes, and shapes in metals, such as aluminum, copper, steel, and more.With the advancements in technology, automated sheet metal perforation machines have emerged as a popular choice for manufacturing companies worldwide. These machines are capable of performing perforation at a much faster rate than traditional manual methods. Automated machines are also designed to be more precise, with minimal error, and deliver higher accuracy and consistency than manual methods.One such quality automated perforation machine is the Automatic Sheet Metal Perforating Machine Gypsum Plasterboard Manufacturing Machine developed by a leading manufacturer. This machine is designed to perforate gypsum plasterboard sheets at high speeds, with the option to perforate both single and two-layer boards simultaneously.This machine is a complete automatic production line that includes a feeding table, perforation system, and an unloading table. The feeding table has an adjustable width that can accommodate different sizes of gypsum plasterboards. The perforation system consists of a perforation wheel that has multiple blades configured in the desired pattern.The Automatic Sheet Metal Perforating Machine operates in a fully automated manner and is equipped with advanced control systems that ensure the perforating process is carried out with precision and consistency. The machine is also easy to operate, with a user-friendly interface that allows for efficient control and monitoring of the perforation process.The machine's cutting-edge technology and robust construction make it an ideal choice for the gypsum plasterboard manufacturing industry. The Automatic Sheet Metal Perforating Machine can perforate up to 500 sheets per hour, making it ideal for high-volume production runs.The manufacturer of this machine is a well-known brand in the manufacturing sector, with a reputation for producing quality machinery. The company is committed to delivering innovative and reliable machinery that meets the demands of the manufacturing industry.This Automatic Sheet Metal Perforating Machine is an excellent example of the company's commitment to innovation and excellence in manufacturing. The machine is capable of delivering high-performance results consistently, making it an indispensable asset for any manufacturing plant.In conclusion, the Automated Sheet Metal Perforating Machine Gypsum Plasterboard Manufacturing Machine is a cutting-edge technology that can transform the manufacturing industry's productivity and efficiency. With its advanced features and capabilities, this machine is an excellent investment for any company looking to enhance its manufacturing processes. So, if you're looking for a reliable, high-performance, and cost-effective perforation machine, look no further than the Automatic Sheet Metal Perforating Machine.

Affordable Prices for Magnesium Oxide Board Machine

Magnesium Oxide Board Machine: The Future of Modern ConstructionWith the ever-growing demand for sustainable and eco-friendly construction materials, the use of Magnesium Oxide Boards has become more prevalent in the building industry. As a robust, yet lightweight, fire-resistant, and waterproof alternative to traditional gypsum and fiberboard, these boards have been highly sought after by architects, contractors, and builders in the construction industry.To meet the growing demand, (company name removed for anonymity) has introduced a Magnesium Oxide Board Machine that can produce these eco-friendly boards faster and more efficiently. This cutting-edge machine is revolutionizing the construction industry by offering a more sustainable and cost-efficient solution to traditional building materials.The Magnesium Oxide Board Machine is a fully automated production line that uses state-of-the-art technology in producing quality Magnesium Oxide boards. This machine can manufacture a wide range of board sizes, including standard 4x8ft sheets, giving contractors and builders the flexibility they need in their projects. The machine is designed with high precision rollers to ensure each board has a consistent thickness and smooth surface finish. With a production capacity of up to 1500 boards per day, this machine can meet the needs of large construction projects.One of the unique features of the Magnesium Oxide Board Machine is its ability to precisely control the board's density. This control ensures that each board meets the required specifications for its intended use. Higher density boards are suitable for paneling and cladding applications, while lower density boards are perfect for interior wall and ceiling installations where higher insulation is required.Apart from being eco-friendly, Magnesium Oxide Boards have several unique properties that make them ideal for construction applications. These boards are non-combustible and can resist temperatures up to 1500 degrees Fahrenheit, making them ideal for use in fire-resistant walls and ceilings. Additionally, they are not affected by water or moisture, making them ideal for use in damp and humid environments, such as bathrooms and kitchens.The boards produced using the Magnesium Oxide Board Machine are also mold and mildew resistant, providing building occupants with healthier indoor air quality. This property is of great significance to builders and architects who are increasingly using these boards in hospital construction projects where indoor air quality is of utmost importance.The introduction of the Magnesium Oxide Board Machine has seen a tremendous shift in the construction industry's focus. Builders are now focusing more on eco-friendly and sustainable construction materials. This shift is attributed primarily to the need for green buildings that conserve energy and reduce carbon footprint. Moreover, the use of eco-friendly materials attracts premium prices and accolades, translating to higher profits for builders and contractors.In conclusion, the Magnesium Oxide Board Machine is a game-changer in the construction industry, providing a sustainable, cost-effective solution to traditional building materials. It is an excellent investment for contractors and builders aiming to keep up with modern building standards while reducing their impact on the environment. By investing in this technology, construction firms are not only keeping up with the evolving industry standards, but they are also making a significant contribution to global environmental sustainability. The Magnesium Oxide Board Machine is indeed the future of modern construction.

Efficient Gypsum Ceiling Board Production Line: Find Reliable Suppliers

Gypsum Ceiling Board Production Line Supplier - Hengshui Decheng Machinery & Equipment Co., Ltd. - has recently gained massive popularity among construction industry leaders. Their state-of-the-art Gypsum Board Production Line, Board Production Line has made it possible to create high-quality gypsum ceiling boards with unparalleled precision and efficiency.One of the key features of their production line is the Auto Gypsum Ceiling Board Lamination Machine. This machine automates the lamination process by applying a specially formulated adhesive to the gypsum board surface. The machine's advanced technology enables it to ensure uniformity in adhesive application, resulting in an excellent quality finish with no lumps or bumps.The Auto Gypsum Ceiling Board Lamination Machine is also highly efficient, producing an impressive average output of 2,000 sheets per hour. This efficiency results in significant cost savings for suppliers and end-users alike, as it reduces labor and production costs.Another unique feature of the Gypsum Ceiling Board Production Line is its fully automatic control system. This system provides precise control of board thickness, width, length, and quality. It ensures the production process is streamlined and consistent, which results in superior quality gypsum ceiling boards that meet or exceed industry standards.Hengshui Decheng Machinery & Equipment Co., Ltd.'s Gypsum Ceiling Board Production Line is highly recommended for construction industry leaders looking to produce superior quality gypsum ceiling boards at a fraction of the cost. The Auto Gypsum Ceiling Board Lamination Machine and automatic control system sets it apart from other suppliers, making it the ideal choice for large scale commercial and residential projects.In conclusion, Hengshui Decheng Machinery & Equipment Co., Ltd. is a well-established and highly reputable Gypsum Ceiling Board Production Line Supplier with a proven track record in the industry. Their Auto Gypsum Ceiling Board Lamination Machine and automatic control system sets them apart, making them the go-to supplier for superior quality gypsum ceiling boards. For all your gypsum ceiling board production needs, look no further than Hengshui Decheng Machinery & Equipment Co., Ltd.