High Quality XPS Foam Board Production Line at Wholesale Prices

By:Admin

The global market for XPS foam board production line has seen a significant surge in demand in recent years, driven by the growing need for energy-efficient and sustainable building materials. As a response to this trend, a leading manufacturer has announced the availability of wholesale XPS foam board production lines, providing an opportunity for businesses to meet the rising market demand for this product.

The XPS foam board production line is a key component in the manufacturing process of extruded polystyrene (XPS) foam boards, which are widely used in the construction industry for insulation and other applications. With the increasing focus on energy efficiency and sustainable building practices, the demand for XPS foam boards has been on the rise, creating a lucrative market opportunity for manufacturers and suppliers.

The wholesale availability of XPS foam board production lines will enable businesses to capitalize on this growing market demand by establishing or expanding their production capacity. This move is expected to benefit not only the manufacturers of XPS foam boards but also the construction industry as a whole, as it will help meet the need for high-quality insulation materials to improve the energy efficiency of buildings.

The production line offered by the company is known for its advanced technology, high efficiency, and reliable performance, making it a valuable asset for businesses looking to enter or expand in the XPS foam board market. The production line is capable of producing XPS foam boards with various specifications and sizes, catering to the diverse needs of customers in the construction industry.

In addition to the wholesale availability of XPS foam board production lines, the company also provides comprehensive technical support and after-sales service to ensure the successful implementation and operation of the production line. This includes assistance with installation, training, and maintenance, as well as troubleshooting and spare parts supply, to help businesses maximize the performance and longevity of their production equipment.

With a solid reputation in the industry and a track record of delivering high-quality products and services, the company is well-positioned to meet the needs of businesses seeking to invest in XPS foam board production lines. Its extensive experience and expertise in the manufacturing and supply of XPS foam board production equipment make it a trusted partner for businesses looking to capitalize on the opportunities in the market.

The wholesale availability of XPS foam board production lines is expected to have a positive impact on the construction industry, as it will contribute to the availability of high-quality insulation materials for building projects. This, in turn, will help improve the energy efficiency and environmental sustainability of buildings, supporting the global push for greener and more sustainable construction practices.

In conclusion, the wholesale availability of XPS foam board production lines presents a promising opportunity for businesses to meet the growing market demand for this essential building material. With advanced technology, high efficiency, and comprehensive support services, the production lines offered by the company are well-suited for businesses looking to enter or expand in the XPS foam board market. This development is expected to benefit the construction industry by enhancing the availability of energy-efficient and sustainable building materials, contributing to a more environmentally friendly built environment.

Company News & Blog

A Guide to the Manufacturing Process of Calcium Silicate Boards

The manufacturing process of Calcium Silicate Board is a crucial step in the production of this highly durable and versatile building material. With the increasing demand for high-quality construction materials, {Company Name} has perfected the process to produce Calcium Silicate Board that meets the highest standards of quality and performance.The manufacturing process begins with the selection of raw materials. Calcium Silicate Board is made from a mixture of silica, lime, and reinforcing fibers. These raw materials are carefully selected to ensure the final product will have the desired strength, durability, and fire resistance. {Company Name} sources the finest quality raw materials from trusted suppliers to guarantee the superior performance of their Calcium Silicate Board.Once the raw materials are obtained, they are carefully measured and mixed in precise proportions. This mixture is then combined with water and additives to form a thick slurry. The slurry is poured into a mold and compressed to remove any air bubbles and to achieve the desired density. This process is crucial to ensure the homogeneity of the board and to enhance its structural integrity.After the initial compression, the boards are left to cure in a controlled environment. This curing process allows the chemical reactions within the mixture to take place, resulting in a rigid and stable board. {Company Name} pays close attention to the curing process to ensure that the Calcium Silicate Boards reach their full strength and durability.Once the boards are fully cured, they undergo a series of finishing processes. This includes cutting the boards to the desired dimensions, sanding the edges to achieve a smooth finish, and applying surface treatments for enhanced performance. {Company Name} has developed advanced finishing techniques to ensure that their Calcium Silicate Boards have a uniform and flawless appearance.Throughout the entire manufacturing process, {Company Name} places a strong emphasis on quality control. Every batch of Calcium Silicate Board is thoroughly inspected to ensure that it meets the highest standards of performance and durability. This commitment to quality has earned {Company Name} a reputation for producing Calcium Silicate Board that exceeds industry standards.In addition to their dedication to quality, {Company Name} is also committed to sustainability. The manufacturing process of Calcium Silicate Board is designed to minimize waste and energy consumption. {Company Name} employs eco-friendly practices and technologies to reduce their environmental impact and to contribute to a more sustainable building industry.With their state-of-the-art manufacturing facility and unwavering commitment to excellence, {Company Name} has become a trusted provider of Calcium Silicate Board for a wide range of construction applications. Their Calcium Silicate Board offers exceptional fire resistance, impact strength, and dimensional stability, making it an ideal choice for high-performance building projects.The exceptional manufacturing process and quality of {Company Name} Calcium Silicate Board have made it a preferred choice for architects, builders, and contractors who demand the best in building materials. Whether it is for commercial, industrial, or residential projects, {Company Name} Calcium Silicate Board is the reliable choice for superior performance and durability.In conclusion, the manufacturing process of Calcium Silicate Board is a complex and crucial process that requires precision, expertise, and a commitment to excellence. {Company Name} has demonstrated their dedication to producing high-quality Calcium Silicate Board through their meticulous manufacturing process, advanced technologies, and unwavering commitment to quality and sustainability. As the demand for high-quality construction materials continues to grow, {Company Name} is well-positioned to meet the needs of the construction industry with their exceptional Calcium Silicate Board.

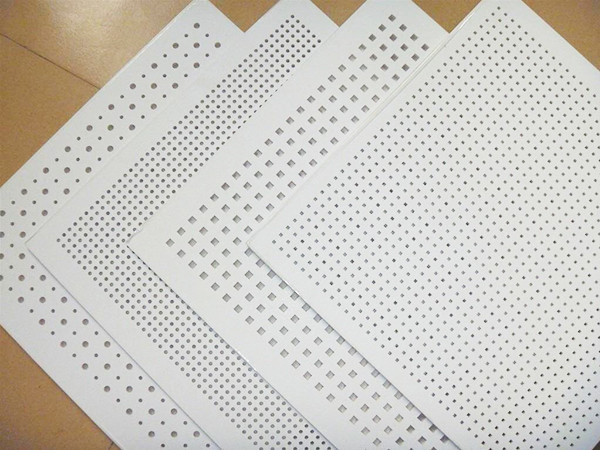

Top Perforated Plasterboard Machine Suppliers in China - Find Quality Machinery for Your Needs

China Perforated Plasterboard Machine Suppliers are making waves in the construction industry with their innovative and high-quality products. These suppliers have been making a name for themselves by providing state-of-the-art machinery for manufacturing perforated plasterboard, also known as drywall.One of the leading suppliers in China is [Company Name], which has gained a reputation for its commitment to excellence and customer satisfaction. The company specializes in the design, manufacture, and supply of perforated plasterboard machines that are used in the production of high-quality drywall for construction projects.[Company Name] takes pride in its advanced manufacturing facilities and cutting-edge technology, which allows them to produce top-of-the-line perforated plasterboard machines. These machines are designed to efficiently perforate gypsum boards, resulting in a product that meets the highest industry standards. With a strong emphasis on research and development, [Company Name] is constantly striving to improve its machinery to meet the evolving needs of the construction industry.The company's dedication to quality has earned them a loyal customer base both in China and internationally. They have successfully supplied their perforated plasterboard machines to numerous construction companies, helping them improve their manufacturing processes and deliver superior drywall products to their clients.In addition to providing high-quality machinery, [Company Name] also offers excellent customer service and technical support. They understand the importance of ensuring that their clients are fully satisfied with their purchases and are always ready to assist with installation, operation, and maintenance of their perforated plasterboard machines.Furthermore, [Company Name] is committed to sustainability and environmental responsibility. Their machinery is designed to optimize energy efficiency and minimize waste, contributing to a greener and more sustainable construction industry. By investing in their products, customers can also contribute to these efforts and reduce their environmental footprint.The success of China Perforated Plasterboard Machine Suppliers like [Company Name] is a testament to the growing demand for high-quality construction materials and machinery in the global market. As the construction industry continues to expand, there is a greater need for advanced and efficient manufacturing solutions, and these suppliers are at the forefront of meeting this demand.In conclusion, China Perforated Plasterboard Machine Suppliers, such as [Company Name], are playing a significant role in revolutionizing the construction industry with their state-of-the-art machinery. Their commitment to excellence, innovation, and customer satisfaction has made them leaders in the market, and they are poised to continue driving progress and innovation in the years to come. For any construction company looking to enhance their drywall manufacturing processes, these suppliers are the go-to choice for high-quality perforated plasterboard machines.

Affordable Mgo Board Making Machine: A Complete Pricelist

Today, we are excited to introduce a new Mgo Board Making Machine that is set to revolutionize the construction industry. The Mgo Board Making Machine is a versatile and efficient piece of equipment that is designed to produce high-quality magnesium oxide boards for various construction applications. The machine is engineered to provide superior performance, speed, and precision, making it an essential addition to any construction operation.The Mgo Board Making Machine offers a wide range of benefits that make it a valuable asset for any construction business. The machine is capable of producing Mgo boards of various sizes and thicknesses, allowing for versatility in construction projects. Additionally, the machine is equipped with advanced technology that ensures uniform board density and smooth surface finish, resulting in superior quality boards that meet industry standards.In terms of efficiency, the Mgo Board Making Machine is designed to optimize production processes, minimize material waste, and reduce labor costs. The machine features a user-friendly interface and automated controls that enable easy operation and monitoring of the production process. This enables construction companies to increase their productivity and meet project deadlines with ease.Furthermore, the Mgo Board Making Machine is built to be durable and reliable, ensuring long-term performance and minimal maintenance requirements. The machine is constructed with high-quality materials and components, and it undergoes stringent quality testing to guarantee its reliability and longevity. This means that construction businesses can rely on the Mgo Board Making Machine to deliver consistent results and minimize downtime.The introduction of the Mgo Board Making Machine is a significant milestone for our company. We are dedicated to providing innovative solutions that empower construction businesses to thrive in today's competitive market. The Mgo Board Making Machine reflects our commitment to delivering high-performance equipment that meets the evolving needs of the construction industry.As a leading manufacturer (), we have a strong track record in developing cutting-edge machinery that enhances construction processes. Our team of experienced engineers and technicians has worked tirelessly to design and create the Mgo Board Making Machine, ensuring that it meets the highest standards of quality, performance, and reliability. We are confident that the machine will make a positive impact on construction operations and contribute to the success of our customers.In conclusion, the Mgo Board Making Machine is a game-changer for the construction industry. Its advanced technology, efficiency, and reliability make it an essential investment for construction businesses looking to enhance their production capabilities and deliver high-quality results. With the introduction of this innovative machine, we are proud to continue our legacy of excellence in providing industry-leading solutions for the construction sector.For more information about the Mgo Board Making Machine and its pricing, please contact us at () or visit our website at (). We look forward to assisting you in integrating this groundbreaking machine into your construction operations and helping you achieve your business goals.

High-Quality Decorative Plastic Ceiling Tiles Made from PVC Gypsum Board Building Material

Decorative Plastic Ceiling Tiles: A High Quality Building MaterialWhen it comes to designing the interior of a building, one of the most important elements to consider is the ceiling. The right ceiling can enhance the overall look and feel of a space, and one of the most popular choices for modern buildings are Decorative Plastic Ceiling Tiles. These tiles are made from durable and high-quality PVC material, which not only offers a sleek and modern aesthetic but also offers several benefits over traditional ceiling options.One of the significant advantages of Decorative Plastic Ceiling Tiles is their flexibility and versatility. They come in a wide range of designs and patterns that can match the style and decor of any space. This is in contrast to conventional ceiling materials that tend to be concrete or drywall, which are limited in terms of customization and pattern options.Another advantage of Decorative Plastic Ceiling Tiles is that they are lightweight and easy to install. This makes them ideal for use in both residential and commercial buildings. The installation process is also relatively straightforward and can be done by a professional or a competent DIYer. The tiles can be easily cut to fit the size and shape of the ceiling and can be installed using adhesive or clips.The durability of Decorative Plastic Ceiling Tiles is another factor that makes it a popular choice. They are made from high-quality PVC, which is resistant to moisture, mold, and mildew. This makes them perfect for use in spaces where humidity and dampness are an issue, such as bathrooms, kitchens, and basements.One of the most popular types of Decorative Plastic Ceiling Tiles is the PVC Gypsum Board Building Material. This is a type of ceiling tile that is made from a combination of gypsum and PVC, which provides an even more substantial and durable ceiling option. Gypsum provides excellent fire resistance and sound insulation properties, making it ideal for use in commercial and public buildings.To produce high-quality PVC Gypsum Board Building Material, manufacturers often use Gypsum Ceiling Tile Making Machines. These machines are designed to produce gypsum boards that are strong, durable, and have excellent finished surfaces that offer an attractive finish.In conclusion, Decorative Plastic Ceiling Tiles are a high-quality building material that offers several advantages over traditional ceiling options. With their flexibility, lightweight, and easy installation, they are an excellent choice for both residential and commercial buildings. The PVC Gypsum Board Building Material is particularly durable and reliable, making it an ideal choice for buildings where safety and security are top priorities. With the help of Gypsum Ceiling Tile Making Machines, the manufacturing process can be streamlined, resulting in high-quality and cost-effective ceiling tiles.

High-Quality Magnesium Oxide Wallboard Making Machine for Sale

A leading manufacturer in the construction materials industry has recently unveiled a new state-of-the-art Magnesium Oxide Wallboard Making Machine, revolutionizing the production process for magnesium oxide wallboards. This innovative machine is set to transform the way magnesium oxide wallboards are manufactured, streamlining the process and improving overall efficiency.The new Magnesium Oxide Wallboard Making Machine, developed by a renowned company in the construction materials sector, is designed to meet the growing demand for high-quality, durable wallboards for both commercial and residential construction projects. The machine's advanced technology and precision engineering capabilities make it a game-changer in the industry, setting a new standard for magnesium oxide wallboard production.Not only does this cutting-edge machine improve the speed and efficiency of the manufacturing process, but it also enhances the quality and consistency of the final product. With its automated operation and advanced control systems, the Magnesium Oxide Wallboard Making Machine ensures that each wallboard meets the highest standards of durability and performance.The company behind this groundbreaking innovation has a strong track record of delivering top-quality construction materials and machinery to customers around the world. With a focus on innovation and continuous improvement, the company has become a trusted name in the industry, known for its commitment to excellence and customer satisfaction.In addition to the new Magnesium Oxide Wallboard Making Machine, the company offers a comprehensive range of construction materials and equipment, including wallboard installation systems, construction adhesives, and specialized tools for wallboard assembly. With a focus on sustainability and environmental responsibility, the company's products are designed to meet the highest standards of quality while minimizing their impact on the environment.Moreover, the company prides itself on its dedication to research and development, continuously investing in new technologies and processes to improve the performance and sustainability of its products. The development of the Magnesium Oxide Wallboard Making Machine is a testament to the company's commitment to innovation, as it aims to set new benchmarks for efficiency and quality in the construction materials industry.With its extensive experience and expertise in construction materials and machinery, the company is well-positioned to lead the market with its latest innovation. The introduction of the Magnesium Oxide Wallboard Making Machine is expected to have a significant impact on the industry, offering a game-changing solution for manufacturers and construction professionals seeking to improve the efficiency and quality of wallboard production.In conclusion, the unveiling of the new Magnesium Oxide Wallboard Making Machine marks a significant milestone for the construction materials industry, showcasing the company's commitment to innovation and excellence. With its advanced technology and precision engineering, the machine is set to revolutionize the production of magnesium oxide wallboards, bringing new levels of efficiency and quality to manufacturers and construction professionals. As the industry continues to evolve, the company remains at the forefront of innovation, driving positive change and creating new opportunities for success in construction materials and machinery.

Top Perforated Plasterboard Machine Factory: A Comprehensive Overview

The Best Perforated Plasterboard Machine Factory is a leading manufacturer and supplier of plasterboard machinery, specializing in the production of perforated plasterboard machines. With a strong focus on quality, innovation, and customer satisfaction, the factory has established itself as a reliable and trusted partner for businesses in the construction industry.With decades of experience in the industry, the factory has developed a deep understanding of the needs and requirements of its customers. This has enabled them to continuously innovate and improve their product offerings, providing solutions that are not only efficient and reliable but also cost-effective. The factory's commitment to excellence is also reflected in its state-of-the-art facilities and strict quality control processes, ensuring that every machine that leaves their premises meets the highest standards of quality and performance.One of the key features that sets the Best Perforated Plasterboard Machine Factory apart from its competitors is its dedication to research and development. The factory invests heavily in the latest technologies and employs a team of highly skilled engineers and technicians who are constantly pushing the boundaries of innovation. This has allowed them to develop cutting-edge perforated plasterboard machines that are designed to streamline the production process, improve productivity, and reduce operational costs for their clients.In addition to their commitment to product innovation, the factory also places a strong emphasis on customer service. They take pride in providing personalized solutions to meet the unique requirements of each client and offer comprehensive after-sales support to ensure that their machines continue to operate at peak performance. This has earned them a solid reputation for reliability and integrity, making them the go-to choice for many businesses looking to invest in high-quality perforated plasterboard machinery.The factory's dedication to quality and customer satisfaction has not gone unnoticed, as they have received numerous accolades and certifications for their commitment to excellence. This includes ISO 9001 certification, which demonstrates their adherence to international quality standards, as well as recognition from industry experts and satisfied customers.As a testament to their success, the Best Perforated Plasterboard Machine Factory has seen a steady increase in demand for their products, both domestically and internationally. This has led to the expansion of their production capacity and distribution network, allowing them to serve a larger customer base and fulfil orders with efficiency and speed.Looking ahead, the factory remains committed to pushing the boundaries of innovation and setting new benchmarks for quality in the industry. With a strong foundation built on expertise, reliability, and customer satisfaction, they are well-positioned to continue their growth and solidify their status as the best perforated plasterboard machine factory in the market.In conclusion, the Best Perforated Plasterboard Machine Factory is not just a manufacturer and supplier, but a trusted partner for businesses in the construction industry. Their unwavering commitment to quality, innovation, and customer satisfaction has made them a leader in the market, and their dedication to excellence ensures that they will continue to thrive in the years to come. With a focus on research and development, state-of-the-art facilities, and a strong emphasis on customer service, the factory is well-equipped to meet the evolving needs of the industry and remain at the forefront of the market.

Efficient Automatic Waterproof Board Production Line for MGO Boards

Automatic waterproof Mgo board production line is a new and innovative technology that has the potential to revolutionize the construction industry. This production line is capable of producing high-quality waterproof Mgo boards in a fully automated fashion, which not only improves efficiency and productivity but also ensures superior product quality. The process of manufacturing Mgo boards involves using a mix of magnesium oxide, magnesium chloride, and other natural materials, which are then combined and formed into sheets. These boards are widely used in construction for their excellent fire resistance, water resistance, and overall durability. However, traditional manufacturing methods have often been labor-intensive and time-consuming, leading to inefficiencies and variations in product quality.The Automatic Waterproof Mgo Board Production Line, developed by a leading manufacturer in the industry, has addressed these challenges by implementing state-of-the-art automation technology. This allows for precise control over the production process, resulting in consistent product quality and a significant increase in output. The production line is capable of handling the entire manufacturing process, from material mixing to board formation, pressing, and cutting, all with minimal human intervention. This not only reduces labor costs but also minimizes the risk of human error, resulting in a more reliable and efficient production process.Moreover, the use of automated technology also ensures that the boards produced are of superior quality, meeting or exceeding industry standards. This is particularly important for waterproof Mgo boards, which are often used in applications where resistance to moisture is critical. The automated production line ensures that every board produced is uniform in composition and free from any defects, thus meeting the stringent requirements for waterproofing in construction.In addition to the technological advancements, the company behind the Automatic Waterproof Mgo Board Production Line prides itself on its commitment to sustainability. The use of natural materials in the manufacturing process, coupled with the efficient production methods, minimizes the environmental impact of producing Mgo boards. This aligns with the company's vision of promoting eco-friendly and sustainable construction practices.Furthermore, the company has a strong focus on research and development, constantly seeking to improve its products and processes. This dedication to innovation has led to the development of the Automatic Waterproof Mgo Board Production Line, showcasing the company's ability to stay at the forefront of technological advancements in the industry.The introduction of the Automatic Waterproof Mgo Board Production Line is expected to have a significant impact on the construction industry. The increased efficiency and productivity it offers can lead to reduced construction costs and shorter project timelines. Additionally, the superior quality of the boards produced can contribute to improved building performance and longevity.Overall, the Automatic Waterproof Mgo Board Production Line represents a leap forward in the manufacturing of Mgo boards. Its combination of automation, quality control, and sustainability make it a game-changer in the construction industry, and the company behind it is poised to lead the way in providing high-quality, reliable, and sustainable building materials. As more construction companies embrace this advanced technology, the industry as a whole stands to benefit from the improvements in efficiency, product quality, and environmental stewardship that the production line offers.

Fireproof Calcium Silicate Board Making Machine: High-Density and Cost-Effective Options Available

The highly anticipated high density fireproof calcium silicate board making machine pricelist has been released by the renowned company. This pricelist is expected to provide valuable insights into the cost of obtaining this state-of-the-art machine, which is known for its exceptional quality and performance.The fireproof calcium silicate board making machine is an essential piece of equipment for companies involved in the production of fireproof calcium silicate boards. These boards are widely used in the construction industry due to their exceptional fire resistance and thermal insulation properties. As a result, the demand for high-quality fireproof calcium silicate board making machines has been on the rise, prompting companies to seek reliable and cost-effective options for acquiring this equipment.In response to this growing demand, the company has introduced its high density fireproof calcium silicate board making machine pricelist, which aims to provide transparency and clarity to potential customers. The pricelist includes detailed information about the cost of the machine, as well as any additional expenses that may be associated with its purchase, such as shipping and installation fees.The release of this pricelist is a significant development for the industry, as it allows companies to make informed decisions about investing in this critical piece of equipment. By providing a comprehensive overview of the costs involved, the company is demonstrating its commitment to delivering transparent and customer-centric solutions to its clients.In addition to offering a detailed pricelist, the company is also known for its extensive experience and expertise in the manufacturing of high-quality fireproof calcium silicate board making machines. With a solid reputation for delivering reliable and efficient equipment, the company has become a trusted partner for businesses seeking to enhance their production capabilities.One of the key advantages of the company's fireproof calcium silicate board making machine is its high density, which contributes to the superior quality and durability of the boards produced. This attribute is essential for ensuring that the boards meet the stringent quality standards required for use in construction projects, where fire resistance and structural integrity are paramount.Furthermore, the machine is designed to be fireproof, ensuring the safety and protection of both the equipment and the operators. This feature is a testament to the company's commitment to prioritizing safety and compliance with industry regulations, further enhancing its appeal to potential customers.As the construction industry continues to grow and evolve, the demand for fireproof calcium silicate boards is expected to remain strong. This trend is likely to drive the need for advanced and reliable manufacturing equipment, making the company's high density fireproof calcium silicate board making machine a valuable asset for businesses looking to stay competitive in the market.With its comprehensive pricelist and a reputation for excellence in manufacturing, the company is well-positioned to meet the needs of companies seeking to invest in top-of-the-line equipment for the production of fireproof calcium silicate boards. By providing transparent pricing and a commitment to quality, the company is poised to make a significant impact in the industry and set new standards for the manufacturing of fireproof building materials.In conclusion, the release of the high density fireproof calcium silicate board making machine pricelist is a significant milestone for the company and the industry as a whole. With its focus on transparency, quality, and safety, the company is demonstrating its dedication to providing reliable and effective solutions for businesses in the construction sector. As the demand for fireproof calcium silicate boards continues to grow, the company is well-positioned to support the industry with its advanced manufacturing equipment, setting a new standard for excellence in the production of fireproof building materials.

Unveiling the Latest PVC Vinyl Film Innovations from China

Title: China's PVC Vinyl Film Manufacturer Set to Revolutionize the MarketIntroduction:China's leading PVC vinyl film manufacturer has emerged as a game-changer in the industry, offering high-quality products that cater to a wide range of sectors. With a commitment to innovation, sustainable practices, and unmatched customer service, this company has established itself as a leader in the production of PVC vinyl films. As a result, it continues to dominate both domestic and international markets.Company Overview:With a strong foundation built on years of experience and expertise, the China-based PVC vinyl film manufacturer is constantly pushing boundaries and redefining industry standards. The company's commitment to research and development, advanced manufacturing processes, and stringent quality control measures has set it apart from competitors.The company's state-of-the-art production facilities, combined with the use of cutting-edge technology, ensure that their PVC vinyl films surpass customer expectations in terms of quality, durability, and versatility. Each product is designed to withstand varying environments and applications. Additionally, the company offers customized solutions to meet the specific requirements of different industries.Key Features and Benefits:1. Unparalleled Quality Assurance: The China-based manufacturer employs stringent quality control measures to ensure its PVC vinyl films meet the highest standards. Each product undergoes rigorous testing, enabling it to withstand extreme weather conditions, corrosion, and other demanding environments.2. Versatility: The PVC vinyl films are available in a wide range of colors, patterns, and finishes, making them suitable for various applications. From automotive interiors and building construction to signage and packaging, the company's films offer endless possibilities.3. Sustainable Production: The company is dedicated to practicing sustainable manufacturing processes. By employing eco-friendly materials and reducing waste generation, it strives to minimize its environmental impact. Additionally, the PVC vinyl films are recyclable, further promoting sustainability in the industry.4. Competitive Pricing: Despite its superior quality, the company's PVC vinyl films are competitively priced to cater to a diverse customer base. The manufacturer's commitment to affordability makes its products accessible to both small-scale businesses and larger enterprises.Market Impact and Global Reach:The China-based PVC vinyl film manufacturer has made significant strides in both domestic and international markets. Its commitment to consistently deliver exceptional products has gained the trust of numerous industries worldwide. By providing tailored solutions and maintaining efficient distribution networks, the company ensures timely delivery to clients across the globe.Future Innovations and Expansion:The company's commitment to innovation is showcased through continuous product development, research, and incorporation of emerging technologies. It aims to stay ahead of evolving market trends and meet the growing demands of customers. With plans to expand its product portfolio further and penetrate new markets, the manufacturer remains focused on its mission to revolutionize the PVC vinyl film industry.Conclusion:China's prominent PVC vinyl film manufacturer has successfully carved a niche for itself by providing high-quality products that meet the diverse needs of global consumers. The company's continuous focus on excellence, sustainability, and innovation has established it as a market leader. As it continues to expand its product range and cater to a wider customer base, the manufacturer is set to shape the future of the PVC vinyl film industry in China and beyond.

High-Quality Mineral Fiber and Mineral Wool Boards for Ceilings

TNT Quality Mineral Fiber Ceilings and Boards: Meeting the Demand for Quality and Aesthetics in Commercial ConstructionFor over a decade, TNT Quality Mineral Fiber Ceilings and Boards have been satisfying the needs of architects, designers, contractors, and building owners for high-performance, aesthetically pleasing, and sustainable ceiling solutions. The company, based in China, has established itself as a leader in the production and marketing of mineral fiber ceiling tiles, mineral wool ceiling panels, and related accessories.TNT Quality Mineral Fiber Ceilings and Boards offers a wide range of products, including acoustic, fire-resistant, moisture-resistant, and thermal insulation ceiling panels, as well as ceiling grids, suspension systems, and accessories. Their products have been widely used in commercial, institutional, industrial, and residential buildings, such as airports, hospitals, hotels, offices, schools, shopping malls, and airports.The company's commitment to quality and innovation is reflected in its modern manufacturing facilities, cutting-edge equipment, ISO 9001 and ISO 14001 certifications, and rigorous quality control measures. They source their raw materials from reliable suppliers and use advanced processes to produce consistent, durable, and cost-effective ceiling solutions.Some of the key features and benefits of TNT Quality Mineral Fiber Ceilings and Boards' products are:- Excellent acoustic performance: mineral fiber and wool are natural sound absorbers that reduce noise and create a comfortable and productive environment.- Fire resistance: mineral fiber and wool are non-combustible and can withstand high temperatures, ensuring safety and compliance with building codes and regulations.- Moisture resistance: mineral fiber and wool can resist humidity, condensation, and sagging, preventing mold, mildew, and deterioration.- Thermal insulation: mineral fiber and wool can conserve energy and reduce heating and cooling costs by providing effective insulation against heat transfer.- Aesthetics: TNT Quality Mineral Fiber Ceilings and Boards' products come in a variety of colors, patterns, textures, and sizes, allowing for creative and customized design options that enhance the visual appeal and functionality of any space.- Sustainability: mineral fiber and wool are eco-friendly, recyclable, and contribute to LEED certification points.TNT Quality Mineral Fiber Ceilings and Boards' commitment to customer satisfaction is evident in its personalized service, fast delivery, competitive pricing, and responsive technical support. They work closely with their clients to understand their needs, provide recommendations, and offer solutions that meet their specific requirements and budget.The company's success is also due to its emphasis on innovation and adaptation to market changes. They continuously invest in research and development to improve their products' performance, quality, and durability. They also keep abreast of emerging trends and technologies, such as digital printing, LED lighting, and acoustic testing, to offer the latest and most advanced ceiling solutions.In conclusion, TNT Quality Mineral Fiber Ceilings and Boards' products have proven themselves to be reliable, versatile, and attractive solutions for all types of commercial construction projects. Their commitment to quality, sustainability, innovation, and customer service sets them apart from their competitors and positions them to meet the growing demand for high-performance ceilings that enhance the built environment and the well-being of its occupants.