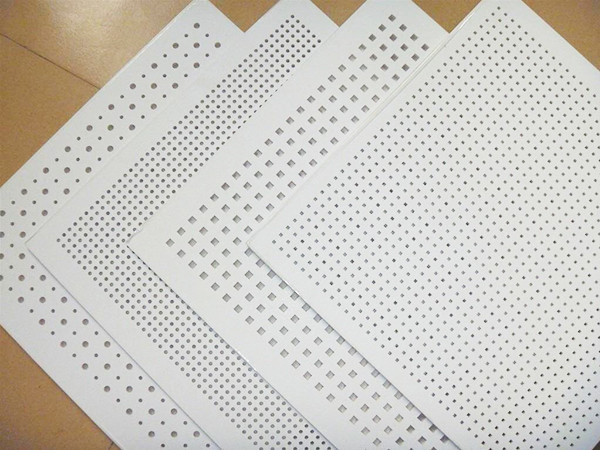

High-Quality Mineral Fiber Tiles Production Line for Chinese Market

By:Admin

China has always been at the forefront of technology and innovation, and its latest achievement in the field of mineral fiber tiles production is a testament to that. With the introduction of the new production line, the country is set to revolutionize the industry and further solidify its position as a global leader in manufacturing.

The mineral fiber tiles production line is the result of years of research and development by a leading Chinese company in the building materials industry. The company, founded in 1995, has been dedicated to the research, development, and production of high-quality building materials, specializing in mineral fiber ceiling tiles, T-grids, and other related products.

The introduction of the new production line represents a significant milestone for the company and the industry as a whole. The state-of-the-art facility is equipped with advanced technology and machinery, allowing for the efficient and cost-effective production of mineral fiber tiles. The production line is capable of producing a wide range of products, tailored to meet the specific requirements of different projects and customers.

The new production line is expected to have a substantial impact on the industry, as it will not only increase the company's production capacity but also enhance the quality and variety of its products. This will enable the company to better serve its customers and meet the growing demands of the market.

Furthermore, the introduction of the production line is expected to create numerous job opportunities, contributing to the country's economic growth and development. The company has always been committed to creating a positive impact on the local community and the industry as a whole, and the new production line is a step further in that direction.

In addition to its commitment to excellence in production, the company also places a strong emphasis on sustainability and environmental responsibility. The new production line is designed to minimize energy consumption and waste generation, ensuring that the company's operations are as environmentally friendly as possible.

The company's dedication to quality, innovation, and sustainability has earned it a reputation as a trusted and reliable partner in the industry. Its products are widely recognized for their superior quality, durability, and aesthetic appeal, making them a popular choice for builders, contractors, and homeowners alike.

The introduction of the new production line is expected to further strengthen the company's position in the market and enhance its competitiveness on a global scale. With its commitment to excellence and continuous innovation, the company is set to play a significant role in shaping the future of the mineral fiber tiles industry.

As the global demand for high-quality building materials continues to grow, the introduction of the new production line couldn't have come at a better time. The company is well-positioned to capitalize on the opportunities presented by the market and establish itself as a leading player in the industry.

In conclusion, the introduction of the new mineral fiber tiles production line marks a significant achievement for the company and the industry as a whole. With its advanced technology, commitment to quality, and focus on sustainability, the company is poised to revolutionize the mineral fiber tiles industry and set new standards for excellence. As the company continues to grow and expand its operations, it is expected to make a lasting impact on the global building materials market.

Company News & Blog

Affordable Machine for Making Gypsum Ceiling Cornices

Title: Revolutionary Gypsum Ceiling Cornice Making Machine Set to Transform the IndustryIntroduction:With an aim to revolutionize the gypsum ceiling cornice manufacturing industry, a renowned machinery company has recently unveiled its cutting-edge and cost-effective solution. Designed to streamline production processes and enhance the quality of gypsum cornices, the innovative machine promises to efficiently meet the increasing demand for decorative ceiling solutions in the construction sector.In partnership with industry experts, the company has developed a state-of-the-art gypsum ceiling cornice making machine that not only improves efficiency but also reduces costs for manufacturers. Let us dive deeper into the features and benefits this machine offers.Efficiency and Streamlined Production:The new machine boasts advanced technology, providing manufacturers with the ability to produce premium quality gypsum ceiling cornices at an unprecedented speed. Equipped with automated processes, it significantly reduces manual labor and the chances of human error. By automating various tasks such as gypsum mixing, molding, drying, and trimming, the machine ensures consistently uniform products within a fraction of the time taken by conventional manual methods.Additionally, the machine's highly advanced computerized control system provides operators with real-time monitoring and reporting, allowing for quick adjustments and increased productivity. This ensures that manufacturers can meet tight project deadlines and deliver orders on time without compromising on quality.Enhanced Quality and Customization Options:The gypsum ceiling cornice making machine is designed to produce cornices with impeccable precision and quality. The automated manufacturing process guarantees consistent dimensions, sharp details, and smooth finishes, eliminating any imperfections that may arise through manual labor.Furthermore, this machine offers a high level of customization options, allowing manufacturers to create a wide range of designs to cater to diverse customer preferences. From intricate patterns to unique motifs, the machine can effortlessly reproduce complex and detailed cornice designs, making it a versatile tool for any construction project.Cost-effective Solution:In addition to improved efficiency and quality, the gypsum ceiling cornice making machine proves to be a cost-effective solution for manufacturers. By eliminating the need for extensive manual labor, this cutting-edge technology significantly reduces labor costs. Moreover, its efficient use of materials ensures minimal wastage, further saving on expenses.The machine operates with minimal maintenance requirements, resulting in reduced downtime and higher machine availability, ultimately improving manufacturer productivity and profitability.Sustainability and Environmental Responsibility:The company behind this groundbreaking machine remains committed to sustainable and eco-friendly manufacturing practices. The gypsum ceiling cornice making machine utilizes environmentally friendly materials and optimized production processes to minimize waste generation, ensuring a greener manufacturing approach.Moreover, the machine's advanced features, such as energy-efficient drying mechanisms and precise material usage, help reduce the overall environmental impact associated with traditional manufacturing methods.Conclusion:The introduction of the state-of-the-art gypsum ceiling cornice making machine marks a significant advancement in the construction industry. By combining efficiency, quality, customization, and cost-effectiveness, this innovative machinery sets a new standard for gypsum cornice manufacturing.Manufacturers can now meet the growing demand for decorative ceiling solutions with ease, delivering consistent and flawless results to their clients. As the construction sector continues to flourish, the gypsum ceiling cornice making machine not only streamlines production processes but also contributes to sustainability, making it an indispensable tool for industry professionals.With this revolutionary technology at their disposal, manufacturers can strive towards excellence, growth, and profitability while delivering visually stunning and durable gypsum ceiling cornices to their customers.

Top Gypsum Ceiling Tile Punching Machine Price List

Best Gypsum Ceiling Tile Punching Machine Pricelist Unveiled by Leading Manufacturing CompanyThe demand for high-quality gypsum ceiling tile punching machines has been on the rise, and manufacturers have been striving to meet this demand by producing advanced and efficient machines. In response to this growing market, a leading manufacturing company has unveiled its latest pricelist for its best-selling gypsum ceiling tile punching machine, capturing the attention of industry professionals and businesses.The gypsum ceiling tile punching machine, known for its precision and reliability, is a key product in the company's extensive lineup of industrial machinery. With a focus on providing advanced solutions for ceiling tile production, the machine has been widely praised for its high performance and user-friendly design. Its ability to punch precise holes in gypsum ceiling tiles with efficiency and accuracy has made it a popular choice among manufacturers in the construction and interior design industries.The newly released pricelist showcases the company's commitment to offering competitive pricing for its top-of-the-line gypsum ceiling tile punching machine. The pricelist is designed to provide transparency and accessibility to potential buyers, allowing them to easily compare pricing options and make informed decisions based on their production needs and budget.In addition to the unveiling of the pricelist, the company has also shared insights into its manufacturing process and the technology behind its gypsum ceiling tile punching machine. With a strong emphasis on innovation and quality control, the company has leveraged its expertise to develop a machine that meets the rigorous demands of modern production facilities.The company's dedication to research and development has resulted in continuous improvements to its gypsum ceiling tile punching machine, ensuring that it remains at the forefront of the industry in terms of performance, efficiency, and durability. By integrating advanced technologies and precision engineering, the machine is capable of delivering consistent results while minimizing downtime and maintenance requirements.Furthermore, the company's commitment to customer satisfaction is reflected in its comprehensive after-sales support and service network. With a team of experienced technicians and engineers, the company offers technical assistance, training, and maintenance services to ensure that its customers can maximize the productivity and lifespan of their gypsum ceiling tile punching machines.In line with its mission to be a trusted partner for businesses in the construction and interior design sectors, the company has established a reputation for delivering high-quality machinery that meets the evolving needs of the industry. Its gypsum ceiling tile punching machine pricelist is a testament to its dedication to providing cost-effective solutions without compromising on performance and reliability.As the demand for innovative ceiling tile production equipment continues to grow, the unveiling of the latest pricelist for the best gypsum ceiling tile punching machine by the leading manufacturing company is poised to make an impact in the market. With its competitive pricing and unwavering commitment to excellence, the company is well-positioned to meet the needs of businesses seeking to enhance their production capabilities and maintain a competitive edge in the industry.For more information about the company and its gypsum ceiling tile punching machine pricelist, interested parties are encouraged to visit its official website or contact its sales representatives for personalized assistance and quotations.

Affordable Gypsum Ceiling Board Making Machine Price Revealed in Latest News

Title: Cutting-Edge Gypsum Ceiling Board Machine Revolutionizes Affordable DecorationIntroduction:In a bid to offer cost-effective solutions to the construction industry, a leading company has unveiled its latest innovation – the state-of-the-art Cheap Decoration Gypsum Ceiling Board Machine. Due to its exceptional features and competitive pricing, this revolutionary device is well-positioned to transform the gypsum ceiling board manufacturing sector and provide an affordable avenue for interior decoration.Company Overview:With a focus on research, development, and manufacturing of construction machinery, our company has gained recognition as a leading player in the industry. Boasting a team of experts and advanced technology, we have continually strived to meet the evolving needs of our customers. Committed to quality, reliability, and affordability, our company constantly endeavors to provide innovative solutions to the market.The Cheap Decoration Gypsum Ceiling Board Machine:Our latest product, the Cheap Decoration Gypsum Ceiling Board Machine, has garnered attention due to its unique capabilities that enhance the production of gypsum ceiling boards. Engineered with cutting-edge technology, this advanced machine offers a cost-effective solution to meet the rising demand for decorative interior construction materials.Key Features:1. High Efficiency: The machine demonstrates admirable productivity, boasting an efficient production capacity that reduces manufacturing time and boosts overall output. This enables faster completion of interior decoration projects and meets strict deadlines.2. Precision Cutting: The device is equipped with a precision cutting system, ensuring accurate dimensions for each gypsum ceiling board produced. This feature eliminates the need for additional trimming or adjustments, resulting in substantial time and cost savings.3. Versatile Design: Our gypsum ceiling board machine offers versatility, accommodating various board dimensions, thicknesses, and patterns. This flexibility gives customers the freedom to fulfill unique interior design requirements while maintaining cost-efficiency.4. User-Friendly Interface: Equipped with an intuitive interface, the machine ensures ease of operation for professionals and technicians. Minimal training is required to navigate its features, thereby reducing labor and training costs.5. Automation and Control: Automated features significantly reduce the reliance on manual labor, further streamlining the manufacturing process. The machine's control systems and sensors ensure consistent product quality, reducing material wastage and minimizing errors.Benefits of the Cheap Decoration Gypsum Ceiling Board Machine:The introduction of this innovative machine brings forth several advantages to the gypsum ceiling board manufacturing sector and beyond:1. Cost Reduction: The affordability of the machine and optimized manufacturing processes result in significant cost reductions for manufacturers. This, in turn, translates to lower prices for consumers seeking gypsum ceiling boards, making interior decoration more budget-friendly.2. Enhanced Product Quality: The machine's precision cutting capabilities, combined with the consistent automation and control systems, ensure superior product quality and dimensional accuracy. This enables manufacturers to deliver high-quality gypsum ceiling boards, meeting customer expectations.3. Accelerated Project Timelines: With increased production capacity and efficient manufacturing processes, interior decoration projects can be completed within shorter timelines. Contractors and builders can meet project deadlines effectively, enhancing overall customer satisfaction.4. Sustainable Solution: The machine's precision and automated control systems reduce material wastage, contributing to a more sustainable manufacturing process. By minimizing resource consumption, manufacturers can lessen their environmental impacts.Conclusion:The introduction of the Cheap Decoration Gypsum Ceiling Board Machine marks a significant milestone in the construction industry. Its remarkable features and competitive pricing are set to revolutionize the gypsum ceiling board manufacturing sector and make interior decoration more accessible. As consumers seek cost-effective solutions, this innovative machine offers improved efficiency, superior product quality, and environmental sustainability. With the unveiling of this cutting-edge technology, our company is proud to contribute to the evolution of the construction industry and meet the ever-growing demand for affordable yet exceptional decorative materials.

Top Co2 Foam Xps Extrusion Board Line

Best Co2 Foam Xps Extrusion Board Line Revolutionizes the Insulation IndustryThe insulation industry has seen a significant advancement with the introduction of the best Co2 foam XPS extrusion board line by [Company Name]. This innovative technology is expected to revolutionize the way insulation boards are manufactured and utilized.[Company Name] is a renowned leader in the field of extrusion technology, with a track record of delivering innovative solutions for the building and construction industry. The company has always been committed to developing sustainable and energy-efficient products, and the best Co2 foam XPS extrusion board line is a testament to that commitment.The new Co2 foam XPS extrusion board line utilizes advanced technology to produce high-quality insulation boards that offer superior thermal performance and energy efficiency. The Co2 foam technology is a game-changer in the industry, as it significantly reduces the environmental impact of the manufacturing process by utilizing carbon dioxide as a blowing agent instead of conventional hydrocarbons.The Co2 foam XPS extrusion board line is designed to meet the growing demand for sustainable building materials that not only provide excellent insulation but also reduce the overall carbon footprint of construction projects. With a focus on energy efficiency and environmental sustainability, the new technology is expected to play a key role in driving the transition towards greener and more sustainable building practices.In addition to its environmental benefits, the best Co2 foam XPS extrusion board line offers superior thermal performance and moisture resistance, making it an ideal choice for a wide range of construction applications. The insulation boards produced by this new technology provide excellent thermal insulation, ensuring energy savings and a comfortable indoor environment for building occupants.Moreover, the Co2 foam XPS extrusion board line is highly versatile and can be used in various construction projects, including residential, commercial, and industrial buildings. Its lightweight and easy-to-install nature make it a preferred choice for architects, contractors, and building owners looking for durable and efficient insulation solutions.[Company Name] has always been at the forefront of innovation in the extrusion technology industry, and the best Co2 foam XPS extrusion board line is a testament to the company's dedication to pushing the boundaries of sustainable building materials. With its focus on sustainability, energy efficiency, and superior performance, the new technology is set to redefine the insulation industry and pave the way for a more sustainable future in construction.The best Co2 foam XPS extrusion board line is a result of [Company Name]'s extensive research and development efforts, as well as its commitment to delivering high-quality products that meet the evolving needs of the construction industry. The company's relentless pursuit of innovation has led to the successful development of this groundbreaking technology, which is poised to make a significant impact on the way insulation boards are manufactured and utilized.In conclusion, the introduction of the best Co2 foam XPS extrusion board line by [Company Name] represents a major milestone in the insulation industry. This innovative technology is set to revolutionize the way insulation boards are produced and used, offering a sustainable and energy-efficient solution for the construction industry. With its superior thermal performance, environmental benefits, and versatility, the Co2 foam XPS extrusion board line is poised to lead the way towards a greener and more sustainable future in construction.

Affordable Automatic Gypsum Cornice Equipment Manufacturers: Enhance Search Engine Optimization

Title: Leading Automatic Gypsum Cornice Equipment Factories Revolutionize Manufacturing ProcessIntroduction:Gypsum cornices are an integral part of interior design, adding a touch of elegance and sophistication to any space. In an exciting development, a leading automatic gypsum cornice equipment factory is transforming the manufacturing process, propelling the industry forward. This groundbreaking technology, combined with the company's commitment to innovation, is revolutionizing the production of gypsum cornices. With unmatched precision and efficiency, these state-of-the-art equipment factories are shaping the future of interior decor.Body:1. The Rise of Automatic Gypsum Cornice Equipment Manufacturing:Over the past decade, there has been a considerable increase in the demand for high-quality gypsum cornices. To meet this growing demand, automatic gypsum cornice equipment factories have emerged, catering to the needs of interior designers, architects, and construction companies. These factories utilize cutting-edge technology to streamline production processes, ensuring increased efficiency and reduced costs.2. Cutting-Edge Technology and Manufacturing Process:The automatic gypsum cornice equipment factories incorporate advanced machinery and automation systems to optimize the manufacturing process. By utilizing computer numerical control (CNC) and robotics, these factories can produce gypsum cornices with unparalleled precision, consistency, and intricate designs. This groundbreaking technology not only enhances the overall quality but also significantly reduces manual labor.3. Benefits of Automatic Gypsum Cornice Equipment:a. Improved Efficiency: The use of automatic equipment has revolutionized gypsum cornice manufacturing, enabling factories to produce a larger quantity of products in a shorter period. This efficiency boost results in an enhanced customer experience and increased satisfaction levels.b. Consistent Quality: The precision offered by automatic machinery ensures consistent quality across all gypsum cornices produced by these factories. Each product adheres to the highest standards, showcasing fine details and impeccable craftsmanship.c. Cost-Effective: By combining automation with precise material usage, these factories can minimize material waste, thereby reducing costs. This cost-effectiveness translates to competitive pricing for customers, attracting a broader range of clients and promoting widespread adoption of gypsum cornices.4. Focus on Innovation:The leading automatic gypsum cornice equipment factories are driven by a relentless focus on innovation and research. They continuously strive to improve their manufacturing processes, developing new techniques and machinery to push the boundaries of what is possible within the industry. By investing in research and development, these companies ensure that their customers have access to the latest advancements in gypsum cornice manufacturing.5. Sustainability and Environmental Responsibility:In addition to technological advancements, automatic gypsum cornice equipment factories also prioritize sustainable production methods. By adhering to environmentally friendly practices, these factories minimize waste, reduce energy consumption, and utilize recyclable materials wherever possible. This commitment to sustainability aligns with contemporary demands for eco-friendly construction materials and contributes to the preservation of our planet.Conclusion:The automatic gypsum cornice equipment factories have ushered in a new era of manufacturing, bringing innovation, precision, and efficiency to the production of gypsum cornices. By embracing cutting-edge technology and focusing on sustainability, these factories provide a competitive advantage while meeting customer demands. With their commitment to innovation, these industry leaders are undoubtedly shaping the future of interior decor, transforming spaces with bespoke gypsum cornice designs that reflect a perfect combination of artistry and automation.

High-Quality Fiber Optic Star Ceiling Panels for Moon Shooting - FCC Approved, 15W Power, 600*600mm Size

China is known for its phenomenal innovation and technological advancements. In recent times, it has been making immense strides with the production of high-quality PMMA 15W Fiber Optic Star Ceiling Panels 600*600mm FCC for moon shooting. These products are second to none with their excellent quality and strict quality control.Leading Fiber Optic Star Ceiling Panels factories have been working tirelessly to ensure that their products meet the high standards of tech enthusiasts and professionals in the industry. With this, they have been producing highly efficient and reliable PMMA 15W Fiber Optic Star Ceiling Panels, designed specifically for moon shooting.The star ceiling panels are rated 15W and are made from Polymethyl methacrylate (PMMA), a highly durable and versatile material that is commonly used to produce high-tech products. The panels are excellent for providing accurate and reliable fiber optic lighting without the need for electricity, making them an eco-friendly lighting solution.The PMMA 15W Fiber Optic Star Ceiling Panels have been particularly successful in moon shooting projects, where the clarity and accuracy of the lighting are critical. They produce a stunning starlight effect that is ideal for creating the illusion of a starry sky, perfect for filming and photography.One of the greatest advantages of using these star ceiling panels is the fact that they do not emit any heat, making them an ideal solution for sensitive lighting projects, such as those required in the filming or photography industry. In addition, the PMMA material used in their production ensures that they are highly durable and long-lasting.China's leading Fiber Optic Star Ceiling Panels product market has been at the forefront of innovating and producing top-quality star ceiling panels, among other high-tech products. With their neck for excellence and their focus on maintaining strict quality control, they have managed to establish themselves as market leaders, providing clients with reliable and efficient products for their lighting needs.In conclusion, PMMA 15W Fiber Optic Star Ceiling Panels 600*600mm FCC for moon shooting from China are some of the most innovative and reliable lighting solutions on the market today. Their high-quality production and strict quality control ensure that they are long-lasting and efficient, making them the perfect fit for any sensitive lighting project. Well done, China, for yet another remarkable achievement in the technological world.

PVC Laminated Gypsum Board for Ceiling: Sizes 595*595mm and 603*603mm Available

PVC Laminated Ceiling Gypsum Board Market: Increasing Use in Construction Industry Drives GrowthAs construction projects continue to surge all around the globe, the market for PVC laminated gypsum board is expected to witness a substantial rise in demand. The use of these boards has been gaining momentum over the years, particularly in the construction industry, due to their superior characteristics that make them an ideal solution for ceilings and walls.PVC laminated gypsum board is a type of highly durable and versatile material that has applications in commercial, industrial, and residential settings. They are known for their thermal insulation properties, excellent fire resistance, easy installation, and aesthetic appeal. Furthermore, they provide an additional layer of protection when used on walls and ceilings, offering remarkable sound absorption and moisture resistance.Factors Driving the Growth of PVC Laminated Gypsum Board MarketOver the past few years, the growing demand for these boards in various industrial applications has played a significant role in driving the market's growth. One of the prominent factors driving this demand is the increasing use of these boards in the construction industry, thanks to their high-performance characteristics.Moreover, the availability of these boards in different shapes, sizes, and finishes has made them an ideal solution for commercial and residential applications. With the ongoing development of modern infrastructure, such as airports, commercial buildings, and shopping malls, the demand for PVC-laminated gypsum boards continues to grow.Furthermore, increasing investment in infrastructural development in emerging economies like India and China is one of the critical drivers of the PVC laminated gypsum board market. Rising disposable income and an increasing number of urban centers are also expected to fuel market growth in the coming years.Additionally, as various environmental regulations are implemented across the globe to reduce carbon emissions, the use of PVC laminated gypsum boards helps in reducing these emissions significantly. PVC laminated gypsum boards are an eco-friendly and sustainable solution that reduces energy consumption, making them an ideal choice for achieving green building ratings such as LEED and BREEAM.Competitive LandscapeMajor players operating in the PVC laminated gypsum board market globally include Saint-Gobain S.A., Knauf, USG Corporation, etc. These companies are expanding their production capacities to cater to the growing demand across various end-users such as healthcare, education, hospitality, and residential.Furthermore, they are also adopting strategies like mergers and acquisitions, partnerships, and collaborations to expand their product offering and increase their foothold in the market. For instance, in 2020, Knauf entered into an agreement to acquire USG Corporation in a bid to expand its product offerings in North America.ConclusionPVC-laminated gypsum boards are versatile building materials with a wide range of applications in the construction industry. Their exceptional properties, such as thermal insulation and fire resistance, have made them an ideal solution for walls and ceilings. The market for PVC-laminated gypsum board is set to grow in the coming years due to the increasing use in various end-user industries such as healthcare, education, and hospitality. The entry of new players and the expansion of production capacities of existing players will further propel market growth.

High-quality Mineral Fiber Ceiling Tiles Machine Factory

Mineral Fiber Ceiling Tiles Machine Factory Leads Innovation and Sustainability in Ceiling Tile ProductionMineral Fiber Ceiling Tiles Machine Factory, a leading manufacturer and supplier of cutting-edge ceiling tile production machinery, is making waves in the industry with their innovative and sustainable approach to manufacturing. The company has been at the forefront of technological innovation and is committed to providing high-quality solutions for the production of mineral fiber ceiling tiles.With a strong focus on research and development, Mineral Fiber Ceiling Tiles Machine Factory has been able to continuously improve their production processes and machinery, making their products highly efficient and cost-effective. The company prides itself on its ability to meet the needs of the market and deliver customized solutions to its clients.Established in {year}, the Mineral Fiber Ceiling Tiles Machine Factory has a solid reputation as a reliable and trustworthy supplier of ceiling tile production machinery. Their machines are known for their precision, durability, and the ability to produce high-quality mineral fiber ceiling tiles at a rapid pace, making them the go-to choice for manufacturers around the world.The company's commitment to sustainability is evident in its manufacturing processes, as they strive to reduce their environmental impact and promote sustainable practices throughout the production cycle. Mineral Fiber Ceiling Tiles Machine Factory has implemented various measures to minimize waste, reduce energy consumption, and optimize resource utilization. By incorporating eco-friendly materials and energy-efficient technologies into their machinery, the company is setting a new standard for sustainable manufacturing in the industry.In addition to their focus on sustainability, Mineral Fiber Ceiling Tiles Machine Factory is dedicated to driving innovation in the field of ceiling tile production. The company's team of engineers and designers are constantly exploring new concepts and technologies to improve their machinery, leading to the development of cutting-edge solutions that are redefining the industry standards.One of the key factors contributing to the success of Mineral Fiber Ceiling Tiles Machine Factory is their ability to provide comprehensive support and training to their clients. The company's team of experts is readily available to offer technical assistance, on-site training, and troubleshooting services to ensure that their clients are able to maximize the efficiency and output of their machinery.As part of their ongoing commitment to excellence, the Mineral Fiber Ceiling Tiles Machine Factory has also established strong partnerships with leading industry suppliers and manufacturers, allowing them to offer a wide range of complementary products and services to their clients. This comprehensive approach enables the company to provide a one-stop solution for all their clients' ceiling tile production needs.Looking ahead, Mineral Fiber Ceiling Tiles Machine Factory is poised to continue leading the way in innovation and sustainability in the ceiling tile production industry. With a strong emphasis on research and development, a commitment to sustainability, and a dedication to providing exceptional support and training to their clients, the company is well-positioned to remain at the forefront of the industry for years to come.In conclusion, Mineral Fiber Ceiling Tiles Machine Factory has established itself as a trailblazer in the field of ceiling tile production machinery, setting new standards for innovation and sustainability. With a focus on research and development, a commitment to sustainability, and a dedication to providing comprehensive support to their clients, the company is driving positive change in the industry and redefining the way ceiling tiles are manufactured.

Efficient Automatic Waterproof Board Production Line for MGO Boards

Automatic waterproof Mgo board production line is a new and innovative technology that has the potential to revolutionize the construction industry. This production line is capable of producing high-quality waterproof Mgo boards in a fully automated fashion, which not only improves efficiency and productivity but also ensures superior product quality. The process of manufacturing Mgo boards involves using a mix of magnesium oxide, magnesium chloride, and other natural materials, which are then combined and formed into sheets. These boards are widely used in construction for their excellent fire resistance, water resistance, and overall durability. However, traditional manufacturing methods have often been labor-intensive and time-consuming, leading to inefficiencies and variations in product quality.The Automatic Waterproof Mgo Board Production Line, developed by a leading manufacturer in the industry, has addressed these challenges by implementing state-of-the-art automation technology. This allows for precise control over the production process, resulting in consistent product quality and a significant increase in output. The production line is capable of handling the entire manufacturing process, from material mixing to board formation, pressing, and cutting, all with minimal human intervention. This not only reduces labor costs but also minimizes the risk of human error, resulting in a more reliable and efficient production process.Moreover, the use of automated technology also ensures that the boards produced are of superior quality, meeting or exceeding industry standards. This is particularly important for waterproof Mgo boards, which are often used in applications where resistance to moisture is critical. The automated production line ensures that every board produced is uniform in composition and free from any defects, thus meeting the stringent requirements for waterproofing in construction.In addition to the technological advancements, the company behind the Automatic Waterproof Mgo Board Production Line prides itself on its commitment to sustainability. The use of natural materials in the manufacturing process, coupled with the efficient production methods, minimizes the environmental impact of producing Mgo boards. This aligns with the company's vision of promoting eco-friendly and sustainable construction practices.Furthermore, the company has a strong focus on research and development, constantly seeking to improve its products and processes. This dedication to innovation has led to the development of the Automatic Waterproof Mgo Board Production Line, showcasing the company's ability to stay at the forefront of technological advancements in the industry.The introduction of the Automatic Waterproof Mgo Board Production Line is expected to have a significant impact on the construction industry. The increased efficiency and productivity it offers can lead to reduced construction costs and shorter project timelines. Additionally, the superior quality of the boards produced can contribute to improved building performance and longevity.Overall, the Automatic Waterproof Mgo Board Production Line represents a leap forward in the manufacturing of Mgo boards. Its combination of automation, quality control, and sustainability make it a game-changer in the construction industry, and the company behind it is poised to lead the way in providing high-quality, reliable, and sustainable building materials. As more construction companies embrace this advanced technology, the industry as a whole stands to benefit from the improvements in efficiency, product quality, and environmental stewardship that the production line offers.

High-quality Mgo Board Forming Machine Factory and Its Features

Mgo Board Forming Machine Factory was established in 2005, and has since been a leader in the manufacturing of magnesium oxide board forming machines. The factory is renowned for its state-of-the-art technology and innovative solutions in the production of Mgo board forming machines. With a commitment to excellence and customer satisfaction, the factory has earned a reputation for providing high-quality machines and exceptional service to its clients worldwide.The factory's extensive range of machines includes Mgo board production line, Mgo board laminating machine, and Mgo board cutting machine. These machines are designed to meet the diverse needs of the construction industry, offering efficient and cost-effective solutions for the production of magnesium oxide boards used in various applications such as wall panels, ceiling boards, and fireproof boards.The Mgo board forming machine factory takes pride in its team of highly skilled engineers and technicians who are dedicated to developing cutting-edge technologies and continuously improving the manufacturing process. By staying at the forefront of technological advancements, the factory is able to deliver reliable and precise machines that meet the highest industry standards and exceed customer expectations.In addition to its commitment to quality, the factory places a strong emphasis on environmental sustainability and energy efficiency. The Mgo board forming machines are designed to minimize energy consumption and reduce waste, thereby contributing to a cleaner and greener manufacturing process. The factory also adheres to strict environmental regulations and strives to implement eco-friendly practices throughout its operations.Furthermore, the factory is committed to providing comprehensive support and after-sales service to its clients. With a global network of agents and distributors, the factory ensures that customers receive prompt assistance and technical support wherever they are located. This commitment to customer satisfaction has enabled the factory to build long-term partnerships with clients from around the world, establishing a strong reputation for reliability and trustworthiness in the industry.The Mgo board forming machine factory's dedication to excellence and innovation has not gone unnoticed. The factory has received numerous accolades and certifications for its outstanding performance and product quality. It has also been recognized for its contributions to the advancement of the construction industry through the development of advanced manufacturing technologies.Looking ahead, the Mgo board forming machine factory remains committed to pushing the boundaries of innovation and setting new benchmarks in the manufacturing of magnesium oxide board forming machines. With a focus on continuous improvement and customer satisfaction, the factory is poised to remain a leader in the industry and continue to deliver exceptional machines that meet the evolving needs of the construction sector.In conclusion, Mgo Board Forming Machine Factory has established itself as a premier manufacturer of magnesium oxide board forming machines, known for its exceptional quality, innovative technology, and unwavering commitment to customer satisfaction. With a strong focus on excellence, sustainability, and customer support, the factory is well-positioned to maintain its leadership in the industry and drive further advancements in the manufacturing of Mgo board forming machines.