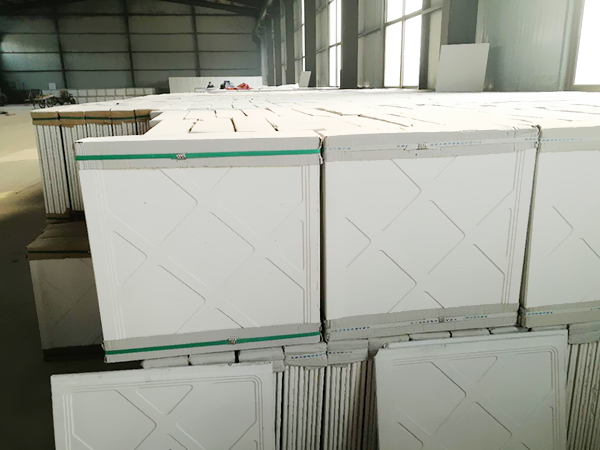

High Quality Magnesium Wall Panels Making Machine Pricelist Revealed

By:Admin

The magnesium wall panel making machine is designed to produce high-quality, lightweight panels that are not only durable and fire-resistant but also easy to install and maintain. These panels are made from magnesium oxide, which is a natural mineral that is abundant in nature and has minimal environmental impact. This makes them an attractive choice for eco-conscious builders and developers who are looking to reduce their carbon footprint.

One of the key advantages of the magnesium wall panel making machine is its efficiency and cost-effectiveness. The machine is capable of producing a large volume of panels in a short period of time, which helps to reduce labor costs and increase productivity. Additionally, the panels themselves are affordable, making them an attractive option for both residential and commercial construction projects.

To further entice potential customers, {} has released a price list for the magnesium wall panel making machine, showcasing its competitive pricing compared to other similar machines on the market. This move is likely to attract interest from construction companies and developers who are looking to invest in the latest technology to stay ahead of the competition.

{} is a leading manufacturer of construction machinery, with a strong reputation for producing high-quality, innovative products. With a focus on research and development, the company is committed to staying at the forefront of technological advancements in the construction industry. The introduction of the magnesium wall panel making machine is a testament to this commitment, demonstrating their dedication to providing cutting-edge solutions to their customers.

The company's CEO expressed excitement about the potential impact of the magnesium wall panel making machine on the construction industry. "We are confident that our machine will revolutionize the way buildings are constructed. Not only are magnesium wall panels a sustainable and cost-effective option, but our machine also streamlines the production process, saving time and resources for our customers," he said.

In addition to the price list for the magnesium wall panel making machine, {} is also offering comprehensive training and technical support to ensure that customers can maximize the potential of their investment. This includes on-site training for operators, as well as ongoing support for maintenance and troubleshooting.

The release of the magnesium wall panel making machine and its accompanying price list marks a significant milestone for {} as they continue to expand their product offerings and solidify their position as a leader in the construction machinery industry. With a focus on innovation and customer satisfaction, the company is well-positioned to meet the evolving needs of the construction sector and drive positive change in the way buildings are designed and constructed.

As the construction industry continues to embrace sustainable and cost-effective building materials, the magnesium wall panel making machine from {} is poised to play a pivotal role in shaping the future of construction. With its advanced technology, competitive pricing, and comprehensive support services, the machine is set to be a game-changer for builders and developers looking to make a positive impact on the environment while maximizing efficiency and productivity.

Company News & Blog

Efficient Mgo Board Production Line for High-Quality Output

MGO Board Manufacturing Machine Supplier: Innovative Solutions for the Construction Industry In the rapidly evolving construction industry, the demand for high-quality building materials is on the rise. One popular choice among architects, builders, and contractors is Magnesium Oxide (MgO) board. This versatile material offers exceptional durability, fire resistance, and eco-friendliness, making it an ideal choice for a wide range of applications.To meet the growing demand for MgO board, manufacturers need reliable and efficient production solutions. This is where the automatic MGO board production line, offered by a leading global supplier, comes into play. With its fashionable design, reasonable structure, and stable running, this machine is revolutionizing the MgO board manufacturing process.The production line is equipped with innovative double ways roll-in technology, ensuring the production of even thickness boards. This advanced feature eliminates any inconsistencies in the board thickness, resulting in superior quality products. The shaking device further enhances the production process by ensuring the uniform distribution of materials and facilitating efficient board formation.Reliability and efficiency are essential when it comes to MgO board production, and this production line delivers on both fronts. With its high-speed capabilities, it enables large-scale production, meeting the requirements of even the most demanding construction projects. The machine's automated functions minimize human error and maximize productivity, significantly reducing production time and costs.Furthermore, this MGO board manufacturing machine adheres to strict environmental standards. The eco-friendly design ensures minimal waste and optimized energy consumption, making it a sustainable choice for any environmentally conscious manufacturer. As the global construction industry increasingly embraces green practices, this production line is a testament to the commitment of suppliers to provide eco-friendly solutions.When choosing a supplier for an MGO board manufacturing machine, various factors should be considered. One crucial aspect is the supplier's expertise and experience in the field. Look for a supplier with a solid reputation and a long history of delivering high-quality machinery to the construction industry. Additionally, it is essential to consider the supplier's commitment to customer satisfaction. A reliable supplier will provide comprehensive technical support, ensuring smooth installation and operation of the production line. They should also offer regular maintenance services to optimize machine performance, extending its lifespan and reducing downtime.In conclusion, the automatic MGO board production line offered by a prominent supplier is revolutionizing the construction industry. With its advanced technology, efficient production process, and eco-friendly design, it meets the demands of modern construction projects. Investing in this machine not only ensures high-quality MgO board production but also demonstrates a commitment to sustainability and innovation.If you are a construction manufacturer looking for an MGO board manufacturing machine supplier, look no further. Contact us today and explore the possibilities of this cutting-edge production line. Experience the benefits of reliability, efficiency, and environmental consciousness in your manufacturing process. Let us help you make your mark in the construction industry with our top-of-the-line machinery.

Affordable Fully Automatic Gypsum Plaster Cornice Manufacturing Machine Factories

Title: Introduction of Budget-Friendly, Fully Automatic Gypsum Plaster Cornice Manufacturing MachinesIntroduction:In a bid to streamline the manufacturing process and cater to the growing demand for decorative gypsum plaster cornices, a number of factories have introduced cost-effective, fully automatic gypsum plaster cornice manufacturing machines. These high-tech machines have revolutionized the industry, allowing manufacturers to produce high-quality cornices efficiently, while maintaining affordable pricing, thus benefiting both consumers and businesses.Company Overview:One such company, with extensive experience in the manufacturing and supply of gypsum plaster cornice manufacturing machines, has become a pioneer in this industry. With a strong focus on research and development, this company has consistently delivered state-of-the-art machines that automate the previously complex and time-consuming manufacturing processes. Their commitment to affordability and quality has made them a go-to choice for factories looking to enhance their production capabilities.Efficiency and Cost-Effectiveness:The fully automatic gypsum plaster cornice manufacturing machines have significantly increased productivity rates, reducing the overall manufacturing time. These machines are capable of seamlessly producing intricate cornice designs with precision, surpassing previous manual methods. By eliminating human error and minimizing material wastage, manufacturers can save both time and money.Furthermore, these machines have an automated plaster mixing system, which ensures consistent plaster quality throughout the production process. This eliminates the need for manual plaster mixing, greatly enhancing efficiency and productivity. The use of fully automatic machines also allows factories to expand their production capabilities without the need for additional labor, contributing to a well-optimized manufacturing operation.Quality and Customization:Despite the affordability of these machines, there is no compromise on the quality of the final product. The automated process ensures consistent and precise results, guaranteeing the highest standards of craftsmanship. Additionally, manufacturers can customize the machines to create unique designs, enabling them to cater to a wider range of customer preferences.The machines offer a high degree of flexibility, allowing manufacturers to produce cornices of various sizes and styles. This versatility ensures that there is a cornice for every architectural need, be it modern, traditional, or contemporary. By minimizing limitations in design and sizing, these machines enable businesses to meet diverse market demands, ultimately driving growth and profitability.Sustainable Manufacturing:In line with the increasing emphasis on sustainable practices, many manufacturers are now incorporating eco-friendly features into their gypsum plaster cornice manufacturing machines. These machines are designed to minimize energy consumption and reduce waste. By prioritizing sustainable manufacturing, factories can not only contribute to the preservation of the environment but also enhance their brand reputation.Conclusion:The introduction of affordable, fully automatic gypsum plaster cornice manufacturing machines has revolutionized the industry. The combination of efficiency, cost-effectiveness, quality, and customization makes these machines invaluable to manufacturers seeking to meet the demands of an ever-evolving market. As more factories adopt this technology, the production of gypsum plaster cornices is expected to become more accessible and diverse, benefitting both businesses and consumers alike.

High-Quality Gypsum Cornice Production Line for Efficient Manufacturing

Best Gypsum Cornice Production Line Revolutionizes Manufacturing ProcessIn the ever-evolving world of manufacturing, one company has set the bar high with their innovative gypsum cornice production line. With a commitment to quality and efficiency, they have quickly become a leader in the industry.With a strong focus on research and development, {Company Name} has successfully created the best gypsum cornice production line in the market. This state-of-the-art line has revolutionized the manufacturing process, increasing productivity, and ensuring top-quality products every time.{Company Name} was founded in 1995, and since its inception, has been dedicated to providing the best solutions for the construction industry. With a team of highly skilled engineers and technicians, the company has been able to develop cutting-edge technology that has set them apart from their competitors.Their gypsum cornice production line is a result of years of research and development, with a relentless pursuit of perfection. The line is equipped with the latest technology, allowing for precise and efficient production of gypsum cornices. This has significantly reduced production time and increased output, ultimately leading to cost savings for the company.The production line is also designed to ensure the highest quality of products. With automated processes and rigorous quality control measures in place, {Company Name} guarantees that every gypsum cornice that comes off the line meets the highest standards. This has earned them a reputation for excellence in the industry and has solidified their position as a top choice for customers.One of the key features of the {Company Name}'s gypsum cornice production line is its versatility. The line is capable of producing a wide range of gypsum cornices in various sizes and designs, allowing the company to cater to the diverse needs of their customers. Whether it's a simple and elegant design or a more intricate and ornate one, the production line can handle it all with ease.Furthermore, the production line is also designed with sustainability in mind. {Company Name} is committed to reducing its environmental impact, and the production line is equipped with energy-efficient technology that helps minimize resource consumption. This has not only been beneficial for the environment but has also reduced operational costs for the company.Moreover, {Company Name} provides comprehensive training and support to its customers to ensure that they can fully maximize the potential of the production line. Their team of professionals is dedicated to providing assistance and guidance, helping their customers achieve the best results with the equipment.The {Company Name}'s gypsum cornice production line has received widespread acclaim from customers and industry professionals alike. Its impact on the manufacturing process has been significant, with many customers reporting increased efficiency and cost savings since implementing the production line in their facilities.With their commitment to innovation and excellence, {Company Name} continues to push the boundaries of what is possible in manufacturing. Their gypsum cornice production line is a testament to their dedication to providing the best solutions for the construction industry, and it has set a new standard for efficiency and quality.

High-Quality Gypsum Plasterboard Ceiling Machine for Sale

Gypsum Plasterboard Ceiling Machine Revolutionizes Construction IndustryThe construction industry has continually evolved over the years, with the introduction of new technologies and innovative solutions that have greatly impacted the way buildings are designed and constructed. One such innovation that has been making waves in the industry is the Gypsum Plasterboard Ceiling Machine, an advanced piece of equipment that has revolutionized the way ceiling materials are manufactured and installed.Manufactured by a leading company in the construction industry, the Gypsum Plasterboard Ceiling Machine is a state-of-the-art piece of equipment that is designed to streamline the production process of plasterboard ceilings. With its advanced technology and precision engineering, this machine has set a new standard in efficiency, quality, and speed in the construction of ceilings.The Gypsum Plasterboard Ceiling Machine is capable of producing high-quality plasterboard panels at a rapid pace, making it an essential tool for construction companies looking to maximize productivity and efficiency. By automating the production process, this machine has significantly reduced the time and labor required to manufacture plasterboard ceilings, allowing construction companies to complete projects faster and with higher precision.In addition to its impressive production capabilities, the Gypsum Plasterboard Ceiling Machine is also designed to ensure the highest quality of plasterboard panels. Equipped with advanced quality control systems and precision engineering, this machine is able to produce flawless plasterboard panels that meet the highest industry standards. This not only ensures the durability and longevity of the ceilings but also reduces the need for rework or repairs, ultimately saving construction companies time and money.Furthermore, the Gypsum Plasterboard Ceiling Machine is also designed with sustainability in mind. By optimizing material usage and reducing waste, this machine is helping construction companies minimize their environmental impact and operate in a more sustainable manner. This is in line with the company's commitment to environmental responsibility and its dedication to promoting sustainable practices in the construction industry.The introduction of the Gypsum Plasterboard Ceiling Machine has been met with great enthusiasm and excitement within the construction industry. Many construction companies have already adopted this innovative technology and are reaping the benefits of increased efficiency and productivity. In fact, some companies have reported significant cost savings and faster project completion times since implementing this machine into their operations.One of the key advantages of the Gypsum Plasterboard Ceiling Machine is its versatility and adaptability to different project requirements. Whether constructing commercial buildings, residential properties, or industrial facilities, this machine can be customized to meet specific design and size specifications, making it a valuable asset for construction companies of all sizes.Looking ahead, the company behind the Gypsum Plasterboard Ceiling Machine is committed to further innovation and advancement in the construction industry. By continuously investing in research and development, the company is aiming to introduce even more advanced technologies that will further revolutionize the way buildings are constructed and improve efficiency in the construction process.In conclusion, the Gypsum Plasterboard Ceiling Machine has proven to be a game-changer in the construction industry, offering construction companies a versatile, efficient, and sustainable solution for the production of plasterboard ceilings. With its cutting-edge technology and commitment to quality, this machine is set to continue shaping the future of construction and contribute to the advancement of the industry as a whole.

High-Performance Gypsum Ceiling Board Pvc Laminating Machine for Sale - 6 Million Sqm Capacity

The [Company Name] Announces the Launch of 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine[Company Name], a leading manufacturer of machinery and equipment for the construction industry, is proud to announce the launch of its latest innovation – the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine. This state-of-the-art machine is set to revolutionize the production of gypsum ceiling boards, delivering exceptional efficiency and quality.The new machine boasts a production capacity of 6 million square meters of gypsum ceiling boards, making it one of the most advanced and high-capacity machines in the industry. With its cutting-edge technology and precision engineering, the machine is designed to meet the growing demand for high-quality gypsum ceiling boards in the construction market.[Company Name] has a long-standing reputation for delivering innovative and reliable machinery for the construction industry. With a strong focus on research and development, the company continuously strives to push the boundaries of technological advancement in its products. The launch of the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine is a testament to [Company Name]'s commitment to providing its customers with the best solutions for their production needs.The machine is equipped with advanced PVC laminating technology, ensuring a smooth and flawless finish on the gypsum ceiling boards. This not only enhances the aesthetics of the boards but also improves their durability and resistance to wear and tear. Additionally, the machine's high-speed production capabilities enable manufacturers to meet their production targets efficiently and effectively.One of the key features of the new machine is its user-friendly interface, which allows for easy operation and maintenance. This ensures that manufacturers can maximize their productivity without compromising on the quality of their products. Furthermore, the machine is designed with energy efficiency in mind, helping companies reduce their operational costs and environmental impact.In addition to its technological advancements, the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine is built to the highest standards of quality and reliability. [Company Name] prides itself on the durability and longevity of its products, and the new machine is no exception. With proper maintenance and care, customers can expect years of trouble-free operation from this cutting-edge piece of equipment.The launch of the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine is set to have a significant impact on the construction industry, particularly in the production of gypsum ceiling boards. With its unrivaled production capacity, advanced technology, and user-friendly design, the machine is poised to become a game-changer for manufacturers seeking to meet the demands of the market.[Company Name] remains committed to providing its customers with the best solutions for their production needs, and the new machine is a testament to this commitment. As the construction industry continues to evolve, [Company Name] will be at the forefront, driving innovation and delivering excellence in machinery and equipment.For more information about the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine and other products offered by [Company Name], please visit their website or contact their sales team for inquiries.

Easy-to-Operate Machine for Making Decorative Gypsum Plaster Mouldings and Cornices

Decorative Gypsum Plaster Mouldings / Cornice Making Machine Easy To Operation: A Game-Changer in the Construction IndustryThe construction industry has experienced a tremendous transformation over the years. The introduction of innovative technologies and equipment has revolutionized the way building structures are erected. Indeed, this industry has become more efficient, cost-effective, and environmentally friendly. Recently, a Chinese company, Hebei Greens Building Material Technology Development Co., Ltd., has launched a cutting-edge machine designed to make decorative gypsum plaster mouldings and cornices with ease. The Decorative Gypsum Plaster Mouldings / Cornice making machine is a game-changer in the construction industry. This machine is programmed to achieve precision and high-quality production of gypsum plaster mouldings and cornices. Its operation is straightforward, even for novices. This newly introduced machine has attracted a lot of attention from the construction industry in China and beyond.Hebei Greens Building Material Technology Development Co., Ltd. is a renowned Chinese company with rich experience in producing building materials. The company has always strived to manufacture high-quality building materials at competitive prices. In recent years, Hebei Greens has invested heavily in research and development to enhance its product offerings, including the Decorative Gypsum Plaster Moulding/Cornice Making Machine. This newly introduced machine is a perfect example of Hebei Greens' commitment to innovation and product excellence. The Decorative Gypsum Plaster Moulding/Cornice Making Machine boasts of several unique features that set it apart from other cornice-making devices on the market. One of its most impressive features is its ease of use. Even novice operators can operate the machine to achieve precision and high-quality production of gypsum plaster mouldings and cornices.Not only is the Decorative Gypsum Plaster Moulding/Cornice Making machine easy to use, but it also boasts of high production efficiency and cost-effectiveness. With the machine's automated production process, users can produce high volumes of decorative gypsum plaster mouldings and cornices in a short period. This feature is especially critical for large-scale construction projects with tight deadlines.Furthermore, the quality of the gypsum plaster mouldings and cornices produced by this machine is unparalleled. The Decorative Gypsum Plaster Moulding/Cornice Making machine produces high-quality, smooth, and durable gypsum plaster creations that can withstand the test of time. In conclusion, the Decorative Gypsum Plaster Mouldings / Cornice Making Machine, manufactured by Hebei Greens Building Material Technology Development Co., Ltd., is a game-changer in the construction industry. Its ease of operation, high production efficiency, and unparalleled quality make it an attractive option for construction companies and contractors worldwide. Moreover, its competitive pricing makes it a cost-effective investment option for businesses looking to save on construction costs. In a world where innovations and efficiency dominate every industry, the Decorative Gypsum Plaster Moulding/Cornice Making Machine is a timely and necessary addition to the building and construction sector.

Affordable Prices for Magnesium Oxide Board Machine

Magnesium Oxide Board Machine: The Future of Modern ConstructionWith the ever-growing demand for sustainable and eco-friendly construction materials, the use of Magnesium Oxide Boards has become more prevalent in the building industry. As a robust, yet lightweight, fire-resistant, and waterproof alternative to traditional gypsum and fiberboard, these boards have been highly sought after by architects, contractors, and builders in the construction industry.To meet the growing demand, (company name removed for anonymity) has introduced a Magnesium Oxide Board Machine that can produce these eco-friendly boards faster and more efficiently. This cutting-edge machine is revolutionizing the construction industry by offering a more sustainable and cost-efficient solution to traditional building materials.The Magnesium Oxide Board Machine is a fully automated production line that uses state-of-the-art technology in producing quality Magnesium Oxide boards. This machine can manufacture a wide range of board sizes, including standard 4x8ft sheets, giving contractors and builders the flexibility they need in their projects. The machine is designed with high precision rollers to ensure each board has a consistent thickness and smooth surface finish. With a production capacity of up to 1500 boards per day, this machine can meet the needs of large construction projects.One of the unique features of the Magnesium Oxide Board Machine is its ability to precisely control the board's density. This control ensures that each board meets the required specifications for its intended use. Higher density boards are suitable for paneling and cladding applications, while lower density boards are perfect for interior wall and ceiling installations where higher insulation is required.Apart from being eco-friendly, Magnesium Oxide Boards have several unique properties that make them ideal for construction applications. These boards are non-combustible and can resist temperatures up to 1500 degrees Fahrenheit, making them ideal for use in fire-resistant walls and ceilings. Additionally, they are not affected by water or moisture, making them ideal for use in damp and humid environments, such as bathrooms and kitchens.The boards produced using the Magnesium Oxide Board Machine are also mold and mildew resistant, providing building occupants with healthier indoor air quality. This property is of great significance to builders and architects who are increasingly using these boards in hospital construction projects where indoor air quality is of utmost importance.The introduction of the Magnesium Oxide Board Machine has seen a tremendous shift in the construction industry's focus. Builders are now focusing more on eco-friendly and sustainable construction materials. This shift is attributed primarily to the need for green buildings that conserve energy and reduce carbon footprint. Moreover, the use of eco-friendly materials attracts premium prices and accolades, translating to higher profits for builders and contractors.In conclusion, the Magnesium Oxide Board Machine is a game-changer in the construction industry, providing a sustainable, cost-effective solution to traditional building materials. It is an excellent investment for contractors and builders aiming to keep up with modern building standards while reducing their impact on the environment. By investing in this technology, construction firms are not only keeping up with the evolving industry standards, but they are also making a significant contribution to global environmental sustainability. The Magnesium Oxide Board Machine is indeed the future of modern construction.

Foaming Sheet Production Equipment: A Breakthrough in Xps Manufacturing Technology

XPS Foaming Sheet Production Equipment Revolutionizing the IndustryXPS foaming sheet production equipment has been making waves in the industry due to its efficiency and high-quality outputs. With the increasing demand for XPS foaming sheets in various applications such as insulation, packaging, and construction, the need for advanced production equipment has become more critical than ever. One company that has been leading the charge in this space is [Company Name].[Company Name] is a renowned manufacturer of XPS foaming sheet production equipment, and they have been at the forefront of innovation in this industry. Their state-of-the-art production equipment has been lauded for its precision, speed, and reliability, making it the go-to choice for many businesses in the XPS foaming sheet manufacturing sector.The company's XPS foaming sheet production equipment is known for its ability to produce high-quality sheets with consistent density and thickness, which is crucial for meeting the strict quality standards of the industry. In addition, the equipment is designed to be highly energy-efficient, helping businesses reduce their operational costs and environmental footprint.One of the key features of [Company Name]'s XPS foaming sheet production equipment is its modular design, which allows for easy customization and scalability. This means that businesses can easily upgrade their production capacity or add new functionalities to their equipment as their needs evolve, without having to invest in entirely new machinery.Furthermore, the company offers comprehensive support and maintenance services for their equipment, ensuring that their customers can maximize uptime and productivity. This level of commitment to customer satisfaction has earned [Company Name] a stellar reputation in the industry, making them the preferred choice for many businesses looking to invest in XPS foaming sheet production equipment.Another factor that sets [Company Name] apart from its competitors is its relentless pursuit of innovation. The company is constantly researching and developing new technologies and processes to improve the performance and capabilities of their equipment. This commitment to innovation has allowed them to stay ahead of the curve and provide their customers with cutting-edge solutions that give them a competitive edge in the market.In terms of market reach, [Company Name] has a global presence, with a network of distributors and partners in key markets around the world. This widespread presence allows them to serve a diverse array of customers, from small businesses to large enterprises, and cater to the specific needs and requirements of different regions and industries.Looking ahead, [Company Name] is poised to continue its leadership in the XPS foaming sheet production equipment industry. With a strong focus on R&D, customer satisfaction, and global expansion, the company is well-positioned to capitalize on the growing demand for high-quality XPS foaming sheets and cement its status as a powerhouse in the industry.In conclusion, XPS foaming sheet production equipment has become an essential component of the manufacturing process for many businesses, and [Company Name] has emerged as a key player in this space. With their advanced technology, commitment to innovation, and global reach, the company is driving the industry forward and empowering businesses to meet the increasing demand for XPS foaming sheets with confidence and efficiency.

Affordable Machine for Manufacturing Magnesium Wall Panels

Title: New Magnesium Wall Panels Manufacturing Machine Revolutionizes Construction IndustryIntroduction:In a groundbreaking development for the construction industry, an innovative company recently unveiled an advanced magnesium wall panels making machine. This cutting-edge technology promises to streamline the production process of magnesium-based building materials, revolutionizing the construction sector.The Importance of Magnesium Wall Panels:Magnesium wall panels have gained rapid popularity in recent years due to their exceptional properties. These panels are lightweight, fire-resistant, and possess excellent acoustic qualities. They are also resistant to mold and pests, making them an ideal solution for both residential and commercial projects.Company Background:{Company Name}, a well-established and renowned manufacturing company, has long been recognized as a leading provider of advanced construction materials. With a strong commitment to innovation, they have invested heavily in research and development, constantly striving to deliver superior products that address industry challenges.Introduction of the Magnesium Wall Panels Making Machine:{Company Name}'s latest breakthrough comes in the form of a highly efficient automated machine specifically designed for the mass-production of magnesium wall panels. This state-of-the-art equipment integrates advanced technology with precision engineering to meet the rising demands of the construction industry.Key Features and Advantages:This new machine offers several key features and advantages, cementing its position as a game-changer in the field of construction materials:1. Increased Production Capacity: The machine allows for a significant increase in production output, fulfilling market demands more efficiently than ever before. This will help alleviate supply shortages and reduce project completion time.2. Enhanced Precision and Quality: By employing advanced automation and artificial intelligence, the machine ensures precise molding and cutting, resulting in consistently high-quality magnesium wall panels. This will provide builders and contractors with reliable and durable construction materials.3. Reduced Labor Requirements: With automated processes, the need for extensive manual labor is greatly minimized. This reduces overall production costs and allows employees to focus on more intricate tasks, ensuring greater productivity.4. Environmentally Friendly: Magnesium wall panels are inherently sustainable due to their low carbon footprint. The new manufacturing machine is designed to further optimize resource utilization, minimizing waste and decreasing energy consumption during production.Impact on the Construction Industry:The introduction of this revolutionary manufacturing machine is set to have a transformative impact on the construction industry. Key benefits include:1. Cost-effectiveness: The increased production capacity and reduced labor requirements will result in significant cost savings for builders and developers. This, in turn, will enable more affordable housing options and stimulate economic growth.2. Enhanced Safety: Magnesium wall panels are renowned for their fire-resistant properties. Widespread adoption of this technology can lead to safer buildings, reducing the risk of fire-related incidents and improving overall occupant safety.3. Sustainable Development: The machine's eco-friendly features align with global efforts to promote sustainable development. With greater accessibility to high-quality magnesium wall panels, the construction industry can contribute to a greener built environment.Conclusion:The unveiling of {Company Name}'s advanced magnesium wall panels making machine marks a major milestone in the construction sector. With its focus on increased production capacity, enhanced precision, and reduced labor requirements, this technology is poised to transform the industry landscape. As the demand for cost-effective and sustainable building materials continues to rise, this innovation promises to meet these evolving needs and shape the future of construction.

Efficient Insulation Foam Making Machine: A Game Changer in Construction Industry

Xps Insulation Foam Making Machine Revolutionizes the IndustryIn recent years, the demand for insulation foam has been on the rise as construction and renovation projects continue to increase. In response to this growing demand, a cutting-edge XPS Insulation Foam Making Machine has been developed, which promises to revolutionize the industry.The XPS Insulation Foam Making Machine is a state-of-the-art piece of equipment that is designed to produce high-quality insulation foam with superior thermal performance. The machine is capable of producing a wide range of foam products, including insulation boards, pipes, and panels, making it incredibly versatile for various applications in the construction industry.One of the key features of this machine is its advanced technology, which allows for the production of foam with exceptional properties. The foam produced by this machine has a closed-cell structure, which provides excellent thermal insulation and moisture resistance. This makes it an ideal choice for both residential and commercial construction projects, where energy efficiency and durability are top priorities.Furthermore, the XPS Insulation Foam Making Machine is highly efficient and cost-effective, making it an attractive option for manufacturers. With its automated production process and minimal waste generation, the machine helps to minimize production costs and environmental impact, ultimately leading to increased profitability for businesses.The company behind the development of this groundbreaking machine, [Company Name], is a leader in the field of insulation technology. With a strong focus on innovation and research, the company has continually pushed the boundaries of what is possible in insulation technology. With a team of skilled engineers and experts, [Company Name] has been able to develop cutting-edge solutions that are not only advanced but also practical for real-world applications.In addition to its technological advancements, [Company Name] also prioritizes quality and reliability in its products. The XPS Insulation Foam Making Machine is no exception, as it undergoes rigorous testing and quality control measures to ensure that it meets the highest industry standards. This dedication to excellence has earned [Company Name] a reputation for delivering products that are dependable and effective, giving customers peace of mind when investing in their equipment.The impact of the XPS Insulation Foam Making Machine on the industry is expected to be significant. By offering a more efficient and cost-effective production solution, the machine has the potential to change the way insulation foam is manufactured and used in construction projects. Its superior thermal performance and durability also make it an attractive option for builders and contractors who are seeking high-quality insulation materials for their projects.As the construction industry continues to grow, the demand for insulation foam is likely to follow suit. With the introduction of the XPS Insulation Foam Making Machine, manufacturers now have access to a cutting-edge solution that meets the needs of the market and sets new standards for quality and efficiency.In conclusion, the development of the XPS Insulation Foam Making Machine represents a significant advancement in insulation technology, with the potential to transform the industry. With its advanced features, efficiency, and reliability, this machine is poised to become a game-changer for manufacturers and builders who are seeking top-quality insulation solutions for their projects. [Company Name]'s commitment to innovation and excellence has once again resulted in a groundbreaking product that is set to make a lasting impact on the construction industry.