High Quality Gypsum Cornice Machine Factories: Your Ultimate Guide

By:Admin

Gypsum cornice products are an essential element in interior finishing and decoration, adding elegance and charm to any space. With the demand for high-quality gypsum cornice products on the rise, one company has been leading the way in innovation and manufacturing excellence. With a focus on advanced technology and precision engineering, Gypsum Cornice Machine Factory has established itself as a trusted source for premium gypsum cornice products.

Founded in 1998, Gypsum Cornice Machine Factory has been a pioneer in the industry, continuously setting new standards for quality and innovation. The company is dedicated to providing customers with the best possible products, utilizing advanced machinery and skilled craftsmanship to ensure every piece meets their high standards.

One of the cornerstones of Gypsum Cornice Machine Factory's success is its commitment to research and development. With a team of experienced engineers and technicians, the company is constantly exploring new techniques and materials to improve their products. This dedication to innovation has allowed Gypsum Cornice Machine Factory to stay ahead of the competition and offer customers cutting-edge solutions for their gypsum cornice needs.

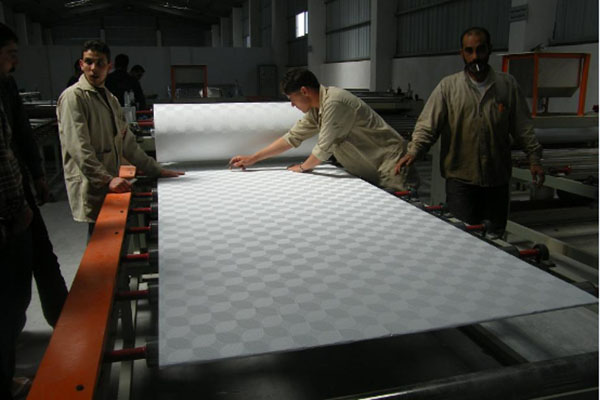

In addition to its dedication to innovation, Gypsum Cornice Machine Factory also places a strong emphasis on quality control. Every step of the manufacturing process is carefully monitored to ensure that each piece meets the company's exacting standards. This commitment to quality has earned Gypsum Cornice Machine Factory a reputation for reliability and consistency, making it a trusted partner for customers around the world.

Not content to rest on its laurels, Gypsum Cornice Machine Factory continues to invest in new technologies and equipment to improve its manufacturing capabilities. The company's state-of-the-art production facility is equipped with the latest machinery, allowing for increased efficiency and precision in the manufacturing process. This investment in technology enables Gypsum Cornice Machine Factory to meet the growing demand for its products while maintaining the highest level of quality.

Gypsum Cornice Machine Factory also places a strong emphasis on environmental sustainability. The company is committed to minimizing its environmental impact and has implemented eco-friendly practices in its manufacturing processes. By utilizing energy-efficient equipment and sustainable materials, Gypsum Cornice Machine Factory is contributing to the preservation of the environment while producing high-quality products.

As a testament to its commitment to quality and innovation, Gypsum Cornice Machine Factory has received numerous accolades and certifications. The company's products meet international standards for quality and safety, and it has earned the trust of customers around the world for its reliability and professionalism.

Furthermore, Gypsum Cornice Machine Factory places great importance on customer satisfaction. The company's dedicated team is always ready to assist customers with their needs, providing personalized service and expert advice. This customer-centric approach has helped Gypsum Cornice Machine Factory build strong, long-lasting relationships with customers and partners alike.

The success of Gypsum Cornice Machine Factory is a testament to its unwavering dedication to excellence. By combining advanced technology, skilled craftsmanship, and a commitment to sustainability, the company has established itself as a leader in the gypsum cornice industry. As the demand for high-quality gypsum cornice products continues to grow, Gypsum Cornice Machine Factory is well-positioned to meet the needs of customers worldwide and continue its legacy of innovation and quality.

Company News & Blog

High-quality Wall Board Machine Manufacturer for Mgo Boards

Mgo Wall Board Machine Manufacturer, a leading manufacturer of construction machinery, recently announced the launch of their new state-of-the-art Mgo Wall Board Machine. The company has been known for its high-quality construction equipment and this latest addition to their product line is no exception.The Mgo Wall Board Machine is designed to produce high-quality Magnesium Oxide Wall Boards, which are widely used in the construction industry for their fire resistance, water resistance, and durability. The machine is equipped with the latest technology and is capable of producing a large volume of Mgo Wall Boards with a high degree of precision and efficiency.The company has invested heavily in research and development to ensure that the Mgo Wall Board Machine meets the highest industry standards. The machine is equipped with advanced features such as automatic feeding, mixing, and molding, as well as precise control of temperature and pressure during the production process. This ensures that the Mgo Wall Boards produced are of consistent quality and meet all the necessary specifications for construction applications.In addition to its advanced technology, the Mgo Wall Board Machine is also designed with user-friendly features that make it easy to operate and maintain. The machine is equipped with a user-friendly interface and is designed for minimal downtime, allowing for continuous production without interruptions.The launch of the Mgo Wall Board Machine is a significant milestone for the company, as it further strengthens their position as a leading manufacturer of construction machinery. With the increasing demand for high-quality construction materials, the company is confident that the Mgo Wall Board Machine will be well-received in the market.The company has a strong focus on customer satisfaction and has a dedicated team of professionals who are committed to providing excellent service and support to their customers. With a global network of sales and service partners, the company is well-equipped to meet the needs of customers around the world.The Mgo Wall Board Machine is the latest addition to the company's comprehensive product line, which includes a wide range of construction machinery such as drywall machines, plasterboard production lines, and other building materials production equipment. The company takes pride in offering a complete solution for the construction industry, providing customers with everything they need to meet their production needs.With a strong track record of delivering high-quality products and exceptional customer service, the company has established itself as a trusted partner for construction companies worldwide. The launch of the Mgo Wall Board Machine is a testament to the company's commitment to innovation and excellence in manufacturing.The company's dedication to quality and innovation has earned them a solid reputation in the industry, and they are continuously striving to stay ahead of the competition by investing in new technologies and expanding their product offerings.In conclusion, the launch of the Mgo Wall Board Machine by Mgo Wall Board Machine Manufacturer is a significant development that further solidifies the company's position as a leading manufacturer of construction machinery. With its advanced technology, user-friendly features, and commitment to customer satisfaction, the Mgo Wall Board Machine is set to make a lasting impact in the construction industry.

Highly Efficient Magnesium Oxide Board Making Machine

High Efficient Mgo Board Making Machine Revolutionizes Construction IndustryIn recent years, the construction industry has witnessed a rapid increase in the use of Magnesium Oxide (MgO) boards due to their numerous benefits such as fire resistance, moisture resistance, and durability. To meet the growing demand for MgO boards, [Company Name], a leading manufacturer of construction materials, has introduced a state-of-the-art High Efficient MgO Board Making Machine that is set to revolutionize the production of MgO boards.The High Efficient MgO Board Making Machine, developed by [Company Name], utilizes advanced technology and innovative processes to ensure the efficient and high-quality production of MgO boards. The machine is designed to significantly increase the output of MgO boards while maintaining the highest standards of quality and reliability. This breakthrough technology is poised to transform the construction industry by providing a sustainable and cost-effective solution for building materials.With the ability to produce MgO boards of various sizes and specifications, the High Efficient MgO Board Making Machine enables construction companies and manufacturers to meet the diverse needs of their projects. Whether it's for residential, commercial, or industrial applications, the machine offers unparalleled flexibility and efficiency in the production of MgO boards.The introduction of this cutting-edge machine underscores [Company Name]'s commitment to innovation and sustainability in the construction industry. With a strong focus on research and development, [Company Name] has continuously invested in advanced technologies to enhance the performance and reliability of its products. The High Efficient MgO Board Making Machine is a testament to [Company Name]'s dedication to providing high-quality and eco-friendly building materials to its customers.In addition to its technological prowess, [Company Name] prides itself on its comprehensive customer support and service. The company offers training and technical assistance to ensure that its customers can maximize the potential of the High Efficient MgO Board Making Machine. This commitment to customer satisfaction sets [Company Name] apart as a reliable partner in the construction industry, empowering its clients to achieve their production goals efficiently and effectively.Furthermore, the introduction of the High Efficient MgO Board Making Machine reflects [Company Name]'s dedication to sustainability and environmental responsibility. By using MgO boards in construction, builders can reduce their carbon footprint and contribute to a greener future. The machine's efficient production processes also minimize waste and energy consumption, aligning with [Company Name]'s commitment to sustainable manufacturing practices.The High Efficient MgO Board Making Machine is a game-changer for the construction industry, offering a cost-effective, eco-friendly, and high-performance solution for building materials. With its innovative technology and robust capabilities, the machine is poised to elevate the production of MgO boards and meet the growing demand for sustainable construction materials.As [Company Name] continues to lead the way in the development of advanced construction technologies, the High Efficient MgO Board Making Machine stands as a testament to the company's unwavering dedication to innovation and excellence. By bringing this groundbreaking machine to the market, [Company Name] is driving positive change in the construction industry and empowering builders to construct with confidence and efficiency.With the High Efficient MgO Board Making Machine, [Company Name] is not only shaping the future of construction but also setting new standards for quality, sustainability, and performance in the industry. The machine's impact is poised to be felt across the construction landscape, ushering in a new era of efficient and eco-friendly building materials.

Laminated Gypsum Ceiling Tiles Machine: Everything You Need to Know

PVC Laminated Gypsum Ceiling Tiles Machine: Revolutionizing the Ceiling IndustryIn today's modern world, the demand for stylish and durable ceilings is increasing rapidly. The use of PVC laminated gypsum ceiling tiles has become a popular choice for architects, interior designers, and homeowners alike. These tiles not only add beauty to the interiors but also provide thermal insulation and are fire-resistant. With the increasing demand for these tiles, the need for advanced manufacturing machines has also risen. This is where the innovative PVC Laminated Gypsum Ceiling Tiles Machine, offered by [company name], comes into play.[Company name] has been a prominent player in the manufacturing industry, specializing in producing high-quality machinery for the construction and interior design sectors. Their PVC Laminated Gypsum Ceiling Tiles Machine has revolutionized the way these ceiling tiles are manufactured. The machine is designed to produce PVC laminated gypsum ceiling tiles with precision and efficiency, meeting the industry's high standards.The machine is equipped with state-of-the-art technology, allowing for seamless production of high-quality tiles. It is capable of producing a wide range of sizes and designs, catering to the diverse needs of customers. The PVC Laminated Gypsum Ceiling Tiles Machine is highly automated, reducing the need for manual labor and improving overall productivity. This not only saves time but also lowers production costs, making it an ideal choice for manufacturers looking to stay competitive in the market.One of the key advantages of [company name]'s machine is its ability to produce PVC laminated gypsum ceiling tiles with excellent flatness and surface finish. This ensures that the tiles are aesthetically pleasing and free from any defects, meeting the aesthetic requirements of modern interior designs. Additionally, the machine is designed to handle various PVC film thicknesses, allowing for flexibility in production and customization options for customers.Furthermore, the PVC Laminated Gypsum Ceiling Tiles Machine is built to be durable and low maintenance, ensuring a longer lifespan and minimal downtime for manufacturers. It is also energy-efficient, contributing to sustainability efforts within the industry. The machine's user-friendly interface and simple operation make it easy for manufacturers to adapt to the system and produce high-quality tiles consistently.With the increasing demand for PVC laminated gypsum ceiling tiles, [company name] is committed to providing top-of-the-line machinery to meet the growing needs of the market. Their machine is not only a game-changer in the manufacturing process but also contributes to the overall quality and reliability of the final product.In conclusion, [company name] has once again raised the bar in the manufacturing industry with its innovative PVC Laminated Gypsum Ceiling Tiles Machine. With its advanced technology, precision production, and cost-saving benefits, this machine is set to make a significant impact on the ceiling industry. As the demand for PVC laminated gypsum ceiling tiles continues to grow, [company name] remains at the forefront, providing cutting-edge solutions for manufacturers worldwide.

Affordable Extrusion Line for Xps Foam Board

Cheap XPS Foam Board Extrusion Line revolutionizes the production process for insulation and construction materials. The company, a leading manufacturer in the industry, has introduced this new line of extrusion equipment with the aim of addressing the growing demand for cost-effective and high-quality XPS foam boards. This development is expected to have a significant impact on the construction and insulation market, providing a more affordable option for building materials.The introduction of the Cheap XPS Foam Board Extrusion Line comes as a response to the increasing need for insulation and construction materials that offer superior thermal performance and energy efficiency. With the rising concerns about energy consumption and environmental impact, there is a growing demand for insulation products that can effectively reduce heating and cooling costs while also minimizing the carbon footprint of buildings. XPS foam boards have long been recognized as a reliable solution for achieving these objectives. However, the high cost of production has often been a barrier to their widespread adoption.The new extrusion line is designed to address this challenge by incorporating innovative technologies that significantly reduce the cost of manufacturing XPS foam boards. With improved efficiency and productivity, the line is capable of producing high-quality insulation materials at a much lower cost, making them more accessible to a wider range of customers. This development is expected to have a positive impact on the construction industry, as builders and contractors will be able to incorporate superior insulation materials into their projects without incurring substantial expenses.In addition to cost savings, the Cheap XPS Foam Board Extrusion Line also offers advantages in terms of product quality and performance. The equipment is equipped with advanced control systems and precision engineering, ensuring that the foam boards produced meet the highest standards for insulation effectiveness and durability. This level of quality is crucial for ensuring the long-term performance of building materials, as well as the overall energy efficiency of structures. With the introduction of this new extrusion line, customers can expect to access XPS foam boards that deliver exceptional thermal performance and contribute to the sustainability of their buildings.As a leading manufacturer in the industry, {} is committed to providing innovative solutions that address the evolving needs of the market. The company has a long-standing reputation for excellence in the production of insulation and construction materials, and the introduction of the Cheap XPS Foam Board Extrusion Line is a testament to its dedication to technological advancement and customer satisfaction. By investing in the development of this new equipment, {} seeks to set new standards for the production of XPS foam boards, offering a compelling combination of affordability, quality, and performance.With the launch of the Cheap XPS Foam Board Extrusion Line, {} is poised to make a significant impact on the construction and insulation market. The company's commitment to affordability and quality, combined with its innovative approach to manufacturing, sets a new benchmark for the industry. As demand for energy-efficient and sustainable building materials continues to grow, the introduction of this new extrusion line represents a valuable opportunity for builders, contractors, and insulation professionals to access superior products that can contribute to the long-term performance and environmental impact of their projects. With the Cheap XPS Foam Board Extrusion Line, {} is redefining the possibilities for insulation and construction materials, positioning itself as a leader in the industry and a valuable partner for customers seeking reliable, cost-effective solutions.

Affordable Machinery for Decorative Mineral Fiber Ceiling Manufacture

Title: Innovative Decorative Mineral Fiber Ceiling Machine Revitalizes Interior Decor MarketIntroduction:In an exciting development, an industry-leading manufacturing company has recently unveiled its groundbreaking and cost-effective Decorative Mineral Fiber Ceiling Machine, poised to revolutionize the interior decoration market. By prioritizing functionality, user-friendliness, and affordability, this cutting-edge machine offers both commercial and residential customers the opportunity to transform their spaces with stunning and durable decorative mineral fiber ceilings. In this article, we will explore the features, benefits, and implications of this innovative product.Empowering Users with Quality and Efficiency:The Cheap Decorative Mineral Fiber Ceiling Machine represents a significant breakthrough in the field of interior design. This state-of-the-art manufacturing equipment enables the production of decorative mineral fiber ceilings at an unprecedented level of speed, efficiency, and precision. By combining advanced technology and meticulous craftsmanship, the machine empowers businesses and individuals to enhance their spaces with high-quality, visually appealing, and environmentally friendly ceiling designs.The incorporation of this cutting-edge machine in both large-scale commercial projects and small residential ventures ensures an effortless transformation of any space, whether it be offices, shopping malls, hotels, or homes. The speed and ease of production provided by the Decorative Mineral Fiber Ceiling Machine offer cost-effective solutions to achieve luxurious and eye-catching interiors within a shorter timeframe as compared to traditional construction methods.Expanding Design Possibilities:The company's comprehensive range of decorative mineral fiber ceiling designs adds depth and creativity to any architectural project. With an extensive selection of patterns, textures, and finishes, customers have the freedom to personalize their spaces to suit their design preferences. Whether striving for a classic, contemporary, or avant-garde aesthetic, this innovative machine provides an endless array of possibilities to create captivating environments.Elevating Durability and Sustainability:One of the standout qualities of decorative mineral fiber ceilings is their durability and sustainability. The Decorative Mineral Fiber Ceiling Machine is specifically designed to optimize these properties. With its precise manufacturing process, the machine ensures seamless integration of materials, resulting in finished products that are resistant to moisture, fire, and wear-and-tear. This longevity significantly reduces maintenance costs, making it an attractive solution for long-term investments.Moreover, the machine's commitment to sustainability cannot be overlooked. It utilizes eco-friendly materials and adheres to strict environmental regulations, making it an ideal choice for environmentally conscious customers. By reducing wastage, energy consumption, and carbon emissions, these ceilings contribute to a greener and more sustainable future.Competitive Advantages:The market entry of the Cheap Decorative Mineral Fiber Ceiling Machine presents significant advantages and opportunities for both manufacturers and clients alike. Manufacturers can streamline their production processes, enhance efficiency, and gain a competitive edge by integrating this technologically advanced equipment into their operations. By meeting the demand for high-quality decorative mineral fiber ceilings, companies can build a solid reputation and expand their customer base.For clients, the introduction of this machine promises cost savings, superior-quality end products, and an elevated scope for creative expression. The affordability and versatility offered by these ceilings enable homeowners and businesses of all sizes to enhance the aesthetics of their spaces without compromising their budgets or design visions.Conclusion:The unveiling of the Decorative Mineral Fiber Ceiling Machine signifies a significant advancement in the realm of interior decoration. By providing an efficient, user-friendly, and affordable solution, this innovative technology empowers customers to access durable, visually captivating, and environmentally friendly decorative mineral fiber ceilings. The machine's integration into the market is expected to inspire creativity, boost manufacturing efficiency, and promote sustainable practices within the industry, promising a bright and exciting future for interior design.

Affordable Mineral Fiber Ceiling Machine for Acoustic Installation

Cheap Acoustic Mineral Fiber Ceiling Machine Revolutionizes Construction Industry In a path-breaking development, a leading machinery manufacturing company has introduced a new and revolutionary product, the Cheap Acoustic Mineral Fiber Ceiling Machine, that is set to transform the construction industry. With its cutting-edge technology and advanced features, this innovative machine is a game-changer in the field of construction and ceiling installation.The company has been a pioneer in the manufacturing of construction machinery for over a decade. With a strong commitment to innovation and quality, the company has consistently developed and launched products that have set new benchmarks in the industry. Their products are known for their durability, reliability, and efficiency, making them the preferred choice for construction companies and contractors worldwide.The Cheap Acoustic Mineral Fiber Ceiling Machine is the latest addition to their extensive range of machinery. It has been designed and engineered to meet the growing demand for cost-effective and efficient solutions for installing acoustic mineral fiber ceilings. The machine's state-of-the-art technology allows for quick and precise installation, saving both time and labor costs for construction projects.One of the key features of the Cheap Acoustic Mineral Fiber Ceiling Machine is its ability to handle a wide range of ceiling materials, including mineral fiber tiles, metal panels, and gypsum boards. This versatility makes it a versatile and valuable asset for construction companies as it can be used for various projects, from commercial buildings to residential properties.The machine's user-friendly interface and intuitive controls make it easy to operate, minimizing the need for specialized training or expertise. This makes it an ideal choice for both experienced professionals and new entrants in the construction industry. Additionally, the machine's compact and portable design allows for easy transportation to different job sites, further enhancing its utility and convenience.Another standout feature of the Cheap Acoustic Mineral Fiber Ceiling Machine is its cost-effectiveness. The machine is priced competitively, offering exceptional value for money compared to other similar products in the market. This makes it an attractive investment for construction companies looking to enhance their efficiency and productivity while controlling costs.The introduction of the Cheap Acoustic Mineral Fiber Ceiling Machine has already generated significant interest and excitement in the construction industry. The machine has been met with positive reviews from early adopters, who have praised its performance, reliability, and cost-saving benefits. Industry experts and analysts have also recognized its potential to drive significant improvements in the construction sector.In addition to its innovative products, the company is known for its commitment to customer satisfaction and after-sales service. They have a dedicated team of professionals who provide comprehensive support and maintenance services for all their products, ensuring smooth operations and long-term reliability for their customers.With its unmatched performance, versatility, and cost-effectiveness, the Cheap Acoustic Mineral Fiber Ceiling Machine is poised to make a significant impact on the construction industry. Its introduction is a testament to the company's ongoing dedication to developing innovative solutions that empower construction professionals and drive progress in the industry.As the construction industry continues to evolve and embrace modern technologies, the Cheap Acoustic Mineral Fiber Ceiling Machine represents a significant step forward in the quest for more efficient and sustainable building practices. It is set to become an indispensable tool for contractors and construction companies, setting new standards for excellence and productivity.In conclusion, the introduction of the Cheap Acoustic Mineral Fiber Ceiling Machine by {} demonstrates the company's unwavering commitment to innovation and excellence in the construction machinery sector. With its game-changing features and benefits, this revolutionary machine is well-positioned to revolutionize the way acoustic mineral fiber ceilings are installed, making it an essential asset for construction professionals around the world.

High-Quality Automatic Co2 Xps Equipment for Efficient Production

High Quality Automatic CO2 XPS Equipment Revolutionizes the Insulation IndustryThe insulation industry is constantly evolving to meet the demands of modern consumers who seek sustainable and energy-efficient solutions for their homes and commercial buildings. In keeping with this trend, the latest innovation in insulation technology comes from the renowned company, which has unveiled their state-of-the-art High Quality Automatic CO2 XPS Equipment. This cutting-edge equipment is set to revolutionize the industry by offering a more efficient and environmentally-friendly solution for insulating buildings.The High Quality Automatic CO2 XPS Equipment is designed to produce extruded polystyrene (XPS) insulation boards with an unprecedented level of quality and precision. The equipment's use of carbon dioxide (CO2) as a blowing agent instead of traditional hydrocarbons makes it an eco-friendlier option for insulation production. This move towards sustainable production methods aligns with the company's commitment to environmental stewardship and the growing demand for sustainable building materials.The new equipment is equipped with advanced automation technology, which enables it to operate with minimal human intervention, ensuring a high level of consistency in the quality of the insulation boards. This not only improves the efficiency of the manufacturing process but also ensures that the end product meets the highest standards in terms of performance and durability. With the ability to produce XPS boards of various thicknesses and densities, the equipment offers versatility to meet the diverse needs of the construction industry.In addition to its technological advancements, the High Quality Automatic CO2 XPS Equipment also boasts a user-friendly interface that simplifies the operation and maintenance of the equipment. This ensures that even non-technical personnel can efficiently operate the equipment, reducing the need for specialized training and expertise.Company A has long been a leader in the insulation industry, known for its commitment to innovation and sustainable practices. With a legacy of over 50 years in the industry, the company has continually set the bar for quality and performance in insulation products. The introduction of the High Quality Automatic CO2 XPS Equipment is a testament to the company's ongoing dedication to pushing the boundaries of what is possible in the field of insulation technology.As a company, we recognize the need for sustainable solutions that minimize environmental impact without compromising on performance. The development of the High Quality Automatic CO2 XPS Equipment is a direct reflection of our commitment to this principle. By incorporating carbon dioxide as a blowing agent, we are reducing our carbon footprint and providing our customers with an environmentally-friendly choice for insulation materials.The introduction of the High Quality Automatic CO2 XPS Equipment has already garnered significant attention in the industry, with builders and contractors expressing enthusiasm for its potential to revolutionize the insulation market. As sustainable building practices continue to gain traction, the demand for eco-friendly insulation materials is expected to grow, positioning the new equipment as a game-changer in the industry.In conclusion, the High Quality Automatic CO2 XPS Equipment represents a significant milestone in the evolution of insulation technology. With its advanced automation, use of environmentally-friendly blowing agents, and commitment to quality, this equipment sets a new standard for the industry. As the company continues to lead the way in innovation and sustainability, the introduction of this cutting-edge equipment reaffirms their position as a market leader and a proponent of environmentally-responsible building practices.

High-Quality Paper Joint Tape for Gypsum Board Installations

Shandong Top Building Materials Co., Ltd, a renowned manufacturer of construction materials, recently announced the launch of their latest product, the Paper Joint Tape. The company is well-known for producing high-quality gypsum board, and this new addition to their product line has already generated considerable interest from construction companies and contractors.The Paper Joint Tape is a self-adhesive, fiberglass mesh tape that is widely used for reinforcing joints between gypsum boards, as well as other plastering and drywall applications. As one of the most important parts of the drywall system, the joint tape is essential for creating smooth and seamless walls and ceilings in new construction and renovation projects.The Shandong Top Building Materials team has spent considerable time and effort in developing a tape that can outperform its competitors in the market. They have used state-of-the-art production facilities and advanced technologies to create a product that meets the highest standards of quality and durability.The Paper Joint Tape is made of high-quality fiberglass mesh, which is embedded in a layer of paper on both sides of the tape. This design allows for excellent bonding to drywall surfaces and ensures that the tape will remain flexible and strong even in extreme weather conditions.One of the most significant advantages of the Paper Joint Tape is its self-adhesive property. The adhesive used in the Shandong Top Building Materials' tape is specially formulated to provide a strong and permanent bond with the drywall surface. This eliminates the need for additional adhesives or compounds, saving time and cost for contractors.The tape is also easy to install, thanks to its pre-cut and pre-creased design. The creases on the tape allow for smooth and wrinkle-free application on corners and curves, ensuring a neat and seamless finish.According to a company spokesperson, "We are confident that our Paper Joint Tape will be a game-changer in the construction industry. Its superior quality, ease of use, and affordability make it an attractive choice for contractors and DIY enthusiasts alike. We are excited to bring this product to the market and look forward to working with our customers to help them achieve their construction goals."The launch of the Paper Joint Tape is in line with Shandong Top Building Materials' commitment to providing innovative and sustainable solutions for the construction industry. The company has a strong focus on research and development, and their products are known for their quality, reliability, and performance.In addition to gypsum board and joint tape, the company also produces a wide range of other construction materials, including plasterboard, ceiling tiles, steel framing, and insulation. Their products are widely used in commercial, industrial, and residential buildings across China and internationally.With its latest product release, Shandong Top Building Materials is poised to become a leading player in the global construction materials market. The company's dedication to innovation and customer satisfaction has earned them a strong reputation in the industry, and their Paper Joint Tape is a testament to their commitment to excellence.

Affordable Insulation Foam Making Machine Factories: Find the Best Deals on XPS Equipment

Cheap XPS Insulation Foam Making Machine Factories Continue to ThriveIn recent years, the demand for XPS insulation foam making machines has been on the rise, leading to the expansion and growth of numerous factories specializing in the production of these machines. The low cost and high efficiency of these factories have made them an attractive option for business owners looking to invest in XPS insulation foam making technology.One such factory that has been making waves in the industry is {reputable factory name}. Specializing in the manufacturing of XPS insulation foam making machines, {factory name} has established itself as a leading supplier of high-quality machinery for the production of XPS insulation foam. With a focus on providing cost-effective solutions for their customers, {factory name} has been able to maintain a strong presence in the market and meet the growing demand for their products.The success of {factory name} can be attributed to a combination of factors, including their commitment to innovation, quality, and customer satisfaction. By continuously investing in research and development, {factory name} has been able to stay ahead of the competition and introduce cutting-edge technology that meets the evolving needs of the industry. This, coupled with their stringent quality control measures, ensures that every XPS insulation foam making machine that leaves their factory is of the highest standards.Furthermore, {factory name} prioritizes customer satisfaction, offering a range of services to support their clients in the setup, installation, and maintenance of their machines. With a dedicated team of technical experts, {factory name} provides comprehensive support to their customers, ensuring that their machines continue to operate at peak performance.The success of {factory name} is a testament to the growing demand for XPS insulation foam making machines, as well as the potential for growth within the industry. With more and more businesses looking to invest in XPS insulation foam technology, the need for reliable and cost-effective machinery has never been greater. This has created a wealth of opportunities for factories like {factory name} to thrive and expand their operations to meet the growing demand.As the market for XPS insulation foam making machines continues to grow, it is expected that more factories will emerge to cater to the increasing demand. This is good news for the industry as a whole, as more competition will drive innovation and push for even higher standards of quality and efficiency. Ultimately, this will benefit businesses looking to invest in XPS insulation foam making technology, as they will have more options to choose from and can expect even greater value for their investment.In conclusion, the success of {factory name} is a testament to the thriving market for XPS insulation foam making machines. With a focus on innovation, quality, and customer satisfaction, {factory name} has been able to establish itself as a leading supplier in the industry. As the demand for XPS insulation foam making machines continues to grow, it is expected that more factories will emerge to meet the increasing need for this technology. This bodes well for the industry, as it will drive further innovation and push for higher standards of quality and efficiency, ultimately benefiting businesses looking to invest in XPS insulation foam making technology.

High-Quality Mineral Fiber Board Machine for Efficient Production

Mineral Fiber Board Machine: Revolutionizing the Construction IndustryThe construction industry is constantly evolving, with new technologies and innovations shaping the way buildings are designed and built. One such innovation that is making waves in the construction industry is the Mineral Fiber Board Machine, a revolutionary piece of equipment that is changing the way mineral fiber boards are manufactured.The Mineral Fiber Board Machine, developed by a leading manufacturer of construction materials, is a state-of-the-art piece of equipment that is designed to produce high-quality mineral fiber boards at a much faster rate than traditional manufacturing methods. This machine has the capability to produce a wide range of mineral fiber boards, from ceiling tiles to wall panels, making it a versatile and essential tool for the construction industry.One of the key features of the Mineral Fiber Board Machine is its advanced automation technology. This machine is equipped with cutting-edge automation systems that allow for precise control and monitoring of the manufacturing process. This not only ensures consistent quality and uniformity in the produced boards but also minimizes the margin of error, thus reducing material wastage and increasing efficiency.Furthermore, the Mineral Fiber Board Machine is also designed with sustainability in mind. The machine is equipped with energy-saving features that reduce power consumption, as well as waste-reduction systems that minimize the environmental impact of the manufacturing process. This aligns with the manufacturer's commitment to sustainable and eco-friendly practices, further establishing the machine as an industry leader in responsible manufacturing.In addition to its advanced technology and sustainable design, the Mineral Fiber Board Machine also offers significant benefits in terms of productivity and cost-effectiveness. The machine is capable of producing a large volume of mineral fiber boards in a relatively short amount of time, making it an ideal solution for large-scale construction projects. This not only saves time but also reduces labor costs, ultimately increasing the overall profitability of the manufacturing process.Moreover, the high-quality output of the Mineral Fiber Board Machine ensures that the produced boards meet and exceed industry standards. This reliability and consistency in product quality have earned the machine a strong reputation among construction professionals, further establishing it as a go-to solution for mineral fiber board manufacturing.{Company name} is a leading manufacturer of construction materials, known for its commitment to innovation and quality. Established in {year}, the company has continuously strived to be at the forefront of the industry, developing cutting-edge solutions that meet the evolving needs of the construction market. With a strong focus on research and development, the company has consistently introduced new technologies and products that have set new benchmarks for quality and efficiency.The development of the Mineral Fiber Board Machine is a testament to {Company name}'s dedication to excellence and innovation. By investing in state-of-the-art technology and sustainable manufacturing practices, the company has not only strengthened its position in the market but has also contributed to the advancement of the construction industry as a whole.Looking ahead, {Company name} remains committed to pushing the boundaries of what is possible in construction materials manufacturing. With a continued focus on research and development, the company is poised to introduce even more game-changing solutions that will shape the future of construction.In conclusion, the Mineral Fiber Board Machine is a game-changing innovation that is revolutionizing the construction industry. With its advanced technology, sustainable design, and productivity benefits, this machine is setting new standards for mineral fiber board manufacturing. Backed by the expertise and commitment of {Company name}, the Mineral Fiber Board Machine is poised to continue making a significant impact on the construction industry for years to come.