High-Quality Gypsum Ceiling Board Lamination Machine for Efficient Production

By:Admin

In a bid to revolutionize the production of gypsum ceiling boards, {company name}, a leading machinery manufacturer, has launched a state-of-the-art Gypsum Ceiling Board Lamination Machine. This innovative machine is set to transform the industry, offering efficiency, precision, and cost-effectiveness like never before.

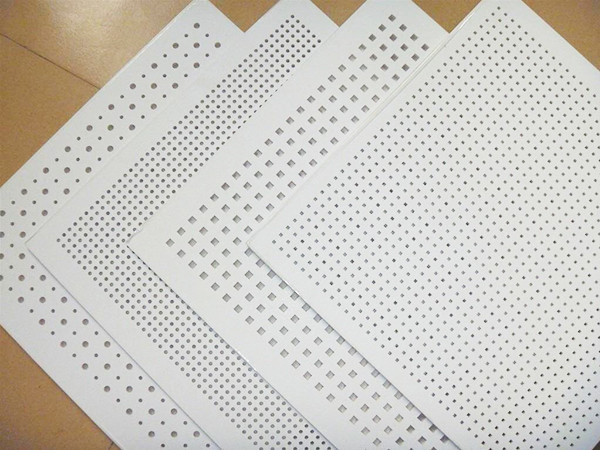

The Gypsum Ceiling Board Lamination Machine is designed to laminate gypsum boards with high quality PVC film for a smooth, glossy finish. This process not only enhances the aesthetic appeal of the ceiling boards but also improves their durability and resistance to wear and tear. With the ability to produce boards of varying thickness and sizes, this machine provides unprecedented flexibility and customization options for manufacturers.

One of the key features of the Gypsum Ceiling Board Lamination Machine is its advanced automation technology. Equipped with intelligent control systems, the machine ensures consistent lamination quality and eliminates the risk of human error. This not only improves the overall efficiency of the production process but also reduces material wastage, ultimately leading to cost savings for manufacturers.

Furthermore, the machine’s high-speed lamination capabilities significantly increase production output, allowing manufacturers to meet growing market demands without compromising on quality. The speedy production also enables manufacturers to fulfill large orders within tight deadlines, thus gaining a competitive edge in the market.

In addition to its speed and precision, the Gypsum Ceiling Board Lamination Machine also prioritizes safety and environmental sustainability. The machine is designed with robust safety features to protect operators and minimize the risk of accidents in the workplace. Moreover, it is equipped with energy-efficient components that reduce power consumption, contributing to a greener and more sustainable production process.

{Company Name} is renowned for its commitment to innovation and excellence in the machinery manufacturing industry. With a strong focus on research and development, the company has continuously pushed the boundaries of technological advancements to provide cutting-edge solutions for various sectors. The launch of the Gypsum Ceiling Board Lamination Machine is yet another testament to {company name}’s dedication to driving progress and efficiency in the manufacturing industry.

The company’s extensive expertise in machinery manufacturing, coupled with a deep understanding of market trends and customer needs, has positioned {company name} as a trusted partner for manufacturers worldwide. Their unrivaled technical support, comprehensive training programs, and responsive customer service have solidified their reputation as a reliable and customer-centric machinery supplier.

The introduction of the Gypsum Ceiling Board Lamination Machine is set to disrupt the status quo in the gypsum board manufacturing industry. As manufacturers strive to meet the increasing demand for high-quality, visually appealing ceiling boards, this innovative machine offers a solution that not only meets these requirements but also sets new benchmarks for efficiency, precision, and sustainability.

With its cutting-edge technology, advanced automation, and unwavering commitment to excellence, {company name} is poised to empower manufacturers to elevate their production capabilities and deliver superior products to the market. As the industry continues to evolve, the Gypsum Ceiling Board Lamination Machine stands as a testament to {company name}’s dedication to driving progress and innovation in the manufacturing sector. By setting new standards for efficiency, quality, and sustainability, this revolutionary machine is poised to shape the future of gypsum board production.

Company News & Blog

High-Quality Mgo Board Equipment Price List

Mgo Board Equipment Pricelist Now Available from Leading Construction Materials CompanyIn the ever-evolving construction industry, it is essential for companies to keep up with the latest innovations and technologies to stay competitive. One such innovation that has been gaining popularity in recent years is the Mgo board, a type of building material that offers numerous benefits over traditional materials such as plywood and gypsum board. With the increasing demand for Mgo board products, [Company Name] is proud to announce the release of their Mgo Board Equipment Pricelist, showcasing a range of cutting-edge machinery designed to facilitate the production of high-quality Mgo boards.[Company Name] has been at the forefront of the construction materials industry for over a decade, specializing in providing top-of-the-line products and equipment to meet the needs of their clients. With a commitment to innovation and quality, the company has established itself as a leading supplier in the market, catering to a wide range of construction projects and applications.The new Mgo Board Equipment Pricelist offers a comprehensive selection of machinery and tools essential for the efficient production of Mgo boards. This includes equipment for the mixing and formulation of Mgo board materials, as well as machinery for the shaping, cutting, and finishing of the boards to meet specific requirements. Additionally, the pricelist also features a variety of accessories and spare parts to ensure the smooth operation of the equipment.One of the standout features of the Mgo board equipment offered by [Company Name] is its advanced technology and precision engineering, which enables manufacturers to produce Mgo boards with superior strength, durability, and fire resistance. The company's commitment to innovation and research has led to the development of cutting-edge equipment that meets the highest industry standards and offers a competitive advantage to their clients.In addition to providing top-quality equipment, [Company Name] also offers comprehensive customer support and technical assistance to ensure that their clients can maximize the performance of their Mgo board equipment. This includes installation and training services, as well as ongoing maintenance and troubleshooting support to address any operational issues that may arise.The release of the Mgo Board Equipment Pricelist is a testament to [Company Name]'s dedication to meeting the evolving needs of the construction industry and providing innovative solutions to their clients. By offering a comprehensive range of equipment and support services, the company aims to empower manufacturers to streamline their production process and achieve the highest standards of quality and efficiency.As the construction industry continues to embrace sustainable and high-performance building materials, the demand for Mgo boards is expected to grow significantly in the coming years. With the release of their Mgo Board Equipment Pricelist, [Company Name] is well-positioned to meet this demand and support manufacturers in their transition to this advanced building material.In conclusion, the release of the Mgo Board Equipment Pricelist by [Company Name] signifies a significant milestone in the company's commitment to innovation and excellence in the construction materials industry. With a comprehensive range of cutting-edge machinery and support services, [Company Name] is poised to play a pivotal role in driving the adoption of Mgo boards and revolutionizing the construction landscape.

High-Quality PVC Laminated Gypsum Ceiling Board for Construction and Decoration

PVC Laminated Gypsum Ceiling Board: Affordable and Durable SolutionIf you are searching for an affordable and durable solution for ceiling installation, then PVC laminated gypsum ceiling board is the answer. These boards are available in different sizes, including 595*595 and 603*603mm. They offer many benefits, from easy installation to excellent sound insulation, fire resistance, and moisture resistance. If you are looking for a low-cost yet high-quality ceiling board, the PVC laminated gypsum ceiling board is the perfect match for you.What is PVC Laminated Gypsum Ceiling Board?PVC laminated gypsum ceiling board is a composite material made of high-quality paper-faced gypsum board with a layer of PVC on the surface. This material is specially designed for interior ceiling decoration, providing an elegant and stylish look to any room.The paper-faced gypsum board acts as a base layer, making the board strong and durable. At the same time, the PVC layer provides an aesthetic finish for the ceiling board. It is an affordable, lightweight, and easy-to-install solution for ceiling decoration.Advantages of PVC Laminated Gypsum Ceiling Board1. AffordablePVC laminated gypsum ceiling board is a low-cost option as compared to other ceiling materials like plaster, wood, or metal. It is an economical solution that doesn't compromise on quality.2. Easy to InstallInstallation of PVC laminated gypsum ceiling board is a breeze. These boards are lightweight, making them easy to handle and install. They come with pre-drilled holes, which makes the installation process fast and simple.3. Moisture ResistantPVC laminated gypsum ceiling board is resistant to moisture, which is why they are perfect for use in areas such as bathrooms, kitchens, and laundry rooms. They don't absorb moisture or water, which prevents the growth of mold and mildew.4. Fire ResistantPVC laminated gypsum ceiling board is also fire-resistant, ensuring the safety of your building. It doesn't catch fire quickly, and even if it does, it doesn't produce toxic gases. This makes it a safe solution for commercial and residential spaces.5. Sound InsulationThe gypsum layer in PVC laminated gypsum ceiling board provides excellent sound insulation. It reduces noise pollution and creates a quiet and comfortable atmosphere.6. Aesthetically PleasingThe PVC layer on the surface of PVC laminated gypsum ceiling board provides an elegant and attractive look to the ceiling. It is available in various designs and colors, giving you the flexibility to choose the best one that matches your style.Cheap PVC Laminated Gypsum Ceiling Board Machine Price listIf you are interested in producing PVC laminated gypsum ceiling boards, you can buy a machine that does this job. The market is full of different machines, and the price list varies depending on the machine's features, capacity, and automation level.You can find a cheap PVC laminated gypsum ceiling board machine on the market. However, keep in mind that cheap doesn't always mean high-quality. It is crucial to choose a machine that meets your needs, budget, and quality standards.In conclusion, PVC laminated gypsum ceiling board is an excellent solution for those who are looking for an affordable and durable ceiling material. It offers many benefits, from easy installation to excellent sound insulation, moisture resistance, and fire resistance. Moreover, if you are interested in producing PVC laminated gypsum ceiling boards, you can search for a cheap PVC Laminated Gypsum Ceiling Board machine on the market.

Affordable Foam Board Making Machine for Sale

Cheap Xps Foam Board Making Machine Revolutionizes Insulation ManufacturingAs the demand for energy-efficient and cost-effective insulation materials continues to rise, the development of advanced production technology has become increasingly important. In response to this, the renowned machinery manufacturer, [Company Name], has introduced a groundbreaking XPS foam board making machine that is set to revolutionize the insulation manufacturing industry.The XPS foam board making machine is designed to produce high-quality extruded polystyrene (XPS) foam boards, which are widely used in construction for thermal insulation. This innovative machine boasts a range of advanced features that set it apart from traditional manufacturing equipment, making it a game-changer for insulation material production.One of the key advantages of the XPS foam board making machine is its cost-effectiveness. By utilizing state-of-the-art technology, the machine is able to significantly reduce production costs, making it an attractive investment for companies in the insulation manufacturing sector. This cost-efficient manufacturing process is expected to have a positive impact on the availability and affordability of XPS foam boards in the market.Furthermore, the XPS foam board making machine is highly efficient, with the ability to produce a large volume of insulation materials in a relatively short period of time. This increased production capacity is expected to address the growing demand for XPS foam boards in the construction industry, where energy-efficient insulation solutions are in high demand.In addition to its cost-effectiveness and efficiency, the XPS foam board making machine also boasts a high level of precision and quality control. This ensures that the produced foam boards meet the highest standards of quality and performance, providing customers with reliable and durable insulation materials for their construction projects.[Company Name] has a long-standing reputation for innovation and excellence in the manufacturing machinery industry. With a strong commitment to research and development, the company has consistently introduced cutting-edge technology to meet the evolving needs of various industries. The introduction of the XPS foam board making machine is a testament to [Company Name]'s dedication to providing state-of-the-art solutions for the insulation manufacturing sector.Furthermore, [Company Name] prides itself on its customer-centric approach, striving to deliver products and services that exceed the expectations of its clients. The XPS foam board making machine is a result of extensive market research and feedback from industry professionals, ensuring that it meets the specific requirements and demands of insulation manufacturers.With its advanced technology, cost-efficiency, and high-quality production capabilities, the XPS foam board making machine is expected to have a significant impact on the insulation manufacturing industry. As companies seek to meet the growing demand for energy-efficient construction materials, this innovative machine is poised to become a vital tool in the production of XPS foam boards.In conclusion, the introduction of the XPS foam board making machine by [Company Name] represents a major advancement in the insulation manufacturing industry. With its cost-effective production process, high efficiency, and precision quality control, the machine is set to revolutionize the production of XPS foam boards, providing a reliable and affordable solution for the construction industry's insulation needs. As [Company Name] continues to lead the way in technological innovation, the future of insulation manufacturing looks brighter than ever.

Magnesium Oxide Board Selling Leads - Find Quality Exporters at EC21

Are you in search of high-quality Mgo board exporters? Look no further than EC21, where you can choose from a wide array of exporters who offer top-notch Mgo board products. Mgo board is becoming increasingly popular in the construction industry due to its exceptional features. It is a versatile and cost-effective building material that is perfect for a wide range of applications.Whether you are working on residential, commercial, or industrial construction projects, Mgo board is an excellent choice. It is a non-toxic, fire-resistant, and durable building material that resists moisture, mold, and mildew. Mgo board also offers excellent sound insulation and thermal insulation properties, making it an excellent choice for energy-efficient buildings.If you are searching for Mgo board exporters, the first step is to consider the quality of their products. The quality of the boards will depend on the type of equipment used in the manufacturing process. That’s where Mgo board machine comes into play.Mgo board machine is a high-tech piece of equipment that is specifically designed for the production of Mgo board. It is an essential component of the production process and plays a vital role in ensuring the quality of the final output. The machine has a control panel that allows you to monitor various parameters, such as temperature, pressure, and speed. This ensures that the manufacturing process is consistent and produces high-quality boards.When looking for Mgo board exporters, it is essential to inquire about the type of Mgo board machine they use. Manufacturers who use modern and advanced equipment typically produce better quality boards than those who use outdated technology. The machine's price is also a crucial factor to consider, as it can significantly impact the final cost of the product.At EC21, you can find various Mgo board machine pricelist options, allowing you to choose a machine that best suits your budget. The price will depend on the size, capacity, and technology of the machine. The pricelist will enable you to compare prices from different manufacturers and choose the one that offers the best value for your money.In conclusion, Mgo board is an excellent building material that offers fantastic properties for a wide range of applications. If you are searching for Mgo board exporters, make sure to inquire about the quality of their products and the type of Mgo board machine they use. You can find a range of Mgo board exporters on EC21, with various pricelist options for Mgo board machine. Choose the one that fits your needs and budget to ensure a successful construction project.

Highly Efficient Gypsum Ceiling Board Production Line for Manufacturing

Gypsum Ceiling Board Production Line Revolutionizes Manufacturing ProcessIn the world of manufacturing, innovation is key to staying ahead of the competition. This is especially true in the production of gypsum ceiling boards, where efficiency and quality are paramount. As such, the introduction of the Gypsum Ceiling Board Production Line by [Company Name] has caused a significant stir in the industry.[Company Name] is a leading manufacturer of gypsum board production equipment, with a strong reputation for quality and innovation. The company has been at the forefront of the industry for many years, and their latest offering, the Gypsum Ceiling Board Production Line, is yet another example of their commitment to advancing the manufacturing process.The Gypsum Ceiling Board Production Line is a state-of-the-art system that is designed to automate and streamline the production of gypsum ceiling boards. It is capable of producing a wide range of board sizes and thicknesses, and can also be customized to meet the specific needs of different manufacturers. This level of flexibility is a key feature of the production line, as it allows manufacturers to tailor their production process to their exact requirements.One of the most impressive aspects of the Gypsum Ceiling Board Production Line is its efficiency. The system is capable of producing a large volume of boards in a relatively short amount of time, without sacrificing on quality. This is achieved through the use of advanced technology and precision engineering, which ensures that each board is of the highest standard.In addition to its efficiency, the Gypsum Ceiling Board Production Line also offers a number of environmental benefits. The system is designed to minimize waste and reduce energy consumption, making it a sustainable choice for manufacturers who are looking to reduce their environmental impact. This is in line with [Company Name]'s commitment to sustainability, and is a key selling point for the production line.Another advantage of the Gypsum Ceiling Board Production Line is its ease of use. The system is designed to be user-friendly, with a simple and intuitive interface that makes it easy for operators to control and monitor the production process. This not only increases productivity, but also reduces the need for extensive training, making it an accessible option for manufacturers of all sizes.The introduction of the Gypsum Ceiling Board Production Line is a significant development for the industry, and one that is sure to have a lasting impact. By combining advanced technology, efficiency, and sustainability, [Company Name] has once again proven itself to be a leader in the field of gypsum board production equipment. With this latest offering, manufacturers can expect to see improvements in their production processes, as well as their bottom line.Overall, the Gypsum Ceiling Board Production Line by [Company Name] represents a new era in manufacturing, one that is characterized by innovation, efficiency, and sustainability. This is a system that has the potential to revolutionize the industry, and one that is sure to be welcomed by manufacturers around the world. As the demand for high-quality gypsum ceiling boards continues to grow, the introduction of this advanced production line could not have come at a better time.

Gypsum Cornice Production Line Prices in China

China has emerged as a global leader in the production of gypsum cornice, a key component in the construction industry. With the increasing demand for high-quality gypsum cornice, manufacturers in China have been at the forefront of developing innovative production lines to meet the growing needs of the market. As a result, China's gypsum cornice production line has become a popular choice for builders and contractors around the world.One of the leading companies in China's gypsum cornice production industry is {}, a well-established manufacturer with a strong reputation for delivering top-notch products. The company has recently introduced its latest gypsum cornice production line, which has garnered considerable attention from industry professionals and observers. With its advanced technology and high production capacity, the new production line is expected to set a new standard in the industry.The company's gypsum cornice production line is designed to maximize efficiency and productivity while maintaining the highest standards of quality. The production line is equipped with state-of-the-art machinery and equipment, ensuring that each piece of gypsum cornice is precisely manufactured to meet the exact specifications and requirements of customers. Additionally, the production line incorporates the latest automation and control systems, allowing for seamless operation and minimal human intervention, further enhancing the overall efficiency of the manufacturing process.In addition to its exceptional technical capabilities, the company's gypsum cornice production line is also notable for its environmental sustainability. The production line is designed to minimize waste and energy consumption, incorporating eco-friendly practices to reduce its environmental impact. As sustainability becomes an increasingly important consideration in the construction industry, the company's commitment to environmentally conscious production methods is viewed as a significant advantage in the market.The introduction of the new gypsum cornice production line has generated significant interest among industry professionals and potential customers. With its impressive technical specifications and commitment to quality and sustainability, the production line is poised to make a significant impact on the global gypsum cornice market. Builders and contractors around the world are expected to benefit from the availability of high-quality gypsum cornice produced by the company's advanced production line.In a statement, a spokesperson for the company highlighted the significance of the new gypsum cornice production line, emphasizing its potential to meet the evolving needs of the construction industry. The spokesperson noted that the company is dedicated to delivering the highest quality products to its customers, and the new production line represents a significant step forward in achieving that goal. The company's investment in advanced technology and sustainable manufacturing practices is a reflection of its commitment to innovation and excellence.Industry analysts have also taken note of the company's new gypsum cornice production line, recognizing it as a game-changing development in the industry. The advanced capabilities of the production line and its potential to drive efficiency and quality in gypsum cornice manufacturing have positioned the company as a leading player in the global market. As the demand for high-quality gypsum cornice continues to rise, the company's new production line is anticipated to play a key role in meeting that demand and solidifying China's position as a dominant force in the industry.Overall, the introduction of the new gypsum cornice production line by {} represents a significant milestone in the construction industry. With its advanced technology, commitment to quality and sustainability, and potential to meet the evolving needs of the market, the production line is set to make a lasting impact on the global gypsum cornice industry. Builders, contractors, and industry professionals can look forward to accessing high-quality gypsum cornice products manufactured by the company's state-of-the-art production line, contributing to the advancement of construction practices and standards around the world.

High-Quality Foam Extrusion Line for XPS Production

XPS Foam Extrusion Line Improves Production EfficiencyThe demand for high-quality insulation materials has been steadily increasing in recent years, driven by the construction industry's focus on energy efficiency and sustainable building practices. In response to this growing demand, [Company Name] has unveiled its latest XPS Foam Extrusion Line, which promises to revolutionize the production of extruded polystyrene (XPS) foam insulation.The new XPS Foam Extrusion Line represents a significant leap forward in technology, offering improved production efficiency, higher output capacity, and enhanced product quality. By incorporating the latest advancements in extrusion technology, [Company Name] has solidified its position as a leader in the manufacturing of XPS foam insulation.One of the key features of the new extrusion line is its increased production efficiency. The line is equipped with state-of-the-art machinery and automation systems, allowing for higher production speeds and reduced downtime. This means that [Company Name] can now meet the growing demand for XPS foam insulation more efficiently, without compromising on quality.In addition to improving production efficiency, the new extrusion line also boasts a higher output capacity. This means that [Company Name] can produce larger quantities of XPS foam insulation in a shorter amount of time, allowing the company to better serve its customers and fulfill large orders more quickly.Furthermore, the new extrusion line has been designed to enhance product quality. By utilizing advanced manufacturing processes and quality control measures, [Company Name] can ensure that its XPS foam insulation meets the highest standards for performance and durability. This is crucial for customers who rely on XPS foam insulation to provide long-lasting and effective thermal insulation in their buildings.In addition to the technical advancements of the new extrusion line, [Company Name] has also made significant investments in research and development to further improve the performance and sustainability of its XPS foam insulation. By leveraging its expertise in materials science and engineering, [Company Name] has developed innovative formulations and production techniques that enhance the thermal efficiency and environmental sustainability of its XPS foam insulation products.In light of these advancements, [Company Name] is confident that its new XPS Foam Extrusion Line will reinforce its position as a preferred supplier of XPS foam insulation in the construction industry. With its commitment to innovation, quality, and sustainability, [Company Name] is poised to meet the evolving needs of its customers and contribute to the ongoing advancement of energy-efficient and sustainable building practices.[Company Name] is a leading manufacturer of XPS foam insulation, offering a comprehensive range of solutions for residential, commercial, and industrial applications. With a focus on innovation, quality, and sustainability, [Company Name] is dedicated to providing high-performance insulation materials that contribute to energy efficiency and environmental responsibility.As a responsible corporate citizen, [Company Name] is committed to sustainable manufacturing practices and environmental stewardship. The company's XPS foam insulation products are designed to minimize environmental impact and contribute to green building initiatives, making them a preferred choice for architects, contractors, and building owners who prioritize sustainability.Overall, the introduction of the new XPS Foam Extrusion Line marks a significant milestone for [Company Name], as it underscores the company's dedication to excellence and innovation in the field of insulation materials. With its superior production efficiency, increased output capacity, and enhanced product quality, the new extrusion line is poised to elevate [Company Name]'s position in the market and meet the growing demand for high-quality XPS foam insulation.

Top Mineral Fiber Ceiling Board Machine Manufacturers and Suppliers

With the increasing demand for mineral fiber ceiling board, the competition among machine factories has been getting intense. To help businesses and customers looking for the best mineral fiber ceiling board machine factories, we have compiled a list of the top manufacturers in the industry.1. Company A: With years of experience in the industry, Company A has established itself as a leading manufacturer of mineral fiber ceiling board machines. The company prides itself on its state-of-the-art production facilities, highly skilled workforce, and commitment to delivering high-quality machines to its clients. Company A's dedication to innovation and continuous improvement has enabled it to stay ahead of the competition and provide cutting-edge solutions to meet the ever-changing needs of the market. From raw material processing to final product inspection, Company A ensures that every step of the manufacturing process is carried out with precision and attention to detail, resulting in top-notch machines that are reliable, efficient, and durable.2. Company B: Another prominent player in the industry, Company B has earned a solid reputation for its superior mineral fiber ceiling board machines. The company's commitment to research and development has enabled it to come up with innovative and efficient solutions that cater to the diverse requirements of its clients. With a focus on quality and performance, Company B's machines are designed to deliver optimal results while ensuring operational efficiency and cost-effectiveness. In addition to its exceptional manufacturing capabilities, the company also provides comprehensive after-sales support, technical assistance, and training to ensure that its clients get the most out of their investment.3. Company C: Known for its cutting-edge technology and unmatched expertise, Company C has become a preferred choice for businesses looking for high-performance mineral fiber ceiling board machines. The company's advanced manufacturing facilities, stringent quality control measures, and commitment to customer satisfaction have allowed it to carve a niche for itself in the market. Company C's machines are engineered to meet the highest standards of reliability, durability, and productivity, making them a valuable asset for businesses seeking to enhance their production capabilities and maintain a competitive edge in the market.4. Company D: Rounding up our list is Company D, a renowned manufacturer of mineral fiber ceiling board machines that has gained recognition for its exceptional product quality and customer-centric approach. The company's extensive industry experience, technical expertise, and relentless pursuit of excellence have enabled it to deliver innovative and reliable machines that exceed the expectations of its clients. Company D's commitment to sustainability and environmental responsibility is reflected in its energy-efficient and eco-friendly manufacturing processes, ensuring that its machines not only deliver outstanding performance but also contribute to a greener and more sustainable future.In conclusion, when it comes to choosing the best mineral fiber ceiling board machines, businesses can rely on the expertise and reputation of these top manufacturers. With their unwavering commitment to quality, innovation, and customer satisfaction, these companies have earned their place as industry leaders and are well-equipped to meet the varying needs of businesses looking to invest in top-of-the-line machines for their mineral fiber ceiling board production.

Get Affordable Quotes for Mgo Board Equipment

Company Introduction:{} is a leading manufacturer and supplier of high-quality building materials, specializing in the production of Mgo boards. With a commitment to innovation and excellence, we have been providing top-of-the-line products to our customers for over a decade. Our Mgo boards are used in various construction projects including residential, commercial, and industrial buildings, due to their durability, fire resistance, and ease of installation.News Content:In the construction industry, the choice of building materials plays a crucial role in the overall quality and safety of a structure. Mgo boards have gained popularity in recent years due to their exceptional properties, and {} is proud to offer competitive quotes on this essential construction material.Mgo boards, also known as magnesium oxide boards, are a type of building material that has gained popularity for their versatility and durability. These boards are made from a mixture of magnesium oxide, perlite, and wood fiber, and are highly regarded for their fire resistance, mold resistance, and strength. They are commonly used in a wide range of construction applications, including wall and ceiling linings, exterior cladding, and flooring.At {}, we understand the importance of high-quality building materials, and we are dedicated to providing our customers with the best products at competitive prices. Our Mgo boards are manufactured using advanced technology and strict quality control measures, ensuring that they meet the highest industry standards.To meet the growing demand for Mgo boards, we are pleased to offer competitive quotes on bulk orders of our products. Whether you are a contractor working on a large-scale construction project or a homeowner embarking on a renovation, our cost-effective quotes make it easier for you to access top-quality Mgo boards without compromising on your budget.Furthermore, our Mgo boards are easy to install, making them a practical choice for construction projects of any size. Their lightweight nature and versatile applications make them suitable for a wide range of building requirements. Additionally, our Mgo boards have a long lifespan, reducing the need for frequent replacements and maintenance, thus providing excellent value for our customers.As a customer-centric company, we also take pride in our exceptional customer service and support. Our team of experts is available to provide assistance and guidance to our clients, ensuring that they have a seamless experience from inquiry to delivery. We prioritize customer satisfaction and are committed to building lasting relationships with our clients based on trust, reliability, and superior products.In conclusion, {} is your one-stop destination for premium Mgo boards at competitive quotes. With our dedication to quality, innovation, and customer satisfaction, we are proud to be a trusted supplier of construction materials to a wide range of clients. Contact us today to learn more about our products and take advantage of our competitive quotes for your next construction project.

Newly Developed 2 Inch XPS Foam Board Machine in China

Title: Chinese Manufacturer Introduces Cutting-edge 2 Inch XPS Foam Board MachineIntroductionChina is known for its rapid advancements in manufacturing technologies, and one such example is the recent introduction of the state-of-the-art 2-inch XPS foam board machine. Developed by a leading Chinese company, this innovative machinery represents a significant breakthrough in the foam insulation industry. With its advanced features and superior quality, the 2-inch XPS foam board machine is poised to revolutionize the insulation market and meet the growing demand for energy-efficient building materials worldwide.Company: A Pioneer in Manufacturing ExcellenceWith a rich history in producing high-quality machinery, the company behind the 2-inch XPS foam board machine has consistently been at the forefront of manufacturing excellence. With a strong commitment to research and development, the company has successfully delivered cutting-edge solutions to various industries worldwide.Harnessing the latest advancements in technology, the company strives to promote sustainable and environmentally friendly practices in the manufacturing arena. By adhering to international quality standards, the company has gained recognition for its exceptional products that consistently exceed customer expectations.Advancements in XPS Foam Board MachineryXPS foam board, an acronym for Extruded Polystyrene insulation, is a popular choice for its superior insulation properties and durability. The 2-inch XPS foam board machine developed by the Chinese manufacturer is specifically designed to meet the increasing demand for insulation materials in the construction industry.1. Enhanced Efficiency: The state-of-the-art XPS foam board machine maximizes efficiency by utilizing advanced automation technology. This ensures smooth operations, increased output, and reduced labor requirements, streamlining the manufacturing process.2. Precise Control System: The machine's precision control system allows for accurate configuration and adjustment of critical parameters, ensuring consistent foam quality and thickness. This advanced control system also aids in minimizing material waste, contributing to cost efficiency.3. Innovative Extrusion Process: The 2-inch XPS foam board machine employs a cutting-edge extrusion process, resulting in foam boards with superior insulation properties. The precise process ensures uniform cell structure, high compressive strength, and excellent resistance to moisture, making it an ideal choice for a wide range of applications.4. Energy Efficiency: The machine's design incorporates energy-saving technologies, promoting sustainability within the production process. By optimizing power consumption and reducing resource wastage, the manufacturing unit significantly lowers carbon emissions, aligning with global environmental goals.Global Impact and Market PotentialThe introduction of the 2-inch XPS foam board machine by the Chinese manufacturer holds immense potential for the global insulation market. As the demand for energy-efficient construction materials continues to rise, this cutting-edge machinery offers a promising solution to meet the growing needs of builders, architects, and contractors around the world.The foam insulation market is projected to see substantial growth, driven by government energy regulations and the increasing focus on sustainable building practices. The 2-inch XPS foam board machine positions the Chinese manufacturer at the forefront of this industry, providing them with a competitive advantage and significant market share.ConclusionWith its commitment to manufacturing excellence and innovation, the Chinese company's introduction of the 2-inch XPS foam board machine revolutionizes the foam insulation industry. This cutting-edge machinery, with its advanced features, precision control, and energy efficiency, is set to meet the rising global demand for sustainable building materials. The impact of this revolutionary technology on the insulation market is poised to drive growth and shape environmentally conscious construction practices worldwide.