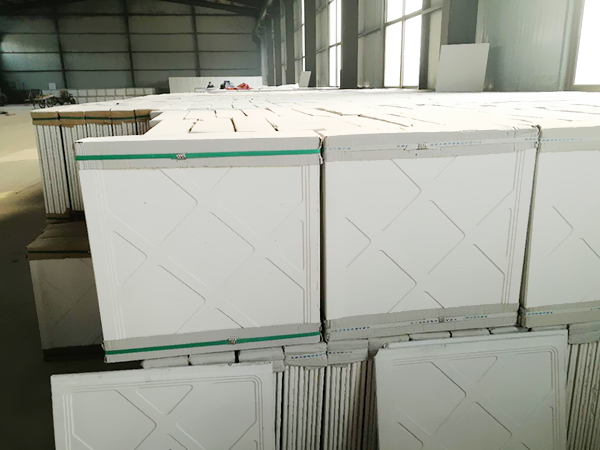

High-Quality Foam Extrusion Line for XPS Production

By:Admin

The demand for high-quality insulation materials has been steadily increasing in recent years, driven by the construction industry's focus on energy efficiency and sustainable building practices. In response to this growing demand, [Company Name] has unveiled its latest XPS Foam Extrusion Line, which promises to revolutionize the production of extruded polystyrene (XPS) foam insulation.

The new XPS Foam Extrusion Line represents a significant leap forward in technology, offering improved production efficiency, higher output capacity, and enhanced product quality. By incorporating the latest advancements in extrusion technology, [Company Name] has solidified its position as a leader in the manufacturing of XPS foam insulation.

One of the key features of the new extrusion line is its increased production efficiency. The line is equipped with state-of-the-art machinery and automation systems, allowing for higher production speeds and reduced downtime. This means that [Company Name] can now meet the growing demand for XPS foam insulation more efficiently, without compromising on quality.

In addition to improving production efficiency, the new extrusion line also boasts a higher output capacity. This means that [Company Name] can produce larger quantities of XPS foam insulation in a shorter amount of time, allowing the company to better serve its customers and fulfill large orders more quickly.

Furthermore, the new extrusion line has been designed to enhance product quality. By utilizing advanced manufacturing processes and quality control measures, [Company Name] can ensure that its XPS foam insulation meets the highest standards for performance and durability. This is crucial for customers who rely on XPS foam insulation to provide long-lasting and effective thermal insulation in their buildings.

In addition to the technical advancements of the new extrusion line, [Company Name] has also made significant investments in research and development to further improve the performance and sustainability of its XPS foam insulation. By leveraging its expertise in materials science and engineering, [Company Name] has developed innovative formulations and production techniques that enhance the thermal efficiency and environmental sustainability of its XPS foam insulation products.

In light of these advancements, [Company Name] is confident that its new XPS Foam Extrusion Line will reinforce its position as a preferred supplier of XPS foam insulation in the construction industry. With its commitment to innovation, quality, and sustainability, [Company Name] is poised to meet the evolving needs of its customers and contribute to the ongoing advancement of energy-efficient and sustainable building practices.

[Company Name] is a leading manufacturer of XPS foam insulation, offering a comprehensive range of solutions for residential, commercial, and industrial applications. With a focus on innovation, quality, and sustainability, [Company Name] is dedicated to providing high-performance insulation materials that contribute to energy efficiency and environmental responsibility.

As a responsible corporate citizen, [Company Name] is committed to sustainable manufacturing practices and environmental stewardship. The company's XPS foam insulation products are designed to minimize environmental impact and contribute to green building initiatives, making them a preferred choice for architects, contractors, and building owners who prioritize sustainability.

Overall, the introduction of the new XPS Foam Extrusion Line marks a significant milestone for [Company Name], as it underscores the company's dedication to excellence and innovation in the field of insulation materials. With its superior production efficiency, increased output capacity, and enhanced product quality, the new extrusion line is poised to elevate [Company Name]'s position in the market and meet the growing demand for high-quality XPS foam insulation.

Company News & Blog

Affordable Gypsum Cornice Machine Factories - Find the Best Deals Here

Mini Gypsum Cornice Machine Factories have been popping up all over the world, providing affordable and efficient solutions for the production of gypsum cornices. These machines have become a staple in the construction industry, as they offer a cost-effective way to create intricate and decorative cornices for a variety of architectural projects.One of the leading manufacturers of these machines is {Company Name}. Specializing in the production of mini gypsum cornice machines, {Company Name} has quickly established itself as a go-to supplier for construction companies and contractors looking to streamline their production processes.With a wide range of models and specifications to choose from, {Company Name} offers a versatile selection of mini gypsum cornice machines to cater to different production needs. Whether it's for a small-scale construction project or a larger commercial endeavor, their machines are designed to deliver high-quality results consistently.The machines are also lauded for their user-friendly interface, making it easy for operators to control and adjust the settings according to the specific requirements of the cornice design. This level of flexibility has made {Company Name} a preferred choice for businesses of all sizes, looking to invest in reliable and efficient equipment.In addition to the quality of their machines, {Company Name} prides itself on its commitment to customer satisfaction. They have a dedicated team of professionals who provide comprehensive support and guidance to clients, ensuring that they are able to maximize the potential of their mini gypsum cornice machines.Furthermore, {Company Name} is known for its emphasis on innovation and technological advancement. They continuously invest in research and development to stay ahead of the curve and introduce cutting-edge features and improvements to their product line. As a result, their machines are equipped with the latest technology, offering enhanced performance and efficiency.The success and excellence of {Company Name} have not gone unnoticed, with their machines being sought after by businesses in various countries. Their extensive network of distributors and partners ensures that their products are accessible to a global market, catering to the needs of construction companies around the world.In light of the increasing demand for mini gypsum cornice machines, {Company Name} is continuously expanding its production capacity to meet the growing needs of the industry. They have made substantial investments in their manufacturing facilities, ensuring that they can deliver high-quality machines in large quantities, without compromising on quality.The rising popularity of mini gypsum cornice machines has been attributed to the numerous benefits they offer. Not only do they streamline the production process, but they also reduce wastage and labor costs, making them a practical choice for businesses looking to improve their efficiency and productivity.Looking ahead, {Company Name} remains committed to its mission of providing innovative and reliable solutions for the construction industry. With a strong focus on quality, customer satisfaction, and technological advancement, they are poised to continue leading the market in the production of mini gypsum cornice machines.In conclusion, the rise of Mini Gypsum Cornice Machine Factories has revolutionized the way gypsum cornices are produced. {Company Name} stands at the forefront of this movement, providing top-of-the-line machines that are in high demand globally. With their dedication to excellence and customer satisfaction, they are well-positioned to play a pivotal role in shaping the future of the construction industry.

Get the Latest Updates on Certified Plasterboard Ceiling Machines

CE Certification Plasterboard Ceiling Machine Ensuring Quality and Efficiency in Construction Industry[City, Date] – In an era where technological advancements play a significant role in improving efficiency and quality, the introduction of the CE Certification Plasterboard Ceiling Machine by [Company Name] is revolutionizing the construction industry. This state-of-the-art machine is equipped with cutting-edge features, granting construction companies easy access to high-quality plasterboard ceiling production.The CE certification is testament to the machine's adherence to European safety, health, and environmental protection standards. With this certification, [Company Name] demonstrates their commitment to providing reliable and safe equipment, ensuring the utmost satisfaction for their customers.The plasterboard ceiling machine allows construction companies to streamline their production processes, significantly reducing time and labor costs. With its advanced automation capabilities, this machine eliminates the need for manual intervention, resulting in enhanced efficiency and precision. [Company Name], a renowned manufacturer with expertise in construction machinery, has developed this machine to meet the diverse needs of the construction sector.Key Features of the CE Certification Plasterboard Ceiling MachineThe innovative and intelligent design of the plasterboard ceiling machine offers numerous features that make it a standout product in the market. These features include:1. High-Speed Production: The advanced automation system allows the machine to produce plasterboard ceilings at an impressive speed, significantly increasing overall productivity.2. Accurate Measurements: Equipped with precise measurement mechanisms, the machine ensures the outputted plasterboard ceilings meet the required specifications, eliminating rework and wastage.3. Easy Operation: The user-friendly interface of the machine enables effortless operation, reducing the need for specialized training and facilitating the smooth integration of the machine into existing production lines.4. Enhanced Durability: The plasterboard ceiling machine is designed and manufactured with robust and durable materials, providing longevity and reliability for years, reinforcing its status as a wise investment for construction companies.5. Customization Options: [Company Name] acknowledges the diverse needs of their customers. To cater to these requirements, the machine offers customization options, allowing construction companies to produce plasterboard ceilings of various sizes, shapes, and designs.[Company Name] – Industry Leader in Construction MachineryWith a strong presence in the construction machinery sector, [Company Name] has been consistently delivering high-quality and reliable equipment to customers worldwide. The introduction of the CE Certification Plasterboard Ceiling Machine further solidifies their position as an industry leader.[Company Name] values customer satisfaction and ensures that their machines go through rigorous quality checks at every stage of production. By adhering to international standards and cultivating an environment of constant innovation, [Company Name] excels at providing cutting-edge solutions that meet the evolving needs of the construction industry.The company's commitment to research and development, coupled with its extensive expertise, has allowed them to introduce an array of construction machinery that caters to various construction needs. These products have gained recognition for their reliability, efficiency, and cost-effectiveness.ConclusionThe CE Certification Plasterboard Ceiling Machine by [Company Name] is set to bring a wave of transformation to the construction industry. With its advanced features, commitment to quality, and compliance with international standards, construction companies can guarantee enhanced productivity and efficiency in plasterboard ceiling production.[Company Name] continues to be a frontrunner in providing construction machinery that meets the highest industry standards. Embracing innovation and quality, they reaffirm their dedication to assisting companies in achieving excellence in construction projects.

High-Quality Gypsum Board Making Machine for Decorative Applications

Innovation in Gypsum Board Making Machine by [Company Name][City, Date] - [Company Name], a leading manufacturer in the construction machinery industry, has recently launched a state-of-the-art Gypsum Board Making Machine, which is set to revolutionize the production process for gypsum board manufacturers.The new Decore Gypsum Board Making Machine is designed to meet the growing demand for high-quality gypsum boards in the construction industry. With advanced technology and a focus on efficiency and precision, the machine offers unparalleled performance and cost-effectiveness.The machine's cutting-edge features include a high-speed production line, automatic control system, and a modular design that allows for easy installation and maintenance. This innovative technology sets a new standard for gypsum board manufacturing, offering increased productivity and superior product quality.[Company Name] has a long history of providing innovative solutions to the construction industry, with a commitment to quality and customer satisfaction. The company's expertise in manufacturing machinery for gypsum board production has earned them a strong reputation in the market.According to [Spokesperson Name], the CEO of [Company Name], "We are thrilled to announce the launch of our new Decore Gypsum Board Making Machine. This machine is the result of years of research and development, and it represents a significant advancement in gypsum board manufacturing technology. We believe that it will provide our customers with a competitive edge in an increasingly demanding market."The Decore Gypsum Board Making Machine is set to be a game-changer for gypsum board manufacturers, offering a solution that streamlines production processes, reduces operational costs, and delivers high-quality products at a faster pace. This will enable manufacturers to meet the growing demand for gypsum boards in construction projects efficiently and effectively.[Company Name] has always been at the forefront of innovation in the construction machinery industry, and the launch of the Decore Gypsum Board Making Machine demonstrates their commitment to pushing the boundaries of technology and providing superior solutions to their customers.The company's extensive expertise in manufacturing machinery for gypsum board production, coupled with their focus on research and development, positions them as a leader in the market. Their commitment to quality, reliability, and customer service has earned them a loyal customer base and a strong reputation in the industry.As a global leader in the construction machinery industry, [Company Name] has a strong presence in the international market, with a wide network of customers and partners worldwide. The launch of the Decore Gypsum Board Making Machine is set to further solidify their position as a trusted and innovative provider of machinery solutions for the construction industry.With the introduction of the Decore Gypsum Board Making Machine, [Company Name] is paving the way for a new era in gypsum board production, offering a solution that combines cutting-edge technology with unmatched performance and reliability. This innovation is set to have a significant impact on the construction industry, providing manufacturers with the tools they need to meet the evolving demands of the market.In conclusion, the launch of the Decore Gypsum Board Making Machine by [Company Name] represents a milestone in the construction machinery industry, offering a groundbreaking solution that will shape the future of gypsum board production. With its advanced technology, efficiency, and precision, this machine sets a new standard for quality and productivity in gypsum board manufacturing, reaffirming [Company Name] as a leader in the industry.

High Quality Vacuum Forming Machinery for MGO Board Door Core Frames Manufactured in China

IntroductionWith the increasing demand for eco-friendly and fire-resistant building materials, the use of Magnesium Oxide (MgO) board is fast becoming popular. This is because it is an excellent substitute for traditional building materials such as gypsum board, cement board, wood, and even steel. The production of Mgo Board Door Core Frame Vacuum Forming Machinery is fundamental to the efficient production of MgO board. In this article, we'll discuss the benefits of using MgO board and how Mgo Board Forming Machine Factories are pivotal in creating high-quality MgO boards.Benefits of Using MgO Board1. Fire-ResistantMgO board is resistant to fire and is non-combustible. In fact, it is classified as Grade A1 non-combustible material in building materials. This means that it can withstand high temperatures without deformation, warping, or cracking. As such, it is perfect for building fire-rated walls, ceilings, and floors.2. Mold and Mildew ResistantMgO board is naturally resistant to mold and mildew, making it ideal for use in areas prone to moisture such as bathrooms and basements. The board is also not affected by termites, making it a great option for building homes, decks, and patios.3. Eco-FriendlyThe production of MgO board does not require the use of harmful chemicals. As such, it's a greener alternative to traditional building materials. The board is also 100% recyclable, and it reduces waste generation.4. DurableMgO board is highly durable and can last for decades without requiring replacement. It is resistant to cracking, breaking, and warping.Mgo Board Forming Machine FactoriesMgO board production requires specialized equipment for optimal results. Mgo Board Forming Machine Factories are responsible for designing, manufacturing, and producing MgO board door core frame vacuum forming machinery. These machines are crucial in the production of MgO boards because they ensure the consistency of the board's thickness, size, and strength.The Mgo Board Forming Machine is an automated vacuum-forming machine that creates a vacuum in a chamber to mold and shape the MgO board. It is equipped with a sophisticated control panel that allows for easy operation and the control of various settings such as temperature, pressure, and time. The machine is also designed in a way that minimizes human error and ensures that the quality of the board is consistent.ConclusionMgO board is proving to be an excellent building material with fire-resistance, mold and mildew resistance, Eco-friendliness, and durability. As such, there is a high demand for MgO board around the world. Mgo Board Forming Machine Factories play a crucial role in meeting this demand by creating the equipment needed to produce high-quality MgO boards efficiently. The use of automation and advanced technology guarantees consistent quality and efficient production of MgO boards. The future of construction materials is bright, and MgO board is poised to take center stage.

Affordable Automatic Gypsum Cornice Making Machine Manufacturers

Cheap Automatic Gypsum Cornice Making Machine Factories are becoming increasingly popular in the manufacturing industry. These factories are revolutionizing the way gypsum cornice products are produced, making it more efficient and cost-effective for companies to meet their production needs. One such company that is leading the charge in this industry is {}.{} is a renowned company that specializes in the manufacturing of automatic gypsum cornice making machines. With their state-of-the-art technology and innovative approach to production, they have quickly become a top choice for businesses looking to invest in high-quality and affordable machinery.One of the key factors that set {} apart from other competitors in the industry is their commitment to providing cheap, automatic gypsum cornice making machines that are of the highest quality. By utilizing advanced manufacturing techniques and cutting-edge technology, {} is able to produce top-of-the-line machinery at a fraction of the cost of their competitors.In addition to their focus on affordability, {} is also committed to providing excellent customer service and support. They understand that investing in machinery is a significant decision for any business, and they strive to ensure that their clients have all the information and assistance they need to make the best choices for their production needs.With a team of highly skilled and experienced professionals, {} is able to offer comprehensive support to their clients at every stage of the process. From initial consultations to installation and ongoing maintenance, {} is dedicated to providing a seamless and stress-free experience for their customers.The automatic gypsum cornice making machines produced by {} are designed to maximize efficiency and productivity. These machines are capable of producing a wide range of gypsum cornice products with precision and consistency, making them an ideal solution for businesses looking to streamline their production processes.Furthermore, {} is constantly innovating and improving their machinery to stay ahead of the curve in the industry. They are always exploring new technologies and methodologies to enhance the performance and capabilities of their machines, ensuring that their clients have access to the most advanced and reliable equipment on the market.In addition to their commitment to quality and innovation, {} also prioritizes sustainability and environmental responsibility in their manufacturing processes. They are dedicated to minimizing waste and reducing their carbon footprint, making them a responsible and conscientious choice for businesses that are mindful of their impact on the environment.As a leading manufacturer of cheap automatic gypsum cornice making machines, {} is well-positioned to meet the growing demand for efficient and cost-effective production solutions in the industry. With their unwavering dedication to quality, affordability, and customer satisfaction, {} is poised to continue making a positive impact on businesses looking to optimize their production processes.In conclusion, the rise of cheap automatic gypsum cornice making machine factories is reshaping the manufacturing landscape, and companies like {} are at the forefront of this revolution. By offering high-quality, affordable machinery and exceptional customer support, {} is helping businesses around the world achieve their production goals with ease and efficiency. As the industry continues to evolve, {} will undoubtedly remain a key player in driving this positive change.

Fiberboard Insulation Developer Advances Plans to Convert Closed Paper Mill into Production Facility

A Maine-based startup company is set to take a significant step forward in the world of green building, as it plans to convert a closed paper mill into a new production facility for fiberboard insulation.The company behind the project has become known for its innovative approach to creating sustainable insulation materials, and its new facility represents a major milestone for both the company and the green building industry as a whole.Fiberboard insulation is a type of insulation made from wood fibers, usually combined with a resin binder. This type of insulation is known for its excellent thermal insulation properties and resistance to moisture, making it an ideal choice for use in buildings, especially those in colder climates.The new production facility will be located in the town of Millinocket, Maine, and will be capable of producing up to 100 million square feet of fiberboard insulation each year. This is a significant increase from the company's existing production capacity, and will allow it to meet growing demand for its products from around the world.According to the company's CEO, the new facility will be equipped with state-of-the-art production equipment, designed to ensure the highest levels of quality and efficiency. Additionally, the company plans to invest in innovative new technologies and processes to further improve the sustainability and environmental performance of its insulation products.The company's fiberboard insulation products are already highly regarded within the green building industry, thanks to their superior performance and eco-friendly credentials. The insulation is made from 100% recycled and reclaimed wood fibers, making it a highly sustainable and renewable material.Furthermore, the company's products are free from harmful chemicals and additives, making them an excellent choice for those with allergies or sensitivities to traditional insulation materials. This is a particularly important consideration for those building or renovating homes or commercial buildings in urban areas, where indoor air quality is a major concern.The CEO of the company, speaking about the new production facility, said: "This is a major milestone for our company and for the green building industry as a whole. We are excited to be bringing our innovative approach to insulation production to a wider audience, and to be able to meet growing demand for sustainable and eco-friendly building materials."The new production facility is expected to create a significant number of new jobs in the local area, providing a welcome boost to the local economy. Additionally, the company's commitment to sustainability and environmental responsibility is expected to have a positive impact on the wider community, both in terms of the materials it produces and the innovative technologies it develops.Overall, this is an exciting development for the green building industry, and one which is sure to be closely watched by those working in the field. With demand for sustainable building materials continuing to grow, the new production facility is a positive step towards a more sustainable and eco-friendly built environment.

High-Quality Equipment for Xps Production

The production of XPS (Extruded Polystyrene) insulation board requires specialized equipment that is able to efficiently and effectively produce high-quality insulation products. {Company} is a leading manufacturer and supplier of equipment for the production of XPS, and they have recently introduced a new line of machinery that is set to revolutionize the industry.The equipment offered by {Company} is designed to meet the growing demand for XPS insulation products in various industries, including construction, automotive, and packaging. The new machinery boasts advanced features that not only enhance the efficiency of the production process but also improve the overall quality of the insulation boards.{Company} takes pride in their commitment to innovation and excellence, and their latest line of equipment for the production of XPS is a testament to their dedication to providing top-of-the-line solutions for their clients. With a team of experienced engineers and technicians, {Company} continuously strives to design and manufacture machinery that meets the evolving needs of the market.The newly introduced equipment for the production of XPS by {Company} incorporates state-of-the-art technologies that ensure precision and consistency in the manufacturing process. The machinery is capable of producing XPS insulation boards of varying thickness and density, catering to the diverse requirements of different applications.Apart from its high precision capabilities, the equipment also focuses on energy efficiency and environmental sustainability. {Company} recognizes the importance of reducing energy consumption and minimizing the environmental impact of production processes. As a result, the new line of machinery is designed to operate with optimal energy efficiency, contributing to a greener and more sustainable approach to XPS insulation board manufacturing.Moreover, {Company} provides comprehensive technical support and training for their clients to ensure the seamless integration and operation of the new equipment. Their team of experts is dedicated to assisting customers in optimizing the performance of the machinery and maximizing the output of high-quality XPS insulation boards.With the introduction of this new line of machinery for the production of XPS, {Company} aims to further solidify its position as a leading provider of equipment for the insulation industry. The company's unwavering commitment to innovation and customer satisfaction is reflected in the continuous development of cutting-edge solutions that address the evolving needs of the market.In conclusion, the launch of the new equipment for the production of XPS by {Company} represents a significant advancement in the insulation industry. The state-of-the-art machinery offers unparalleled precision, energy efficiency, and sustainability, catering to the growing demand for high-quality XPS insulation products. As {Company} continues to lead the way in innovation and excellence, their latest line of equipment is set to elevate the standards of XPS manufacturing and set a new benchmark for the industry.

Affordable Gypsum Cornice Machine Prices for Your Business Needs

Gypsum Cornice Machine PricelistGypsum cornices are an essential element in the construction and interior decoration industry. They are used to add a decorative touch to ceilings and walls, giving them a more elegant and refined look. With the increasing demand for gypsum cornices, the need for efficient and cost-effective production methods has also grown. This is where the Gypsum Cornice Machine comes into play.The Gypsum Cornice Machine is an innovative piece of equipment that is designed to streamline the production process of gypsum cornices. By automating the production process, this machine can significantly reduce labor costs and increase production efficiency. With the ability to produce a wide range of designs and sizes, the Gypsum Cornice Machine offers a versatile solution for companies in the construction and interior decoration industry.In addition to its efficiency and versatility, the Gypsum Cornice Machine also comes with a competitive price tag. The pricelist for this machine has been carefully curated to ensure that it offers great value for money. Companies can now invest in this state-of-the-art equipment without breaking the bank. The pricelist includes various models and configurations to cater to different production needs, making it accessible to businesses of all sizes.The company behind the Gypsum Cornice Machine is a well-established and reputable manufacturer in the industry. With years of experience in the production of gypsum-related machinery, they have gained a strong foothold in the market. Their commitment to quality, innovation, and customer satisfaction has earned them a loyal customer base and a positive reputation in the industry.The company takes pride in its ability to deliver reliable and high-performance equipment that meets the evolving needs of its customers. With a strong focus on research and development, they continue to push the boundaries of technology to provide cutting-edge solutions for the construction and interior decoration industry. The Gypsum Cornice Machine is a testament to their dedication to innovation and excellence.To further support their customers, the company also offers comprehensive after-sales services for the Gypsum Cornice Machine. From installation and training to maintenance and technical support, they ensure that their customers can maximize the potential of their investment. This commitment to customer satisfaction sets them apart from other manufacturers in the market.With the introduction of the Gypsum Cornice Machine pricelist, the company aims to make this advanced technology more accessible to businesses across the industry. By offering competitive pricing and exceptional value, they seek to empower companies to enhance their production capabilities and stay ahead of the competition. With the right equipment in place, businesses can achieve higher productivity, lower costs, and greater flexibility in meeting customer demands.In conclusion, the Gypsum Cornice Machine pricelist offers an enticing opportunity for companies in the construction and interior decoration industry to elevate their production capabilities. With its efficiency, versatility, and competitive pricing, this machine is set to revolutionize the way gypsum cornices are produced. Backed by a reputable and customer-centric company, the Gypsum Cornice Machine is a game-changer that promises to drive innovation and success in the industry.

Gypsum Board Lamination Machine for Ceiling Board Production - EC21

Gypsum board ceiling tiles are a popular choice for many commercial and residential buildings due to their durability, fire resistance, and ability to be easily transformed to fit any design. Gypsum ceiling board making machines are essential to producing high-quality gypsum board ceiling tiles. In this article, we will discuss the features and benefits of investing in a double side gypsum board ceiling tiles laminating machine.Features and Benefits of Double Side Gypsum Board Ceiling Tiles Laminating Machine1. High-Quality Lamination: Double side gypsum board ceiling tiles laminating machine is designed to produce high-quality laminated gypsum board ceiling tiles. The machine uses advanced technology to ensure that the lamination is even, smooth, and free from bubbles.2. Increased Efficiency: The machine is equipped with high-speed rollers that enable fast lamination of the gypsum board ceiling tiles. This feature helps to increase the production capacity of the machine, reducing the time taken to produce a significant number of tiles.3. Easy to Use: The double side gypsum board ceiling tiles laminating machine is user-friendly, and operators require minimal training to operate the machine. The machine's simple design and automated features make it easy for operators to produce high-quality tiles with minimal supervision.4. Cost-Effective: Investing in a double side gypsum board ceiling tiles laminating machine is a cost-effective solution for businesses involved in the production of gypsum board ceiling tiles. The machine's high production capacity ensures that companies can produce a significant number of tiles in a short period, increasing their revenue.5. Versatile: The double side gypsum board ceiling tiles laminating machine can be used to produce a variety of gypsum board ceiling tiles, making it a versatile machine. The machine's flexibility allows businesses to accommodate different customer preferences and design requirements easily.Investing in a double side gypsum board ceiling tiles laminating machine is an excellent decision for companies involved in the production of gypsum board ceiling tiles. The machine's advanced features, high-speed rollers, ease of use, cost-effectiveness, and versatility make it an ideal choice for businesses looking to increase their production capacity and revenue. The keyword "Double Side Gypsum Board Ceiling Tiles Laminating Machine" is an essential aspect of this article and can help increase the article's visibility, especially in search engines.

Why Fiberboard Sheathing is a Wise Selection for Building Materials in India

Fiberboard sheathing is a cost-effective and smart choice for builders and homeowners who want to ensure that their homes are energy-efficient, moisture-resistant, and soundproof. This versatile building material is made from compressed wood fibers and is ideal for a variety of applications, including sheathing, roofing, insulation, and soundproofing.One of the key benefits of using fiberboard sheathing is its low cost. Compared to other building materials like plywood or OSB, fiberboard is significantly cheaper, making it an attractive option for those with a tight budget. The cost savings don’t stop there, though. Fiberboard sheathing is also lightweight, which reduces transportation costs, and it’s easy to install, which means lower labor costs.Another benefit of fiberboard sheathing is its superior insulating properties. This material has a high R-value, which refers to its ability to resist heat flow. This means that buildings with fiberboard sheathing will be better insulated, resulting in reduced heating and cooling costs. Additionally, fiberboard is also an effective soundproofing material, making it ideal for buildings located in noisy areas or for those who want to enjoy a quieter living or working environment.Fiberboard sheathing is also highly resistant to moisture, which makes it an ideal choice for areas with high humidity or frequent rain. Unlike other building materials like plywood, which can absorb water and become distorted or weakened, fiberboard sheathing resists moisture and maintains its shape and structural integrity.Nowadays, more and more builders are looking for sustainable building materials that minimize environmental impact. Fiberboard sheathing fits the bill on this front as well. Made from renewable resources like wood fibers and free of harmful chemicals, fiberboard is a sustainable and eco-friendly choice for building projects.If you’re looking to invest in fiberboard sheathing, there are a few key things to keep in mind. First, be sure to choose a reputable supplier that can provide high-quality materials. Additionally, you’ll need to consider the thickness of the fiberboard, as thicker materials provide better insulation and soundproofing. Finally, if you’re planning to build a large-scale project, it may be worth investing in a cheap mineral fiber board making machine to produce your own fiberboard sheathing materials, which can be cost-effective over time.In conclusion, fiberboard sheathing is a smart choice for anyone looking to build an energy-efficient, soundproof, and moisture-resistant home or commercial building. Its low cost, insulating properties, and resistance to moisture make it an ideal choice for a wide range of applications. And with the availability of cheap mineral fiber board making machines, there’s never been a better time to invest in this versatile and sustainable building material.