High-Quality Automatic Co2 Xps Equipment for Efficient Production

By:Admin

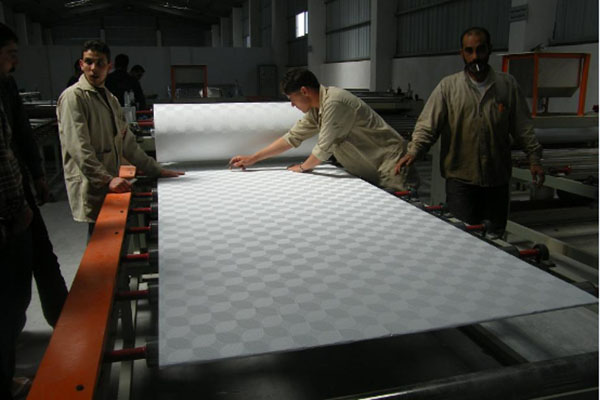

The insulation industry is constantly evolving to meet the demands of modern consumers who seek sustainable and energy-efficient solutions for their homes and commercial buildings. In keeping with this trend, the latest innovation in insulation technology comes from the renowned company, which has unveiled their state-of-the-art High Quality Automatic CO2 XPS Equipment. This cutting-edge equipment is set to revolutionize the industry by offering a more efficient and environmentally-friendly solution for insulating buildings.

The High Quality Automatic CO2 XPS Equipment is designed to produce extruded polystyrene (XPS) insulation boards with an unprecedented level of quality and precision. The equipment's use of carbon dioxide (CO2) as a blowing agent instead of traditional hydrocarbons makes it an eco-friendlier option for insulation production. This move towards sustainable production methods aligns with the company's commitment to environmental stewardship and the growing demand for sustainable building materials.

The new equipment is equipped with advanced automation technology, which enables it to operate with minimal human intervention, ensuring a high level of consistency in the quality of the insulation boards. This not only improves the efficiency of the manufacturing process but also ensures that the end product meets the highest standards in terms of performance and durability. With the ability to produce XPS boards of various thicknesses and densities, the equipment offers versatility to meet the diverse needs of the construction industry.

In addition to its technological advancements, the High Quality Automatic CO2 XPS Equipment also boasts a user-friendly interface that simplifies the operation and maintenance of the equipment. This ensures that even non-technical personnel can efficiently operate the equipment, reducing the need for specialized training and expertise.

Company A has long been a leader in the insulation industry, known for its commitment to innovation and sustainable practices. With a legacy of over 50 years in the industry, the company has continually set the bar for quality and performance in insulation products. The introduction of the High Quality Automatic CO2 XPS Equipment is a testament to the company's ongoing dedication to pushing the boundaries of what is possible in the field of insulation technology.

As a company, we recognize the need for sustainable solutions that minimize environmental impact without compromising on performance. The development of the High Quality Automatic CO2 XPS Equipment is a direct reflection of our commitment to this principle. By incorporating carbon dioxide as a blowing agent, we are reducing our carbon footprint and providing our customers with an environmentally-friendly choice for insulation materials.

The introduction of the High Quality Automatic CO2 XPS Equipment has already garnered significant attention in the industry, with builders and contractors expressing enthusiasm for its potential to revolutionize the insulation market. As sustainable building practices continue to gain traction, the demand for eco-friendly insulation materials is expected to grow, positioning the new equipment as a game-changer in the industry.

In conclusion, the High Quality Automatic CO2 XPS Equipment represents a significant milestone in the evolution of insulation technology. With its advanced automation, use of environmentally-friendly blowing agents, and commitment to quality, this equipment sets a new standard for the industry. As the company continues to lead the way in innovation and sustainability, the introduction of this cutting-edge equipment reaffirms their position as a market leader and a proponent of environmentally-responsible building practices.

Company News & Blog

High-Quality Gypsum Board Making Machine for Decorative Applications

Innovation in Gypsum Board Making Machine by [Company Name][City, Date] - [Company Name], a leading manufacturer in the construction machinery industry, has recently launched a state-of-the-art Gypsum Board Making Machine, which is set to revolutionize the production process for gypsum board manufacturers.The new Decore Gypsum Board Making Machine is designed to meet the growing demand for high-quality gypsum boards in the construction industry. With advanced technology and a focus on efficiency and precision, the machine offers unparalleled performance and cost-effectiveness.The machine's cutting-edge features include a high-speed production line, automatic control system, and a modular design that allows for easy installation and maintenance. This innovative technology sets a new standard for gypsum board manufacturing, offering increased productivity and superior product quality.[Company Name] has a long history of providing innovative solutions to the construction industry, with a commitment to quality and customer satisfaction. The company's expertise in manufacturing machinery for gypsum board production has earned them a strong reputation in the market.According to [Spokesperson Name], the CEO of [Company Name], "We are thrilled to announce the launch of our new Decore Gypsum Board Making Machine. This machine is the result of years of research and development, and it represents a significant advancement in gypsum board manufacturing technology. We believe that it will provide our customers with a competitive edge in an increasingly demanding market."The Decore Gypsum Board Making Machine is set to be a game-changer for gypsum board manufacturers, offering a solution that streamlines production processes, reduces operational costs, and delivers high-quality products at a faster pace. This will enable manufacturers to meet the growing demand for gypsum boards in construction projects efficiently and effectively.[Company Name] has always been at the forefront of innovation in the construction machinery industry, and the launch of the Decore Gypsum Board Making Machine demonstrates their commitment to pushing the boundaries of technology and providing superior solutions to their customers.The company's extensive expertise in manufacturing machinery for gypsum board production, coupled with their focus on research and development, positions them as a leader in the market. Their commitment to quality, reliability, and customer service has earned them a loyal customer base and a strong reputation in the industry.As a global leader in the construction machinery industry, [Company Name] has a strong presence in the international market, with a wide network of customers and partners worldwide. The launch of the Decore Gypsum Board Making Machine is set to further solidify their position as a trusted and innovative provider of machinery solutions for the construction industry.With the introduction of the Decore Gypsum Board Making Machine, [Company Name] is paving the way for a new era in gypsum board production, offering a solution that combines cutting-edge technology with unmatched performance and reliability. This innovation is set to have a significant impact on the construction industry, providing manufacturers with the tools they need to meet the evolving demands of the market.In conclusion, the launch of the Decore Gypsum Board Making Machine by [Company Name] represents a milestone in the construction machinery industry, offering a groundbreaking solution that will shape the future of gypsum board production. With its advanced technology, efficiency, and precision, this machine sets a new standard for quality and productivity in gypsum board manufacturing, reaffirming [Company Name] as a leader in the industry.

High-Quality Fiber Cement Ceiling Board Production Line Unveiled: Optimizing Efficiency and Precision

Title: Revolutionizing Ceiling Board Manufacturing: Fiber Cement Ceiling Board Production LineIntroduction:In an era of constant innovation and evolution, the construction industry is witnessing a transformation in the way building materials are manufactured. One such groundbreaking development is the Fiber Cement Ceiling Board Production Line, a state-of-the-art manufacturing system that is set to revolutionize the production of ceiling boards. This cutting-edge technology, developed by a leading company in the construction sector, is poised to redefine the standards of quality, efficiency, and sustainability in the industry.Company Introduction:{} is a renowned company that has been at the forefront of introducing innovative solutions in the construction industry for over three decades. The company's commitment to research and development has resulted in a wide range of high-quality products that meet the needs of various construction projects. With a focus on sustainability and technological advancements, {} has consistently been recognized as an industry leader, driving growth and setting new benchmarks.Revolutionary Advancements in Ceiling Board Manufacturing:The Fiber Cement Ceiling Board Production Line developed by {} is aimed at revolutionizing the manufacturing process, making it more efficient and environmentally friendly. By combining high-quality raw materials with advanced manufacturing techniques, this production line offers numerous benefits such as improved durability, enhanced fire resistance, and greater design flexibility.1. Enhanced Durability: Fiber cement ceiling boards produced by this innovative production line exhibit superior durability and longevity. The use of high-quality materials ensures resistance to moisture, corrosion, and impact, making them suitable for a wide range of applications in commercial and residential buildings.2. Strong Fire Resistance: Ensuring the safety of buildings is paramount, and the fiber cement ceiling boards produced by this production line have exceptional fire resistance properties. The incorporation of fire-retardant materials during the manufacturing process greatly reduces the risk of fire spread, providing valuable time for safe evacuation.3. Design Flexibility: The Fiber Cement Ceiling Board Production Line allows for unmatched design flexibility, catering to the diverse requirements of architects, interior designers, and builders. With the ability to be produced in various sizes, thicknesses, and textures, these ceiling boards can seamlessly integrate with any architectural style, enhancing the aesthetic appeal of the space.4. Sustainability: Recognizing the importance of sustainable production practices, {} has ensured that the Fiber Cement Ceiling Board Production Line adheres to strict environmental standards. The use of eco-friendly materials and energy-efficient processes significantly reduces carbon emissions and waste generation, contributing towards a greener future.Benefits to the Construction Industry:The introduction of the Fiber Cement Ceiling Board Production Line will have a transformative impact on the construction industry. Here are some notable benefits:1. Streamlined Production: The automated nature of this production line allows for increased output and reduced manufacturing time, enabling faster project completion while maintaining product quality.2. Cost Efficiency: The enhanced productivity and reduced wastage achieved through the production line translate into cost savings for construction companies, making projects more affordable without compromising on quality.3. Improved Safety Standards: The fire-resistant properties of these ceiling boards ensure compliance with building regulations, enhancing the safety of both the construction process and the occupants of the building.4. Customer Satisfaction: With the unmatched durability and design flexibility offered by the Fiber Cement Ceiling Board Production Line, builders and homeowners can create aesthetically pleasing spaces that provide enhanced comfort and longevity.Conclusion:The Fiber Cement Ceiling Board Production Line developed by {} represents a game-changing technological advancement in the construction industry. With its exceptional quality, efficiency, and sustainability features, this production line is set to redefine industry standards. As {} continues to innovate and drive growth, the construction sector can expect to witness an exciting transformation in the manufacturing and utilization of building materials, revolutionizing the way we build for a better future.

High-Performance Gypsum Ceiling Board Pvc Laminating Machine for Sale - 6 Million Sqm Capacity

The [Company Name] Announces the Launch of 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine[Company Name], a leading manufacturer of machinery and equipment for the construction industry, is proud to announce the launch of its latest innovation – the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine. This state-of-the-art machine is set to revolutionize the production of gypsum ceiling boards, delivering exceptional efficiency and quality.The new machine boasts a production capacity of 6 million square meters of gypsum ceiling boards, making it one of the most advanced and high-capacity machines in the industry. With its cutting-edge technology and precision engineering, the machine is designed to meet the growing demand for high-quality gypsum ceiling boards in the construction market.[Company Name] has a long-standing reputation for delivering innovative and reliable machinery for the construction industry. With a strong focus on research and development, the company continuously strives to push the boundaries of technological advancement in its products. The launch of the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine is a testament to [Company Name]'s commitment to providing its customers with the best solutions for their production needs.The machine is equipped with advanced PVC laminating technology, ensuring a smooth and flawless finish on the gypsum ceiling boards. This not only enhances the aesthetics of the boards but also improves their durability and resistance to wear and tear. Additionally, the machine's high-speed production capabilities enable manufacturers to meet their production targets efficiently and effectively.One of the key features of the new machine is its user-friendly interface, which allows for easy operation and maintenance. This ensures that manufacturers can maximize their productivity without compromising on the quality of their products. Furthermore, the machine is designed with energy efficiency in mind, helping companies reduce their operational costs and environmental impact.In addition to its technological advancements, the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine is built to the highest standards of quality and reliability. [Company Name] prides itself on the durability and longevity of its products, and the new machine is no exception. With proper maintenance and care, customers can expect years of trouble-free operation from this cutting-edge piece of equipment.The launch of the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine is set to have a significant impact on the construction industry, particularly in the production of gypsum ceiling boards. With its unrivaled production capacity, advanced technology, and user-friendly design, the machine is poised to become a game-changer for manufacturers seeking to meet the demands of the market.[Company Name] remains committed to providing its customers with the best solutions for their production needs, and the new machine is a testament to this commitment. As the construction industry continues to evolve, [Company Name] will be at the forefront, driving innovation and delivering excellence in machinery and equipment.For more information about the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine and other products offered by [Company Name], please visit their website or contact their sales team for inquiries.

Affordable Mgo Board Making Machine: A Complete Pricelist

Today, we are excited to introduce a new Mgo Board Making Machine that is set to revolutionize the construction industry. The Mgo Board Making Machine is a versatile and efficient piece of equipment that is designed to produce high-quality magnesium oxide boards for various construction applications. The machine is engineered to provide superior performance, speed, and precision, making it an essential addition to any construction operation.The Mgo Board Making Machine offers a wide range of benefits that make it a valuable asset for any construction business. The machine is capable of producing Mgo boards of various sizes and thicknesses, allowing for versatility in construction projects. Additionally, the machine is equipped with advanced technology that ensures uniform board density and smooth surface finish, resulting in superior quality boards that meet industry standards.In terms of efficiency, the Mgo Board Making Machine is designed to optimize production processes, minimize material waste, and reduce labor costs. The machine features a user-friendly interface and automated controls that enable easy operation and monitoring of the production process. This enables construction companies to increase their productivity and meet project deadlines with ease.Furthermore, the Mgo Board Making Machine is built to be durable and reliable, ensuring long-term performance and minimal maintenance requirements. The machine is constructed with high-quality materials and components, and it undergoes stringent quality testing to guarantee its reliability and longevity. This means that construction businesses can rely on the Mgo Board Making Machine to deliver consistent results and minimize downtime.The introduction of the Mgo Board Making Machine is a significant milestone for our company. We are dedicated to providing innovative solutions that empower construction businesses to thrive in today's competitive market. The Mgo Board Making Machine reflects our commitment to delivering high-performance equipment that meets the evolving needs of the construction industry.As a leading manufacturer (), we have a strong track record in developing cutting-edge machinery that enhances construction processes. Our team of experienced engineers and technicians has worked tirelessly to design and create the Mgo Board Making Machine, ensuring that it meets the highest standards of quality, performance, and reliability. We are confident that the machine will make a positive impact on construction operations and contribute to the success of our customers.In conclusion, the Mgo Board Making Machine is a game-changer for the construction industry. Its advanced technology, efficiency, and reliability make it an essential investment for construction businesses looking to enhance their production capabilities and deliver high-quality results. With the introduction of this innovative machine, we are proud to continue our legacy of excellence in providing industry-leading solutions for the construction sector.For more information about the Mgo Board Making Machine and its pricing, please contact us at () or visit our website at (). We look forward to assisting you in integrating this groundbreaking machine into your construction operations and helping you achieve your business goals.

Automatic Gypsum Cornice Manufacturing Machine for High Production

High Automatic Gypsum Cornice Manufacturing Machine Revolutionizes the IndustryIn today's fast-paced world, technological advancements are constantly shaping and revolutionizing industries around the globe. The manufacturing sector is no exception, as companies strive to innovate and improve their production processes. One such innovation that is making waves in the manufacturing industry is the High Automatic Gypsum Cornice Manufacturing Machine.This state-of-the-art machine, developed by a leading manufacturing company, is designed to revolutionize the production of gypsum cornices. The machine is equipped with advanced automation technology, allowing for high-speed and precise manufacturing of gypsum cornices with minimal human intervention. This not only improves the overall efficiency of the manufacturing process but also ensures consistent and high-quality products.The key features of the High Automatic Gypsum Cornice Manufacturing Machine include a fully automated production line, precise gypsum mixing and forming capabilities, as well as advanced cutting and finishing processes. These features not only streamline the production process but also significantly reduce production costs and increase overall productivity.Furthermore, the machine is designed to be user-friendly, with intuitive controls and easy maintenance. This ensures that even employees with minimal technical expertise can operate and maintain the machine, further increasing its efficiency and reducing downtime.In addition to its technological capabilities, the machine is also designed with environmental sustainability in mind. It is equipped with energy-efficient components and designed to minimize waste during the production process. This aligns with the company's commitment to sustainability and responsible manufacturing practices.The introduction of the High Automatic Gypsum Cornice Manufacturing Machine has garnered significant attention from industry experts and professionals. Many have praised its potential to revolutionize the manufacturing of gypsum cornices, making the process more efficient, cost-effective, and environmentally friendly.In a statement, the company's CEO expressed their excitement about the potential impact of the new machine, stating, "We are proud to introduce the High Automatic Gypsum Cornice Manufacturing Machine to the market. This cutting-edge technology represents our ongoing commitment to innovation and excellence in manufacturing. We believe that this machine will not only streamline our production processes but also set a new standard for the industry as a whole."The introduction of this machine is expected to have a profound impact on the manufacturing industry, particularly for companies involved in the production of gypsum cornices. With its advanced technology and innovative design, the High Automatic Gypsum Cornice Manufacturing Machine is poised to become a game-changer for manufacturers, offering them a competitive edge in the market.Industry experts have also noted that the introduction of this machine reflects a broader trend in the manufacturing sector, as companies increasingly prioritize automation, efficiency, and sustainability in their production processes. This shift towards advanced technology and responsible manufacturing practices is expected to shape the future of the industry, driving further innovation and improvement in manufacturing processes.As the manufacturing sector continues to evolve, it is clear that advancements such as the High Automatic Gypsum Cornice Manufacturing Machine will play a crucial role in shaping the industry's future. With its potential to revolutionize the production of gypsum cornices, this innovative machine is a testament to the power of technological innovation in driving progress and growth within the manufacturing sector.

Ce Certification Gypsum Cornice Making Machine Price List: Top Options for Your Business

The latest advancement in the construction industry comes in the form of the CE certification of the Gypsum Cornice Making Machine by a leading company in the field. This certification serves as a testament to the machine's adherence to the highest standards of quality and safety, making it an ideal choice for construction professionals and businesses.The Gypsum Cornice Making Machine is an innovative piece of equipment that is designed to streamline the process of creating decorative cornices for buildings. These cornices are an essential element in adding a touch of elegance and sophistication to interior spaces. With the CE certification, customers can now have added confidence in the machine's performance and reliability.The Gypsum Cornice Making Machine is equipped with advanced technology and features that ensure precision and efficiency in the production process. Its user-friendly interface and automated functions make it easy to operate, saving time and labor costs for businesses. Additionally, the machine is built to last, with high-quality materials and components that guarantee durability and longevity.In addition to its impressive capabilities, the Gypsum Cornice Making Machine also comes with a competitive price list, making it a cost-effective investment for construction companies. By automating the production of gypsum cornices, businesses can increase their output while minimizing expenses, ultimately leading to improved profitability.The company behind the Gypsum Cornice Making Machine has a strong reputation in the industry for delivering top-notch equipment and excellent customer service. With years of experience and expertise, they have become a trusted partner for construction professionals seeking reliable solutions for their projects.The company's commitment to quality and innovation is evident in its continuous investment in research and development. This dedication has led to the creation of the Gypsum Cornice Making Machine, which is setting new standards for efficiency and performance in the construction industry. The CE certification is a reflection of the company's unwavering dedication to providing customers with products that meet the highest standards of excellence.With the CE certification and competitive pricing of the Gypsum Cornice Making Machine, the company is poised to capture a larger share of the market and establish itself as a leader in the industry. Customers can now have peace of mind knowing that they are investing in a machine that is not only reliable and efficient but also certified for its adherence to strict quality and safety standards.In conclusion, the CE certification of the Gypsum Cornice Making Machine by the leading company is a significant milestone that reinforces its position as a provider of top-quality equipment for the construction industry. With its advanced technology, competitive pricing, and commitment to customer satisfaction, the company is well-positioned to meet the growing demand for innovative and reliable solutions in the market. Construction professionals and businesses can now look forward to harnessing the benefits of this certified machine to elevate the quality and efficiency of their projects.Overall, the CE certification of the Gypsum Cornice Making Machine is a game-changer for the construction industry, and the company's dedication to excellence ensures that customers can expect nothing but the best from this innovative piece of equipment.

Advanced Production Line for High Capacity Mineral Fiber Ceiling Tiles from China

High Capacity Mineral Fiber Ceiling Tiles Production Line Unveiled by Chinese ManufacturerA leading Chinese manufacturer has unveiled its latest product – the High Capacity Mineral Fiber Ceiling Tiles Production Line. The new system is designed to boost the manufacturing process of mineral fiber ceiling tiles, increasing efficiency, speed and output.The production line, produced by China-based machinery and equipment manufacturer, will be available for both commercial and industrial use, with a variety of customizable options to meet a diverse range of production requirements. The product launch represents a new innovation in the construction industry and has met with a lot of interest from manufacturers both within China and internationally.The High Capacity Mineral Fiber Ceiling Tiles Production Line boasts some impressive features, including a high level of automation, precision control, high output capacity, and energy efficiency. These features allow manufacturers to streamline their production processes, save time and energy, reduce production costs while ensuring that quality is not compromised.The production line comprises various core components, including a frame forming machine that forms the tiles' core structure, a dryer unit providing heat treatment to the tiles, and a surface treatment unit that adds a finishing touch to the tiles. The production line also includes a cutting unit, which can cut the tiles to different sizes and shapes.The high-capacity production line's frame forming machine uses a high-precision servo motor, which reduces manufacturing errors and improves efficiency. The dryer unit is equipped with advanced heating technology that can reach temperatures of up to 300 degrees Celsius, ensuring that the tiles are dried quickly and thoroughly. The surface treatment unit is responsible for the tiles' final finish, which can be customized to suit the customer’s requirements.The company behind the production line has a long-standing reputation for producing high-quality machinery and equipment. The firm has been in the industry for many years and has built a strong reputation for quality and reliability. The launch of the new product builds on this reputation and reflects the company’s commitment to innovation and staying up-to-date with the latest technologies and manufacturing processes.The spokesperson for the company highlighted the importance of its latest product launch, stating:"The High Capacity Mineral Fiber Ceiling Tiles Production Line represents a game-changing innovation in the production process of mineral fiber ceiling tiles. The product boasts high efficiency, quality, consistency, and customizability, enabling manufacturers to meet the demands of their customers quickly. We are thrilled to bring this revolutionary product to the market, and we believe it will significantly benefit the construction industry both locally and internationally."The launch of the High Capacity Mineral Fiber Ceiling Tiles Production Line is set to have a positive impact on the construction industry globally, particularly in regions that require a high number of ceiling tiles for use in the construction of buildings. The production line's ability to produce customized tiles in large volumes quickly and efficiently is a significant breakthrough for the manufacture of ceiling tiles, and it is hoped that it will lead to greater efficiency and cost-effectiveness in the construction industry.Overall, the unveiling of the High Capacity Mineral Fiber Ceiling Tiles Production Line is a significant milestone for the manufacturing industry, and it represents a bright future for the construction industry. With its impressive features and innovative technology, the production line is sure to generate interest and lead to greater efficiency and cost-effectiveness in the production of mineral fiber ceiling tiles.

Plastic Extruder Production Line: Energy Efficient and Cost-Effective

When it comes to manufacturing XPS insulation boards, the technology and equipment used in the production process are crucial aspects that can determine the quality and efficiency of the end product. One of the most critical pieces of equipment in this process is the extruder, which plays a fundamental role in the production of XPS insulation boards.An extruder is a machine that transforms raw plastic materials into a consistent and uniform plastic profile that can be used in the production of various forms of plastic products. In the context of XPS insulation boards, the extruder plays a crucial role in melting and mixing polystyrene beads, allowing them to expand and grow into the rigid foam board structure used in insulation applications.If you're looking for a reliable and energy-efficient extruder for your XPS production line, then you should consider the options available from Chinese manufacturers. China Plastic Extruder manufacturers have been making significant strides in recent years, with innovations aimed at improving the efficiency and performance of their equipment.One of the key features of the extruders manufactured by China Plastic Extruder manufacturers is energy efficiency. The use of advanced technology to improve energy efficiency can result in significant cost savings for the manufacturer in the long run. This feature has become increasingly crucial in recent years, as more companies begin to implement sustainable manufacturing practices.Another key feature of the extruders from Chinese manufacturers is stability and efficiency with high capacity. This feature ensures that the extruders can handle high volumes of materials without compromising the quality of the output. This aspect is particularly important in an industry where efficiency and consistency are so crucial.Additionally, Chinese extruders can support the use of CO2, butane, and LPG as foam agents without CFC, HFC, HCFC. This feature makes them an environmentally friendly option for manufacturers looking to minimize their carbon footprint. Furthermore, the extruders are compatible with HFC and HCFC as foam agents, providing greater flexibility in the production process.Finally, the extruders from Chinese manufacturers are compatible with recycled materials to reduce costs. This feature is essential in today's circular economy, where there is an increasing demand for eco-friendly and sustainable manufacturing practices. As such, these extruders are perfectly positioned to meet the needs of XPS insulation board manufacturers looking to reduce their environmental impact.In conclusion, the extruder is a crucial component in the XPS insulation board production process. The latest models from China Plastic Extruder manufacturers come equipped with advanced features that are designed to improve efficiency, reduce costs, and promote sustainable manufacturing practices. If you're looking for an extruder for your XPS production line, then you should definitely check out what Chinese manufacturers have to offer.

Top Mineral Fiber Ceiling Board Machine Manufacturers and Suppliers

With the increasing demand for mineral fiber ceiling board, the competition among machine factories has been getting intense. To help businesses and customers looking for the best mineral fiber ceiling board machine factories, we have compiled a list of the top manufacturers in the industry.1. Company A: With years of experience in the industry, Company A has established itself as a leading manufacturer of mineral fiber ceiling board machines. The company prides itself on its state-of-the-art production facilities, highly skilled workforce, and commitment to delivering high-quality machines to its clients. Company A's dedication to innovation and continuous improvement has enabled it to stay ahead of the competition and provide cutting-edge solutions to meet the ever-changing needs of the market. From raw material processing to final product inspection, Company A ensures that every step of the manufacturing process is carried out with precision and attention to detail, resulting in top-notch machines that are reliable, efficient, and durable.2. Company B: Another prominent player in the industry, Company B has earned a solid reputation for its superior mineral fiber ceiling board machines. The company's commitment to research and development has enabled it to come up with innovative and efficient solutions that cater to the diverse requirements of its clients. With a focus on quality and performance, Company B's machines are designed to deliver optimal results while ensuring operational efficiency and cost-effectiveness. In addition to its exceptional manufacturing capabilities, the company also provides comprehensive after-sales support, technical assistance, and training to ensure that its clients get the most out of their investment.3. Company C: Known for its cutting-edge technology and unmatched expertise, Company C has become a preferred choice for businesses looking for high-performance mineral fiber ceiling board machines. The company's advanced manufacturing facilities, stringent quality control measures, and commitment to customer satisfaction have allowed it to carve a niche for itself in the market. Company C's machines are engineered to meet the highest standards of reliability, durability, and productivity, making them a valuable asset for businesses seeking to enhance their production capabilities and maintain a competitive edge in the market.4. Company D: Rounding up our list is Company D, a renowned manufacturer of mineral fiber ceiling board machines that has gained recognition for its exceptional product quality and customer-centric approach. The company's extensive industry experience, technical expertise, and relentless pursuit of excellence have enabled it to deliver innovative and reliable machines that exceed the expectations of its clients. Company D's commitment to sustainability and environmental responsibility is reflected in its energy-efficient and eco-friendly manufacturing processes, ensuring that its machines not only deliver outstanding performance but also contribute to a greener and more sustainable future.In conclusion, when it comes to choosing the best mineral fiber ceiling board machines, businesses can rely on the expertise and reputation of these top manufacturers. With their unwavering commitment to quality, innovation, and customer satisfaction, these companies have earned their place as industry leaders and are well-equipped to meet the varying needs of businesses looking to invest in top-of-the-line machines for their mineral fiber ceiling board production.

High-Quality Equipment for Manufacturing Gypsum Cornice Automatically

Title: Advanced Automatic Gypsum Cornice Equipment Revolutionizes Manufacturing ProcessIntroduction:In a remarkable leap towards streamlining the manufacturing process of gypsum cornices, an innovative new Automatic Gypsum Cornice Equipment has been introduced by a prominent industry player. This cutting-edge machinery promises to revolutionize the sector, offering increased efficiency, precision, and cost-effectiveness.Body:1. Background of the Automatic Gypsum Cornice Equipment: The Automatic Gypsum Cornice Equipment is a breakthrough development that aims to improve the traditional manufacturing process of gypsum cornices. This advanced system integrates modern machinery and technology, harnessing automation and precision to produce high-quality cornices with minimal human intervention.2. Features and Benefits of the Automatic Gypsum Cornice Equipment: a. Streamlined Production: The equipment's automated nature ensures a significant reduction in production time, as well as a streamlined workflow that eliminates human errors and inconsistencies. b. Enhanced Precision: Utilizing state-of-the-art technology, the equipment guarantees exceptional precision and accuracy in the manufacturing process. This ensures uniformity of every cornice produced, meeting the highest standards of quality. c. Cost-Effectiveness: By optimizing the production process and minimizing wastage, the automatic equipment enables manufacturers to operate more efficiently, reducing overall costs and enhancing the profitability of the business. d. Minimal Maintenance: The equipment incorporates robust engineering design, resulting in a reliable and low-maintenance system that maximizes uptime and minimizes downtime.3. Key Industries Benefitting from the Automatic Gypsum Cornice Equipment: a. Construction Industry: The construction sector is one of the primary beneficiaries of this advanced equipment. Gypsum cornices hold a significant place in interior decoration, and with the rapid pace of construction globally, the demand for efficient manufacturing solutions is higher than ever. b. Interior Designers and Architects: Design professionals can now rely on the consistency and accuracy offered by this innovative machinery, allowing them to achieve their creative visions with ease. The equipment empowers them to provide clients with bespoke gypsum cornices, tailored to their unique requirements. c. Export Market: With the ability to produce high-quality gypsum cornices at a faster rate, manufacturers using the automatic equipment gain a competitive edge in the export market. This technology puts them in a position to meet increased demand from overseas customers, further bolstering the industry's growth.4. Environmental Benefits of the Automatic Gypsum Cornice Equipment: This advanced machinery not only enhances manufacturing processes but also contributes to eco-friendliness: a. Reduced Material Waste: With precise measurements and automated cutting, the equipment minimizes material waste, effectively utilizing resources, and reducing environmental impact. b. Energy Efficiency: The Automatic Gypsum Cornice Equipment incorporates energy-saving measures, reducing power consumption during production, in line with sustainable manufacturing practices.5. Company's Commitment to Innovation: The company behind this revolutionary equipment has a proven track record of innovation and a commitment to driving the industry forward. By investing in research and development, they continuously strive to improve their products and stay ahead of market trends. In addition, adherence to international quality standards ensures customer satisfaction and trust in their offerings.Conclusion:The introduction of the Automatic Gypsum Cornice Equipment marks a significant milestone in the gypsum cornice manufacturing sector. Its advanced features, improved efficiency, and reduced costs have propelled the industry into a new era of production. With the ability to meet global demand with precision and reliability, the equipment is set to solidify its position as a game-changer in manufacturing technology.