High-Quality 2 Inch Xps Foam Board Machine in China

By:Admin

The 2 Inch XPS Foam Board Machine is designed to produce foam boards with a thickness of 2 inches, making it ideal for a wide range of applications including insulation, construction, and packaging. The machine is equipped with state-of-the-art components and advanced automation features to ensure efficient and precise production processes.

The company behind this innovative machinery, which we will refer to as "the company" for the purpose of this article, has been at the forefront of the foam board manufacturing industry for over a decade. With a strong focus on research and development, the company has continuously strived to innovate and improve its product offerings to meet the evolving needs of its customers.

"We are excited to introduce our latest 2 Inch XPS Foam Board Machine to the market," said a spokesperson for the company. "This new machinery represents a significant milestone for us and reaffirms our commitment to delivering high-quality, efficient, and reliable solutions to our customers."

The 2 Inch XPS Foam Board Machine is equipped with advanced extrusion technology, precision cutting systems, and automated stacking mechanisms, allowing for seamless and uninterrupted production processes. The machine also features a user-friendly interface and intuitive controls, making it easy to operate and maintain.

In addition to its technological advancements, the 2 Inch XPS Foam Board Machine is designed with sustainability in mind. It incorporates energy-efficient components and optimized production processes to minimize environmental impact and reduce operating costs for manufacturers.

With the launch of the 2 Inch XPS Foam Board Machine, the company aims to further strengthen its position as a leading provider of foam board manufacturing solutions in China and beyond. The company's extensive portfolio of machinery and equipment caters to the diverse needs of manufacturers in various industries, providing them with the tools they need to streamline their production processes and enhance the quality of their products.

The company's commitment to customer satisfaction is reflected in its comprehensive after-sales support and technical services. With a team of highly skilled engineers and technicians, the company ensures that its customers receive prompt assistance and guidance to maximize the performance and longevity of their machinery.

The 2 Inch XPS Foam Board Machine is the latest addition to the company's extensive range of foam board manufacturing equipment, which includes machines for producing a variety of foam board thicknesses and sizes. With its innovative features and robust construction, the 2 Inch XPS Foam Board Machine is poised to set a new standard for efficiency, reliability, and quality in the foam board manufacturing industry.

As the demand for high-quality foam board continues to grow across a wide range of industries, the introduction of the 2 Inch XPS Foam Board Machine comes at a critical time. The company's dedication to innovation and excellence positions it as a trusted partner for manufacturers seeking cutting-edge solutions for their foam board production needs.

In conclusion, the launch of the 2 Inch XPS Foam Board Machine by the company represents a significant advancement in foam board manufacturing technology. With its advanced features, sustainability focus, and commitment to customer satisfaction, this new machinery is set to make a lasting impact on the industry and further solidify the company's reputation as a leader in the field.

Company News & Blog

High-quality Magnesium Oxide Board Machine for Sale - Complete Solutions

[Company Introduction]With years of experience in the magnesium oxide board industry, our company has become a leading manufacturer and supplier of magnesium oxide board machines. Our cutting-edge technology and innovative machinery have enabled us to meet the growing demand for high-quality magnesium oxide board production equipment.We have a team of experienced engineers and technicians who are dedicated to designing and manufacturing state-of-the-art magnesium oxide board machines that are efficient, reliable, and cost-effective. Our commitment to quality and customer satisfaction has earned us a strong reputation in the industry, and we are proud to serve customers from all around the world.[News Content]Magnesium oxide board, also known as MgO board, is a versatile and environmentally friendly building material that has gained popularity in recent years due to its excellent fire resistance, moisture resistance, and durability. As the demand for magnesium oxide board continues to rise, the need for advanced production equipment has become increasingly important.In response to this growing demand, our company has introduced a new and improved magnesium oxide board machine that is set to revolutionize the industry. The new machine incorporates the latest technological advancements in magnesium oxide board production, offering increased efficiency, precision, and output capacity.One of the key features of the new magnesium oxide board machine is its advanced automation system, which allows for seamless and precise control of the production process. This not only improves the overall quality of the magnesium oxide boards but also significantly reduces production time and resource wastage.Additionally, the machine is equipped with state-of-the-art sensors and monitoring systems that enable real-time data collection and analysis, ensuring consistent and uniform board quality. These technological advancements not only streamline the production process but also reduce the margin of error, resulting in higher-quality magnesium oxide boards.Furthermore, the new magnesium oxide board machine has been designed with sustainability in mind. It utilizes energy-efficient components and processes, reducing overall energy consumption and environmental impact. This reflects our company’s commitment to sustainable and eco-friendly manufacturing practices, aligning with the global trend towards green building materials.The introduction of the new magnesium oxide board machine marks a significant milestone for our company, showcasing our dedication to innovation and advancement in the magnesium oxide board industry. We are confident that the new machine will set a new standard for magnesium oxide board production, providing our customers with a reliable and efficient solution for their manufacturing needs.In addition to the new magnesium oxide board machine, our company offers a comprehensive range of services, including technical support, equipment installation, and training programs. We are committed to ensuring that our customers receive the highest level of support and expertise, allowing them to maximize the potential of their magnesium oxide board production operations.As we continue to push the boundaries of magnesium oxide board manufacturing, we are excited to embark on this new chapter with the launch of our state-of-the-art magnesium oxide board machine. We are dedicated to providing our customers with the tools and resources they need to succeed in the competitive magnesium oxide board market, and we are confident that our new machine will help them achieve their production goals efficiently and effectively.

Affordable PVC Laminated Gypsum Board Machine Price List Unveiled in Recent News

PVC Laminated Gypsum Board Machine Aims to Reinforce Efficiency and Quality in Manufacturing ProcessIn recent industry news, a leading company in the manufacturing and distribution of gypsum board machinery, known for their commitment to innovative technology and exceptional quality, announced the introduction of a new PVC laminated gypsum board machine. This advanced machinery aims to provide a solution for enhancing efficiency and elevating the quality of gypsum board production.The machinery, which leverages cutting-edge technology and industry expertise, offers numerous advantages to manufacturers in the gypsum board industry. With a focus on increasing productivity, this machine can significantly reduce the production time required for manufacturing gypsum boards while maintaining high-quality standards. By streamlining the entire manufacturing process, companies can optimize their production output, allowing for greater profitability and customer satisfaction.One of the key features of this PVC laminated gypsum board machine is its ability to integrate the lamination process directly into the manufacturing line, eliminating the need for a separate lamination process. This integration not only saves time and labor but also ensures consistent and superior adhesion between the PVC layer and the gypsum board. By eliminating the risk of delamination, manufacturers can guarantee a longer lifespan for their gypsum boards, making them more reliable for various construction applications.Furthermore, this state-of-the-art machinery incorporates advanced control systems that enable real-time monitoring and adjustment of production parameters. This ensures precision in the manufacturing process, resulting in consistently high-quality boards with accurate dimensions and smooth surfaces. Manufacturers can also benefit from the machine's versatility, as it offers customizable settings to meet specific industry requirements or produce various board sizes and designs.With sustainability being a significant concern in today's manufacturing industry, this PVC laminated gypsum board machine incorporates eco-friendly features to reduce its environmental impact. The machinery optimizes energy consumption through efficient power management systems, minimizing energy waste during production. Additionally, it utilizes low-emission technology, reducing harmful emissions and promoting cleaner air quality in the workplace.Alongside the introduction of this new machinery, the company aims to provide comprehensive technical support and after-sales service to their clients. Their team of highly skilled engineers and technicians will be available to assist manufacturers with machine installation, training, and troubleshooting, ensuring a seamless transition into the new production process. By offering ongoing support, the company establishes a strong partnership with their clients, strengthening their reputation as a reliable and customer-oriented provider.As global demand for gypsum board continues to rise, driven by the booming construction industry, manufacturers must invest in advanced machinery to remain competitive. This new PVC laminated gypsum board machine addresses the industry's need for improved efficiency, productivity, and quality standards. By adopting this innovative solution, manufacturers can enhance their production capabilities, streamline their operations, and deliver superior gypsum board products to meet market demands.In conclusion, the introduction of the PVC laminated gypsum board machine represents a significant milestone for the manufacturing industry. With its advanced technology, integration of lamination processes, precise control systems, and eco-friendly features, this machinery aims to revolutionize the gypsum board manufacturing process. The company's commitment to providing technical support and after-sales service further demonstrates their dedication to customer satisfaction. As manufacturers embrace this groundbreaking solution, they will be well-equipped to meet the growing demand for high-quality gypsum boards in construction projects worldwide.

How to Start a Mineral Fiber Ceiling Tiles Manufacturing Plant?

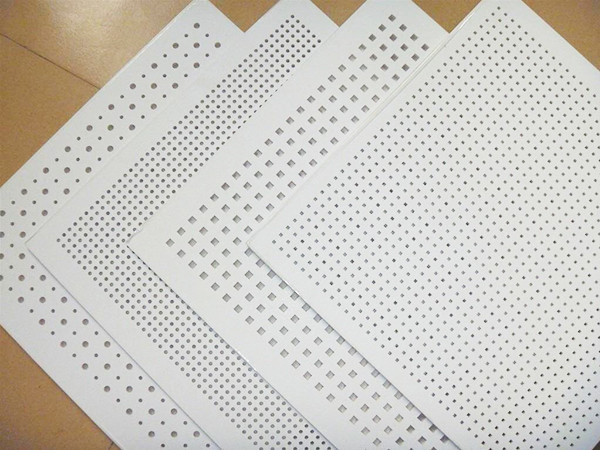

reporting the factory's production line.Mineral Fiber Ceiling Tiles Machine Factory is a renowned name in the manufacturing industry, specializing in producing mineral fiber ceiling tiles. The factory is equipped with state-of-the-art machinery and highly qualified personnel, providing a wide range of products that meet the diverse needs of its customers. The company has established itself as a leader in the industry, focusing on innovation, quality, and customer satisfaction.The manufacturing process at Mineral Fiber Ceiling Tiles Machine Factory is a well-structured and seamless operation. Starting with the raw materials, a mixture of mineral wool, perlite, and other raw materials is blended to create the base material used in making the tiles. The base material is then sent to a forming machine, which molds the material into a flat surface before it is trimmed to the desired size. The excess material is collected and recycled, making the production process environmentally friendly.Once the tiles are formed, they are sent to a drying oven, where they are allowed to dry and firm up. This crucial step ensures that the tiles are strong enough to withstand handling and installation. After drying, the tiles are sanded and inspected to ensure compliance with the strict quality standards set by the factory.The next stage of the production process involves painting the tiles to enhance their aesthetic appeal. Mineral Fiber Ceiling Tiles Machine Factory uses high-quality paint that is resistant to scratches and peels. The painting process is done using automated machinery, which ensures consistency in color and texture across all the tiles. After painting, the tiles are sent to a curing oven, where they are allowed to dry and cure, making the paint permanent.The final stage of the production process involves packaging and shipping the tiles to customers. Mineral Fiber Ceiling Tiles Machine Factory uses state-of-the-art packaging machinery that ensures that the tiles reach the customers in perfect condition. The packaging materials used are eco-friendly, and special care is taken to label the packages accurately, ensuring that the correct number of tiles is delivered to customers.Mineral Fiber Ceiling Tiles Machine Factory is known for its commitment to quality and innovation. The factory invests heavily in research and development, continually seeking to improve the quality of its products and innovate new designs that meet the changing needs of its customers. The factory's team of engineers and designers is always on the lookout for new technologies and techniques that can improve the production process and ensure that customers get the best value for their money.In conclusion, Mineral Fiber Ceiling Tiles Machine Factory is a leading manufacturer of mineral fiber ceiling tiles, providing high-quality products to customers all over the world. The factory's commitment to innovation and quality has made it a preferred choice for customers who demand the best in terms of durability, functionality, and aesthetics. The factory's modern production line, comprising state-of-the-art machinery and highly skilled personnel, is a testament to its dedication to delivering exceptional results that meet the highest standards. Mineral Fiber Ceiling Tiles Machine Factory is setting the pace for the industry and remains a model for other factories to emulate.

High-Quality Fiber Optic Star Ceiling Panels for Moon Shooting - FCC Approved, 15W Power, 600*600mm Size

China is known for its phenomenal innovation and technological advancements. In recent times, it has been making immense strides with the production of high-quality PMMA 15W Fiber Optic Star Ceiling Panels 600*600mm FCC for moon shooting. These products are second to none with their excellent quality and strict quality control.Leading Fiber Optic Star Ceiling Panels factories have been working tirelessly to ensure that their products meet the high standards of tech enthusiasts and professionals in the industry. With this, they have been producing highly efficient and reliable PMMA 15W Fiber Optic Star Ceiling Panels, designed specifically for moon shooting.The star ceiling panels are rated 15W and are made from Polymethyl methacrylate (PMMA), a highly durable and versatile material that is commonly used to produce high-tech products. The panels are excellent for providing accurate and reliable fiber optic lighting without the need for electricity, making them an eco-friendly lighting solution.The PMMA 15W Fiber Optic Star Ceiling Panels have been particularly successful in moon shooting projects, where the clarity and accuracy of the lighting are critical. They produce a stunning starlight effect that is ideal for creating the illusion of a starry sky, perfect for filming and photography.One of the greatest advantages of using these star ceiling panels is the fact that they do not emit any heat, making them an ideal solution for sensitive lighting projects, such as those required in the filming or photography industry. In addition, the PMMA material used in their production ensures that they are highly durable and long-lasting.China's leading Fiber Optic Star Ceiling Panels product market has been at the forefront of innovating and producing top-quality star ceiling panels, among other high-tech products. With their neck for excellence and their focus on maintaining strict quality control, they have managed to establish themselves as market leaders, providing clients with reliable and efficient products for their lighting needs.In conclusion, PMMA 15W Fiber Optic Star Ceiling Panels 600*600mm FCC for moon shooting from China are some of the most innovative and reliable lighting solutions on the market today. Their high-quality production and strict quality control ensure that they are long-lasting and efficient, making them the perfect fit for any sensitive lighting project. Well done, China, for yet another remarkable achievement in the technological world.

Advanced Automatic Mgo Board Production Line in China

China Advanced Automatic Mgo Board Production Line is set to revolutionize the construction industry with its cutting-edge technology and high-quality production capabilities. This state-of-the-art production line is a game changer in the manufacturing of Magnesium Oxide (MgO) boards, offering improved efficiency, precision, and productivity.The new production line is a significant milestone for the company, as it reflects its commitment to innovation and excellence in the building materials sector. With the installation of this advanced automatic production line, the company aims to meet the growing demand for MgO boards in both domestic and international markets.The production line is equipped with the latest automated machinery and technology, ensuring the highest level of efficiency and precision in the manufacturing process. This advanced system allows for seamless integration of raw materials, precise mixing, accurate forming, and rapid curing of MgO boards. The result is a superior quality product that meets the highest industry standards and surpasses customer expectations.In addition to the advanced technological capabilities, the production line also prioritizes environmental sustainability and energy efficiency. By optimizing the production process and minimizing waste, the company is demonstrating its commitment to reducing carbon footprint and promoting eco-friendly manufacturing practices.With the installation of the new production line, the company is poised to significantly increase its production capacity, meeting the growing demand for MgO boards in the global construction market. This expansion is a strategic move to strengthen the company's position as a leading manufacturer of high-quality building materials, catering to the diverse needs of customers across various industries.The advanced automatic production line is expected to streamline the manufacturing process, reduce production lead times, and improve overall operational efficiency. This will enable the company to meet tight deadlines and deliver orders in a timely manner, contributing to enhanced customer satisfaction and loyalty.Furthermore, the company's investment in this advanced production line is a testament to its dedication to continuous improvement and technological advancement. By staying at the forefront of innovation, the company is positioning itself as an industry leader, driving progress and setting new standards for MgO board manufacturing.The company's decision to invest in this state-of-the-art production line also reflects its confidence in the growing demand for MgO boards in the construction industry. With its superior quality, durability, and fire resistance, MgO boards are increasingly becoming the preferred choice for architects, builders, and contractors in various construction projects.Moreover, the company's commitment to research and development has played a crucial role in the development of this advanced automatic production line. By leveraging the expertise of its dedicated team of engineers and technicians, the company has been able to create a cutting-edge manufacturing system that sets new benchmarks in the industry.Overall, the launch of the China Advanced Automatic Mgo Board Production Line marks a significant achievement for the company and the construction industry as a whole. With its state-of-the-art technology, commitment to quality, and focus on sustainability, the company is well-positioned to meet the evolving needs of the market and drive innovation in the manufacturing of MgO boards. This investment underscores the company's vision to lead the way in delivering exceptional products and solutions for the construction sector, setting a new standard of excellence in the industry.

Improving Productivity: A Comprehensive Guide to Mgo Board Production Line

Title: Innovative Mgo Board Production Line Redefines Manufacturing Efficiency Introduction: In a rapidly evolving industry, it is crucial for companies to invest in advanced technologies to maintain a competitive edge. One such innovation, the Mgo Board production line, has captured the attention of manufacturers worldwide. This versatile production line, unveiled by an industry-leading manufacturer, has revolutionized the production of Magnesium Oxide (Mgo) boards. Offering remarkable efficiency, increased productivity, and exceptional product quality, the new Mgo Board production line is transforming the construction and building materials sector.Efficiency Redefined:The newly developed Mgo Board production line incorporates state-of-the-art technology, reducing the production process time significantly. By leveraging automation and precision engineering, the line offers faster board production from raw materials to the final output. This unprecedented speed ensures manufacturers can meet market demand efficiently, ultimately boosting their revenue.Unparalleled Product Quality:The Mgo Board production line introduces cutting-edge techniques that guarantee consistent, high-quality boards. The precision control systems integrated into the production process ensure accurate measurements, resulting in Mgo boards with superior strength, durability, and fire-resistance. These boards are increasingly preferred by builders and architects for their exceptional performance and safety features.Enhanced Productivity:With the Mgo Board production line, manufacturers can substantially increase their daily output without compromising on quality. The line's seamless integration of raw material handling, mixing, molding, and finishing operations optimizes productivity while reducing waste. The versatility of the production line allows customization of board sizes, thicknesses, and surface finishes to cater to varying project requirements.Streamlined Operation:This innovative production line is engineered with user-friendliness in mind. Automated processes, coupled with an intuitive control panel, facilitate smooth operation and minimize human error. Moreover, the line features comprehensive safety measures, ensuring a secure working environment for the production staff.Environmental Sustainability:The Mgo Board production line exemplifies the manufacturer's commitment to sustainability. The line incorporates eco-friendly practices, such as efficient energy consumption and reduced water usage, minimizing its environmental footprint. Furthermore, the Mgo boards produced by this line are non-toxic, making them an ideal choice for environmentally conscious projects.Market Implications:The introduction of the Mgo Board production line is projected to have widespread implications for the construction and building materials industry. With its efficient production process and superior product quality, this innovative solution is anticipated to stimulate growth in the sector. Manufacturers can now efficiently meet the increasing demand for environmentally friendly and durable building materials, while simultaneously contributing to sustainable development.Global Reach:The appeal of the Mgo Board production line extends far beyond national borders. The industry-leading manufacturer plans to market this innovative solution worldwide, targeting regions with burgeoning construction projects. By establishing partnerships and collaborations with industry players globally, the manufacturer aims to create a global network that revolutionizes the construction industry.Conclusion:The Mgo Board production line represents a breakthrough in the manufacturing of Magnesium Oxide boards, capitalizing on cutting-edge technology to transform the construction and building materials sector. With improved efficiency, exceptional product quality, and enhanced productivity, this innovative solution offers manufacturers a competitive advantage. Furthermore, its eco-friendly design aligns with the growing global emphasis on sustainability. As this revolutionary production line reaches international markets, it is set to reshape the way construction projects are executed worldwide.

High-Quality Decorative Plastic Ceiling Tiles Made from PVC Gypsum Board Building Material

Decorative Plastic Ceiling Tiles: A High Quality Building MaterialWhen it comes to designing the interior of a building, one of the most important elements to consider is the ceiling. The right ceiling can enhance the overall look and feel of a space, and one of the most popular choices for modern buildings are Decorative Plastic Ceiling Tiles. These tiles are made from durable and high-quality PVC material, which not only offers a sleek and modern aesthetic but also offers several benefits over traditional ceiling options.One of the significant advantages of Decorative Plastic Ceiling Tiles is their flexibility and versatility. They come in a wide range of designs and patterns that can match the style and decor of any space. This is in contrast to conventional ceiling materials that tend to be concrete or drywall, which are limited in terms of customization and pattern options.Another advantage of Decorative Plastic Ceiling Tiles is that they are lightweight and easy to install. This makes them ideal for use in both residential and commercial buildings. The installation process is also relatively straightforward and can be done by a professional or a competent DIYer. The tiles can be easily cut to fit the size and shape of the ceiling and can be installed using adhesive or clips.The durability of Decorative Plastic Ceiling Tiles is another factor that makes it a popular choice. They are made from high-quality PVC, which is resistant to moisture, mold, and mildew. This makes them perfect for use in spaces where humidity and dampness are an issue, such as bathrooms, kitchens, and basements.One of the most popular types of Decorative Plastic Ceiling Tiles is the PVC Gypsum Board Building Material. This is a type of ceiling tile that is made from a combination of gypsum and PVC, which provides an even more substantial and durable ceiling option. Gypsum provides excellent fire resistance and sound insulation properties, making it ideal for use in commercial and public buildings.To produce high-quality PVC Gypsum Board Building Material, manufacturers often use Gypsum Ceiling Tile Making Machines. These machines are designed to produce gypsum boards that are strong, durable, and have excellent finished surfaces that offer an attractive finish.In conclusion, Decorative Plastic Ceiling Tiles are a high-quality building material that offers several advantages over traditional ceiling options. With their flexibility, lightweight, and easy installation, they are an excellent choice for both residential and commercial buildings. The PVC Gypsum Board Building Material is particularly durable and reliable, making it an ideal choice for buildings where safety and security are top priorities. With the help of Gypsum Ceiling Tile Making Machines, the manufacturing process can be streamlined, resulting in high-quality and cost-effective ceiling tiles.

Gypsum Cornice Production: High-Quality Mold and Template Suppliers

and Gypsum Cornice Production Line to improve search engine optimization.Gypsum cornice is a popular choice for homeowners, builders, and architects alike to add a touch of elegance and style to homes and buildings. The ornamental plaster is typically used to decorate the gap between the ceiling and walls, providing a smooth transition from one to the other. However, creating gypsum cornices can be a labor-intensive process. That's where a gypsum cornice machine comes in, streamlining the process.A gypsum cornice machine is a production line that's designed to manufacture and produce gypsum cornices. These machines eliminate the need for the traditional and tedious hand labor required to create gypsum cornices. These machines have become a popular choice among manufacturers and builders to speed up the process, increase efficiency, and reduce costs.Producing high-quality gypsum cornices requires precision and accuracy. The gypsum cornice machine can create intricate designs with ease and accuracy, delivering an identical finish every time, ensuring that every gypsum cornice is perfect.The production process of a gypsum cornice machine involves several stages. First, the gypsum cornice machine uses a plaster casting technique, which involves pouring a liquid plaster into the desired mold. The mold is then allowed to set and dry. The gypsum cornices that are produced through this process are strong and durable, which makes them ideal for any architectural or home décor project.Second, the gypsum cornice machine typically includes a fiberglass cornice frame. The frame provides extra support and strength for the plaster of the cornice. The fiberglass material used in this process is lightweight and durable, making it a superior choice for the production of gypsum cornices. Additionally, the fiberglass frame helps create ornamental shapes and designs that are intricate and beautiful.Third, the gypsum cornice machine utilizes PU/polyurethane, which helps seal the molds and prevents any leakage. The PU/Polyurethane used in the production process gives the gypsum cornice machine the ability to create smooth, seamless, and breathtaking gypsum cornices that are perfect for any building.Furthermore, the drywall gypsum board used in the production process creates a solid foundation that helps provide a foundation for the gypsum cornices. It also helps reinforce the cornice, making it strong and durable, while also reducing the risk of cracking or warping.In conclusion, the gypsum cornice machine has revolutionized the production process of gypsum cornices, allowing for more efficient, accurate, and cost-effective production. The gypsum cornice machine is capable of producing stunning designs and intricate shapes, delivering a finish that is perfect every time. Using a gypsum cornice machine for your decorative needs is an excellent choice, whether you're an individual decorating your home or a builder looking to add exquisite details to a building. The use of keywords such as Gypsum Cornice Machine and Gypsum Cornice Production Line in this blog will not only help readers better understand the topic but also improve search engine optimization for those looking for relevant information online.

Efficient Mgo Board Making Machine for High Quality Production

High Efficient Mgo Board Making Machine Revolutionizes Construction IndustryWith the constant evolution of technology, the construction industry has seen a significant shift towards more efficient and sustainable building materials. One such innovation is the High Efficient Mgo Board Making Machine, a cutting-edge technology that has revolutionized the production of magnesium oxide (MgO) boards.This advanced machine is the brainchild of a leading manufacturer in the construction materials industry. The company, known for its commitment to quality and innovation, has been at the forefront of developing state-of-the-art machinery to meet the growing demands of the construction sector. With a strong focus on research and development, the company has successfully launched the High Efficient Mgo Board Making Machine, which has garnered widespread attention for its ability to enhance the manufacturing process of MgO boards.The High Efficient Mgo Board Making Machine is equipped with advanced features that streamline the production of MgO boards, making it a game-changer in the industry. The machine boasts high efficiency and precision, allowing for the seamless creation of MgO boards with minimal waste and maximum output. Its automated processes and user-friendly interface make it easy to operate, reducing the need for extensive training and manpower.One of the key advantages of this cutting-edge machine is its ability to produce MgO boards with superior quality and consistency. By leveraging advanced technology, the machine ensures that the boards are manufactured to exact specifications, meeting the highest standards of strength, durability, and fire resistance. This level of precision and reliability has positioned the High Efficient Mgo Board Making Machine as a preferred choice for construction companies and manufacturers seeking top-notch MgO boards for their projects.Furthermore, the High Efficient Mgo Board Making Machine is designed with sustainability in mind. It utilizes eco-friendly materials and processes, minimizing environmental impact while delivering excellent results. As the construction industry continues to prioritize sustainable practices, this machine is well-aligned with the shifting trends towards green building materials and sustainable production methods.The introduction of the High Efficient Mgo Board Making Machine has not only raised the bar for MgO board production, but it has also opened up new possibilities for innovation in the construction industry. The machine's capabilities have the potential to drive advancements in building design and construction techniques, as it offers a reliable and high-quality material for various applications, including wall panels, ceilings, and flooring.In addition to its technical capabilities, the company behind the High Efficient Mgo Board Making Machine is committed to providing exceptional customer support and service. With a team of skilled professionals and a dedication to exceeding customer expectations, the company has established itself as a trusted partner for construction companies and manufacturers seeking to elevate their production processes.As the demand for high-quality building materials continues to grow, the High Efficient Mgo Board Making Machine stands out as a game-changing innovation that is reshaping the construction industry. Its impact is far-reaching, from enhancing manufacturing efficiency to driving sustainable practices and advancing the quality of construction materials.In conclusion, the High Efficient Mgo Board Making Machine represents a significant leap forward in the production of MgO boards, offering a combination of efficiency, quality, and sustainability. Its introduction underscores the ongoing commitment of the company to delivering innovative solutions that meet the evolving needs of the construction industry. As the machine gains traction and recognition, it is poised to make a lasting impact on how MgO boards are manufactured and utilized in construction projects, paving the way for a more efficient and sustainable future in the industry.

Find Quality Mineral Fiber Sheet Board Machine at Competitive Prices

Mineral Fiber Sheet Board Machine Pricelist Unveiled by Leading Manufacturer{Company Name}, a renowned manufacturer of industrial machinery and equipment, has recently announced the release of its latest mineral fiber sheet board machine pricelist. This new addition to the company's product lineup is set to provide customers with a high-quality and efficient solution for producing mineral fiber sheet boards.{Company Name} has a strong reputation in the industry for delivering cutting-edge machines that offer superior performance and reliability. With an extensive experience in the manufacturing of industrial equipment, the company has solidified its position as a trusted and innovative supplier to various sectors including construction, building materials, and manufacturing.The mineral fiber sheet board machine pricelist release comes as a response to the increasing demand for advanced machinery in the production of mineral fiber sheet boards. As the construction and building materials market continues to expand, there is a growing need for efficient and cost-effective solutions to meet the demands of this thriving industry.The new mineral fiber sheet board machine from {Company Name} is designed to meet the specific requirements of manufacturers looking to enhance their production capabilities. The machine boasts advanced features and cutting-edge technology that ensure the production of high-quality mineral fiber sheet boards with consistent results.One of the key highlights of the mineral fiber sheet board machine is its efficient production process, which allows for increased output while maintaining high levels of precision and quality. This is made possible through the integration of state-of-the-art automation and control systems, as well as durable and reliable components that are designed to withstand the rigors of continuous operation.In addition to its superior performance, the mineral fiber sheet board machine also offers a user-friendly interface and intuitive operation, making it easy for operators to set up and manage the production process. This streamlined operation not only enhances productivity but also minimizes the need for manual intervention, thereby reducing the risk of errors and ensuring consistent output.Furthermore, {Company Name} has emphasized the importance of affordability and cost-effectiveness in the development of the mineral fiber sheet board machine. By optimizing the design and engineering of the machine, the company has successfully managed to offer a competitive pricing structure without compromising on the quality and performance of the equipment.The unveiling of the mineral fiber sheet board machine pricelist demonstrates {Company Name}'s commitment to meeting the evolving needs of its customers and the market. By providing a comprehensive solution for mineral fiber sheet board production, the company aims to support manufacturers in achieving their production goals while maintaining high standards of quality and efficiency.The release of the mineral fiber sheet board machine pricelist is expected to generate significant interest from companies operating in the construction, building materials, and manufacturing sectors. With its proven track record of delivering reliable and innovative machinery, {Company Name} is poised to strengthen its position as a leading supplier of industrial equipment in the global market.In summary, {Company Name} has introduced its latest mineral fiber sheet board machine pricelist, catering to the increasing demand for advanced production solutions in the construction and building materials industry. With its focus on performance, reliability, and affordability, the company is set to provide customers with a competitive edge in their production operations, solidifying its position as a trusted and innovative supplier of industrial machinery.