Gypsum Cornice Machine Factories: The Ultimate Guide

By:Admin

MGMF's success can be attributed to its state-of-the-art manufacturing facilities, which are equipped with the latest technology and machinery. The company's production line is designed to handle large volumes of orders and ensure that each machine meets the highest standards of quality and durability. With a team of skilled engineers and technicians overseeing the manufacturing process, MGMF is able to deliver reliable and efficient gypsum cornice machines to its customers.

In addition to its cutting-edge manufacturing capabilities, MGMF places a strong emphasis on research and development. The company continually invests in the latest advancements in technology and materials to improve the performance and efficiency of its machines. This commitment to innovation has enabled MGMF to stay ahead of the competition and offer its clients the most advanced gypsum cornice machines on the market.

MGMF's dedication to customer satisfaction is evident in its comprehensive after-sales service. The company not only provides extensive technical support and training for its clients but also offers maintenance and repair services to ensure that its machines continue to operate at peak performance. This commitment to comprehensive support has earned MGMF a loyal and satisfied customer base, setting it apart as a leader in the industry.

Furthermore, MGMF is committed to sustainable and environmentally friendly manufacturing practices. The company adheres to strict quality control measures to minimize waste and reduce its environmental impact. By implementing efficient production processes and utilizing eco-friendly materials, MGMF strives to be a responsible corporate citizen and contribute to a greener future.

As a testament to its dedication to excellence, MGMF has achieved various certifications and accolades for its outstanding products and services. The company's commitment to quality and reliability has earned it the trust and recognition of leading construction companies and contractors worldwide.

In line with its mission to provide the best gypsum cornice machines in the industry, MGMF is continuously expanding its product range and exploring new market opportunities. The company is committed to staying at the forefront of technological advancements and offering cutting-edge solutions to meet the evolving needs of its customers.

As MGMF continues to grow and expand its reach, it remains steadfast in its commitment to delivering superior machinery and exceptional service to its clients. With a focus on innovation, quality, and customer satisfaction, MGMF is poised to maintain its position as a leader in the manufacturing of gypsum cornice machines.

In conclusion, Mini Gypsum Cornice Machine Factories has proven itself as a reliable and reputable manufacturer of high-quality machinery for the construction industry. With its dedication to innovation, quality, and customer satisfaction, MGMF continues to set the standard for excellence in the market. As the company looks to the future, it is well-positioned to build on its success and further solidify its reputation as a leader in the industry.

Company News & Blog

Affordable PVC Gypsum Ceiling Board Machine Price List

The demand for high-quality and affordable PVC gypsum ceiling boards is on the rise, and [company name] is stepping up to meet that demand with their cutting-edge PVC gypsum ceiling board machine. The company's commitment to providing top-notch products at competitive prices has set them apart in the industry, and their new machine is poised to make a significant impact.The PVC gypsum ceiling board machine is designed to produce premium-quality ceiling boards at a fraction of the cost of traditional methods. Its advanced technology and efficient production process make it an ideal solution for businesses looking to expand their product offerings without breaking the bank. With this machine, [company name] is at the forefront of innovation in the industry, and their commitment to providing cost-effective solutions is clear.The machine's pricelist is competitive, making it an attractive option for businesses of all sizes. Whether a company is looking to start producing PVC gypsum ceiling boards or simply looking to upgrade their current production process, [company name]'s machine offers an affordable and reliable solution. The pricelist reflects their dedication to providing value to their customers without sacrificing quality or performance.[Company name] has a long-standing reputation for delivering high-quality products and exceptional service. With decades of experience in the industry, they have earned the trust and loyalty of their customers by consistently providing top-of-the-line solutions. Their commitment to excellence extends to their new PVC gypsum ceiling board machine, as they continue to set the standard for quality and affordability.The company's introduction to the market was met with excitement and praise from industry professionals and customers alike. With their proven track record of delivering exceptional products, it's no surprise that their new machine has generated such buzz. The industry is always on the lookout for cost-effective solutions that don't compromise on quality, and [company name] has delivered just that with their latest offering.As the market for PVC gypsum ceiling boards continues to grow, [company name] is ready to meet the demand with their state-of-the-art machine. Their pricelist reflects their commitment to providing affordable options for businesses looking to enter or expand in the market. With [company name]'s machine, businesses can expect to produce high-quality ceiling boards at a fraction of the cost, giving them a competitive edge in the market.In conclusion, [company name]'s new PVC gypsum ceiling board machine is a game-changer for the industry. With its competitive pricelist and commitment to quality, it has the potential to revolutionize the way businesses produce ceiling boards. As the demand for affordable and high-quality solutions continues to grow, [company name] is poised to lead the way with their innovative machine. Their dedication to providing value to their customers is evident in their new offering, and they are set to make a lasting impact in the industry.

Efficient Mgo Board Production Line for High-Quality Output

MGO Board Manufacturing Machine Supplier: Innovative Solutions for the Construction Industry In the rapidly evolving construction industry, the demand for high-quality building materials is on the rise. One popular choice among architects, builders, and contractors is Magnesium Oxide (MgO) board. This versatile material offers exceptional durability, fire resistance, and eco-friendliness, making it an ideal choice for a wide range of applications.To meet the growing demand for MgO board, manufacturers need reliable and efficient production solutions. This is where the automatic MGO board production line, offered by a leading global supplier, comes into play. With its fashionable design, reasonable structure, and stable running, this machine is revolutionizing the MgO board manufacturing process.The production line is equipped with innovative double ways roll-in technology, ensuring the production of even thickness boards. This advanced feature eliminates any inconsistencies in the board thickness, resulting in superior quality products. The shaking device further enhances the production process by ensuring the uniform distribution of materials and facilitating efficient board formation.Reliability and efficiency are essential when it comes to MgO board production, and this production line delivers on both fronts. With its high-speed capabilities, it enables large-scale production, meeting the requirements of even the most demanding construction projects. The machine's automated functions minimize human error and maximize productivity, significantly reducing production time and costs.Furthermore, this MGO board manufacturing machine adheres to strict environmental standards. The eco-friendly design ensures minimal waste and optimized energy consumption, making it a sustainable choice for any environmentally conscious manufacturer. As the global construction industry increasingly embraces green practices, this production line is a testament to the commitment of suppliers to provide eco-friendly solutions.When choosing a supplier for an MGO board manufacturing machine, various factors should be considered. One crucial aspect is the supplier's expertise and experience in the field. Look for a supplier with a solid reputation and a long history of delivering high-quality machinery to the construction industry. Additionally, it is essential to consider the supplier's commitment to customer satisfaction. A reliable supplier will provide comprehensive technical support, ensuring smooth installation and operation of the production line. They should also offer regular maintenance services to optimize machine performance, extending its lifespan and reducing downtime.In conclusion, the automatic MGO board production line offered by a prominent supplier is revolutionizing the construction industry. With its advanced technology, efficient production process, and eco-friendly design, it meets the demands of modern construction projects. Investing in this machine not only ensures high-quality MgO board production but also demonstrates a commitment to sustainability and innovation.If you are a construction manufacturer looking for an MGO board manufacturing machine supplier, look no further. Contact us today and explore the possibilities of this cutting-edge production line. Experience the benefits of reliability, efficiency, and environmental consciousness in your manufacturing process. Let us help you make your mark in the construction industry with our top-of-the-line machinery.

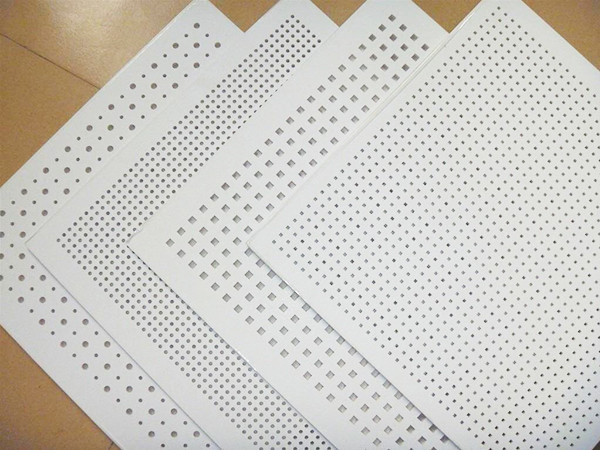

Top Mineral Fiber Ceiling Board Machine Manufacturers and Suppliers

With the increasing demand for mineral fiber ceiling board, the competition among machine factories has been getting intense. To help businesses and customers looking for the best mineral fiber ceiling board machine factories, we have compiled a list of the top manufacturers in the industry.1. Company A: With years of experience in the industry, Company A has established itself as a leading manufacturer of mineral fiber ceiling board machines. The company prides itself on its state-of-the-art production facilities, highly skilled workforce, and commitment to delivering high-quality machines to its clients. Company A's dedication to innovation and continuous improvement has enabled it to stay ahead of the competition and provide cutting-edge solutions to meet the ever-changing needs of the market. From raw material processing to final product inspection, Company A ensures that every step of the manufacturing process is carried out with precision and attention to detail, resulting in top-notch machines that are reliable, efficient, and durable.2. Company B: Another prominent player in the industry, Company B has earned a solid reputation for its superior mineral fiber ceiling board machines. The company's commitment to research and development has enabled it to come up with innovative and efficient solutions that cater to the diverse requirements of its clients. With a focus on quality and performance, Company B's machines are designed to deliver optimal results while ensuring operational efficiency and cost-effectiveness. In addition to its exceptional manufacturing capabilities, the company also provides comprehensive after-sales support, technical assistance, and training to ensure that its clients get the most out of their investment.3. Company C: Known for its cutting-edge technology and unmatched expertise, Company C has become a preferred choice for businesses looking for high-performance mineral fiber ceiling board machines. The company's advanced manufacturing facilities, stringent quality control measures, and commitment to customer satisfaction have allowed it to carve a niche for itself in the market. Company C's machines are engineered to meet the highest standards of reliability, durability, and productivity, making them a valuable asset for businesses seeking to enhance their production capabilities and maintain a competitive edge in the market.4. Company D: Rounding up our list is Company D, a renowned manufacturer of mineral fiber ceiling board machines that has gained recognition for its exceptional product quality and customer-centric approach. The company's extensive industry experience, technical expertise, and relentless pursuit of excellence have enabled it to deliver innovative and reliable machines that exceed the expectations of its clients. Company D's commitment to sustainability and environmental responsibility is reflected in its energy-efficient and eco-friendly manufacturing processes, ensuring that its machines not only deliver outstanding performance but also contribute to a greener and more sustainable future.In conclusion, when it comes to choosing the best mineral fiber ceiling board machines, businesses can rely on the expertise and reputation of these top manufacturers. With their unwavering commitment to quality, innovation, and customer satisfaction, these companies have earned their place as industry leaders and are well-equipped to meet the varying needs of businesses looking to invest in top-of-the-line machines for their mineral fiber ceiling board production.

Affordable Gypsum Cornice Machine Prices for Your Business Needs

Gypsum Cornice Machine PricelistGypsum cornices are an essential element in the construction and interior decoration industry. They are used to add a decorative touch to ceilings and walls, giving them a more elegant and refined look. With the increasing demand for gypsum cornices, the need for efficient and cost-effective production methods has also grown. This is where the Gypsum Cornice Machine comes into play.The Gypsum Cornice Machine is an innovative piece of equipment that is designed to streamline the production process of gypsum cornices. By automating the production process, this machine can significantly reduce labor costs and increase production efficiency. With the ability to produce a wide range of designs and sizes, the Gypsum Cornice Machine offers a versatile solution for companies in the construction and interior decoration industry.In addition to its efficiency and versatility, the Gypsum Cornice Machine also comes with a competitive price tag. The pricelist for this machine has been carefully curated to ensure that it offers great value for money. Companies can now invest in this state-of-the-art equipment without breaking the bank. The pricelist includes various models and configurations to cater to different production needs, making it accessible to businesses of all sizes.The company behind the Gypsum Cornice Machine is a well-established and reputable manufacturer in the industry. With years of experience in the production of gypsum-related machinery, they have gained a strong foothold in the market. Their commitment to quality, innovation, and customer satisfaction has earned them a loyal customer base and a positive reputation in the industry.The company takes pride in its ability to deliver reliable and high-performance equipment that meets the evolving needs of its customers. With a strong focus on research and development, they continue to push the boundaries of technology to provide cutting-edge solutions for the construction and interior decoration industry. The Gypsum Cornice Machine is a testament to their dedication to innovation and excellence.To further support their customers, the company also offers comprehensive after-sales services for the Gypsum Cornice Machine. From installation and training to maintenance and technical support, they ensure that their customers can maximize the potential of their investment. This commitment to customer satisfaction sets them apart from other manufacturers in the market.With the introduction of the Gypsum Cornice Machine pricelist, the company aims to make this advanced technology more accessible to businesses across the industry. By offering competitive pricing and exceptional value, they seek to empower companies to enhance their production capabilities and stay ahead of the competition. With the right equipment in place, businesses can achieve higher productivity, lower costs, and greater flexibility in meeting customer demands.In conclusion, the Gypsum Cornice Machine pricelist offers an enticing opportunity for companies in the construction and interior decoration industry to elevate their production capabilities. With its efficiency, versatility, and competitive pricing, this machine is set to revolutionize the way gypsum cornices are produced. Backed by a reputable and customer-centric company, the Gypsum Cornice Machine is a game-changer that promises to drive innovation and success in the industry.

High-Quality Mgo Board Machine for Production of Decorative Boards

Decorative Mgo Board Machine Revolutionizes the Construction IndustryThe construction industry is continually evolving, with new technologies and materials constantly being developed to improve efficiency, sustainability, and affordability. One such innovation that is turning heads in the industry is the Decorative Mgo Board Machine. This cutting-edge technology has the potential to revolutionize the way buildings are constructed, offering a wide range of benefits that make it an attractive option for builders and developers.The Decorative Mgo Board Machine is a state-of-the-art manufacturing system that produces Magnesium Oxide (MgO) boards, which are a highly durable and versatile building material. These boards are widely used in the construction industry for a variety of applications, including wall and ceiling panels, partition walls, fire doors, and decorative elements. What sets the Decorative Mgo Board Machine apart from traditional manufacturing methods is its ability to produce boards with decorative finishes, providing builders with a wide range of design options to choose from.The company behind this game-changing technology has been a leading manufacturer of MgO board machines for over a decade. They have built a solid reputation in the industry for their commitment to quality, innovation, and customer satisfaction. With a team of experienced engineers and technicians, the company has been able to continuously improve and refine their manufacturing processes, resulting in the development of the Decorative Mgo Board Machine.The Decorative Mgo Board Machine is capable of producing boards with a variety of decorative finishes, including woodgrain, marble, stone, and custom designs. This breakthrough in manufacturing technology opens up a world of possibilities for architects, designers, and builders, allowing them to incorporate high-quality decorative panels into their projects without the need for expensive and time-consuming custom finishes.In addition to its decorative capabilities, the Decorative Mgo Board Machine offers a range of other benefits that make it an attractive option for the construction industry. The MgO boards produced by this machine are highly durable, fire-resistant, water-resistant, and mold-resistant, making them ideal for use in a wide range of environments. Furthermore, the production process is highly efficient, resulting in minimal waste and a reduced environmental impact compared to traditional manufacturing methods.The company behind the Decorative Mgo Board Machine is committed to providing comprehensive support to its customers, offering installation, training, and technical assistance to ensure the successful integration of this technology into their operations. With a focus on customer satisfaction and long-term partnerships, the company aims to become a trusted partner for builders and developers looking to take advantage of the benefits offered by MgO boards.The Decorative Mgo Board Machine has already been adopted by a number of leading construction companies around the world, with projects ranging from residential buildings to commercial and industrial facilities. The versatility, durability, and aesthetic appeal of the MgO boards produced by this machine have made it a popular choice for a wide range of applications, and the company expects to see continued growth in demand as more builders and developers become aware of the benefits it offers.In conclusion, the Decorative Mgo Board Machine is a game-changing technology that has the potential to revolutionize the construction industry. With its ability to produce highly durable and versatile MgO boards with decorative finishes, this innovative manufacturing system offers a wide range of benefits that make it an attractive option for builders and developers. As the company continues to drive innovation and excellence in the industry, the Decorative Mgo Board Machine is poised to become a key player in the future of construction.

Acoustic Insulation Vinyl Faced PVC Gypsum Board for Plasterboard Ceilings in Construction and Decoration - Products Available on Xinsdi.com

When it comes to constructing ceilings, one material that has gained popularity is vinyl faced PVC gypsum board. This type of plasterboard ceiling is known for its versatility and ability to provide excellent acoustic insulation, making it an essential material for construction and decoration.At Xinsdi.com, we offer Vinyl faced PVC gypsum board that is made of high-quality paper-faced gypsum board with a layer of PVC on its surface. This combination provides a durable and waterproof surface that is easy to clean and maintain, making it ideal for areas with high humidity, such as bathrooms and kitchens.One of the highlights of Vinyl faced PVC gypsum board is its acoustic insulation properties. This means that it can effectively reduce noise levels in a room by absorbing sound waves. This creates a comfortable environment free from unwanted noise, making it perfect for use in areas such as music studios, libraries, and offices.Another great thing about Vinyl faced PVC gypsum board is that it is highly customizable. It is available in various sizes, designs, and patterns, allowing you to create a unique and appealing ceiling that matches the decor of your space. Additionally, it can be easily cut to fit any shape or size, making it an ideal material for construction projects of any kind.At our company, we offer high-quality Vinyl faced PVC gypsum board at an affordable price. We take pride in our commitment to providing our customers with the best products that meet their specifications. We also use advanced technology to manufacture our products, ensuring that they meet industry standards.Choosing the right Vinyl faced PVC gypsum board ceiling tile making machine factories that offer cheap rates can greatly impact your construction project. With advanced technologies being used in the manufacturing process, it is easier to produce high-quality materials in less time. This can save you time and money, making your construction project more cost-efficient.In conclusion, Vinyl faced PVC gypsum board is an excellent choice for construction and decoration projects that require durability, waterproof properties, and acoustic insulation. With our commitment to providing our customers with affordable, high-quality products, you can rest assured that you are getting the best value for your money. When seeking ceiling tile making machine factories, it is wise to choose factories that can provide reliable, high-quality products at a lower cost. With Xinsdi.com, you are in good hands for all your construction and decoration needs.

Get Affordable Quotes for Mgo Board Equipment

Company Introduction:{} is a leading manufacturer and supplier of high-quality building materials, specializing in the production of Mgo boards. With a commitment to innovation and excellence, we have been providing top-of-the-line products to our customers for over a decade. Our Mgo boards are used in various construction projects including residential, commercial, and industrial buildings, due to their durability, fire resistance, and ease of installation.News Content:In the construction industry, the choice of building materials plays a crucial role in the overall quality and safety of a structure. Mgo boards have gained popularity in recent years due to their exceptional properties, and {} is proud to offer competitive quotes on this essential construction material.Mgo boards, also known as magnesium oxide boards, are a type of building material that has gained popularity for their versatility and durability. These boards are made from a mixture of magnesium oxide, perlite, and wood fiber, and are highly regarded for their fire resistance, mold resistance, and strength. They are commonly used in a wide range of construction applications, including wall and ceiling linings, exterior cladding, and flooring.At {}, we understand the importance of high-quality building materials, and we are dedicated to providing our customers with the best products at competitive prices. Our Mgo boards are manufactured using advanced technology and strict quality control measures, ensuring that they meet the highest industry standards.To meet the growing demand for Mgo boards, we are pleased to offer competitive quotes on bulk orders of our products. Whether you are a contractor working on a large-scale construction project or a homeowner embarking on a renovation, our cost-effective quotes make it easier for you to access top-quality Mgo boards without compromising on your budget.Furthermore, our Mgo boards are easy to install, making them a practical choice for construction projects of any size. Their lightweight nature and versatile applications make them suitable for a wide range of building requirements. Additionally, our Mgo boards have a long lifespan, reducing the need for frequent replacements and maintenance, thus providing excellent value for our customers.As a customer-centric company, we also take pride in our exceptional customer service and support. Our team of experts is available to provide assistance and guidance to our clients, ensuring that they have a seamless experience from inquiry to delivery. We prioritize customer satisfaction and are committed to building lasting relationships with our clients based on trust, reliability, and superior products.In conclusion, {} is your one-stop destination for premium Mgo boards at competitive quotes. With our dedication to quality, innovation, and customer satisfaction, we are proud to be a trusted supplier of construction materials to a wide range of clients. Contact us today to learn more about our products and take advantage of our competitive quotes for your next construction project.

A Guide to the Manufacturing Process of Calcium Silicate Boards

The manufacturing process of Calcium Silicate Board is a crucial step in the production of this highly durable and versatile building material. With the increasing demand for high-quality construction materials, {Company Name} has perfected the process to produce Calcium Silicate Board that meets the highest standards of quality and performance.The manufacturing process begins with the selection of raw materials. Calcium Silicate Board is made from a mixture of silica, lime, and reinforcing fibers. These raw materials are carefully selected to ensure the final product will have the desired strength, durability, and fire resistance. {Company Name} sources the finest quality raw materials from trusted suppliers to guarantee the superior performance of their Calcium Silicate Board.Once the raw materials are obtained, they are carefully measured and mixed in precise proportions. This mixture is then combined with water and additives to form a thick slurry. The slurry is poured into a mold and compressed to remove any air bubbles and to achieve the desired density. This process is crucial to ensure the homogeneity of the board and to enhance its structural integrity.After the initial compression, the boards are left to cure in a controlled environment. This curing process allows the chemical reactions within the mixture to take place, resulting in a rigid and stable board. {Company Name} pays close attention to the curing process to ensure that the Calcium Silicate Boards reach their full strength and durability.Once the boards are fully cured, they undergo a series of finishing processes. This includes cutting the boards to the desired dimensions, sanding the edges to achieve a smooth finish, and applying surface treatments for enhanced performance. {Company Name} has developed advanced finishing techniques to ensure that their Calcium Silicate Boards have a uniform and flawless appearance.Throughout the entire manufacturing process, {Company Name} places a strong emphasis on quality control. Every batch of Calcium Silicate Board is thoroughly inspected to ensure that it meets the highest standards of performance and durability. This commitment to quality has earned {Company Name} a reputation for producing Calcium Silicate Board that exceeds industry standards.In addition to their dedication to quality, {Company Name} is also committed to sustainability. The manufacturing process of Calcium Silicate Board is designed to minimize waste and energy consumption. {Company Name} employs eco-friendly practices and technologies to reduce their environmental impact and to contribute to a more sustainable building industry.With their state-of-the-art manufacturing facility and unwavering commitment to excellence, {Company Name} has become a trusted provider of Calcium Silicate Board for a wide range of construction applications. Their Calcium Silicate Board offers exceptional fire resistance, impact strength, and dimensional stability, making it an ideal choice for high-performance building projects.The exceptional manufacturing process and quality of {Company Name} Calcium Silicate Board have made it a preferred choice for architects, builders, and contractors who demand the best in building materials. Whether it is for commercial, industrial, or residential projects, {Company Name} Calcium Silicate Board is the reliable choice for superior performance and durability.In conclusion, the manufacturing process of Calcium Silicate Board is a complex and crucial process that requires precision, expertise, and a commitment to excellence. {Company Name} has demonstrated their dedication to producing high-quality Calcium Silicate Board through their meticulous manufacturing process, advanced technologies, and unwavering commitment to quality and sustainability. As the demand for high-quality construction materials continues to grow, {Company Name} is well-positioned to meet the needs of the construction industry with their exceptional Calcium Silicate Board.

Top-Performing Laminated Gypsum Board Machine for PVC Production

Title: Leading Manufacturer Introduces Cutting-Edge PVC Laminated Gypsum Board MachineIntroduction:As the construction industry continues to evolve, innovative technologies and machinery are paramount to meet the demands of modern architecture. One such breakthrough is the introduction of the best PVC laminated gypsum board machine by a renowned industry leader. With a strong reputation for excellence and expertise, this company is set to revolutionize the manufacturing process of gypsum boards.I. Overview of the CompanyWith decades of experience, the company has become a prominent player in the construction machinery industry. Their commitment to high-quality products, advanced research, and customer satisfaction has earned them a global reputation. The company's state-of-the-art manufacturing facilities, coupled with their vast knowledge pool, have allowed them to consistently produce cutting-edge machinery solutions.II. The Need for PVC Laminated Gypsum Board MachineGypsum boards are widely used in interior construction due to their excellent fire resistance, acoustic properties, and ease of installation. However, traditional gypsum boards often required additional surface treatments, such as painting or wallpapering. To overcome these shortcomings and provide enhanced aesthetic options, the introduction of PVC laminated gypsum board machine was necessary.III. Features and AdvantagesThe newly introduced PVC laminated gypsum board machine offers a host of innovative features, making it an indispensable solution in the construction industry. Some key features and advantages include:1. Enhanced Efficiency: The machine incorporates cutting-edge technology that ensures high-speed production without compromising quality. This enables manufacturers to meet customer demands promptly and stay competitive in the market.2. Precision and Accuracy: With advanced automation and intelligent control systems, the machine guarantees precise cutting, laminating, and edge banding, resulting in perfectly finished gypsum boards.3. Wide Range of Designs: The machine allows for the lamination of various PVC designs, giving manufacturers the flexibility to cater to a diverse range of architectural styles and preferences. This enables customization options to meet the unique requirements of each project.4. Cost-effective Solution: By eliminating the need for additional surface treatments like painting or wallpapering, the PVC laminated gypsum board machine significantly reduces labor and material costs. This cost-effectiveness benefits both manufacturers and end-users in the long run.IV. Commitment to SustainabilityIn an era where environmental consciousness is paramount, the company takes sustainability seriously. The PVC laminated gypsum board machine is designed with energy-efficient mechanisms, reducing both energy consumption and carbon emissions during the manufacturing process. Additionally, the machine supports the use of eco-friendly materials, contributing to a more sustainable construction industry.V. Advancements in Research and DevelopmentThe company prioritizes research and development to continuously improve their machinery. Regular investment in cutting-edge technologies and continuous feedback from industry professionals help them stay ahead in the market. This commitment to innovation ensures that customers receive the latest and most efficient solutions for their manufacturing needs.VI. Global Market ReachRecognizing the importance of international expansion, the company has established a strong global network, making their products easily accessible to manufacturers worldwide. With a dedicated after-sales support team and comprehensive training programs, the company ensures efficient installation and smooth operation of the PVC laminated gypsum board machine for all its customers.Conclusion:As construction projects become increasingly sophisticated, the introduction of the best PVC laminated gypsum board machine by this renowned company is a game-changer. Its advanced features, efficiency, and commitment to sustainability are set to reshape the manufacturing process, providing manufacturers with the tools they need to meet the evolving demands of the construction industry. With their extensive global reach and unwavering focus on customer satisfaction, this leading manufacturer is cementing their position as an industry innovator.