Fully Automatic Pvc Film Gypsum Ceiling Board Lamination Machine: Price List and Features

By:Admin

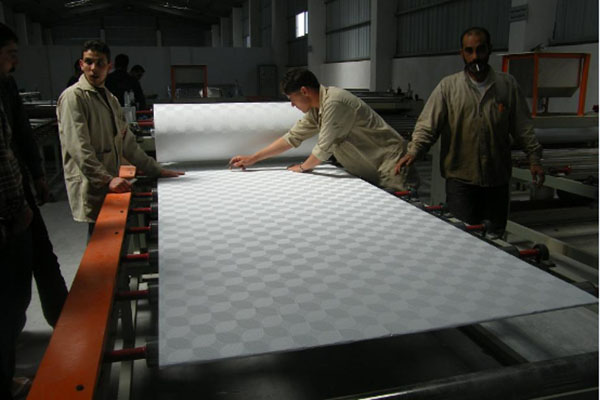

The Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine represents a significant advancement in the manufacturing process of gypsum ceiling boards. This state-of-the-art machine is designed to provide a seamless and efficient lamination process, ensuring high-quality output and increased productivity for gypsum board manufacturers.

The machine is equipped with advanced automation features that eliminate the need for manual intervention, resulting in improved efficiency and reduced production costs. Its fully automatic operation also reduces the risk of human error, ensuring consistent and uniform lamination of PVC film on gypsum boards.

The machine's versatility allows for the lamination of PVC film on gypsum boards of varying sizes and thickness, making it suitable for a wide range of production requirements. This flexibility enables gypsum board manufacturers to cater to diverse market demands and customize their products according to specific customer needs.

In addition to its advanced automation capabilities, the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine is also designed with user-friendly controls and intuitive interface, making it easy to operate and maintain. This ensures that operators can quickly adapt to the machine and optimize its performance, further enhancing overall production efficiency.

The introduction of this cutting-edge lamination machine underscores {Company}'s commitment to providing innovative solutions that empower gypsum board manufacturers to stay ahead in a competitive market. By leveraging the latest technology, {Company} aims to support its customers in improving their production capabilities, streamlining their operations, and delivering superior quality products to their clients.

Furthermore, {Company} prides itself on its dedication to customer satisfaction, offering comprehensive technical support and training programs to ensure that customers can maximize the benefits of the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine. This commitment to customer success reflects {Company}'s long-standing reputation as a trusted partner in the industry.

The launch of the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine has generated significant interest and anticipation within the gypsum board manufacturing sector. With its potential to revolutionize the lamination process, this innovative machine is set to redefine industry standards and elevate the efficiency and quality of gypsum board production.

As {Company} continues to push the boundaries of technological innovation, the introduction of the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine underscores its position as a leading provider of advanced solutions for the manufacturing industry. With a proven track record of delivering reliable and high-performance equipment, {Company} remains at the forefront of driving progress and transformation in the gypsum board manufacturing sector.

In conclusion, the unveiling of the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine marks a significant milestone for {Company} and the gypsum board manufacturing industry. With its advanced automation, versatility, and user-friendly design, this cutting-edge machine is poised to revolutionize the lamination process and empower manufacturers to achieve greater efficiency and quality in their production operations. As {Company} continues to uphold its commitment to innovation and customer satisfaction, the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine stands as a testament to its relentless pursuit of excellence in providing state-of-the-art solutions for the manufacturing sector.

Company News & Blog

Top-rated Gypsum Ceiling Tile Punching Machine Pricelist Unveiled in Latest News

Title: Advanced Gypsum Ceiling Tile Punching Machine Offers Cost-Efficiency and PrecisionIntroduction:In the rapidly evolving construction industry, innovative equipment plays a crucial role in enhancing productivity and meeting customer demands. One such groundbreaking machine is the advanced Gypsum Ceiling Tile Punching Machine, designed to revolutionize the manufacturing of ceiling tiles. This state-of-the-art technology combines cost-efficiency with precision, offering unparalleled benefits to manufacturers worldwide.Cost-Efficiency:The Gypsum Ceiling Tile Punching Machine is a game-changer for manufacturers seeking cost optimization without compromising on quality. With its automated operations, the machine significantly reduces labor costs, minimizing the need for manual intervention during the entire production process. Its cutting-edge technology enables swift punching and precise sizing of each tile, leading to a remarkable increase in the overall efficiency of the manufacturing process. Additionally, the machine's low power consumption and maintenance costs contribute to substantial savings, making it a financially viable choice for businesses.Enhanced Precision:Accurate dimensions and flawless cuts are paramount in the production of gypsum ceiling tiles. The Gypsum Ceiling Tile Punching Machine maintains the highest levels of precision, ensuring consistent and perfectly formed tiles with every punch. By eliminating human error, this advanced technology guarantees standardized sizes and hole placements, meeting the strictest quality standards in the industry. Manufacturers can now confidently supply their customers with seamless tiles that fit seamlessly for installation, resulting in improved customer satisfaction and fewer wastages.Robust Machinery Design:The Gypsum Ceiling Tile Punching Machine embodies a robust machinery design engineered to withstand high-volume production requirements. Constructed with durable materials, the machine offers longevity and reliability, reducing the need for frequent repairs or replacements. Its user-friendly interface allows operators to easily set preferences, select patterns, and monitor production progress, promoting seamless workflow and reducing downtime significantly. The machine's compact size ensures it can be integrated into existing production lines effortlessly, further enhancing its versatility and compatibility.Revolutionary Automation:Automation is a driving force behind increased productivity, and the Gypsum Ceiling Tile Punching Machine exemplifies this concept. By utilizing state-of-the-art technology, this machine streamlines the production process, eliminating manual errors and empowering manufacturers to meet rising market demands. With the ability to punch multiple tiles simultaneously, this machine enables an exponential increase in production rates, catering to large-scale orders within significantly reduced timelines. With automation, manufacturers can now scale their businesses and remain competitive in the industry.Market Outlook and Future Prospects:As the demand for affordable and diverse ceiling tiles continues to grow, the Gypsum Ceiling Tile Punching Machine is poised to transform the market. Its efficiency, precision, and cost-effectiveness position it as an essential tool for manufacturers aiming to meet customer expectations promptly. The machine's adaptability to different sizes, shapes, and hole patterns allows it to cater to the ever-changing aesthetic preferences and requirements of the industry. With its consistent quality output, the Gypsum Ceiling Tile Punching Machine enables manufacturers to build trust with customers and expand their market share in this highly competitive sector.Conclusion:The Gypsum Ceiling Tile Punching Machine has revolutionized the ceiling tile manufacturing process by offering an unmatched combination of cost-efficiency and precision. Manufacturers can now expect increased productivity, reduced labor costs, improved product quality, and quicker turnaround times. With its advanced automation technology and robust design, this groundbreaking machine is set to maximize productivity for businesses worldwide. The future of gypsum ceiling tile production is undoubtedly optimized and streamlined with the introduction of this exceptional machine.

High-Quality Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery from China's Leading Manufacturer

Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery: The Perfect Solution for Your Manufacturing NeedsThe world of manufacturing has evolved significantly in recent years. With the advent of new technologies, the process of producing goods has become more efficient, effective, and streamlined. One such technology that has gained immense popularity in recent years is the Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery. This cutting-edge equipment is the perfect solution for all your manufacturing needs and has revolutionized the industry in many ways.What is Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery?Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is a state-of-the-art machinery used for manufacturing MgO board door cores and frames. This fully automated equipment is designed to produce high-quality MgO board door cores and frames with precision and accuracy. The machinery is equipped with advanced technology to ensure the highest standards of quality and performance. It is the perfect solution for businesses seeking to improve their manufacturing processes and increase their productivity levels.Features of Fully Automatic Mgo Board Door Core Frame Vacuum Forming MachineryThe Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is designed with several features that make it a standout product. Some of its key features include:1. Fully Automated: The machinery is fully automated, which means it requires little or no human intervention during the manufacturing process. This feature ensures that the entire process is fast, efficient, and error-free.2. High-Quality Output: The machinery produces high-quality MgO board door cores and frames that meet industry standards. The equipment is designed to produce precise and accurate products that are of superior quality and durability.3. Cost-Effective: The Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is a cost-effective solution for businesses seeking to improve their manufacturing processes. The machinery saves time, reduces waste, and minimizes production costs, making it a profitable investment for any business.4. Easy to Operate: The machinery is easy to operate, even for those with little or no experience in manufacturing. The user-friendly interface makes it easy to set up, operate, and maintain.Benefits of Fully Automatic Mgo Board Door Core Frame Vacuum Forming MachineryThe Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery offers numerous benefits to businesses seeking to improve their manufacturing processes. These benefits include:1. Increased Productivity: The machinery is designed to produce high-quality products quickly and efficiently, increasing productivity levels and reducing lead times.2. Cost Savings: The equipment saves businesses money by minimizing production costs associated with waste, labor, and maintenance.3. Improved Quality: The machinery produces high-quality products that meet industry standards, ensuring customer satisfaction and reducing product recalls.4. Better Control: The machinery provides better control over the manufacturing process, allowing for adjustments and modifications as needed.Mgo Board Forming Machine PricelistThe price of Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery varies depending on the manufacturer, model, and features. In general, the price ranges from $50,000 to $150,000. However, it is advisable to request a quote from the manufacturer for a more accurate price estimate.ConclusionThe Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is the perfect solution for businesses seeking to improve their manufacturing processes and increase their productivity levels. With its advanced technology, high-quality output, and cost-effective features, the machinery offers numerous benefits to businesses of all sizes. If you are looking for a reliable and efficient solution for your manufacturing needs, consider investing in Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery.

High-Quality Mgo Board Production Line for Lamination PVC Film Deep Process from China

Are you in the market for high-quality Mgo boards that are perfect for all your construction projects? If yes, then you should consider investing in the China Advanced Automatic Mgo Board Production Line.China's leading industrial laminating machine product is one of the most innovative production lines on the market today. The machine is designed to provide you with high-quality Mgo boards that are ideal for all your construction needs. Moreover, the machine comes with advanced features which make it stand out from the rest of the competition.One of the key selling points of this Mgo Board Production Line is that it is perfect for deep processing PVC film. The machine is capable of laminating PVC film onto the Mgo board surface, which provides superior protection to the board while giving it a more appealing appearance. The deep-processing capability of this production line is what sets it apart from its competitors.Another advantage of the China Advanced Automatic Mgo Board Production Line is its advanced design. The machine comes with strict quality control automatic laminating systems, which ensure that each board produced under the line is consistent in quality. In addition, the machine comes with advanced control systems, which makes the whole line easy to operate and understand.The production line is designed to provide high-speed operation, which is perfect for high-volume production. With a production rate up to 6.5m per minute, this line can produce more boards in a shorter time compared to other similar machines.The Mgo boards produced by this line are strong, durable, and have an excellent fire resistance rating. The fire resistance rating of these boards makes them perfect for construction projects that require materials that can withstand the risk of fire.Overall, the China Advanced Automatic Mgo Board Production Line is the perfect investment for anyone in the construction business. With its advanced features, high-quality output, and excellent fire resistance rating, this line is changing the future of the construction industry.In conclusion, if you are looking for high-quality Mgo boards, then the China Advanced Automatic Mgo Board Production Line is the perfect investment for you. The line is designed to provide high-speed operation, strict quality control, and superior protection for Mgo boards. Moreover, the line is easy to operate, and its high-quality output is ideal for all your construction needs. So, invest in the Future today, and choose the China Advanced Automatic Mgo Board Production Line for all your construction projects.

Affordable Mineral Fiber Ceiling Equipment Manufacturers

Cheap Mineral Fiber Ceiling Equipment Factories Have Emerged as a Key Player in the IndustryThe mineral fiber ceiling industry has been growing at a rapid pace, and the demand for affordable and high-quality equipment has been on the rise. In response to this, several new cheap mineral fiber ceiling equipment factories have emerged, offering a wide range of products to meet the diverse needs of the market.One such company that has been making waves in this industry is {Company}. With a strong focus on innovation and quality, {Company} has quickly established itself as a leading manufacturer of mineral fiber ceiling equipment. Their state-of-the-art manufacturing facilities and cutting-edge technology have allowed them to produce a wide range of products that are not only cost-effective but also of premium quality.{Company} was founded with the vision of providing cost-effective solutions to meet the growing demands of the mineral fiber ceiling industry. With a team of highly skilled engineers and technicians, they have been able to develop and manufacture a diverse range of equipment that includes ceiling tile production line, mineral wool board production line, and ceiling grid production line, among others.The company's commitment to quality and affordability has set them apart from their competitors. They have strict quality control measures in place to ensure that every product that leaves their factory meets the highest standards. This dedication to quality has earned them a strong reputation in the industry and has helped them gain the trust of customers worldwide.In addition to their focus on quality, {Company} also takes pride in their commitment to innovation. They constantly strive to stay ahead of the curve by investing in research and development to improve their existing products and develop new and innovative solutions. This has allowed them to cater to the evolving needs of the market and provide customers with cutting-edge equipment that delivers exceptional performance.With a strong emphasis on customer satisfaction, {Company} has built a strong network of clients that spans across the globe. They have successfully established long-term partnerships with businesses in various countries, and their dedication to providing top-notch products and exceptional service has made them a preferred choice for many.In a recent statement, a spokesperson for {Company} expressed their commitment to continue delivering high-quality and cost-effective solutions to meet the evolving needs of the mineral fiber ceiling industry. They highlighted their focus on sustainable and eco-friendly practices, as well as their dedication to staying at the forefront of technological advancements.With the emergence of cheap mineral fiber ceiling equipment factories like {Company}, the industry is poised to witness significant growth and innovation. As the demand for affordable and high-quality equipment continues to rise, companies like {Company} are well-positioned to play a key role in shaping the future of the industry.In conclusion, the rise of cheap mineral fiber ceiling equipment factories has brought about a positive change in the industry. With their focus on quality, affordability, and innovation, companies like {Company} are setting new standards and paving the way for a brighter future in the mineral fiber ceiling industry. As they continue to expand their reach and capabilities, they are poised to make a significant impact and solidify their position as key players in the market.

Top Factories for Quality Gypsum Ceiling Pressing Machines

Title: Revolutionizing Gypsum Ceiling Production: Cutting-edge Pressing Machine Factories Challenge Industry StandardsIntroduction:The global demand for high-quality gypsum ceilings has been on the rise, prompting manufacturers to explore innovative technologies to meet the increasing needs of the market. Several pioneering companies have stepped up, establishing themselves as leaders in the realm of gypsum ceiling pressing machines. In this article, we will delve into some of the best gypsum ceiling pressing machine factories, highlighting their contributions and commitment to revolutionizing the industry.Gypsum Ceiling Pressing Machine Factory A:One of the leading players in the industry, Factory A, has gained a formidable reputation for its breakthrough technologies and commitment to quality. With state-of-the-art facilities, Factory A has revolutionized the gypsum ceiling production process, streamlining efficiency while maintaining exceptional standards. By employing advanced automation and precision engineering, the factory assures optimal performance of their pressing machines, resulting in flawless, finely finished gypsum ceiling panels.Moreover, Factory A's dedication to sustainability is commendable. They have implemented eco-friendly measures throughout their manufacturing process, such as recycling and minimizing waste generation. The factory's adherence to sustainable practices underscores their commitment to creating a greener future for the construction industry.Gypsum Ceiling Pressing Machine Factory B:Factory B has carved a niche for itself by consistently delivering cutting-edge gypsum ceiling pressing machines. Recognized for their attention to detail and continuous innovation, this factory has successfully impressed industry experts and customers alike. Engineers at Factory B have developed pressing machines that leverage advanced computerized technology, ensuring unparalleled accuracy and precision.In addition to their technological expertise, Factory B prioritizes customer satisfaction. By working closely with their clients, the factory ensures that their machines are tailored to meet specific requirements and optimize production processes. This customer-centric approach has allowed Factory B to build lasting relationships and maintain a loyal customer base.Gypsum Ceiling Pressing Machine Factory C:Factory C has earned its place among the best gypsum ceiling pressing machine factories due to its relentless pursuit of excellence. Notably, the factory's state-of-the-art research and development division constantly strives to innovate machinery to enhance efficiency and convenience. Through extensive market research and collaboration with industry leaders, Factory C consistently introduces groundbreaking features that set new benchmarks in gypsum ceiling production.Furthermore, Factory C emphasizes the importance of quality control throughout the manufacturing process. Every machine undergoes rigorous testing to ensure exceptional performance and durability. This commitment to uncompromising quality has positioned Factory C as a reliable and preferred choice for gypsum ceiling manufacturers worldwide.Conclusion:The gypsum ceiling pressing machine factories mentioned above, Factory A, Factory B, and Factory C, represent the pinnacle of innovation and quality in the industry. Their dedication to advanced technology, sustainability, customer satisfaction, and stringent quality control sets them apart from their competitors. These factories continue to challenge industry standards through their continuous pursuit of excellence, revolutionizing the gypsum ceiling production landscape. As the demand for high-quality gypsum ceilings continues to grow, manufacturers can rely on these factories to provide them with state-of-the-art pressing machines, ensuring a bright future for the industry.

Unveiling the Latest PVC Vinyl Film Innovations from China

Title: China's PVC Vinyl Film Manufacturer Set to Revolutionize the MarketIntroduction:China's leading PVC vinyl film manufacturer has emerged as a game-changer in the industry, offering high-quality products that cater to a wide range of sectors. With a commitment to innovation, sustainable practices, and unmatched customer service, this company has established itself as a leader in the production of PVC vinyl films. As a result, it continues to dominate both domestic and international markets.Company Overview:With a strong foundation built on years of experience and expertise, the China-based PVC vinyl film manufacturer is constantly pushing boundaries and redefining industry standards. The company's commitment to research and development, advanced manufacturing processes, and stringent quality control measures has set it apart from competitors.The company's state-of-the-art production facilities, combined with the use of cutting-edge technology, ensure that their PVC vinyl films surpass customer expectations in terms of quality, durability, and versatility. Each product is designed to withstand varying environments and applications. Additionally, the company offers customized solutions to meet the specific requirements of different industries.Key Features and Benefits:1. Unparalleled Quality Assurance: The China-based manufacturer employs stringent quality control measures to ensure its PVC vinyl films meet the highest standards. Each product undergoes rigorous testing, enabling it to withstand extreme weather conditions, corrosion, and other demanding environments.2. Versatility: The PVC vinyl films are available in a wide range of colors, patterns, and finishes, making them suitable for various applications. From automotive interiors and building construction to signage and packaging, the company's films offer endless possibilities.3. Sustainable Production: The company is dedicated to practicing sustainable manufacturing processes. By employing eco-friendly materials and reducing waste generation, it strives to minimize its environmental impact. Additionally, the PVC vinyl films are recyclable, further promoting sustainability in the industry.4. Competitive Pricing: Despite its superior quality, the company's PVC vinyl films are competitively priced to cater to a diverse customer base. The manufacturer's commitment to affordability makes its products accessible to both small-scale businesses and larger enterprises.Market Impact and Global Reach:The China-based PVC vinyl film manufacturer has made significant strides in both domestic and international markets. Its commitment to consistently deliver exceptional products has gained the trust of numerous industries worldwide. By providing tailored solutions and maintaining efficient distribution networks, the company ensures timely delivery to clients across the globe.Future Innovations and Expansion:The company's commitment to innovation is showcased through continuous product development, research, and incorporation of emerging technologies. It aims to stay ahead of evolving market trends and meet the growing demands of customers. With plans to expand its product portfolio further and penetrate new markets, the manufacturer remains focused on its mission to revolutionize the PVC vinyl film industry.Conclusion:China's prominent PVC vinyl film manufacturer has successfully carved a niche for itself by providing high-quality products that meet the diverse needs of global consumers. The company's continuous focus on excellence, sustainability, and innovation has established it as a market leader. As it continues to expand its product range and cater to a wider customer base, the manufacturer is set to shape the future of the PVC vinyl film industry in China and beyond.

Fully Automatic Pvc Film Gypsum Ceiling Board Lamination Machine: Price List and Features

Integrating innovation and technology into the manufacturing process has always been a key drive for the {Company} since its inception. The company has continuously evolved its operations to meet the growing demands of the industry and the market. In line with this commitment, {Company} has recently introduced the latest addition to its product lineup - the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine.The Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine represents a significant advancement in the manufacturing process of gypsum ceiling boards. This state-of-the-art machine is designed to provide a seamless and efficient lamination process, ensuring high-quality output and increased productivity for gypsum board manufacturers.The machine is equipped with advanced automation features that eliminate the need for manual intervention, resulting in improved efficiency and reduced production costs. Its fully automatic operation also reduces the risk of human error, ensuring consistent and uniform lamination of PVC film on gypsum boards.The machine's versatility allows for the lamination of PVC film on gypsum boards of varying sizes and thickness, making it suitable for a wide range of production requirements. This flexibility enables gypsum board manufacturers to cater to diverse market demands and customize their products according to specific customer needs.In addition to its advanced automation capabilities, the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine is also designed with user-friendly controls and intuitive interface, making it easy to operate and maintain. This ensures that operators can quickly adapt to the machine and optimize its performance, further enhancing overall production efficiency.The introduction of this cutting-edge lamination machine underscores {Company}'s commitment to providing innovative solutions that empower gypsum board manufacturers to stay ahead in a competitive market. By leveraging the latest technology, {Company} aims to support its customers in improving their production capabilities, streamlining their operations, and delivering superior quality products to their clients.Furthermore, {Company} prides itself on its dedication to customer satisfaction, offering comprehensive technical support and training programs to ensure that customers can maximize the benefits of the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine. This commitment to customer success reflects {Company}'s long-standing reputation as a trusted partner in the industry.The launch of the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine has generated significant interest and anticipation within the gypsum board manufacturing sector. With its potential to revolutionize the lamination process, this innovative machine is set to redefine industry standards and elevate the efficiency and quality of gypsum board production.As {Company} continues to push the boundaries of technological innovation, the introduction of the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine underscores its position as a leading provider of advanced solutions for the manufacturing industry. With a proven track record of delivering reliable and high-performance equipment, {Company} remains at the forefront of driving progress and transformation in the gypsum board manufacturing sector.In conclusion, the unveiling of the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine marks a significant milestone for {Company} and the gypsum board manufacturing industry. With its advanced automation, versatility, and user-friendly design, this cutting-edge machine is poised to revolutionize the lamination process and empower manufacturers to achieve greater efficiency and quality in their production operations. As {Company} continues to uphold its commitment to innovation and customer satisfaction, the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine stands as a testament to its relentless pursuit of excellence in providing state-of-the-art solutions for the manufacturing sector.

Purchase High-Quality Automatic Potato Pringles Chips Production Line at Competitive Price

article on the benefits of using a full automatic semi-automatic potato pringles chips machine production line for businesses in the food industry.As the demand for snack foods continues to grow, especially in the fast food industry, businesses in the food industry need to keep up with the competition. One of the most popular snacks on the market today is the potato chips, which has been a favorite among people for generations. A major challenge consumer goods companies are facing globally, is meeting the demand for high-quality, delicious and healthy snack options. However, with the use of a full automatic semi-automatic potato pringles chips machine production line, businesses can produce more chips in less time and without compromising on quality.The full automatic semi-automatic potato pringles chips machine production line is a revolutionary machine that offers a wide range of benefits to businesses in the food industry. For starters, the machine ensures that the production process is properly automated. Automation helps reduce human errors and increase efficiency while reducing production costs. With this machine, businesses can produce potato chips at a faster rate, while maintaining excellent quality.Moreover, the machine has a user-friendly interface that makes it easy to operate. It also saves on space since most of the processes are conducted in one unit, making it easy to move around. Additionally, the machine is made from durable materials which ensure durability, even when used for extended periods of time.The full automatic semi-automatic potato pringles chips machine production line ensures that the production process is more hygienic. This is due to the fact that the machine is designed with food grade materials that help reduce contamination. The machines’ automatic cleaning system also ensures that the production process is more efficient and safer for workers.Businesses in the food industry who are looking to expand their production capabilities should consider investing in this machine. This is because it produces high-quality chips that are nutritious and packed with flavor. This machine ensures that businesses can meet the demand for healthier snack options by producing chips that are made with less oil. The chips are also made using fresh potatoes, making them even healthier.Furthermore, the full automatic semi-automatic potato pringles chips machine production line offers businesses an opportunity to diversify their products. Businesses can use the machine to produce different types of chips which include potato, banana, sweet potatoes, among others. The machine can produce chips with different shapes and sizes, thus allowing the business to cater to different clients’ preferences.In conclusion, any business serious about the food industry must strive to deliver high-quality products that meet the growing demand for healthier snacking options. Investing in a full automatic semi-automatic potato pringles chips machine production line will not only increase productivity but will also improve the quality of your products. The machine will help businesses automate the process, reduce production costs, increase efficiency, and expand their product line.

Affordable Roof Panel Roll Forming Machine Manufacturers and Suppliers in China with Stock Availability

If you're searching for affordable, high-quality roof panel roll forming machines, look no further than Xinhonghua. As a leading manufacturer and supplier of roll forming machines in China, we offer a comprehensive range of machines specifically designed to meet the needs of roofing contractors and others working in the construction industry. With our cheap prices and extensive inventory of machines, you're sure to find the perfect roll forming machine for your application.Our roof panel roll forming machines are meticulously designed and crafted to ensure high-quality, precision performance. We use only the best materials and components, and our machines are engineered to provide long-lasting, reliable service. Whether you're looking for a machine to produce metal roofing panels, corrugated panels, or other types of roofing panels, we have the perfect machine to meet your needs.In addition to roof panel roll forming machines, we also offer a range of other roll forming machines, including Cheap Mgo Board Forming Machine Pricelist. Our MGO board forming machines are designed to produce high-quality, fire-resistant MGO boards that are perfect for use in construction, interior finishing, and other applications. With our MGO board forming machines, you can easily produce high-volume quantities of boards quickly and efficiently.At Xinhonghua, we pride ourselves on our dedication to quality, reliability, and customer service. We understand that our success depends on the satisfaction of our customers, and we work tirelessly to ensure that our machines are up to the highest standards of excellence. Whether you're a small contractor or a large construction firm, we have the expertise and experience to provide you with the products and services you need to succeed.So if you're in the market for a new roof panel roll forming machine or Cheap Mgo Board Forming Machine Pricelist, be sure to contact us today. Our friendly and knowledgeable staff are always on hand to answer any questions you may have, and we're committed to providing you with the best possible service and support. Let us help you transform your construction business with high-quality, affordable rolling forming machines from Xinhonghua.

Lightweight MGO Board Making Machine Manufacturers - Breaking News

Headline: Light Weight Mgo Board Making Machine Factories Revolutionize Construction IndustryIntroduction (100 words):In a bid to revolutionize the construction industry, Light Weight Mgo Board Making Machine factories are emerging as pioneers in producing quality construction materials. These cutting-edge factories facilitate the production of Magnesium Oxide (Mgo) boards, which offer exceptional lightweight and fire-resistant properties. By incorporating advanced technology and highly efficient production methods, Light Weight Mgo Board Making Machine factories are paving the way for sustainable and eco-friendly construction practices. With their emphasis on superior product quality and environmental consciousness, these factories are poised to shape the future of construction materials.Paragraph 1 (100 words):Light Weight Mgo Board Making Machine factories, led by the visionary mission of {}, are setting new benchmarks in the construction industry. Their state-of-the-art machinery and production facilities are designed to produce Mgo boards that offer numerous advantages over traditional construction materials. These boards are significantly lighter in weight, making transportation and installation a breeze. Moreover, Mgo boards are highly durable and fire-resistant, ensuring the safety and longevity of buildings. With such exceptional qualities, Mgo boards have gained popularity among architects, builders, and homeowners alike.Paragraph 2 (150 words):The technology employed by Light Weight Mgo Board Making Machine factories is at the forefront of construction innovation. Their precise control systems and advanced production techniques enable the manufacturing of Mgo boards with unmatched accuracy and consistency. The factories' commitment to quality assurance and stringent quality control measures ensures that each board meets the highest industry standards. Furthermore, the high-speed production capabilities of these machines facilitate large-scale manufacturing, reducing production time significantly. As a result, construction projects can be completed faster, leading to increased efficiency and reduced labor costs.Paragraph 3 (200 words):Light Weight Mgo Board Making Machine factories prioritize sustainable and eco-friendly practices. By utilizing Magnesium Oxide as the main ingredient, their manufacturing process significantly reduces carbon emissions when compared to traditional cement-based materials. Additionally, Mgo boards are highly recyclable and can be repurposed after the lifespan of a building, further reducing environmental impact.These factories are also dedicated to minimizing waste during production. The adoption of innovative recycling techniques allows for the reuse of byproducts and waste materials generated during manufacturing, resulting in a more circular and sustainable production process. Furthermore, the lightweight nature of Mgo boards translates to reduced energy consumption during transportation and installation, minimizing the carbon footprint associated with construction projects.Paragraph 4 (150 words):In recent years, Light Weight Mgo Board Making Machine factories have gained global recognition for their contributions to sustainable construction. Their products have been adopted in a wide range of applications, including residential, commercial, and industrial buildings. Architects and designers appreciate the flexibility offered by Mgo boards, as they can be molded and shaped to fit various architectural designs. The lightweight feature also allows for seismic and wind-resistant structures, ensuring the safety of people in earthquake-prone regions.Furthermore, the fire-resistant properties of Mgo boards are highly sought after, especially in areas where building regulations require enhanced fire safety measures. Compared to traditional materials, Mgo boards offer superior fire protection, making them invaluable in safeguarding the lives and assets of building occupants.Conclusion (100 words):Light Weight Mgo Board Making Machine factories have emerged as leaders in the construction industry, pioneering sustainable and efficient construction practices. Through their advanced machinery and production methods, these factories produce lightweight, durable, and fire-resistant Mgo boards that have revolutionized the way buildings are constructed. With a focus on quality, environmentally friendly processes, and innovation, these factories are reshaping the future of construction materials. Architects, builders, and homeowners around the world are increasingly opting for Mgo boards, benefiting from their versatility, safety, and eco-friendliness.