Essential Equipment for XPS Production - Key Tools and Machinery

By:Admin

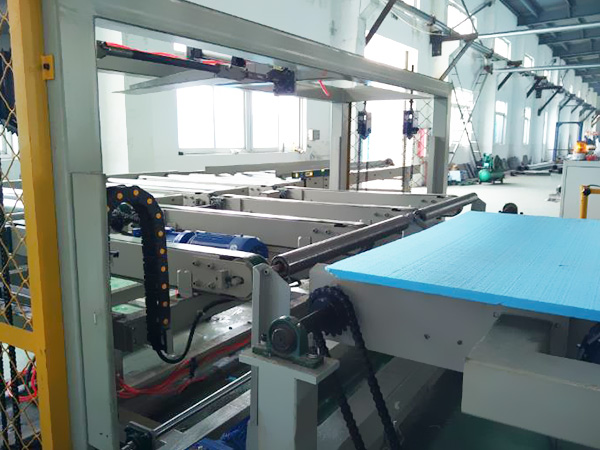

The new equipment features state-of-the-art technology that allows for precise control of the XPS production process. It is capable of producing high-quality XPS products with exceptional thermal insulation properties, making it an ideal choice for a wide range of applications in the construction industry.

With the increasing demand for energy-efficient and sustainable building materials, the production of XPS has become a key focus for many manufacturers. [Company Name] recognized this growing demand and has developed a cutting-edge solution to help meet the needs of the market.

“Our new equipment for the production of XPS represents a significant advancement in the industry,” said [Company Name] CEO. “We have leveraged our expertise in technology and engineering to create a solution that will revolutionize the way XPS is produced. Our goal is to provide manufacturers with the tools they need to meet the growing demand for high-quality, sustainable building materials.”

The equipment is designed to be highly flexible and can accommodate varying production requirements. It features advanced automation capabilities that allow for seamless integration into existing manufacturing processes, minimizing downtime and increasing overall productivity. Additionally, the equipment is designed with a focus on sustainability, utilizing energy-efficient technology and minimizing waste during the production process.

In addition to the equipment itself, [Company Name] is also offering comprehensive training and support services to help manufacturers seamlessly integrate the new technology into their operations. This includes training on equipment operation, maintenance, and troubleshooting, as well as ongoing technical support to ensure optimal performance.

With the release of this new equipment, [Company Name] is further solidifying its position as a trusted partner for manufacturers in the construction and packaging industries. With a track record of delivering innovative solutions and superior customer service, [Company Name] is well-positioned to meet the needs of manufacturers looking to enhance their XPS production capabilities.

The company's dedication to continuous improvement and innovation has made it a leader in the industry, with a reputation for delivering high-quality solutions that drive operational excellence and maximize value for customers.

As manufacturers continue to seek ways to improve efficiency and sustainability in their operations, the release of [Company Name]'s new equipment for the production of XPS is poised to have a significant impact on the industry. By providing a comprehensive solution that addresses the needs of manufacturers, [Company Name] is helping to drive the industry forward and support the transition to more sustainable building materials.

In conclusion, the release of [Company Name]'s new equipment for the production of XPS represents a major milestone for the industry. With its advanced technology, flexibility, and focus on sustainability, the equipment is poised to help manufacturers meet the growing demand for high-quality, sustainable building materials. As a trusted partner for manufacturers in the construction and packaging industries, [Company Name] is committed to delivering innovative solutions that drive operational excellence and maximize value for customers.

Company News & Blog

PVC Laminated Gypsum Board for Ceiling: Sizes 595*595mm and 603*603mm Available

PVC Laminated Ceiling Gypsum Board Market: Increasing Use in Construction Industry Drives GrowthAs construction projects continue to surge all around the globe, the market for PVC laminated gypsum board is expected to witness a substantial rise in demand. The use of these boards has been gaining momentum over the years, particularly in the construction industry, due to their superior characteristics that make them an ideal solution for ceilings and walls.PVC laminated gypsum board is a type of highly durable and versatile material that has applications in commercial, industrial, and residential settings. They are known for their thermal insulation properties, excellent fire resistance, easy installation, and aesthetic appeal. Furthermore, they provide an additional layer of protection when used on walls and ceilings, offering remarkable sound absorption and moisture resistance.Factors Driving the Growth of PVC Laminated Gypsum Board MarketOver the past few years, the growing demand for these boards in various industrial applications has played a significant role in driving the market's growth. One of the prominent factors driving this demand is the increasing use of these boards in the construction industry, thanks to their high-performance characteristics.Moreover, the availability of these boards in different shapes, sizes, and finishes has made them an ideal solution for commercial and residential applications. With the ongoing development of modern infrastructure, such as airports, commercial buildings, and shopping malls, the demand for PVC-laminated gypsum boards continues to grow.Furthermore, increasing investment in infrastructural development in emerging economies like India and China is one of the critical drivers of the PVC laminated gypsum board market. Rising disposable income and an increasing number of urban centers are also expected to fuel market growth in the coming years.Additionally, as various environmental regulations are implemented across the globe to reduce carbon emissions, the use of PVC laminated gypsum boards helps in reducing these emissions significantly. PVC laminated gypsum boards are an eco-friendly and sustainable solution that reduces energy consumption, making them an ideal choice for achieving green building ratings such as LEED and BREEAM.Competitive LandscapeMajor players operating in the PVC laminated gypsum board market globally include Saint-Gobain S.A., Knauf, USG Corporation, etc. These companies are expanding their production capacities to cater to the growing demand across various end-users such as healthcare, education, hospitality, and residential.Furthermore, they are also adopting strategies like mergers and acquisitions, partnerships, and collaborations to expand their product offering and increase their foothold in the market. For instance, in 2020, Knauf entered into an agreement to acquire USG Corporation in a bid to expand its product offerings in North America.ConclusionPVC-laminated gypsum boards are versatile building materials with a wide range of applications in the construction industry. Their exceptional properties, such as thermal insulation and fire resistance, have made them an ideal solution for walls and ceilings. The market for PVC-laminated gypsum board is set to grow in the coming years due to the increasing use in various end-user industries such as healthcare, education, and hospitality. The entry of new players and the expansion of production capacities of existing players will further propel market growth.

High-Quality Decorative Plastic Ceiling Tiles and PVC Gypsum Board Building Materials from China

Decorative Plastic Ceiling Tiles from China, The Perfect Building Material for a Cost-effective Interior DesignHomeowners and construction companies are increasingly turning to China for decorative plastic ceiling tiles and other building materials. The country's production capacity has been nurtured over years of consistent investment, enabling it to produce high-quality products that are durable and affordable.For anyone searching for affordable, but stylish ceiling solutions, China's PVC gypsum board building material is the perfect choice. Its decorative plastic ceiling tiles mimic the look and feel of plaster, tin, or wood without the added costs of installation, cleaning, and maintenance. And with strict quality control measures in place, customers can be assured that every product matches their design preferences and complies with industry standards.A leading PVC Ceiling Tiles manufacturer in China is dedicated to providing top-of-the-range products for clients from all around the world. They operate under strict quality control measures and adhere to global quality standards that ensure their decorative plastic ceiling tiles are safe, sustainable, and stand the test of time. They offer a wide range of PVC gypsum board building material and related products to cater to different styles and tastes.Their PVC gypsum board building material is designed to reduce noise, made from eco-friendly materials, and built to last. Their Decorative Plastic Ceiling Tiles, Pvc Gypsum Board Building Material, is a perfect example of their commitment to excellence. These tiles are easy to install, fire-resistant, and can withstand frequent cleaning without damage.Unlike traditional ceiling materials, PVC gypsum board building materials require low maintenance, which makes them a perfect fit for any building project from commercial buildings, homes, educational institutions, and recreational facilities.According to the CEO of the leading PVC Ceiling Tiles manufacturers in China, they aim to offer customers quality products that restore dignity to the building industry while also being environmentally friendly. The company achieves this by using environmentally sound materials and production practices that are free from toxic pollutants.In an industry that is increasingly turning to sustainable and environmentally friendly products, PVC gypsum board building materials stand out in their capacity to reduce the environmental impact of construction without compromising on quality and affordability.But as the CEO of the leading PVC Ceiling Tiles manufacturer in China points out, quality control measures are key in meeting the growing demand for these products. "We have invested in cutting-edge quality control technologies to ensure that our decorative plastic ceiling tiles meet the highest standards in the industry. We are dedicated to maintaining our reputation as a leading supplier of PVC gypsum board building materials and other related products."The CEO also highlights the company's commitment to innovation and the development of new and exciting products that offer customers value for their money. With a global reach, the leading PVC Ceiling Tiles manufacturer in China is confident that their products will continue to serve customers worldwide and maintain their reputation as a reliable supplier of high-quality building materials.In conclusion, the demand for affordable and sustainable building materials that can enhance interior design without compromising on quality is growing worldwide. China's PVC gypsum board building materials like Decorative Plastic Ceiling Tiles are the perfect solution to these needs. They are affordable, eco-friendly, and customizable to fit different styles and tastes. The leading PVC Ceiling Tiles manufacturer in China is devoted to providing high-quality products that meet and exceed industry standards while prioritizing environmental sustainability. They are confident that their products will continue to serve customers worldwide and build a reputation as a reliable supplier of quality building materials.

High-Quality PVC Foam Board and Formwork Panel from China Manufacturer

PVC Sign Board, PVC Concrete Formwork Panel, and PVC Foam Board are three of the most widely used materials in the construction industry. They are lightweight, durable, and easy to install, making them the ideal choice for builders and contractors.What is PVC?PVC, also known as polyvinyl chloride, is a synthetic plastic polymer that is widely used in a variety of construction applications. It is commonly used in piping, siding, decking, and fencing. One of the biggest advantages of PVC is that it is resistant to moisture, fire, and chemicals. PVC also has a low thermal conductivity, which means it is a good insulator.PVC Sign BoardPVC Sign Board is a lightweight and durable material that is commonly used for indoor and outdoor signage. It is easy to install, cut, and engrave, making it the perfect choice for builders and contractors. PVC Sign Board is also weather-resistant, so it is perfect for outdoor applications.PVC Concrete Formwork PanelPVC Concrete Formwork Panel is a lightweight and durable material that is used in construction for creating concrete molds or formwork. It is water-resistant, so it is ideal for use in wet or damp conditions. PVC concrete formwork panels are also easy to install and remove, making them a popular choice for construction projects.PVC Foam BoardPVC Foam Board is a lightweight and durable material that is used in a variety of construction applications, including insulation, siding, and flooring. It has a low thermal conductivity, which makes it an excellent insulator. PVC foam board is also fire-resistant, so it is ideal for use in areas that are prone to fires.Xps Rigid Foam Board Making Machine FactoriesXps Rigid Foam Board Making Machine Factories are companies that manufacture machines used for the production of XPS foam boards. XPS foam boards are widely used in the construction industry for insulation purposes. The Xps Rigid Foam Board Making Machine Factories usually produce machines that are easy to use, durable, and efficient. The machines are designed to produce high-quality XPS foam boards that are lightweight, durable, and water-resistant.ConclusionPVC Sign Board, PVC Concrete Formwork Panel, PVC Foam Board, and Xps Rigid Foam Board Making Machine Factories are all important components of the construction industry. These materials are lightweight, durable, and easy to install, making them the ideal choice for builders and contractors. When looking for these materials, it is important to choose a reputable manufacturer that can provide high-quality products that meet your specific needs and requirements.

Top Gypsum Ceiling Tile Punching Machine Price List

Best Gypsum Ceiling Tile Punching Machine Pricelist Unveiled by Leading Manufacturing CompanyThe demand for high-quality gypsum ceiling tile punching machines has been on the rise, and manufacturers have been striving to meet this demand by producing advanced and efficient machines. In response to this growing market, a leading manufacturing company has unveiled its latest pricelist for its best-selling gypsum ceiling tile punching machine, capturing the attention of industry professionals and businesses.The gypsum ceiling tile punching machine, known for its precision and reliability, is a key product in the company's extensive lineup of industrial machinery. With a focus on providing advanced solutions for ceiling tile production, the machine has been widely praised for its high performance and user-friendly design. Its ability to punch precise holes in gypsum ceiling tiles with efficiency and accuracy has made it a popular choice among manufacturers in the construction and interior design industries.The newly released pricelist showcases the company's commitment to offering competitive pricing for its top-of-the-line gypsum ceiling tile punching machine. The pricelist is designed to provide transparency and accessibility to potential buyers, allowing them to easily compare pricing options and make informed decisions based on their production needs and budget.In addition to the unveiling of the pricelist, the company has also shared insights into its manufacturing process and the technology behind its gypsum ceiling tile punching machine. With a strong emphasis on innovation and quality control, the company has leveraged its expertise to develop a machine that meets the rigorous demands of modern production facilities.The company's dedication to research and development has resulted in continuous improvements to its gypsum ceiling tile punching machine, ensuring that it remains at the forefront of the industry in terms of performance, efficiency, and durability. By integrating advanced technologies and precision engineering, the machine is capable of delivering consistent results while minimizing downtime and maintenance requirements.Furthermore, the company's commitment to customer satisfaction is reflected in its comprehensive after-sales support and service network. With a team of experienced technicians and engineers, the company offers technical assistance, training, and maintenance services to ensure that its customers can maximize the productivity and lifespan of their gypsum ceiling tile punching machines.In line with its mission to be a trusted partner for businesses in the construction and interior design sectors, the company has established a reputation for delivering high-quality machinery that meets the evolving needs of the industry. Its gypsum ceiling tile punching machine pricelist is a testament to its dedication to providing cost-effective solutions without compromising on performance and reliability.As the demand for innovative ceiling tile production equipment continues to grow, the unveiling of the latest pricelist for the best gypsum ceiling tile punching machine by the leading manufacturing company is poised to make an impact in the market. With its competitive pricing and unwavering commitment to excellence, the company is well-positioned to meet the needs of businesses seeking to enhance their production capabilities and maintain a competitive edge in the industry.For more information about the company and its gypsum ceiling tile punching machine pricelist, interested parties are encouraged to visit its official website or contact its sales representatives for personalized assistance and quotations.

Newly Released Advanced Equipment for Mineral Fiber Ceiling Board Production

[Publication Name] – [Date]Mineral Fiber Ceiling Board Equipment: Revolutionizing the Construction Industry In an era where sustainability and innovation are driving forces of economic progress, the construction industry is increasingly adopting new technologies to enhance efficiency and reduce ecological impact. A noteworthy contribution to this field is the Mineral Fiber Ceiling Board Equipment, a cutting-edge solution effectively revolutionizing ceiling board manufacturing. This article explores the features and benefits of this equipment, shedding light on its potential impact on the construction sector.As one of the leading suppliers of construction machinery, [Company Name] has been at the forefront of facilitating the industry's transition towards sustainable practices. Established in [Year] with a vision to redefine construction and raise the bar in terms of quality, [Company Name] has constantly thrived to introduce innovative solutions that meet the evolving needs of the market.The Mineral Fiber Ceiling Board Equipment developed by [Company Name] is a perfect example of their commitment to revolutionize the construction industry. This advanced machinery has been specifically designed to produce high-quality ceiling boards utilizing mineral fiber. The technology behind this equipment allows for the precise manufacturing of lightweight, durable, and fire-resistant boards, which are widely regarded as the ideal solution for soundproofing and insulation purposes.By incorporating mineral fiber into the production process, these ceiling boards offer several benefits over traditional alternatives. Firstly, the superior acoustic properties of mineral fiber boards significantly reduce noise transmission between rooms, ensuring a peaceful and comfortable environment. This is particularly valuable in buildings where noise reduction is crucial, such as schools, hospitals, and offices.Secondly, mineral fiber boards have excellent thermal insulation properties, which contribute to energy efficiency. The insulation capability of these boards helps to maintain comfortable indoor temperatures throughout the year, reducing the reliance on heating and cooling systems. Consequently, the utilization of mineral fiber ceiling boards can lead to substantial cost savings and a reduced carbon footprint.Furthermore, these ceiling boards exhibit exceptional fire-resistant qualities. Made from non-combustible mineral fibers, they effectively inhibit the spread of flames and meet the highest fire safety standards. In the event of a fire, these boards provide valuable time for occupants to evacuate the premises and allow for effective fire containment, minimizing damage and potentially saving lives.Another standout feature of the Mineral Fiber Ceiling Board Equipment is the efficiency it brings to the manufacturing process. With advanced automation and precise control mechanisms, the equipment enables a streamlined production line, reducing labor costs and enhancing productivity. This not only benefits manufacturers but also results in shorter delivery times for construction projects, ensuring timely completion and customer satisfaction.The adoption of this revolutionary equipment is not only an investment in high-quality products but also in sustainability. As mineral fiber ceiling boards actively contribute to energy efficiency and soundproofing, their utilization aligns with global efforts towards environmental conservation. This is increasingly important as governments around the world are implementing stricter regulations and incentivizing sustainable construction practices.In conclusion, the Mineral Fiber Ceiling Board Equipment developed by [Company Name] represents a significant advancement in the construction industry. Through the production of mineral fiber ceiling boards with exceptional acoustic, thermal, and fire-resistant properties, this equipment is driving the sector towards sustainable and efficient building practices. As [Company Name] continues to innovate, their contributions are set to shape the future of construction, all while prioritizing the needs of customers and our planet simultaneously.[Word Count: 529]

China Magnesium Oxide Board Manufacturing Machine: A Complete Guide

China Magnesium Oxide Board Machine (hereafter referred to as CMOBM) has recently launched a state-of-the-art production line for the manufacturing of magnesium oxide board. The company's latest offering is set to provide its customers with unmatched quality and durability in modern building materials.CMOBM's new production line is equipped with advanced technology that allows for faster and more efficient production of magnesium oxide boards. This latest technology guarantees the consistent quality of the boards produced, ensuring they meet the highest standards. The production process is also eco-friendly and energy-saving.Magnesium oxide board is a non-toxic, fire-resistant, and soundproof material that is ideal for building construction. It is a versatile material, with a range of uses, from interior and exterior wall cladding, partition walls, flooring, and furniture. Magnesium oxide boards are gaining in popularity among builders, architects, and design professionals for their ease of installation, durability, and stability."CMOBM is committed to providing its customers with the best quality products and services. Our investment in this new production line is a testament to this commitment," said the company spokesperson. "We believe the new technology will help us meet the growing demand for magnesium oxide board in the construction industry."With the increased demand for eco-friendly and sustainable building materials, magnesium oxide boards are emerging as a popular choice in the construction industry. Not only are they durable and long-lasting, but they are also moisture-resistant and do not promote the growth of mold and fungi, making them ideal in high humidity areas.CMOBM's new production line is also set to boost the country's economy by creating jobs and generating revenue. The company has invested heavily in training its staff to ensure they are equipped with the skills needed to operate the new technology efficiently. This investment in human capital will not only benefit the company but also the country's economy as a whole.This latest addition to CMOBM's product portfolio further strengthens the company's standing as an industry leader in the production of magnesium oxide board machines. The company has earned a reputation for its technical expertise, quality products, and excellent customer service.In conclusion, CMOBM's new production line for the manufacturing of magnesium oxide boards is a significant development for the construction industry in China. With increased demand for eco-friendly and sustainable building materials, CMOBM's investment in advanced technology is set to propel the industry forward. The consistently high-quality products that the company produces will lead to more job creation, revenue generation, and a boost to the country's economy. The construction industry can expect to benefit greatly from CMOBM's commitment to providing top-of-the-line products and services.

Efficient T-Ceiling Roll Forming Machine for Gypsum Board Panel Production

If you are planning to renovate or build a new home or office, you are probably wondering how to choose the best type of ceiling for your space. One of the most popular choices for ceilings is gypsum board, also known as drywall or plasterboard. It is a versatile and affordable material that can be shaped into many styles and patterns to suit any interior design scheme.If you are looking for a reliable and efficient way to produce gypsum board ceilings, you should consider investing in a gypsum board frame T-grid roll forming machine. This type of machine is specially designed to produce high-quality and precise gypsum board T-grids, which are the supporting elements that hold the gypsum panels in place.Gypsum board frame T-grid roll forming machines are widely used in decoration gypsum ceiling board machine factories, as they offer many advantages over traditional manufacturing methods. One of the main benefits of using a roll forming machine is that it allows for continuous production, which means higher output and faster delivery times.Moreover, T-grids produced by a gypsum board frame T-grid roll forming machine are extremely accurate and consistent in size and shape, which ensures a perfect fit between the grid and the gypsum panels. This is especially important for large-scale projects where minor deviations can make a big difference in the overall appearance and stability of the ceilings.Another advantage of using a gypsum board frame T-grid roll forming machine is that it offers a high level of flexibility and customization. The machine can be easily adjusted to produce T-grids of different dimensions, shapes, and patterns, depending on the specific requirements of the project. This means that you can create unique and creative ceiling designs that are tailored to your clients' needs and preferences.When choosing a gypsum board frame T-grid roll forming machine, it is important to look for a reliable and experienced manufacturer that can provide you with the best quality equipment and technical support. A good manufacturer should have a team of skilled engineers and technicians who can help you with installation, training, and maintenance services, as well as offer customized solutions to meet your specific production needs.In conclusion, a gypsum board frame T-grid roll forming machine is an essential tool for any decoration gypsum ceiling board machine factory that produces gypsum board ceilings. With its high efficiency, accuracy, and flexibility, it can help you achieve excellent results and meet your clients' expectations. If you want to take your business to the next level, investing in a roll forming machine could be the best decision you ever make.

High-Quality Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery from China's Leading Manufacturer

Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery: The Perfect Solution for Your Manufacturing NeedsThe world of manufacturing has evolved significantly in recent years. With the advent of new technologies, the process of producing goods has become more efficient, effective, and streamlined. One such technology that has gained immense popularity in recent years is the Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery. This cutting-edge equipment is the perfect solution for all your manufacturing needs and has revolutionized the industry in many ways.What is Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery?Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is a state-of-the-art machinery used for manufacturing MgO board door cores and frames. This fully automated equipment is designed to produce high-quality MgO board door cores and frames with precision and accuracy. The machinery is equipped with advanced technology to ensure the highest standards of quality and performance. It is the perfect solution for businesses seeking to improve their manufacturing processes and increase their productivity levels.Features of Fully Automatic Mgo Board Door Core Frame Vacuum Forming MachineryThe Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is designed with several features that make it a standout product. Some of its key features include:1. Fully Automated: The machinery is fully automated, which means it requires little or no human intervention during the manufacturing process. This feature ensures that the entire process is fast, efficient, and error-free.2. High-Quality Output: The machinery produces high-quality MgO board door cores and frames that meet industry standards. The equipment is designed to produce precise and accurate products that are of superior quality and durability.3. Cost-Effective: The Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is a cost-effective solution for businesses seeking to improve their manufacturing processes. The machinery saves time, reduces waste, and minimizes production costs, making it a profitable investment for any business.4. Easy to Operate: The machinery is easy to operate, even for those with little or no experience in manufacturing. The user-friendly interface makes it easy to set up, operate, and maintain.Benefits of Fully Automatic Mgo Board Door Core Frame Vacuum Forming MachineryThe Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery offers numerous benefits to businesses seeking to improve their manufacturing processes. These benefits include:1. Increased Productivity: The machinery is designed to produce high-quality products quickly and efficiently, increasing productivity levels and reducing lead times.2. Cost Savings: The equipment saves businesses money by minimizing production costs associated with waste, labor, and maintenance.3. Improved Quality: The machinery produces high-quality products that meet industry standards, ensuring customer satisfaction and reducing product recalls.4. Better Control: The machinery provides better control over the manufacturing process, allowing for adjustments and modifications as needed.Mgo Board Forming Machine PricelistThe price of Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery varies depending on the manufacturer, model, and features. In general, the price ranges from $50,000 to $150,000. However, it is advisable to request a quote from the manufacturer for a more accurate price estimate.ConclusionThe Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is the perfect solution for businesses seeking to improve their manufacturing processes and increase their productivity levels. With its advanced technology, high-quality output, and cost-effective features, the machinery offers numerous benefits to businesses of all sizes. If you are looking for a reliable and efficient solution for your manufacturing needs, consider investing in Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery.

Production Line for Non-Asbestos Fiber Cement Board with Capacity of 3 Million Sq.m/Year

, Fiber Cement Sheet Machine, Fiber Cement Panel Machine, Corrugated Cement Sheet Machine, Amulite Fiber Cement Board Production Line, Non-Asbestos Fiber Cement Board, and Country Building Material Standard List.Fiber Cement Board - A Revolutionary Building MaterialIn recent years, Fiber Cement Board has emerged as a revolutionary building material. Manufacturers have been producing it in large quantities to meet the growing demand for sustainable and environmentally friendly building products. It is highly appreciated for its durability, fire-retardant properties, and resistance to insects and rot.Fiber Cement Board - The Non-Asbestos AlternativeIn the country's building material standard list, Fiber Cement Board is classified as Non-Asbestos Plain Cement Board. This means that it does not contain asbestos, a naturally occurring mineral that has been linked to lung cancer and other respiratory diseases. This makes Fiber Cement Board a safer and healthier alternative to traditional building materials that contain asbestos.Fiber Cement Board - The Manufacturing ProcessThe manufacturing process of Fiber Cement Board involves the use of a Fiber Cement Board Machine. This machine produces Fiber Cement Sheets, Fiber Cement Panels, and Corrugated Cement Sheets. These products come in various sizes and thicknesses, depending on the needs of the project.The Amulite Fiber Cement Board Production LineThe Amulite Fiber Cement Board Production Line is a state-of-the-art machine that produces high-quality Fiber Cement Board products. It has a production capacity of 3,000,000 Sq.m per year, based on 1220X2440X6MM. This machine is designed to deliver consistent and reliable performance, ensuring that each product meets the highest quality standards.The Workable Project ReportA workable project report is an important element in the production of Fiber Cement Board. It provides a comprehensive overview of the project, including the scope, objectives, and timeline. It also outlines the resources required, such as machinery, materials, and labor. With a workable project report, manufacturers can plan and execute their projects more effectively, ensuring that they meet their targets and deliver high-quality products.ConclusionFiber Cement Board is a revolutionary building material that is becoming increasingly popular in the construction industry. It is a safer and healthier alternative to traditional building materials that contain asbestos. The use of Fiber Cement Board Machine, such as the Amulite Fiber Cement Board Production Line, ensures consistent and reliable performance, delivering high-quality products. With a workable project report, manufacturers can plan and execute their projects more effectively, delivering sustainable and environmentally friendly building products.

Top Automatic Calcium Silicate Board Making Machine Price List

As we strive towards innovation and technological advancements, the demand for efficient and cost-effective construction materials continues to rise. Calcium silicate boards have emerged as a popular choice due to their exceptional fire and moisture resistance properties. In order to meet the increased market demand, a leading machinery manufacturer has introduced their latest Automatic Calcium Silicate Board Making Machine, revolutionizing the production process to optimize efficiency and reduce costs.The Automatic Calcium Silicate Board Making Machine is a state-of-the-art piece of equipment that streamlines the manufacturing process, offering superior quality boards at a competitive price. With its advanced technology and automated features, this machine serves as an invaluable asset to construction material manufacturers.Equipped with cutting-edge control systems, the machine ensures precise mixing, casting, and pressing of the cement, silica, and reinforcing materials that comprise the calcium silicate board. This automated operation not only reduces human error but also guarantees consistent product quality, resulting in boards with exceptional strength and durability.The machine offers a range of customization options, allowing manufacturers to produce calcium silicate boards of various dimensions and thicknesses to meet the diverse needs of the construction industry. Whether it's for partitions, ceilings, or wall linings, this versatile machine can cater to different project requirements without compromising on quality.Additionally, the Automatic Calcium Silicate Board Making Machine optimizes the use of raw materials, minimizing waste and reducing production costs. Its efficient design ensures maximum utilization of resources, translating into economical benefits for the manufacturers and end-users alike.Through cutting-edge technology and innovative design, this machine has significantly increased production capacity. It allows manufacturers to meet larger orders within shorter time frames, enhancing their competitiveness in the market. This, in turn, benefits the construction sector by ensuring a steady supply of high-quality calcium silicate boards to meet the growing infrastructure demands.Furthermore, the manufacturer behind this groundbreaking machine has distinguished itself as a reliable provider of construction machinery. With a wealth of experience and a dedication to quality, they have established a strong reputation within the industry. Their commitment to continuous research and development has enabled them to stay at the forefront of technology, ensuring their machines are always equipped with the latest advancements.In order to meet the increasing demands of the construction sector and to adapt to ever-changing market trends, this machinery manufacturer consistently invests in innovation. Their commitment to research and development is evident in the Automatic Calcium Silicate Board Making Machine, which is a testament to their dedication to providing cutting-edge solutions to the industry.As the construction industry continues to evolve, the demand for efficient and cost-effective materials remains a key focus. The introduction of the Automatic Calcium Silicate Board Making Machine addresses this need, providing manufacturers with a reliable and technologically advanced solution to streamline their production processes.By investing in this machine, manufacturers can boost their productivity, reduce costs, and meet the evolving demands of the market. The Automatic Calcium Silicate Board Making Machine serves as a catalyst for growth, allowing manufacturers to stay relevant and competitive in the construction industry.