Automatic Fireproof Mgo Board Production Line: Wholesale Pricing Available

By:Admin

The demand for high-quality fireproof building materials is on the rise, and now, with the introduction of the Wholesale Automatic Fireproof Mgo Board Production Line, businesses have the opportunity to meet this demand with ease. This new production line is designed to streamline the manufacturing process, making it easier and more cost-effective to produce fireproof Mgo (Magnesium Oxide) boards at a high volume.

Manufactured by a leading company in the industry, the production line is equipped with state-of-the-art technology that ensures the consistent quality of the Mgo boards. The company has been a trusted name in the building materials market for many years, and their expertise in the production of fireproof materials is evident in the design and functionality of the production line.

The Wholesale Automatic Fireproof Mgo Board Production Line offers a wide range of capabilities, including automatic mixing, forming, cutting, and stacking of the Mgo boards. This automation not only increases the speed of production but also ensures that every board meets the required fireproof standards. This level of efficiency and precision is essential for businesses looking to satisfy the growing demand for fireproof building materials in the construction industry.

Furthermore, the production line comes with a competitive pricelist, making it a cost-effective investment for businesses of all sizes. The company understands the importance of providing affordable solutions for manufacturers, and this pricelist reflects their commitment to making the production of fireproof Mgo boards accessible to a wide range of businesses.

In addition to the production line itself, the company also offers comprehensive support and training to help businesses get the most out of their investment. This includes guidance on the setup and operation of the production line, as well as ongoing technical support to ensure smooth and efficient production processes.

The introduction of the Wholesale Automatic Fireproof Mgo Board Production Line is a game-changer for businesses involved in the manufacturing of fireproof building materials. With its advanced technology, competitive pricelist, and expert support, it is set to revolutionize the production of fireproof Mgo boards and help businesses meet the increasing demand for these materials.

As the construction industry continues to prioritize fire safety, the availability of a high-quality, automatic production line for fireproof Mgo boards comes as welcome news. Businesses can now take advantage of this opportunity to enhance their manufacturing capabilities and contribute to the creation of safer and more resilient buildings.

Overall, the Wholesale Automatic Fireproof Mgo Board Production Line is a significant advancement in the field of fireproof building materials. With its innovative technology, cost-effective pricing, and comprehensive support, it offers businesses a competitive edge in meeting the demand for high-quality fireproof Mgo boards. As the construction industry embraces the importance of fire safety, this production line is poised to make a significant impact on the market and help businesses uphold the highest standards of building safety.

Company News & Blog

High-Performance Gypsum Ceiling Board Pvc Laminating Machine for Sale - 6 Million Sqm Capacity

The [Company Name] Announces the Launch of 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine[Company Name], a leading manufacturer of machinery and equipment for the construction industry, is proud to announce the launch of its latest innovation – the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine. This state-of-the-art machine is set to revolutionize the production of gypsum ceiling boards, delivering exceptional efficiency and quality.The new machine boasts a production capacity of 6 million square meters of gypsum ceiling boards, making it one of the most advanced and high-capacity machines in the industry. With its cutting-edge technology and precision engineering, the machine is designed to meet the growing demand for high-quality gypsum ceiling boards in the construction market.[Company Name] has a long-standing reputation for delivering innovative and reliable machinery for the construction industry. With a strong focus on research and development, the company continuously strives to push the boundaries of technological advancement in its products. The launch of the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine is a testament to [Company Name]'s commitment to providing its customers with the best solutions for their production needs.The machine is equipped with advanced PVC laminating technology, ensuring a smooth and flawless finish on the gypsum ceiling boards. This not only enhances the aesthetics of the boards but also improves their durability and resistance to wear and tear. Additionally, the machine's high-speed production capabilities enable manufacturers to meet their production targets efficiently and effectively.One of the key features of the new machine is its user-friendly interface, which allows for easy operation and maintenance. This ensures that manufacturers can maximize their productivity without compromising on the quality of their products. Furthermore, the machine is designed with energy efficiency in mind, helping companies reduce their operational costs and environmental impact.In addition to its technological advancements, the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine is built to the highest standards of quality and reliability. [Company Name] prides itself on the durability and longevity of its products, and the new machine is no exception. With proper maintenance and care, customers can expect years of trouble-free operation from this cutting-edge piece of equipment.The launch of the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine is set to have a significant impact on the construction industry, particularly in the production of gypsum ceiling boards. With its unrivaled production capacity, advanced technology, and user-friendly design, the machine is poised to become a game-changer for manufacturers seeking to meet the demands of the market.[Company Name] remains committed to providing its customers with the best solutions for their production needs, and the new machine is a testament to this commitment. As the construction industry continues to evolve, [Company Name] will be at the forefront, driving innovation and delivering excellence in machinery and equipment.For more information about the 6 Million Sqm Gypsum Ceiling Board PVC Laminating Machine and other products offered by [Company Name], please visit their website or contact their sales team for inquiries.

High Quality Magnesium Wall Panels Making Machine Pricelist Revealed

Recently, there has been a surge in the demand for magnesium wall panels, as they are an innovative and environmentally-friendly alternative to traditional building materials. In response to this growing demand, {} has introduced a state-of-the-art magnesium wall panel making machine that is set to revolutionize the construction industry.The magnesium wall panel making machine is designed to produce high-quality, lightweight panels that are not only durable and fire-resistant but also easy to install and maintain. These panels are made from magnesium oxide, which is a natural mineral that is abundant in nature and has minimal environmental impact. This makes them an attractive choice for eco-conscious builders and developers who are looking to reduce their carbon footprint.One of the key advantages of the magnesium wall panel making machine is its efficiency and cost-effectiveness. The machine is capable of producing a large volume of panels in a short period of time, which helps to reduce labor costs and increase productivity. Additionally, the panels themselves are affordable, making them an attractive option for both residential and commercial construction projects.To further entice potential customers, {} has released a price list for the magnesium wall panel making machine, showcasing its competitive pricing compared to other similar machines on the market. This move is likely to attract interest from construction companies and developers who are looking to invest in the latest technology to stay ahead of the competition.{} is a leading manufacturer of construction machinery, with a strong reputation for producing high-quality, innovative products. With a focus on research and development, the company is committed to staying at the forefront of technological advancements in the construction industry. The introduction of the magnesium wall panel making machine is a testament to this commitment, demonstrating their dedication to providing cutting-edge solutions to their customers.The company's CEO expressed excitement about the potential impact of the magnesium wall panel making machine on the construction industry. "We are confident that our machine will revolutionize the way buildings are constructed. Not only are magnesium wall panels a sustainable and cost-effective option, but our machine also streamlines the production process, saving time and resources for our customers," he said.In addition to the price list for the magnesium wall panel making machine, {} is also offering comprehensive training and technical support to ensure that customers can maximize the potential of their investment. This includes on-site training for operators, as well as ongoing support for maintenance and troubleshooting.The release of the magnesium wall panel making machine and its accompanying price list marks a significant milestone for {} as they continue to expand their product offerings and solidify their position as a leader in the construction machinery industry. With a focus on innovation and customer satisfaction, the company is well-positioned to meet the evolving needs of the construction sector and drive positive change in the way buildings are designed and constructed.As the construction industry continues to embrace sustainable and cost-effective building materials, the magnesium wall panel making machine from {} is poised to play a pivotal role in shaping the future of construction. With its advanced technology, competitive pricing, and comprehensive support services, the machine is set to be a game-changer for builders and developers looking to make a positive impact on the environment while maximizing efficiency and productivity.

Manufacturers of Gypsum Cornice Production Line and Moulds for Plaster and Fiberglass Frames

Gypsum Cornice Machine Factory: A One-Stop Solution for Your Cornice NeedsWhether you're an architect, interior designer, or homeowner, finding the right cornice design can complete the look and feel of any room. A cornice, also known as crown molding, is a decorative element that's installed on the upper edge of a wall. It can add class and elegance to any space, and make it look larger and more visually appealing.However, creating the perfect cornice design requires the right tools, skills, and materials. That's where a gypsum cornice machine factory comes in. As a specialized manufacturer of cornice-related products and equipment, they can provide the following:Gypsum Cornice Production Line / Making MachineA gypsum cornice machine factory is equipped with a production line or making machine that produces high-quality gypsum cornice molds. The production line is designed to make cornice production more efficient and less time-consuming. With the help of an automated system, the cornice molds are produced quickly, accurately, and with minimal waste.Plaster Cornice TemplateA plaster cornice template is a pre-made template or pattern that serves as a guide for creating a plaster cornice. It's used to create a precise and consistent design for the cornice. A gypsum cornice machine factory can provide a wide range of plaster cornice templates that can be customized to fit any project.Fiberglass Cornice Frame ManufacturersFiberglass cornice frames are made from fiberglass-reinforced plastic (FRP) materials that are lightweight, durable, and easy to install. Their lightweight nature makes them ideal for use in structures where weight is a factor. A gypsum cornice machine factory can provide fiberglass cornice frames that are designed to fit any size or shape of the cornice.Crown MouldingCrown molding is a decorative element that's designed to add a finishing touch to a room. It's typically installed where the ceiling meets the wall, and can be made from a variety of materials, including wood, plaster, and gypsum. A gypsum cornice machine factory can provide crown molding that's made to order and customized to fit any style or design.Plaster CastingPlaster casting is the process of creating a plaster mold from an existing object or model. It's a common technique used in the production of cornices and other decorative elements. A gypsum cornice machine factory can provide plaster casting services that can create a perfect replica of any object or model.Pop Gypsum PlasterPop gypsum plaster, also known as Plaster of Paris, is a white powder made from gypsum that hardens when mixed with water. It's commonly used in the production of cornices and other decorative elements. A gypsum cornice machine factory can provide high-quality pop gypsum plaster that's specifically designed for cornice production.Drywall Gypsum BoardDrywall gypsum board is a construction material made from gypsum plaster and a paper covering. It's commonly used in interior walls and ceilings, and can be used as a base material for the installation of cornices and other decorative elements. A gypsum cornice machine factory can provide drywall gypsum boards customized to fit any size or shape of the cornice.Fiberglass Reinforced Plastic Moulds SupplierFiberglass reinforced plastic (FRP) moulds are made from fiberglass that's reinforced with plastic materials. They're lightweight, durable, and can be used to create complex shapes and designs. A gypsum cornice machine factory can provide a wide range of FRP moulds that can be customized to fit any size or shape of the cornice.China PU/Polyurethane c (need remove brand name)PU or polyurethane c (need remove brand name) is a type of material commonly used in the production of cornices and other decorative elements. It's known for its durability, flexibility, and resistance to moisture and temperature changes. A gypsum cornice machine factory can provide PU or polyurethane c (need remove brand name) that's specifically designed for cornice production.In conclusion, a gypsum cornice machine factory can provide a one-stop solution for all your cornice needs. From production line or making machine to plaster cornice templates, fiberglass cornice frames, crown molding, plaster casting, pop gypsum plaster, drywall gypsum board, fiberglass reinforced plastic moulds supplier, and China PU/polyurethane c (need remove brand name), they have everything you need to create the perfect cornice design for your project. So, if you want to create a stunning and elegant look for your space, contact a gypsum cornice machine factory today!

High-Quality Gypsum Board Making Machine for Decorative Applications

Innovation in Gypsum Board Making Machine by [Company Name][City, Date] - [Company Name], a leading manufacturer in the construction machinery industry, has recently launched a state-of-the-art Gypsum Board Making Machine, which is set to revolutionize the production process for gypsum board manufacturers.The new Decore Gypsum Board Making Machine is designed to meet the growing demand for high-quality gypsum boards in the construction industry. With advanced technology and a focus on efficiency and precision, the machine offers unparalleled performance and cost-effectiveness.The machine's cutting-edge features include a high-speed production line, automatic control system, and a modular design that allows for easy installation and maintenance. This innovative technology sets a new standard for gypsum board manufacturing, offering increased productivity and superior product quality.[Company Name] has a long history of providing innovative solutions to the construction industry, with a commitment to quality and customer satisfaction. The company's expertise in manufacturing machinery for gypsum board production has earned them a strong reputation in the market.According to [Spokesperson Name], the CEO of [Company Name], "We are thrilled to announce the launch of our new Decore Gypsum Board Making Machine. This machine is the result of years of research and development, and it represents a significant advancement in gypsum board manufacturing technology. We believe that it will provide our customers with a competitive edge in an increasingly demanding market."The Decore Gypsum Board Making Machine is set to be a game-changer for gypsum board manufacturers, offering a solution that streamlines production processes, reduces operational costs, and delivers high-quality products at a faster pace. This will enable manufacturers to meet the growing demand for gypsum boards in construction projects efficiently and effectively.[Company Name] has always been at the forefront of innovation in the construction machinery industry, and the launch of the Decore Gypsum Board Making Machine demonstrates their commitment to pushing the boundaries of technology and providing superior solutions to their customers.The company's extensive expertise in manufacturing machinery for gypsum board production, coupled with their focus on research and development, positions them as a leader in the market. Their commitment to quality, reliability, and customer service has earned them a loyal customer base and a strong reputation in the industry.As a global leader in the construction machinery industry, [Company Name] has a strong presence in the international market, with a wide network of customers and partners worldwide. The launch of the Decore Gypsum Board Making Machine is set to further solidify their position as a trusted and innovative provider of machinery solutions for the construction industry.With the introduction of the Decore Gypsum Board Making Machine, [Company Name] is paving the way for a new era in gypsum board production, offering a solution that combines cutting-edge technology with unmatched performance and reliability. This innovation is set to have a significant impact on the construction industry, providing manufacturers with the tools they need to meet the evolving demands of the market.In conclusion, the launch of the Decore Gypsum Board Making Machine by [Company Name] represents a milestone in the construction machinery industry, offering a groundbreaking solution that will shape the future of gypsum board production. With its advanced technology, efficiency, and precision, this machine sets a new standard for quality and productivity in gypsum board manufacturing, reaffirming [Company Name] as a leader in the industry.

How to Start a Mineral Fiber Ceiling Tiles Manufacturing Plant?

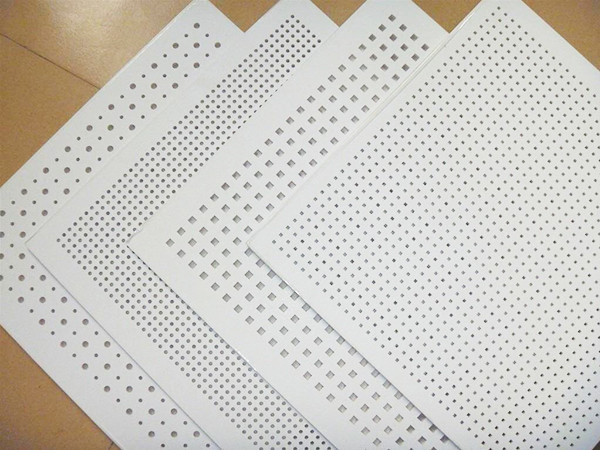

reporting the factory's production line.Mineral Fiber Ceiling Tiles Machine Factory is a renowned name in the manufacturing industry, specializing in producing mineral fiber ceiling tiles. The factory is equipped with state-of-the-art machinery and highly qualified personnel, providing a wide range of products that meet the diverse needs of its customers. The company has established itself as a leader in the industry, focusing on innovation, quality, and customer satisfaction.The manufacturing process at Mineral Fiber Ceiling Tiles Machine Factory is a well-structured and seamless operation. Starting with the raw materials, a mixture of mineral wool, perlite, and other raw materials is blended to create the base material used in making the tiles. The base material is then sent to a forming machine, which molds the material into a flat surface before it is trimmed to the desired size. The excess material is collected and recycled, making the production process environmentally friendly.Once the tiles are formed, they are sent to a drying oven, where they are allowed to dry and firm up. This crucial step ensures that the tiles are strong enough to withstand handling and installation. After drying, the tiles are sanded and inspected to ensure compliance with the strict quality standards set by the factory.The next stage of the production process involves painting the tiles to enhance their aesthetic appeal. Mineral Fiber Ceiling Tiles Machine Factory uses high-quality paint that is resistant to scratches and peels. The painting process is done using automated machinery, which ensures consistency in color and texture across all the tiles. After painting, the tiles are sent to a curing oven, where they are allowed to dry and cure, making the paint permanent.The final stage of the production process involves packaging and shipping the tiles to customers. Mineral Fiber Ceiling Tiles Machine Factory uses state-of-the-art packaging machinery that ensures that the tiles reach the customers in perfect condition. The packaging materials used are eco-friendly, and special care is taken to label the packages accurately, ensuring that the correct number of tiles is delivered to customers.Mineral Fiber Ceiling Tiles Machine Factory is known for its commitment to quality and innovation. The factory invests heavily in research and development, continually seeking to improve the quality of its products and innovate new designs that meet the changing needs of its customers. The factory's team of engineers and designers is always on the lookout for new technologies and techniques that can improve the production process and ensure that customers get the best value for their money.In conclusion, Mineral Fiber Ceiling Tiles Machine Factory is a leading manufacturer of mineral fiber ceiling tiles, providing high-quality products to customers all over the world. The factory's commitment to innovation and quality has made it a preferred choice for customers who demand the best in terms of durability, functionality, and aesthetics. The factory's modern production line, comprising state-of-the-art machinery and highly skilled personnel, is a testament to its dedication to delivering exceptional results that meet the highest standards. Mineral Fiber Ceiling Tiles Machine Factory is setting the pace for the industry and remains a model for other factories to emulate.

Affordable Mineral Fiber Board Machine Manufacturers Unveil Budget-Friendly Options

article in third person voice.Cheap Mineral Fiber Board Machine Factories Introduce Advanced Manufacturing Techniques for Affordable Production in the MarketAs the construction industry in many parts of the world continues to grow, so does the demand for high-quality building materials. This is why Cheap Mineral Fiber Board Machine Factories are growing in popularity around the globe and have stepped up to cater to this growing demand.One of the reasons these companies are leading the charge is because they have invested in the latest manufacturing technologies that enable them to produce high-quality mineral fiber boards at more affordable prices than ever before. With a commitment to quality, efficiency, and sustainability, these factories are paving the way for a brighter future in construction manufacturing.One of the best examples of a cheap mineral fiber board machine factory in the market today is a company that has been around since 1995. It started as a small workshop with a single production line and only a handful of workers. But with tireless dedication and an unwavering commitment to innovation, the factory has now expanded to more than 70 production lines and employs over 500 skilled workers.With a customer-first approach, this cheap mineral fiber board machine factory has always focused on producing top-quality mineral fiber boards at affordable prices. They make this possible by investing in advanced production equipment, such as their own fiber blowing machines and high-speed pick and place machines.These machines have made it possible for the factory to create mineral fiber boards that are not only superior in quality but are also more affordable on a large scale. By using this innovative approach to manufacturing, this particular factory has managed to streamline its production process, reduce production costs, and reduce waste significantly.However, there is a lot more to Cheap Mineral Fiber Board Machine Factories than just affordable pricing and advanced manufacturing techniques. These factories are also dedicated to preserving the environment and combating climate change by using renewable resources and reducing their carbon footprint.The factory mentioned above has invested in a variety of renewable energy sources to reduce their reliance on traditional energy sources. They have also implemented strict energy-saving measures such as automated lighting systems, low energy lighting, and the use of solar panels.Sustainability is something that is taken seriously by cheap mineral fiber board machines factories, and this company is a perfect example of how dedication to the environment can go hand in hand with manufacturing efficiency and affordability.In addition to their commitment to quality, efficiency, and sustainability, these factories are also continuously adapting to new markets. This is because the construction industry is always changing, and these factories are always up to the challenge.The factory mentioned earlier, for example, started with producing mineral fiber boards suitable for ceiling tiles. But as the construction industry evolved, the demand for different types of boards grew. This is why the factory now produces a wide variety of mineral fiber boards suitable for various types of ceilings, wall systems, and even flooring.With cheap mineral fiber board machine factories, you can be confident that you’re getting the best value for your money without sacrificing quality. Their commitment to innovation, customer service, and sustainability is what sets them apart from the rest. As the demand for high-quality building materials continues to grow worldwide, cheap mineral fiber board machine factories remain committed to providing top-quality products at affordable prices, made with the most advanced and sustainable manufacturing techniques available.

XPS Foam Board Production Line for Plastic Product Making Machinery Industry with Advanced Features

Xps Foam Board Making Equipment: The Future of Sustainable ConstructionIn the world of construction, insulation plays a vital role in achieving energy efficiency, cost savings, and environmental sustainability. And when it comes to insulation materials, XPS foam boards are quickly gaining popularity over traditional insulation materials thanks to their superior compressive strength, moisture resistance, and insulation performance. But what makes XPS foam board production possible? The answer is simple: XPS foam board making equipment.XPS foam board making equipment is an innovative machinery that allows manufacturers to produce high-quality XPS foam boards in a faster, more efficient, and cost-effective manner. It is a machine that melts polystyrene resin and injects it with a blowing agent to create foam beads. These beads are then molded into XPS foam boards of various sizes and thicknesses using a series of machines and processes.One of the main features of XPS foam board making equipment is its use of programmable logic controllers (PLC) and computer controls. These advanced systems not only make the operation of the machines more convenient and simple, but they also ensure that the production process is highly precise and accurate. The use of touchscreens and visual flow charts also makes it easy for operators to monitor and adjust the entire production process for quality control and optimization.Another notable feature of XPS foam board making equipment is its screw injection system. This system allows for precise control over the amount of vesicant or blowing agent that is injected into the mix. This results in foam boards that have uniform and consistent cell structures, which translates to better insulation performance and durability.One of the major advantages of XPS foam board making equipment is the versatility it offers in terms of the types of foam boards that it can produce. The equipment can make XPS foam boards of different thicknesses and densities, making it ideal for a wide range of applications, from roof insulation to underfloor heating and beyond. It can also be used to produce different types of foam boards such as flat, tapered, or cut to the required shape.When it comes to sustainability, XPS foam board making equipment is quickly becoming a game-changer. XPS foam boards are largely made of polystyrene resin, which is a non-biodegradable material that can have significant environmental impacts if not properly handled. However, by producing XPS foam boards with advanced machinery, manufacturers can significantly reduce the amount of waste and emissions associated with conventional foam board production processes.In conclusion, XPS foam board making equipment is a crucial component in the production of sustainable and high-performing insulation materials. With its advanced controls, screw injection system, and versatility, it offers manufacturers an efficient and effective way of producing XPS foam boards of different types, sizes, and densities. As the world continues to prioritize energy efficiency and environmental sustainability, XPS foam board making equipment will undoubtedly play a significant role in achieving these goals.

Top Manufacturers of Magnesium Plate Board Machines Revealed in Latest News

[News Title]: A Breakthrough in Magnesium Plate Board Production: Innovative Machine Introduced by Leading Manufacturers[News Content]:[date]Magnesium has long been recognized as a versatile metal with numerous industrial applications. Its lightweight, high strength, and exceptional resistance to corrosion have made it a popular choice for manufacturers across various sectors. Considered a superior alternative to traditional materials such as aluminum, steel, and plastic, magnesium plates have become increasingly sought after in recent years for use in construction, automotive, aerospace, and other industries. In line with the growing demand, {Company Name}, a leading manufacturer in the field, has introduced an innovative magnesium plate board machine that promises to revolutionize the production process.{Company Name}, operating for over [number of years] years, has established itself as a trusted name in the industry. Driven by a commitment to innovation, the company has continuously invested in research and development to improve the efficiency and quality of their products. The introduction of their new magnesium plate board machine represents a significant milestone for both the company and the industry as a whole.The cutting-edge machine, developed by a team of skilled engineers and technicians, combines state-of-the-art technology with years of experience in magnesium processing. The unique design of the machine allows for precise control over the production process, resulting in magnesium plates of unparalleled quality. With the ability to produce a wide range of thicknesses and sizes, the machine caters to the diverse needs of customers in various sectors.One of the key features of the new machine is its enhanced automation capabilities. Through an advanced control system, the machine can streamline production, ensuring a faster and more efficient manufacturing process. This not only maximizes output but also reduces human error, leading to consistently high-quality magnesium plates. Furthermore, the machine's automated material feeding system optimizes resource utilization, minimizing waste and improving overall sustainability.In addition to its exceptional performance, the magnesium plate board machine developed by {Company Name} prioritizes worker safety. Equipped with multiple safety features, including emergency stop buttons and protective barriers, the machine ensures a safe operating environment for its operators. This focus on occupational health and safety reflects the company's dedication to promoting a responsible and sustainable manufacturing process.{Company Name}'s commitment to quality extends beyond the machine itself. As a socially responsible manufacturer, the company sources its magnesium from certified suppliers, ensuring compliance with international standards and best practices. This not only guarantees the integrity of the final product but also contributes to a more sustainable supply chain overall.Given the ever-growing demand for magnesium plates, {Company Name}'s introduction of this advanced machine marks a significant step forward for the industry. By combining cutting-edge technology, efficient production processes, and a commitment to quality and safety, the company solidifies its position as a leader in the magnesium plate board manufacturing sector.Looking ahead, {Company Name} plans to continue its research and development efforts, aiming to further improve the machine's capabilities. Through ongoing innovation, they strive to meet evolving market demands, enhance customer satisfaction, and contribute to the advancement of the magnesium industry as a whole.In conclusion, the introduction of {Company Name}'s innovative magnesium plate board machine represents a groundbreaking development for the industry. With its advanced automation, emphasis on safety, and commitment to quality, the machine is set to reshape the production of magnesium plates, catering to the increasing demand across various sectors. As a leading manufacturer, {Company Name} continues to demonstrate its dedication to pushing boundaries and driving progress within the magnesium industry.

Mineral Fiber Ceiling Board Machine Receives CE Certification and Priced Competitively

Ce Certification Mineral Fiber Ceiling Board Machine PricelistThe mineral fiber ceiling board machine is a piece of equipment that is used in the production of high-quality mineral fiber ceiling boards. These boards are widely used in the construction industry for their soundproofing and fireproofing properties. The ce certification mineral fiber ceiling board machine pricelist is now available at our company, and we are proud to offer our clients this highly advanced equipment at a competitive price.Our company has been in the business of manufacturing and supplying mineral fiber ceiling board machines for over two decades. We specialize in the design and production of high-quality machines that are built to last. Our machines are not only reliable and efficient, but they are also environmentally friendly and energy-saving.We have a team of highly skilled engineers who work around the clock to ensure that our machines are up to the highest standards. Each machine is rigorously tested before it leaves our factory to ensure that it meets our strict quality control standards. We are confident in the durability and reliability of our machines and offer our clients a comprehensive warranty program that covers any defects in workmanship or materials.Our mineral fiber ceiling board machines are designed to be easy to use, with a user-friendly interface that simplifies the production process. We understand that time is of the essence in the construction industry, which is why we have designed our machines to be as automated as possible. This not only speeds up the production process but also reduces the risk of errors or accidents. Our machines can produce up to 6,000 square meters of mineral fiber ceiling boards per day.The mineral fiber ceiling board machine pricelist is highly competitive, reflecting our commitment to providing our clients with the best value for their investment. We offer a range of machines to suit different production needs and budgets. Our clients can choose from our standard range of machines or opt for a custom-built machine that is tailored to their specific needs.In addition to our mineral fiber ceiling board machines, we also offer a range of ancillary equipment, including cutting machines, edge-sealing machines, laminating machines, and packing machines. This allows our clients to have everything they need to complete the production process under one roof, making it easier and more efficient.At our company, we are committed to providing our clients with exceptional customer service. We understand that the purchase of a mineral fiber ceiling board machine is a significant investment, and we are here to support our clients every step of the way. We offer technical support, training, and maintenance services to ensure that our clients get the most out of their investment.In conclusion, the ce certification mineral fiber ceiling board machine pricelist is now available at our company, and we are proud to offer our clients this highly advanced equipment at a competitive price. Our machines are built to last and are designed to be easy to use, environmentally friendly, and energy-saving. We offer a comprehensive warranty program, ancillary equipment, and exceptional customer service to ensure that our clients get the best value for their investment. Contact us today to learn more about our mineral fiber ceiling board machines and how we can help your business grow.

Gypsum Board Production Line Supplier for Ceiling Boards

Gypsum Ceiling Board Production Line SupplierIf you are looking for high-quality gypsum board production line, then you must find the right supplier. A reliable supplier will offer you all the necessary equipment that you need to make gypsum ceiling board production without any complications.A gypsum ceiling board production line is a complex process that requires expertise and precision equipment. So, when looking for gypsum board equipment, you need to make sure that you choose a trustworthy supplier that can deliver the latest technologies without compromising the quality.Gypsum Ceiling Board Equipment PricelistWhen it comes to buying gypsum ceiling board equipment, pricing is a critical factor to consider. Therefore, you need to find a supplier that offers reasonable prices without compromising the quality of the equipment.A good supplier should provide a gypsum ceiling board equipment pricelist to help you budget for the project. This pricelist should include all the necessary equipment for gypsum board production, including the production line, raw materials, and additives. Moreover, the supplier should also provide you with all the necessary training on how to operate the equipment safely and efficiently. This will ensure that you get the most out of your investment and produce high-quality gypsum ceiling boards that meet all the relevant industry standards.Hengshui Decheng Machinery & Equipment Co., Ltd.One of the most reliable suppliers of gypsum board production equipment is Hengshui Decheng Machinery & Equipment Co., Ltd. This company has been in the business of manufacturing and selling gypsum board equipment for many years.They offer a wide range of gypsum ceiling board equipment, including the gypsum board production line, raw materials, and additives. They also provide complete solutions for the manufacturing of gypsum board, including installation, commissioning, and technical support.What makes Hengshui Decheng Machinery & Equipment Co., Ltd stand out from the rest is their commitment to quality. All their gypsum ceiling board equipment is made from high-quality materials, and they use the latest technologies to ensure that their products perform at the highest levels.ConclusionIn conclusion, finding the right gypsum ceiling board production line supplier is crucial to the success of your project. You need to find a reliable supplier that can offer you the latest equipment, reasonable prices, and excellent customer service.Hengshui Decheng Machinery & Equipment Co., Ltd is one of the leading suppliers of gypsum board production equipment. They offer a wide range of equipment, including the gypsum board production line, raw materials, and additives, at competitive prices.Therefore, if you are planning to invest in gypsum board production equipment, you can trust Hengshui Decheng Machinery & Equipment Co., Ltd to provide you with the best equipment and services for your project.