Automatic Fiber Cement Making Machine with Ce Certification at Competitive Prices

By:Admin

The fiber cement making machine is an advanced and efficient piece of equipment that is designed to produce high-quality fiber cement products, such as flat sheets, corrugated sheets, and other building materials. With the CE certification, customers can be assured that the machine meets the strict safety and quality requirements set forth by the European Union.

In order to obtain the CE certification, the company's automatic fiber cement making machine had to undergo a series of rigorous tests and inspections to ensure that it complies with all relevant EU directives and standards. This process not only validates the quality and safety of the machine but also gives customers peace of mind knowing that they are investing in a product that meets the highest industry standards.

With the CE certification in hand, the company is now able to offer its automatic fiber cement making machine to a wider range of customers in the European market. This certification opens up new opportunities for the company to expand its business and reach a larger customer base, further solidifying its position as a leading manufacturer of fiber cement production equipment.

The company takes great pride in the quality and performance of its automatic fiber cement making machine, and the CE certification is a testament to its dedication to delivering top-notch products to its customers. With this certification, the company aims to reassure its customers that they are investing in a reliable and high-quality machine that meets all necessary safety and quality standards.

In addition to the CE certification, the company is also known for its comprehensive customer support and after-sales service. The company's team of experienced professionals is dedicated to providing the highest level of support to its customers, offering assistance with installation, training, and ongoing maintenance to ensure that the automatic fiber cement making machine operates at its best.

The company is committed to remaining at the forefront of innovation in the fiber cement production industry, continually improving its products and services to meet the evolving needs of its customers. The CE certification of its automatic fiber cement making machine is a testament to the company's dedication to maintaining the highest standards of quality and safety in its products.

With the CE certification, the company is well-positioned to continue its growth and success in the European market, offering its high-quality automatic fiber cement making machine to a broader customer base. The company's commitment to excellence and customer satisfaction, combined with its industry-leading products, makes it a top choice for businesses looking to invest in cutting-edge fiber cement production equipment.

Overall, the CE certification of the company's automatic fiber cement making machine marks a significant achievement for the company and reinforces its reputation as a trusted and reliable manufacturer in the industry. As the company continues to expand its presence in the European market, it is poised to continue providing top-quality products and services to its valued customers.

Company News & Blog

Affordable Foam Board Making Machine Factories for XPS

Cheap XPS Foam Board Making Machine FactoriesIn recent years, the demand for XPS foam board has been on the rise due to its versatile applications in the construction industry. In order to meet the increasing demand, several factories have been established to manufacture XPS foam board making machines. These factories have been playing a crucial role in the production and distribution of affordable and high-quality XPS foam board making machines.One of the leading XPS foam board making machine factories is located in China, where the company has gained a reputation for providing top-notch machines at competitive prices. The company has been at the forefront of technological advancements in the field of XPS foam board making machines and has been serving customers worldwide.The XPS foam board making machines produced by the company are known for their efficiency, durability, and precision. The machines are designed to produce XPS foam boards of various sizes and densities, catering to the diverse needs of the construction industry. In addition, the company offers customization options, allowing customers to tailor the machines according to their specific requirements.The XPS foam board making machine factories have been instrumental in the advancement of the construction industry, as they have made it possible for contractors and builders to access high-quality XPS foam board making machines at affordable prices. This has not only contributed to the growth of the construction industry but has also led to the development of eco-friendly and energy-efficient buildings.The XPS foam board making machine factories are committed to providing exceptional customer service, offering technical support, and maintenance services to ensure the smooth operation of their machines. Furthermore, the factories have a strong focus on continuous research and development, aiming to improve the efficiency and performance of their machines.In addition to manufacturing XPS foam board making machines, the factories also offer training and consultation services to their customers, equipping them with the necessary knowledge and skills to maximize the potential of the machines. This level of support and dedication sets the XPS foam board making machine factories apart from the competition, making them the go-to choice for construction companies and contractors.With the increasing demand for XPS foam board, the XPS foam board making machine factories are poised to play a significant role in the construction industry. Their commitment to innovation, quality, and affordability has made them indispensable partners for construction companies looking to enhance their production capabilities.In conclusion, the XPS foam board making machine factories have emerged as key players in the advancement of the construction industry. With their dedication to providing affordable and high-quality machines, they have become crucial enablers for the production of XPS foam board. As the demand for eco-friendly and energy-efficient construction materials continues to grow, the XPS foam board making machine factories are expected to play an even more prominent role in shaping the future of the industry. Their commitment to excellence and customer satisfaction makes them the preferred choice for construction companies and contractors worldwide.For more information on the XPS foam board making machine factories, please visit their website {} for details on their products and services.

Lightweight Wall Panel Production Line for Mgo Board - Benefits and Cost Analysis

Jinan Zhongke Building Material Machinery Co., Ltd., a leading building material machinery manufacturer in China, has recently launched its latest Mgo Board Light Weight Wall Panel Production Line. The product line is designed to produce high-quality wall panels that are lightweight, fire-resistant, waterproof, and energy-efficient.The company has invested heavily in research and development to create a leading-edge Mgo Board Light Weight Wall Panel Production Line that is capable of producing wall panels of up to 3660mm*1220mm*3mm size at a rate of 1-30m/min. The production line is energy-efficient, cost-effective, and requires minimal labor for operation.According to the benefit analysis conducted by Jinan Zhongke Building Material Machinery Co., Ltd., the cost accounting for producing one wall panel includes raw material cost, water-electricity fee, and labor cost. The raw material cost for one panel is 15 yuan/piece, which is significantly lower than the price of traditional wall panels. The water-electricity fee is 0.2 yuan/piece, and the labor cost is 1.5 yuan/piece. Therefore, the total cost for one panel is 16.7 yuan/piece, which is much lower than the cost of traditional wall panels.Moreover, the Mgo Board Light Weight Wall Panel Production Line is fully automated, requiring only two workers for its operation. Thus, the labor cost is reduced, leading to higher profits for the manufacturers. The production line also has a low energy consumption rate, which reduces the overall manufacturing costs and is environmentally friendly.Jinan Zhongke Building Material Machinery Co., Ltd. is a reputable manufacturer that prioritizes customer satisfaction. The company has a team of experienced and professional engineers who provide customization services to meet the specific requirements of its clients.The Mgo Board Light Weight Wall Panel Production Line is suitable for manufacturing various types of lightweight wall panels, including partition walls, external walls, internal walls, and fire-resistant walls. The wall panels can be used in various residential and commercial buildings, such as hotels, schools, hospitals, and office complexes.In conclusion, Jinan Zhongke Building Material Machinery Co., Ltd.'s latest Mgo Board Light Weight Wall Panel Production Line is a revolutionary product that will transform the construction industry. It is cost-effective, energy-efficient, and produces high-quality wall panels that have numerous benefits over traditional wall panels. The product line's superior quality design, advanced technology, and customization services set it apart from its competitors, making it the go-to product for all lightweight wall panel needs.

High-Quality Mineral Fiber Tiles Production Line for Chinese Market

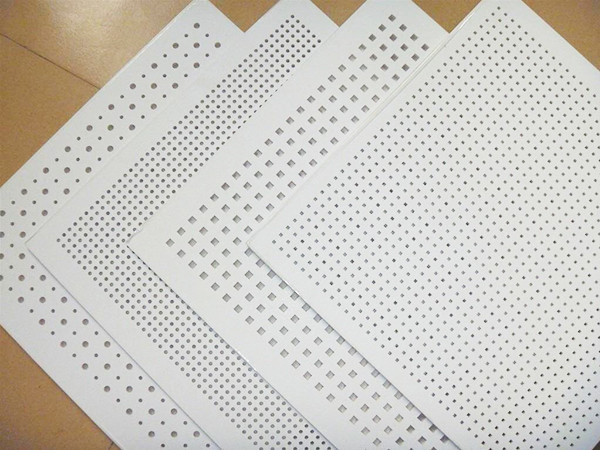

China Mineral Fiber Tiles Production Line (Company Introduction)China has always been at the forefront of technology and innovation, and its latest achievement in the field of mineral fiber tiles production is a testament to that. With the introduction of the new production line, the country is set to revolutionize the industry and further solidify its position as a global leader in manufacturing.The mineral fiber tiles production line is the result of years of research and development by a leading Chinese company in the building materials industry. The company, founded in 1995, has been dedicated to the research, development, and production of high-quality building materials, specializing in mineral fiber ceiling tiles, T-grids, and other related products.The introduction of the new production line represents a significant milestone for the company and the industry as a whole. The state-of-the-art facility is equipped with advanced technology and machinery, allowing for the efficient and cost-effective production of mineral fiber tiles. The production line is capable of producing a wide range of products, tailored to meet the specific requirements of different projects and customers.The new production line is expected to have a substantial impact on the industry, as it will not only increase the company's production capacity but also enhance the quality and variety of its products. This will enable the company to better serve its customers and meet the growing demands of the market.Furthermore, the introduction of the production line is expected to create numerous job opportunities, contributing to the country's economic growth and development. The company has always been committed to creating a positive impact on the local community and the industry as a whole, and the new production line is a step further in that direction.In addition to its commitment to excellence in production, the company also places a strong emphasis on sustainability and environmental responsibility. The new production line is designed to minimize energy consumption and waste generation, ensuring that the company's operations are as environmentally friendly as possible.The company's dedication to quality, innovation, and sustainability has earned it a reputation as a trusted and reliable partner in the industry. Its products are widely recognized for their superior quality, durability, and aesthetic appeal, making them a popular choice for builders, contractors, and homeowners alike.The introduction of the new production line is expected to further strengthen the company's position in the market and enhance its competitiveness on a global scale. With its commitment to excellence and continuous innovation, the company is set to play a significant role in shaping the future of the mineral fiber tiles industry.As the global demand for high-quality building materials continues to grow, the introduction of the new production line couldn't have come at a better time. The company is well-positioned to capitalize on the opportunities presented by the market and establish itself as a leading player in the industry.In conclusion, the introduction of the new mineral fiber tiles production line marks a significant achievement for the company and the industry as a whole. With its advanced technology, commitment to quality, and focus on sustainability, the company is poised to revolutionize the mineral fiber tiles industry and set new standards for excellence. As the company continues to grow and expand its operations, it is expected to make a lasting impact on the global building materials market.

High-Quality Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery from China's Leading Manufacturer

Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery: The Perfect Solution for Your Manufacturing NeedsThe world of manufacturing has evolved significantly in recent years. With the advent of new technologies, the process of producing goods has become more efficient, effective, and streamlined. One such technology that has gained immense popularity in recent years is the Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery. This cutting-edge equipment is the perfect solution for all your manufacturing needs and has revolutionized the industry in many ways.What is Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery?Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is a state-of-the-art machinery used for manufacturing MgO board door cores and frames. This fully automated equipment is designed to produce high-quality MgO board door cores and frames with precision and accuracy. The machinery is equipped with advanced technology to ensure the highest standards of quality and performance. It is the perfect solution for businesses seeking to improve their manufacturing processes and increase their productivity levels.Features of Fully Automatic Mgo Board Door Core Frame Vacuum Forming MachineryThe Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is designed with several features that make it a standout product. Some of its key features include:1. Fully Automated: The machinery is fully automated, which means it requires little or no human intervention during the manufacturing process. This feature ensures that the entire process is fast, efficient, and error-free.2. High-Quality Output: The machinery produces high-quality MgO board door cores and frames that meet industry standards. The equipment is designed to produce precise and accurate products that are of superior quality and durability.3. Cost-Effective: The Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is a cost-effective solution for businesses seeking to improve their manufacturing processes. The machinery saves time, reduces waste, and minimizes production costs, making it a profitable investment for any business.4. Easy to Operate: The machinery is easy to operate, even for those with little or no experience in manufacturing. The user-friendly interface makes it easy to set up, operate, and maintain.Benefits of Fully Automatic Mgo Board Door Core Frame Vacuum Forming MachineryThe Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery offers numerous benefits to businesses seeking to improve their manufacturing processes. These benefits include:1. Increased Productivity: The machinery is designed to produce high-quality products quickly and efficiently, increasing productivity levels and reducing lead times.2. Cost Savings: The equipment saves businesses money by minimizing production costs associated with waste, labor, and maintenance.3. Improved Quality: The machinery produces high-quality products that meet industry standards, ensuring customer satisfaction and reducing product recalls.4. Better Control: The machinery provides better control over the manufacturing process, allowing for adjustments and modifications as needed.Mgo Board Forming Machine PricelistThe price of Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery varies depending on the manufacturer, model, and features. In general, the price ranges from $50,000 to $150,000. However, it is advisable to request a quote from the manufacturer for a more accurate price estimate.ConclusionThe Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is the perfect solution for businesses seeking to improve their manufacturing processes and increase their productivity levels. With its advanced technology, high-quality output, and cost-effective features, the machinery offers numerous benefits to businesses of all sizes. If you are looking for a reliable and efficient solution for your manufacturing needs, consider investing in Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery.

High-quality Fireproof Board Machine for Magnesium Oxide Production

The demand for fireproof building materials has been on the rise in recent years, particularly in the construction industry. As a result, (company name) has been at the forefront of developing innovative solutions to meet these demands. Their latest advancement is the Magnesium Oxide Fireproof Board Machine, which is set to revolutionize the industry.The Magnesium Oxide Fireproof Board Machine is the result of years of research and development by (company name). It is designed to produce high-quality fireproof boards using magnesium oxide as the main ingredient. This advanced machine is equipped with state-of-the-art technology and features that ensure the production of boards that are not only fireproof but also durable and sustainable.One of the key benefits of the Magnesium Oxide Fireproof Board Machine is its ability to produce boards that are resistant to fire, water, and impact. This makes them an ideal choice for use in a wide range of building applications, including walls, ceilings, and flooring. In addition, these boards are also resistant to mold and mildew, making them a reliable and long-lasting option for construction projects.The production process of the Magnesium Oxide Fireproof Board Machine is highly efficient and environmentally friendly. It minimizes waste and reduces energy consumption, making it a sustainable and cost-effective solution for manufacturers. This is in line with (company name)'s commitment to sustainability and eco-friendly practices in all of its operations.In addition to the advanced technology and features of the machine, (company name) also provides comprehensive training and support for its customers. This ensures that manufacturers are able to operate the machine effectively and maximize its capabilities. The company's team of experts is dedicated to helping customers integrate the Magnesium Oxide Fireproof Board Machine into their production processes and achieve the best results.The introduction of the Magnesium Oxide Fireproof Board Machine is a significant milestone for (company name) and the industry as a whole. It represents a major advancement in the production of fireproof building materials and sets a new standard for quality, performance, and sustainability. With this innovative machine, (company name) is well-positioned to meet the growing demand for fireproof boards and to continue leading the way in the development of cutting-edge solutions for the construction industry.In conclusion, the Magnesium Oxide Fireproof Board Machine is a game-changer for the industry. Its advanced technology, sustainable production process, and comprehensive support make it a valuable asset for manufacturers looking to meet the demand for fireproof building materials. With this groundbreaking machine, (company name) is demonstrating its commitment to innovation, quality, and sustainability, and is poised to shape the future of the construction industry.

Fully Automatic Pvc Film Gypsum Ceiling Board Lamination Machine: Price List and Features

Integrating innovation and technology into the manufacturing process has always been a key drive for the {Company} since its inception. The company has continuously evolved its operations to meet the growing demands of the industry and the market. In line with this commitment, {Company} has recently introduced the latest addition to its product lineup - the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine.The Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine represents a significant advancement in the manufacturing process of gypsum ceiling boards. This state-of-the-art machine is designed to provide a seamless and efficient lamination process, ensuring high-quality output and increased productivity for gypsum board manufacturers.The machine is equipped with advanced automation features that eliminate the need for manual intervention, resulting in improved efficiency and reduced production costs. Its fully automatic operation also reduces the risk of human error, ensuring consistent and uniform lamination of PVC film on gypsum boards.The machine's versatility allows for the lamination of PVC film on gypsum boards of varying sizes and thickness, making it suitable for a wide range of production requirements. This flexibility enables gypsum board manufacturers to cater to diverse market demands and customize their products according to specific customer needs.In addition to its advanced automation capabilities, the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine is also designed with user-friendly controls and intuitive interface, making it easy to operate and maintain. This ensures that operators can quickly adapt to the machine and optimize its performance, further enhancing overall production efficiency.The introduction of this cutting-edge lamination machine underscores {Company}'s commitment to providing innovative solutions that empower gypsum board manufacturers to stay ahead in a competitive market. By leveraging the latest technology, {Company} aims to support its customers in improving their production capabilities, streamlining their operations, and delivering superior quality products to their clients.Furthermore, {Company} prides itself on its dedication to customer satisfaction, offering comprehensive technical support and training programs to ensure that customers can maximize the benefits of the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine. This commitment to customer success reflects {Company}'s long-standing reputation as a trusted partner in the industry.The launch of the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine has generated significant interest and anticipation within the gypsum board manufacturing sector. With its potential to revolutionize the lamination process, this innovative machine is set to redefine industry standards and elevate the efficiency and quality of gypsum board production.As {Company} continues to push the boundaries of technological innovation, the introduction of the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine underscores its position as a leading provider of advanced solutions for the manufacturing industry. With a proven track record of delivering reliable and high-performance equipment, {Company} remains at the forefront of driving progress and transformation in the gypsum board manufacturing sector.In conclusion, the unveiling of the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine marks a significant milestone for {Company} and the gypsum board manufacturing industry. With its advanced automation, versatility, and user-friendly design, this cutting-edge machine is poised to revolutionize the lamination process and empower manufacturers to achieve greater efficiency and quality in their production operations. As {Company} continues to uphold its commitment to innovation and customer satisfaction, the Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine stands as a testament to its relentless pursuit of excellence in providing state-of-the-art solutions for the manufacturing sector.

Affordable Roof Panel Roll Forming Machine Manufacturers and Suppliers in China with Stock Availability

If you're searching for affordable, high-quality roof panel roll forming machines, look no further than Xinhonghua. As a leading manufacturer and supplier of roll forming machines in China, we offer a comprehensive range of machines specifically designed to meet the needs of roofing contractors and others working in the construction industry. With our cheap prices and extensive inventory of machines, you're sure to find the perfect roll forming machine for your application.Our roof panel roll forming machines are meticulously designed and crafted to ensure high-quality, precision performance. We use only the best materials and components, and our machines are engineered to provide long-lasting, reliable service. Whether you're looking for a machine to produce metal roofing panels, corrugated panels, or other types of roofing panels, we have the perfect machine to meet your needs.In addition to roof panel roll forming machines, we also offer a range of other roll forming machines, including Cheap Mgo Board Forming Machine Pricelist. Our MGO board forming machines are designed to produce high-quality, fire-resistant MGO boards that are perfect for use in construction, interior finishing, and other applications. With our MGO board forming machines, you can easily produce high-volume quantities of boards quickly and efficiently.At Xinhonghua, we pride ourselves on our dedication to quality, reliability, and customer service. We understand that our success depends on the satisfaction of our customers, and we work tirelessly to ensure that our machines are up to the highest standards of excellence. Whether you're a small contractor or a large construction firm, we have the expertise and experience to provide you with the products and services you need to succeed.So if you're in the market for a new roof panel roll forming machine or Cheap Mgo Board Forming Machine Pricelist, be sure to contact us today. Our friendly and knowledgeable staff are always on hand to answer any questions you may have, and we're committed to providing you with the best possible service and support. Let us help you transform your construction business with high-quality, affordable rolling forming machines from Xinhonghua.

Affordable Mgo Board Equipment Quotes: Cost-Effective Solutions for Your Needs

Article:Cheap Mgo Board Equipment QuotesThe construction industry is always looking for ways to improve the quality of building materials and structural systems. The use of magnesium oxide boards (MgO) has become popular due to their durability, fire resistance, and ease of installation. MgO boards are an excellent alternative to traditional materials, providing a higher level of safety and sustainability for construction projects.The demand for MgO boards is higher than ever, with manufacturers struggling to keep up with the increased orders. In response to this demand, several companies are investing in new MgO board equipment to improve the production efficiency and reduce production costs.One such company is a leading industrial manufacturer with extensive experience in the design and production of MgO board equipment. The company believes in providing customers with high-quality, reliable, and cost-effective equipment solutions.The MgO board equipment is versatile, with a flexible production line capable of producing various MgO board sizes, thicknesses, and densities. It includes an automatic batching and mixing system, spraying system, and hydraulic pressing system. The system uses cutting-edge technology to ensure a uniform and stable board structure, achieving excellent surface flatness and density.The company's MgO board equipment is designed to be energy-efficient, reducing the energy consumption by up to 30% compared to traditional equipment. The production process is automated, reducing the labor cost, improving the production efficiency, and ensuring a consistent product quality.The company's MgO board equipment is easy to operate, with the production process controlled by a user-friendly interface. The system is also equipped with a maintenance and diagnostic system that identifies any issues and provides timely warning and maintenance instructions. This ensures a safe and reliable production process, improving the overall equipment lifespan.In response to the increased demand for MgO board equipment, the company is now offering competitive quotes for MgO board equipment and excellent after-sales service, ensuring customer satisfaction. This enables builders and contractors to access high-quality, reliable, and cost-effective equipment solutions, helping them to stay competitive in the market.The company is committed to providing innovative and sustainable solutions for the construction industry, continually improving the quality and performance of their equipment to meet the market's changing needs.ConclusionThe demand for MgO boards is rising, with more people looking for durable, fire-resistant, and environmentally-friendly construction materials. The use of new MgO board equipment is improving the production efficiency, reducing costs, and increasing product quality. The company's investment in MgO board equipment is a testament to their commitment to providing innovative and sustainable solutions for the construction industry. As builders and contractors search for durable construction materials, MgO board equipment is quickly emerging as a favored alternative to traditional materials. Their investments in magnesium oxide boards are paying off, as more builders and contractors are likely to rely on these boards in their building projects. The demand for MgO board equipment is likely to continue to rise, as builders and contractors look for better, more reliable ways to build safe, sustainable structures.

Create Custom Decorative Gypsum Ceiling Tiles with this Machine

Decorative Gypsum Ceiling Tiles Machine Revolutionizes the Construction IndustryThe construction industry has seen a significant revolution in recent years, and the introduction of the Decorative Gypsum Ceiling Tiles Machine has further cemented this change. The machine, developed by a leading company in the industry, has become a game-changer in the production of decorative gypsum ceiling tiles, breathing new life into the construction and interior design sectors.The machine, which leverages cutting-edge technology and innovative design, has redefined the production process of decorative gypsum ceiling tiles. It boasts high efficiency, precision, and versatility, allowing for the creation of intricate and unique designs that were once thought to be unattainable. This has enabled construction and design professionals to push the boundaries of creativity and offer clients a wide range of stunning and visually appealing options for their projects.In addition to revolutionizing the production process, the Decorative Gypsum Ceiling Tiles Machine has also had a significant impact on the overall quality of the tiles produced. The machine ensures that each tile is uniform in shape and size, with crisp and clean edges, resulting in an impeccable finish that is sure to impress even the most discerning clients. This level of precision and consistency has raised the bar for the industry, setting a new standard for excellence in decorative gypsum ceiling tiles.The company behind the Decorative Gypsum Ceiling Tiles Machine has a long-standing reputation for excellence and innovation in the construction and interior design industries. With a focus on customer satisfaction and a commitment to quality, the company has consistently pushed the boundaries of what is possible in the production of building materials and interior decor. This latest innovation is a testament to their dedication to advancing the industry and providing clients with the best products and solutions available.In addition to their technical expertise, the company also prides itself on its commitment to sustainability and environmental responsibility. The Decorative Gypsum Ceiling Tiles Machine is designed with energy efficiency in mind, minimizing waste and reducing the environmental impact of the production process. This aligns with the company's overarching goal of promoting sustainable and eco-friendly practices within the construction and design sectors, ensuring that they are not only meeting the needs of their clients but also contributing to a more sustainable future.The impact of the Decorative Gypsum Ceiling Tiles Machine is already being felt across the industry, with construction and design professionals embracing the new possibilities it offers. Clients are also reaping the rewards, with access to a wider range of high-quality, visually striking decorative gypsum ceiling tiles for their projects. The machine has sparked a new wave of creativity and innovation, inspiring a fresh approach to interior design and construction that is sure to shape the industry for years to come.With the introduction of the Decorative Gypsum Ceiling Tiles Machine, the company has once again positioned itself as a leader in the construction and interior design sectors. Their dedication to excellence, innovation, and sustainability has paid off, resulting in a groundbreaking development that is reshaping the way decorative gypsum ceiling tiles are produced. As the industry continues to evolve, it is clear that the company will remain at the forefront, driving progress and setting new standards for quality and creativity.

High-Quality Equipment for Xps Production

The production of XPS (Extruded Polystyrene) insulation board requires specialized equipment that is able to efficiently and effectively produce high-quality insulation products. {Company} is a leading manufacturer and supplier of equipment for the production of XPS, and they have recently introduced a new line of machinery that is set to revolutionize the industry.The equipment offered by {Company} is designed to meet the growing demand for XPS insulation products in various industries, including construction, automotive, and packaging. The new machinery boasts advanced features that not only enhance the efficiency of the production process but also improve the overall quality of the insulation boards.{Company} takes pride in their commitment to innovation and excellence, and their latest line of equipment for the production of XPS is a testament to their dedication to providing top-of-the-line solutions for their clients. With a team of experienced engineers and technicians, {Company} continuously strives to design and manufacture machinery that meets the evolving needs of the market.The newly introduced equipment for the production of XPS by {Company} incorporates state-of-the-art technologies that ensure precision and consistency in the manufacturing process. The machinery is capable of producing XPS insulation boards of varying thickness and density, catering to the diverse requirements of different applications.Apart from its high precision capabilities, the equipment also focuses on energy efficiency and environmental sustainability. {Company} recognizes the importance of reducing energy consumption and minimizing the environmental impact of production processes. As a result, the new line of machinery is designed to operate with optimal energy efficiency, contributing to a greener and more sustainable approach to XPS insulation board manufacturing.Moreover, {Company} provides comprehensive technical support and training for their clients to ensure the seamless integration and operation of the new equipment. Their team of experts is dedicated to assisting customers in optimizing the performance of the machinery and maximizing the output of high-quality XPS insulation boards.With the introduction of this new line of machinery for the production of XPS, {Company} aims to further solidify its position as a leading provider of equipment for the insulation industry. The company's unwavering commitment to innovation and customer satisfaction is reflected in the continuous development of cutting-edge solutions that address the evolving needs of the market.In conclusion, the launch of the new equipment for the production of XPS by {Company} represents a significant advancement in the insulation industry. The state-of-the-art machinery offers unparalleled precision, energy efficiency, and sustainability, catering to the growing demand for high-quality XPS insulation products. As {Company} continues to lead the way in innovation and excellence, their latest line of equipment is set to elevate the standards of XPS manufacturing and set a new benchmark for the industry.