Affordable Mineral Fiber Ceiling Equipment Manufacturers

By:Admin

The mineral fiber ceiling industry has been growing at a rapid pace, and the demand for affordable and high-quality equipment has been on the rise. In response to this, several new cheap mineral fiber ceiling equipment factories have emerged, offering a wide range of products to meet the diverse needs of the market.

One such company that has been making waves in this industry is {Company}. With a strong focus on innovation and quality, {Company} has quickly established itself as a leading manufacturer of mineral fiber ceiling equipment. Their state-of-the-art manufacturing facilities and cutting-edge technology have allowed them to produce a wide range of products that are not only cost-effective but also of premium quality.

{Company} was founded with the vision of providing cost-effective solutions to meet the growing demands of the mineral fiber ceiling industry. With a team of highly skilled engineers and technicians, they have been able to develop and manufacture a diverse range of equipment that includes ceiling tile production line, mineral wool board production line, and ceiling grid production line, among others.

The company's commitment to quality and affordability has set them apart from their competitors. They have strict quality control measures in place to ensure that every product that leaves their factory meets the highest standards. This dedication to quality has earned them a strong reputation in the industry and has helped them gain the trust of customers worldwide.

In addition to their focus on quality, {Company} also takes pride in their commitment to innovation. They constantly strive to stay ahead of the curve by investing in research and development to improve their existing products and develop new and innovative solutions. This has allowed them to cater to the evolving needs of the market and provide customers with cutting-edge equipment that delivers exceptional performance.

With a strong emphasis on customer satisfaction, {Company} has built a strong network of clients that spans across the globe. They have successfully established long-term partnerships with businesses in various countries, and their dedication to providing top-notch products and exceptional service has made them a preferred choice for many.

In a recent statement, a spokesperson for {Company} expressed their commitment to continue delivering high-quality and cost-effective solutions to meet the evolving needs of the mineral fiber ceiling industry. They highlighted their focus on sustainable and eco-friendly practices, as well as their dedication to staying at the forefront of technological advancements.

With the emergence of cheap mineral fiber ceiling equipment factories like {Company}, the industry is poised to witness significant growth and innovation. As the demand for affordable and high-quality equipment continues to rise, companies like {Company} are well-positioned to play a key role in shaping the future of the industry.

In conclusion, the rise of cheap mineral fiber ceiling equipment factories has brought about a positive change in the industry. With their focus on quality, affordability, and innovation, companies like {Company} are setting new standards and paving the way for a brighter future in the mineral fiber ceiling industry. As they continue to expand their reach and capabilities, they are poised to make a significant impact and solidify their position as key players in the market.

Company News & Blog

Affordable PVC Laminated Gypsum Board Machine Price List Unveiled in Recent News

PVC Laminated Gypsum Board Machine Aims to Reinforce Efficiency and Quality in Manufacturing ProcessIn recent industry news, a leading company in the manufacturing and distribution of gypsum board machinery, known for their commitment to innovative technology and exceptional quality, announced the introduction of a new PVC laminated gypsum board machine. This advanced machinery aims to provide a solution for enhancing efficiency and elevating the quality of gypsum board production.The machinery, which leverages cutting-edge technology and industry expertise, offers numerous advantages to manufacturers in the gypsum board industry. With a focus on increasing productivity, this machine can significantly reduce the production time required for manufacturing gypsum boards while maintaining high-quality standards. By streamlining the entire manufacturing process, companies can optimize their production output, allowing for greater profitability and customer satisfaction.One of the key features of this PVC laminated gypsum board machine is its ability to integrate the lamination process directly into the manufacturing line, eliminating the need for a separate lamination process. This integration not only saves time and labor but also ensures consistent and superior adhesion between the PVC layer and the gypsum board. By eliminating the risk of delamination, manufacturers can guarantee a longer lifespan for their gypsum boards, making them more reliable for various construction applications.Furthermore, this state-of-the-art machinery incorporates advanced control systems that enable real-time monitoring and adjustment of production parameters. This ensures precision in the manufacturing process, resulting in consistently high-quality boards with accurate dimensions and smooth surfaces. Manufacturers can also benefit from the machine's versatility, as it offers customizable settings to meet specific industry requirements or produce various board sizes and designs.With sustainability being a significant concern in today's manufacturing industry, this PVC laminated gypsum board machine incorporates eco-friendly features to reduce its environmental impact. The machinery optimizes energy consumption through efficient power management systems, minimizing energy waste during production. Additionally, it utilizes low-emission technology, reducing harmful emissions and promoting cleaner air quality in the workplace.Alongside the introduction of this new machinery, the company aims to provide comprehensive technical support and after-sales service to their clients. Their team of highly skilled engineers and technicians will be available to assist manufacturers with machine installation, training, and troubleshooting, ensuring a seamless transition into the new production process. By offering ongoing support, the company establishes a strong partnership with their clients, strengthening their reputation as a reliable and customer-oriented provider.As global demand for gypsum board continues to rise, driven by the booming construction industry, manufacturers must invest in advanced machinery to remain competitive. This new PVC laminated gypsum board machine addresses the industry's need for improved efficiency, productivity, and quality standards. By adopting this innovative solution, manufacturers can enhance their production capabilities, streamline their operations, and deliver superior gypsum board products to meet market demands.In conclusion, the introduction of the PVC laminated gypsum board machine represents a significant milestone for the manufacturing industry. With its advanced technology, integration of lamination processes, precise control systems, and eco-friendly features, this machinery aims to revolutionize the gypsum board manufacturing process. The company's commitment to providing technical support and after-sales service further demonstrates their dedication to customer satisfaction. As manufacturers embrace this groundbreaking solution, they will be well-equipped to meet the growing demand for high-quality gypsum boards in construction projects worldwide.

PVC Laminated Gypsum Board for Ceiling Construction - Various Sizes

If you're looking for a cost-effective solution to enhance the appearance of your ceiling, then you might want to consider PVC laminated gypsum ceiling boards. These boards offer many benefits and are becoming increasingly popular in the construction industry.What are PVC Laminated Gypsum Ceiling Boards?PVC laminated gypsum ceiling boards are made of high-quality paper-faced gypsum board with a layer of PVC on the surface. The gypsum board is a composite material made of gypsum plaster and a paper backing. PVC is a synthetic plastic polymer that is resistant to water, chemical damage, fire, and weathering.Advantages of PVC Laminated Gypsum Ceiling Boards1. Fire Resistance:One of the biggest advantages of PVC laminated gypsum ceiling boards is their fire resistance. Gypsum board has a natural resistance to fire, and when combined with PVC, it becomes even more fire-resistant. In case of a fire, these boards will slow the spread of flames, providing you with valuable time to evacuate the building.2. Moisture Resistant:PVC laminated gypsum ceiling boards also have good moisture resistance. With their PVC coating layer, they resist water and moisture, making them ideal for use in humid environments such as bathrooms, kitchens, and basements.3. Easy to Install:PVC laminated gypsum ceiling boards are easy to install and require minimal tools. They can be glued directly onto the ceiling or attached using furring strips. This makes them a popular choice for DIY enthusiasts and project managers alike.4. Versatile:PVC laminated gypsum ceiling boards come in a variety of sizes and designs, making them a versatile option for all kinds of residential and commercial projects. They are available in both square and rectangular shapes, allowing you to choose the size that best fits your ceiling.5. Cost-Effective:PVC laminated gypsum ceiling boards are a cost-effective option compared to other ceiling materials such as wood, metal, or plaster. They are a great way to add a decorative touch to your home or office without breaking the bank.Cheap PVC Gypsum Ceiling MachineIf you're looking for a cheap PVC gypsum ceiling machine, you're in luck. There are quite a few manufacturers producing affordable machines that can make your PVC laminated gypsum ceiling boards quickly and efficiently.When looking for a cheap PVC gypsum ceiling machine, it's essential to choose a reliable manufacturer. Ensure that the machine comes with a warranty and meets all the necessary safety standards.In conclusion, PVC laminated gypsum ceiling boards are a fantastic alternative to traditional ceiling materials. They are fire-resistant, moisture-resistant, easy to install, versatile, and cost-effective. If you're considering upgrading your ceiling, PVC laminated gypsum ceiling boards are undoubtedly worth considering. Combine that with a cheap PVC gypsum ceiling machine, and you have a winning combination that can provide a beautiful, functional, and affordable solution for your construction project.

Top Automatic Factories Producing the Best Gypsum Cornice Designs

Gypsum cornices have been used as a decorative element for centuries. They add elegance and character to any interior space. However, manually producing these ornate designs is a time-consuming and difficult process. To overcome this challenge, several automatic equipment factories have been established. Among these, one of the best gypsum cornice design automatic equipment factories is located in China.This factory, which shall remain unnamed for confidentiality reasons, specializes in the manufacture of gypsum cornice molding machines. With its highly advanced technology, this factory has gained popularity among its customers for its efficiency and quality. The automatic equipment produced by this factory is used in the production of gypsum cornices, which are widely used in interior decoration.The gypsum cornice molding machine produced by this factory is fully automatic and operates with high precision. This equipment eliminates the manual labor and production errors that often occur in traditional methods. In addition, the machine has a high production capacity which means that it can produce a large number of gypsum cornices in a shorter time without sacrificing quality.The factory uses high-quality raw materials to manufacture its machinery. The machines are made of sturdy materials that ensure the long life span of the production equipment. The factory also has strict quality control measures in place during the production process. This quality control ensures that the machinery produced is of the highest standard.The gypsum cornice molding machine produced by this factory can produce various designs and sizes of gypsum cornices. The machine can produce classic, contemporary, and customized designs. This production flexibility makes it an ideal solution for contractors and designers seeking a customizable finishing touch to their projects.The factory also provides training and after-sales services to its clients. This support ensures that clients can use the equipment properly and efficiently. It also provides assistance if there are any issues with the equipment.The gypsum cornices produced using the automatic equipment from this factory are in high demand across the world. The cornices produced are of superior quality and are used in various settings, including commercial, residential, and public spaces. The gypsum cornice design automatic equipment factory is known for its commitment to excellence and innovation. The use of technology to produce gypsum cornices has revolutionized the industry, and this factory is leading the way in this expansion of the industry.The factory's commitment to quality and innovation has made it a leader in the industry. The use of automatic equipment has made the production process efficient and cost-effective. The factory has been able to provide quality products to the market at competitive prices. This commitment to quality has earned the factory a strong reputation and a loyal customer base.The use of gypsum cornices in interior design is growing, and this factory is poised to take advantage of this upward trend. With its state-of-the-art technology and commitment to quality, this factory is positioned to remain as a leader in the industry for many years to come.In conclusion, the best gypsum cornice design automatic equipment factory, located in China, is using advanced technology to produce high-quality gypsum cornices. Their commitment to excellence and innovation has made them a leader in the industry. Their machines are efficient, cost-effective, and produce superior quality gypsum cornices. Their dedication to quality and service has earned them a loyal customer base. They have positioned themselves to remain at the forefront of the industry, contributing to the growth of the gypsum cornice industry.

How to Start a Mineral Fiber Ceiling Tiles Manufacturing Plant?

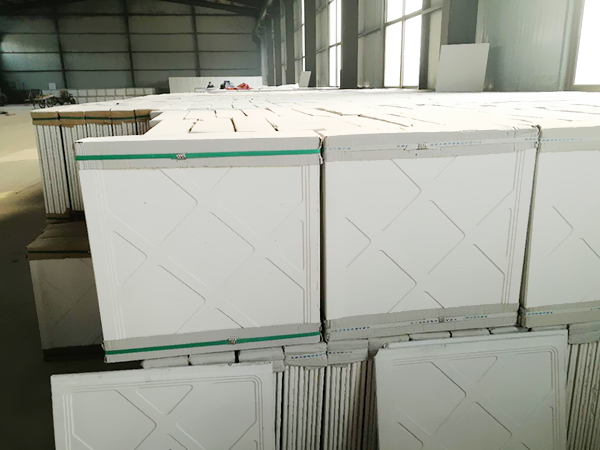

reporting the factory's production line.Mineral Fiber Ceiling Tiles Machine Factory is a renowned name in the manufacturing industry, specializing in producing mineral fiber ceiling tiles. The factory is equipped with state-of-the-art machinery and highly qualified personnel, providing a wide range of products that meet the diverse needs of its customers. The company has established itself as a leader in the industry, focusing on innovation, quality, and customer satisfaction.The manufacturing process at Mineral Fiber Ceiling Tiles Machine Factory is a well-structured and seamless operation. Starting with the raw materials, a mixture of mineral wool, perlite, and other raw materials is blended to create the base material used in making the tiles. The base material is then sent to a forming machine, which molds the material into a flat surface before it is trimmed to the desired size. The excess material is collected and recycled, making the production process environmentally friendly.Once the tiles are formed, they are sent to a drying oven, where they are allowed to dry and firm up. This crucial step ensures that the tiles are strong enough to withstand handling and installation. After drying, the tiles are sanded and inspected to ensure compliance with the strict quality standards set by the factory.The next stage of the production process involves painting the tiles to enhance their aesthetic appeal. Mineral Fiber Ceiling Tiles Machine Factory uses high-quality paint that is resistant to scratches and peels. The painting process is done using automated machinery, which ensures consistency in color and texture across all the tiles. After painting, the tiles are sent to a curing oven, where they are allowed to dry and cure, making the paint permanent.The final stage of the production process involves packaging and shipping the tiles to customers. Mineral Fiber Ceiling Tiles Machine Factory uses state-of-the-art packaging machinery that ensures that the tiles reach the customers in perfect condition. The packaging materials used are eco-friendly, and special care is taken to label the packages accurately, ensuring that the correct number of tiles is delivered to customers.Mineral Fiber Ceiling Tiles Machine Factory is known for its commitment to quality and innovation. The factory invests heavily in research and development, continually seeking to improve the quality of its products and innovate new designs that meet the changing needs of its customers. The factory's team of engineers and designers is always on the lookout for new technologies and techniques that can improve the production process and ensure that customers get the best value for their money.In conclusion, Mineral Fiber Ceiling Tiles Machine Factory is a leading manufacturer of mineral fiber ceiling tiles, providing high-quality products to customers all over the world. The factory's commitment to innovation and quality has made it a preferred choice for customers who demand the best in terms of durability, functionality, and aesthetics. The factory's modern production line, comprising state-of-the-art machinery and highly skilled personnel, is a testament to its dedication to delivering exceptional results that meet the highest standards. Mineral Fiber Ceiling Tiles Machine Factory is setting the pace for the industry and remains a model for other factories to emulate.

High-Quality 12mm Calcium Silicate Board Production Line for Sale

12mm Calcium Silicate Board Production Line Now in Operation at {}{}, a leading manufacturer of construction materials, is proud to announce the successful installation and operation of their new 12mm Calcium Silicate Board Production Line. This state-of-the-art production line is set to revolutionize the production process for calcium silicate boards, offering improved efficiency, increased output, and higher quality products.The new production line is a result of {}'s commitment to innovation and delivering top-of-the-line products to their customers. With the increasing demand for high-quality construction materials, especially in the rapidly growing infrastructure and building construction sectors, {} recognized the need for a more advanced and efficient production process for calcium silicate boards.The 12mm Calcium Silicate Board Production Line is equipped with the latest technology and machinery, allowing for a seamless and automated production process. This not only ensures a higher level of precision and consistency in the production of calcium silicate boards but also significantly increases the production capacity, allowing {} to meet the growing demand from their customers.With the new production line now in operation, {} is poised to take a leading position in the market for calcium silicate boards. The company is committed to maintaining the highest standards of quality in their products, and the new production line is a testament to this commitment.One of the key features of the new production line is its ability to produce 12mm calcium silicate boards, which are widely used in various construction applications. These boards are known for their high strength, durability, and resistance to fire and moisture, making them an ideal choice for a wide range of construction projects. With the new production line, {} will be able to produce these boards in larger quantities without compromising on quality.The installation of the 12mm Calcium Silicate Board Production Line also represents {}'s contribution to promoting sustainable and environmentally friendly construction practices. The production line is designed to minimize waste and optimize energy usage, reducing the environmental impact of the manufacturing process.In addition to the new production line, {} is also investing in research and development to further improve the quality and performance of their calcium silicate boards. The company is committed to staying ahead of the curve and meeting the evolving needs of the construction industry.The successful installation and operation of the 12mm Calcium Silicate Board Production Line marks a significant milestone for {}. It not only showcases their dedication to innovation and excellence but also positions them as a key player in the market for construction materials.With the new production line now fully operational, {} is ready to meet the increasing demand for high-quality calcium silicate boards and continue to serve their customers with the best products on the market. As the construction industry continues to grow, {} is well-positioned to meet the needs of the market and contribute to the development of sustainable and resilient infrastructure.

Gypsum Board Lamination Machine for Ceiling Board Production - EC21

Gypsum board ceiling tiles are a popular choice for many commercial and residential buildings due to their durability, fire resistance, and ability to be easily transformed to fit any design. Gypsum ceiling board making machines are essential to producing high-quality gypsum board ceiling tiles. In this article, we will discuss the features and benefits of investing in a double side gypsum board ceiling tiles laminating machine.Features and Benefits of Double Side Gypsum Board Ceiling Tiles Laminating Machine1. High-Quality Lamination: Double side gypsum board ceiling tiles laminating machine is designed to produce high-quality laminated gypsum board ceiling tiles. The machine uses advanced technology to ensure that the lamination is even, smooth, and free from bubbles.2. Increased Efficiency: The machine is equipped with high-speed rollers that enable fast lamination of the gypsum board ceiling tiles. This feature helps to increase the production capacity of the machine, reducing the time taken to produce a significant number of tiles.3. Easy to Use: The double side gypsum board ceiling tiles laminating machine is user-friendly, and operators require minimal training to operate the machine. The machine's simple design and automated features make it easy for operators to produce high-quality tiles with minimal supervision.4. Cost-Effective: Investing in a double side gypsum board ceiling tiles laminating machine is a cost-effective solution for businesses involved in the production of gypsum board ceiling tiles. The machine's high production capacity ensures that companies can produce a significant number of tiles in a short period, increasing their revenue.5. Versatile: The double side gypsum board ceiling tiles laminating machine can be used to produce a variety of gypsum board ceiling tiles, making it a versatile machine. The machine's flexibility allows businesses to accommodate different customer preferences and design requirements easily.Investing in a double side gypsum board ceiling tiles laminating machine is an excellent decision for companies involved in the production of gypsum board ceiling tiles. The machine's advanced features, high-speed rollers, ease of use, cost-effectiveness, and versatility make it an ideal choice for businesses looking to increase their production capacity and revenue. The keyword "Double Side Gypsum Board Ceiling Tiles Laminating Machine" is an essential aspect of this article and can help increase the article's visibility, especially in search engines.

Customized Abs Board Extrusion Line for XPS Heat Insulation Foamed Plate Production

Qingdao JBD Machinery is a leading manufacturer and supplier of extrusion lines that are used to produce various types of foam boards. With the advanced technology and cutting-edge machinery, the company provides a diverse range of innovative and high-performance extrusion lines to meet the growing demands of the market. The Factory Customized Abs Board Extrusion Line and XPS Heat Insulation Foamed Plate Production Line are some of its popular products with excellent performance and high reliability.The Factory Customized Abs Board Extrusion Line is designed to produce high-quality ABS foam boards, which can be used in a variety of applications such as automotive dashboards, instrument panels, and interior parts. The machine is equipped with a high-quality screw and barrel that ensures the homogeneity and consistency of the mixing process. The production line is also equipped with a precision cut-off system that produces a precise cut and ensures the uniformity of the board thickness.The XPS Heat Insulation Foamed Plate Production Line is one of the best products offered by Qingdao JBD Machinery. The extrusion line is designed to produce lightweight and strong XPS foamed boards, which are widely used as heat insulation and soundproofing materials in construction, refrigeration, and packaging industries. The board offers incomparable heat insulation traits, non-water absorption, high compressive strength, excellent heat preservation performance, and low cost. The foamed plate production line is easy and quick to execute, making it an ideal solution for various industrial applications.The XPS Heat Insulation Foamed Plate Production Line is a fully automatic extrusion line with high productivity and efficiency. The machine is equipped with a high-quality screw and barrel that ensures the uniformity of the foaming process and the homogeneity of the foam structure. The production line also features a precise cutting system that produces high-quality foam boards with uniform thickness and size. The machine can be customized according to customer requirements and can produce boards of different sizes and shapes.Qingdao JBD Machinery is committed to providing customers with high-quality products and services. The company has a team of highly qualified professionals who have extensive experience in manufacturing and designing extrusion lines. The company also provides excellent after-sales service to ensure customer satisfaction. As a leading manufacturer in China, the company has been exporting its products to different parts of the world, including North America, South America, Europe, Asia, Africa, and Oceania. The company has established long-term relationships with its customers by providing them with high-quality products, prompt delivery, and excellent service. In conclusion, Qingdao JBD Machinery is a reputable and reliable manufacturer of extrusion lines that produces high-quality products such as Factory Customized Abs Board Extrusion Line and XPS Heat Insulation Foamed Plate Production Line. The company is committed to providing innovative and cost-effective solutions to its customers, and its products are widely used in various industrial applications. With its cutting-edge technology and excellent service, Qingdao JBD Machinery is poised to become a leading player in the extrusion line manufacturing industry.

Affordable Mineral Fiber Ceiling Sheet Machine: A Cost-Effective Solution for Manufacturing

Title: Innovating Productivity: Introducing the Cheap Mineral Fiber Ceiling Sheet MachineIntroduction:In today's fast-paced and ever-changing business landscape, companies are constantly on the lookout for innovative technologies and production processes to increase efficiency and profitability. One such company leading the charge is [Company Name]. Their latest development, the Cheap Mineral Fiber Ceiling Sheet Machine, is poised to revolutionize the industry by offering an affordable solution to manufacturing high-quality mineral fiber ceiling sheets. This advanced machinery is set to transform the way businesses operate, allowing them to optimize production and meet growing consumer demands effectively.Advantages of the Cheap Mineral Fiber Ceiling Sheet Machine:The Cheap Mineral Fiber Ceiling Sheet Machine offers several advantages over traditional manufacturing methods, ultimately improving productivity, reducing costs, and ensuring superior quality. First and foremost, this state-of-the-art machine automates the production process, minimizing the need for manual labor and creating a streamlined workflow. As a result, businesses can significantly increase output while reducing production time and costs.The machine’s intelligent design enables manufacturers to customize and control various aspects of the ceiling sheet production. With adjustable speed settings, thickness control, and easy-to-use interface, businesses can tailor the manufacturing process to meet specific customer requirements efficiently. This flexibility ensures that each product matches the desired specifications, resulting in high customer satisfaction and brand loyalty.The Cheap Mineral Fiber Ceiling Sheet Machine also boasts advanced quality control mechanisms. Equipped with sensors and monitoring technology, it ensures consistent sheet quality by detecting any deviations or flaws during production. This eliminates the possibility of manufacturing defects and reduces material wastage, enhancing overall cost-effectiveness.Environmental consciousness is another key aspect of this machine. It incorporates eco-friendly features, such as energy-efficient modules, minimized noise emissions, and effective waste management systems. By reducing energy consumption and promoting sustainability, businesses can demonstrate their commitment towards a greener future.Applications and Market Impact:The global demand for mineral fiber ceiling sheets has been steadily rising, primarily driven by the construction and interior design sectors. The versatility of these sheets makes them ideal for various applications, including commercial spaces, residential buildings, schools, hospitals, and hotels. With the introduction of the Cheap Mineral Fiber Ceiling Sheet Machine, manufacturers can now cater to this increasing demand effectively.The cost-effective production capabilities provided by this machine make it an attractive proposition for businesses of all sizes, enabling small and medium enterprises to compete with larger players in the market. The affordability factor allows manufacturers to sell the end products at competitive prices, thereby gaining a significant market share. The increased accessibility to high-quality mineral fiber ceiling sheets will undoubtedly contribute to the growth and expansion of the industry.Conclusion:[Company Name] has once again proven itself as a leader in innovation by introducing the Cheap Mineral Fiber Ceiling Sheet Machine. With its automation capabilities, customizable options, and advanced quality control mechanisms, this machinery is set to redefine the manufacturing process for mineral fiber ceiling sheets. The market impact of this technology is expected to be substantial, as manufacturers now have the tools to optimize production while meeting the growing demands of consumers.In an era where productivity and efficiency are crucial for business success, the Cheap Mineral Fiber Ceiling Sheet Machine stands as a testament to the continuous advancements within the manufacturing industry. Embracing this technology ensures that companies can stay ahead of the competition, cater to evolving market demands, and deliver superior quality products in a cost-effective manner.

Top-Quality Automatic Fiber Cement Board Production Line from China

When it comes to building a sustainable and durable house, one of the most important materials to consider is the fiber cement board. This material is commonly used as siding, roofing, and even as a base for flooring. With its strength and resistance to weathering, it is a perfect choice for prefabricated houses that need to withstand harsh environmental conditions. Thanks to the latest technology, fulla Automatic Fiber Cement Board with Deep Process Lamination Production Line is now available to manufacture high-quality fiber cement boards.Fulla Automatic Fiber Cement Board with Deep Process Lamination Production Line is one of the latest advancements in the construction industry. It is a machine designed to manufacture fiber cement board efficiently and effectively. The machine is equipped with the latest technology that ensures the production of high-quality fiber cement board. The full-automatic production line can produce fiber cement boards in various sizes and thicknesses as per the customer’s requirement.The deep process lamination production line of the fulla automatic fiber cement board enhances the strength and durability of the boards. The process of lamination involves the use of high-pressure rollers that compress the fiber cement board layers. This process not only intensifies the strength of the board but also makes it more resistant to weather and moisture.One of the advantages of using fulla Automatic Fiber Cement Board with Deep Process Lamination Production Line is that it can produce a large quantity of panels in a short time. This machine can produce up to thousands of panels per day. This feature makes it ideal for mass production, especially for prefabricated housing industries.The fulla Automatic Fiber Cement Board with Deep Process Lamination Production Line is also energy-efficient. The machine is designed to reduce energy consumption, thus reducing production costs. The use of this machine ensures that the manufacturing process is environmentally friendly, as it reduces the amount of waste generated.The fulla Automatic Fiber Cement Board with Deep Process Lamination Production Line is user-friendly. It requires minimal training to operate, which means that even novice operators can operate it easily. Its user-friendly interface allows operators to monitor the production process closely.The prefabricated house industry is one of the fastest-growing sectors in the construction industry, and fiber cement boards are an essential material in building such houses. The use of fulla Automatic Fiber Cement Board with Deep Process Lamination Production Line ensures that the production of these boards is efficient, cost-effective, and environmentally friendly. The boards produced by this machine will ensure the construction of sustainable and durable prefabricated houses.In conclusion, fulla Automatic Fiber Cement Board with Deep Process Lamination Production Line is a game-changer in the construction industry. It is a machine that can produce high-quality fiber cement boards efficiently and effectively. The machine is user-friendly and energy-efficient, making it ideal for mass production. With its advanced technology, the fulla Automatic Fiber Cement Board with Deep Process Lamination Production Line ensures that the manufactured boards are durable, sustainable, and ideal for the construction of prefabricated houses.

Discover Reliable Mini Gypsum Cornice Machine Factories with CE Certification

CE Certification Mini Gypsum Cornice Machine Factories Bolster Quality Assurance in the Industry[introduction]In an exciting development for the gypsum cornice manufacturing industry, several mini gypsum cornice machine factories have received CE certification, enhancing the industry's quality assurance practices. The certification, granted by an independent certification body, affirms that these factories comply with the European Union's health, safety, and environmental protection standards. This achievement showcases the factories' commitment to delivering high-quality products while prioritizing the well-being of end-users and the environment.[Development of the Mini Gypsum Cornice Machine Factories]The mini gypsum cornice machine factories, which have recently obtained CE certification, have established themselves as key players in the industry. Offering smaller-sized machinery, these factories cater to the needs of small-scale gypsum cornice manufacturers. Their focus on mini machines reflects the industry's evolving demand for flexibility and efficiency in production processes.The development of these factories is guided by a dedication to innovation and continuous improvement in cornice manufacturing technology. Through rigorous research and development efforts, these factories have successfully developed mini gypsum cornice machines that meet the industry's standards of precision, productivity, and quality.[Advantages of CE Certification]Acquiring CE certification has numerous advantages for mini gypsum cornice machine factories. It not only demonstrates their compliance with EU regulations but also increases their competitiveness in the market. CE certification serves as a credible endorsement of these factories' commitment to providing safe and reliable miniature machines, bolstering their reputation as industry leaders.Furthermore, CE certification enables manufacturers to enter new markets and cater to a wider range of customers, domestically and internationally. Exporting machinery with CE certification removes potential barriers to trade, as many countries now require such certification for imported goods. This certification goes a long way in instilling confidence in potential buyers and strengthens business relationships across borders.[Quality Assurance and Consumer Satisfaction]CE certification plays a vital role in ensuring the quality and safety of mini gypsum cornice machines. It verifies that these machines adhere to strict manufacturing standards, including materials used, construction, and electrical safety. Through rigorous testing and inspections, accredited certification bodies assess and confirm compliance with these standards, guaranteeing that the machines do not pose any health or safety risks.This commitment to quality assurance extends to the end-users of these mini gypsum cornice machines as well. By obtaining CE certification, these factories prioritize delivering machinery that meets the highest standards of functionality, durability, and performance. Customers can rest assured knowing that their investment in these certified machines will result in efficient gypsum cornice production, minimizing downtime and maximizing productivity.[The Way Forward]The attainment of CE certification by mini gypsum cornice machine factories marks a significant milestone for the industry. It elevates the level of quality assurance within the manufacturing processes and underscores the commitment of these factories to delivering top-notch products. With increased market competitiveness and enhanced consumer satisfaction, these certified factories are poised to contribute to the continued growth and advancement of the gypsum cornice industry.In conclusion, the recent achievement of CE certification by several mini gypsum cornice machine factories reinforces the industry's commitment to excellence. This certification not only ensures compliance with EU regulations but also boosts market competitiveness. With a focus on quality assurance and customer satisfaction, these certified factories are set to drive innovation and advancement in the gypsum cornice manufacturing sector, fostering a future of sustainable growth and success.