Affordable Gypsum Cornice Machine Factories - Find the Best Deals Here

By:Admin

One of the leading manufacturers of these machines is {Company Name}. Specializing in the production of mini gypsum cornice machines, {Company Name} has quickly established itself as a go-to supplier for construction companies and contractors looking to streamline their production processes.

With a wide range of models and specifications to choose from, {Company Name} offers a versatile selection of mini gypsum cornice machines to cater to different production needs. Whether it's for a small-scale construction project or a larger commercial endeavor, their machines are designed to deliver high-quality results consistently.

The machines are also lauded for their user-friendly interface, making it easy for operators to control and adjust the settings according to the specific requirements of the cornice design. This level of flexibility has made {Company Name} a preferred choice for businesses of all sizes, looking to invest in reliable and efficient equipment.

In addition to the quality of their machines, {Company Name} prides itself on its commitment to customer satisfaction. They have a dedicated team of professionals who provide comprehensive support and guidance to clients, ensuring that they are able to maximize the potential of their mini gypsum cornice machines.

Furthermore, {Company Name} is known for its emphasis on innovation and technological advancement. They continuously invest in research and development to stay ahead of the curve and introduce cutting-edge features and improvements to their product line. As a result, their machines are equipped with the latest technology, offering enhanced performance and efficiency.

The success and excellence of {Company Name} have not gone unnoticed, with their machines being sought after by businesses in various countries. Their extensive network of distributors and partners ensures that their products are accessible to a global market, catering to the needs of construction companies around the world.

In light of the increasing demand for mini gypsum cornice machines, {Company Name} is continuously expanding its production capacity to meet the growing needs of the industry. They have made substantial investments in their manufacturing facilities, ensuring that they can deliver high-quality machines in large quantities, without compromising on quality.

The rising popularity of mini gypsum cornice machines has been attributed to the numerous benefits they offer. Not only do they streamline the production process, but they also reduce wastage and labor costs, making them a practical choice for businesses looking to improve their efficiency and productivity.

Looking ahead, {Company Name} remains committed to its mission of providing innovative and reliable solutions for the construction industry. With a strong focus on quality, customer satisfaction, and technological advancement, they are poised to continue leading the market in the production of mini gypsum cornice machines.

In conclusion, the rise of Mini Gypsum Cornice Machine Factories has revolutionized the way gypsum cornices are produced. {Company Name} stands at the forefront of this movement, providing top-of-the-line machines that are in high demand globally. With their dedication to excellence and customer satisfaction, they are well-positioned to play a pivotal role in shaping the future of the construction industry.

Company News & Blog

PVC Laminated Gypsum Board for Ceiling: Sizes 595*595mm and 603*603mm Available

PVC Laminated Ceiling Gypsum Board Market: Increasing Use in Construction Industry Drives GrowthAs construction projects continue to surge all around the globe, the market for PVC laminated gypsum board is expected to witness a substantial rise in demand. The use of these boards has been gaining momentum over the years, particularly in the construction industry, due to their superior characteristics that make them an ideal solution for ceilings and walls.PVC laminated gypsum board is a type of highly durable and versatile material that has applications in commercial, industrial, and residential settings. They are known for their thermal insulation properties, excellent fire resistance, easy installation, and aesthetic appeal. Furthermore, they provide an additional layer of protection when used on walls and ceilings, offering remarkable sound absorption and moisture resistance.Factors Driving the Growth of PVC Laminated Gypsum Board MarketOver the past few years, the growing demand for these boards in various industrial applications has played a significant role in driving the market's growth. One of the prominent factors driving this demand is the increasing use of these boards in the construction industry, thanks to their high-performance characteristics.Moreover, the availability of these boards in different shapes, sizes, and finishes has made them an ideal solution for commercial and residential applications. With the ongoing development of modern infrastructure, such as airports, commercial buildings, and shopping malls, the demand for PVC-laminated gypsum boards continues to grow.Furthermore, increasing investment in infrastructural development in emerging economies like India and China is one of the critical drivers of the PVC laminated gypsum board market. Rising disposable income and an increasing number of urban centers are also expected to fuel market growth in the coming years.Additionally, as various environmental regulations are implemented across the globe to reduce carbon emissions, the use of PVC laminated gypsum boards helps in reducing these emissions significantly. PVC laminated gypsum boards are an eco-friendly and sustainable solution that reduces energy consumption, making them an ideal choice for achieving green building ratings such as LEED and BREEAM.Competitive LandscapeMajor players operating in the PVC laminated gypsum board market globally include Saint-Gobain S.A., Knauf, USG Corporation, etc. These companies are expanding their production capacities to cater to the growing demand across various end-users such as healthcare, education, hospitality, and residential.Furthermore, they are also adopting strategies like mergers and acquisitions, partnerships, and collaborations to expand their product offering and increase their foothold in the market. For instance, in 2020, Knauf entered into an agreement to acquire USG Corporation in a bid to expand its product offerings in North America.ConclusionPVC-laminated gypsum boards are versatile building materials with a wide range of applications in the construction industry. Their exceptional properties, such as thermal insulation and fire resistance, have made them an ideal solution for walls and ceilings. The market for PVC-laminated gypsum board is set to grow in the coming years due to the increasing use in various end-user industries such as healthcare, education, and hospitality. The entry of new players and the expansion of production capacities of existing players will further propel market growth.

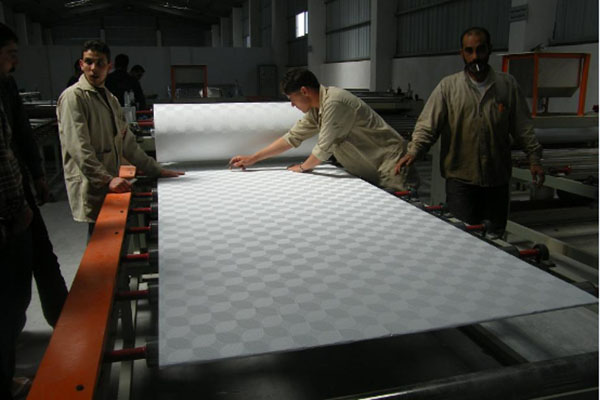

High-Quality Mineral Fiber Tiles Production Line in China

China's mineral fiber tiles production line has seen a significant boost in activity in recent times. The production line, provided by a company that specializes in the manufacturing and exporting of mineral fiber tiles, has been instrumental in meeting the growing demand for these products.The company, with its state-of-the-art production line, has been at the forefront of supplying high-quality mineral fiber tiles to various construction projects in China and abroad. With a strong focus on innovation and product development, the company has been able to establish itself as a leading player in the mineral fiber tiles industry.The mineral fiber tiles production line is designed to meet the diverse needs of customers, offering a wide range of products that cater to different design preferences and functional requirements. The production line is equipped with advanced machinery and technology, allowing for efficient and precise manufacturing processes.One of the key features of the production line is its ability to produce mineral fiber tiles in a variety of sizes, shapes, and patterns. This flexibility has enabled the company to meet the specific requirements of each project, while also offering a high level of customization to its customers.In addition to its focus on product quality and customization, the company has also prioritized sustainability and environmental responsibility in its production processes. The mineral fiber tiles production line has been designed to minimize waste and energy consumption, ensuring that the company's operations are as eco-friendly as possible.Furthermore, the company has implemented rigorous quality control measures throughout the production process, ensuring that each mineral fiber tile that leaves the production line meets the highest standards of quality and durability. This dedication to quality has earned the company a strong reputation among its customers and stakeholders.The company's commitment to excellence extends beyond its products, as it also provides exceptional customer service and support. With a team of experienced professionals, the company is able to offer technical assistance, design consultation, and project management expertise to its clients, ensuring that their needs are met at every step of the process.The success of the mineral fiber tiles production line can be attributed to the company's relentless pursuit of excellence and its ability to adapt to the ever-changing needs of the market. By staying ahead of industry trends and investing in cutting-edge technology, the company has been able to maintain its competitive edge and continue to grow its market share.Looking ahead, the company plans to further expand its production capacity and capabilities, in order to meet the increasing demand for mineral fiber tiles both domestically and internationally. With a strong track record of success and a commitment to innovation, the company is well-positioned to play a leading role in the global mineral fiber tiles industry.In conclusion, the mineral fiber tiles production line provided by the company has been a game-changer for the industry, offering high-quality, customizable products that meet the diverse needs of customers. With a focus on sustainability, quality, and customer satisfaction, the company has established itself as a trusted partner for construction projects around the world. As the company continues to grow and innovate, it is poised to remain a dominant force in the mineral fiber tiles market for years to come.

Affordable Mineral Fiber Board Machine Manufacturers Unveil Budget-Friendly Options

article in third person voice.Cheap Mineral Fiber Board Machine Factories Introduce Advanced Manufacturing Techniques for Affordable Production in the MarketAs the construction industry in many parts of the world continues to grow, so does the demand for high-quality building materials. This is why Cheap Mineral Fiber Board Machine Factories are growing in popularity around the globe and have stepped up to cater to this growing demand.One of the reasons these companies are leading the charge is because they have invested in the latest manufacturing technologies that enable them to produce high-quality mineral fiber boards at more affordable prices than ever before. With a commitment to quality, efficiency, and sustainability, these factories are paving the way for a brighter future in construction manufacturing.One of the best examples of a cheap mineral fiber board machine factory in the market today is a company that has been around since 1995. It started as a small workshop with a single production line and only a handful of workers. But with tireless dedication and an unwavering commitment to innovation, the factory has now expanded to more than 70 production lines and employs over 500 skilled workers.With a customer-first approach, this cheap mineral fiber board machine factory has always focused on producing top-quality mineral fiber boards at affordable prices. They make this possible by investing in advanced production equipment, such as their own fiber blowing machines and high-speed pick and place machines.These machines have made it possible for the factory to create mineral fiber boards that are not only superior in quality but are also more affordable on a large scale. By using this innovative approach to manufacturing, this particular factory has managed to streamline its production process, reduce production costs, and reduce waste significantly.However, there is a lot more to Cheap Mineral Fiber Board Machine Factories than just affordable pricing and advanced manufacturing techniques. These factories are also dedicated to preserving the environment and combating climate change by using renewable resources and reducing their carbon footprint.The factory mentioned above has invested in a variety of renewable energy sources to reduce their reliance on traditional energy sources. They have also implemented strict energy-saving measures such as automated lighting systems, low energy lighting, and the use of solar panels.Sustainability is something that is taken seriously by cheap mineral fiber board machines factories, and this company is a perfect example of how dedication to the environment can go hand in hand with manufacturing efficiency and affordability.In addition to their commitment to quality, efficiency, and sustainability, these factories are also continuously adapting to new markets. This is because the construction industry is always changing, and these factories are always up to the challenge.The factory mentioned earlier, for example, started with producing mineral fiber boards suitable for ceiling tiles. But as the construction industry evolved, the demand for different types of boards grew. This is why the factory now produces a wide variety of mineral fiber boards suitable for various types of ceilings, wall systems, and even flooring.With cheap mineral fiber board machine factories, you can be confident that you’re getting the best value for your money without sacrificing quality. Their commitment to innovation, customer service, and sustainability is what sets them apart from the rest. As the demand for high-quality building materials continues to grow worldwide, cheap mineral fiber board machine factories remain committed to providing top-quality products at affordable prices, made with the most advanced and sustainable manufacturing techniques available.

High-Quality Decorative Plastic Ceiling Tiles and PVC Gypsum Board Building Materials from China

Decorative Plastic Ceiling Tiles from China, The Perfect Building Material for a Cost-effective Interior DesignHomeowners and construction companies are increasingly turning to China for decorative plastic ceiling tiles and other building materials. The country's production capacity has been nurtured over years of consistent investment, enabling it to produce high-quality products that are durable and affordable.For anyone searching for affordable, but stylish ceiling solutions, China's PVC gypsum board building material is the perfect choice. Its decorative plastic ceiling tiles mimic the look and feel of plaster, tin, or wood without the added costs of installation, cleaning, and maintenance. And with strict quality control measures in place, customers can be assured that every product matches their design preferences and complies with industry standards.A leading PVC Ceiling Tiles manufacturer in China is dedicated to providing top-of-the-range products for clients from all around the world. They operate under strict quality control measures and adhere to global quality standards that ensure their decorative plastic ceiling tiles are safe, sustainable, and stand the test of time. They offer a wide range of PVC gypsum board building material and related products to cater to different styles and tastes.Their PVC gypsum board building material is designed to reduce noise, made from eco-friendly materials, and built to last. Their Decorative Plastic Ceiling Tiles, Pvc Gypsum Board Building Material, is a perfect example of their commitment to excellence. These tiles are easy to install, fire-resistant, and can withstand frequent cleaning without damage.Unlike traditional ceiling materials, PVC gypsum board building materials require low maintenance, which makes them a perfect fit for any building project from commercial buildings, homes, educational institutions, and recreational facilities.According to the CEO of the leading PVC Ceiling Tiles manufacturers in China, they aim to offer customers quality products that restore dignity to the building industry while also being environmentally friendly. The company achieves this by using environmentally sound materials and production practices that are free from toxic pollutants.In an industry that is increasingly turning to sustainable and environmentally friendly products, PVC gypsum board building materials stand out in their capacity to reduce the environmental impact of construction without compromising on quality and affordability.But as the CEO of the leading PVC Ceiling Tiles manufacturer in China points out, quality control measures are key in meeting the growing demand for these products. "We have invested in cutting-edge quality control technologies to ensure that our decorative plastic ceiling tiles meet the highest standards in the industry. We are dedicated to maintaining our reputation as a leading supplier of PVC gypsum board building materials and other related products."The CEO also highlights the company's commitment to innovation and the development of new and exciting products that offer customers value for their money. With a global reach, the leading PVC Ceiling Tiles manufacturer in China is confident that their products will continue to serve customers worldwide and maintain their reputation as a reliable supplier of high-quality building materials.In conclusion, the demand for affordable and sustainable building materials that can enhance interior design without compromising on quality is growing worldwide. China's PVC gypsum board building materials like Decorative Plastic Ceiling Tiles are the perfect solution to these needs. They are affordable, eco-friendly, and customizable to fit different styles and tastes. The leading PVC Ceiling Tiles manufacturer in China is devoted to providing high-quality products that meet and exceed industry standards while prioritizing environmental sustainability. They are confident that their products will continue to serve customers worldwide and build a reputation as a reliable supplier of quality building materials.

Find Quality Mineral Fiber Sheet Board Machine at Competitive Prices

Mineral Fiber Sheet Board Machine Pricelist Unveiled by Leading Manufacturer{Company Name}, a renowned manufacturer of industrial machinery and equipment, has recently announced the release of its latest mineral fiber sheet board machine pricelist. This new addition to the company's product lineup is set to provide customers with a high-quality and efficient solution for producing mineral fiber sheet boards.{Company Name} has a strong reputation in the industry for delivering cutting-edge machines that offer superior performance and reliability. With an extensive experience in the manufacturing of industrial equipment, the company has solidified its position as a trusted and innovative supplier to various sectors including construction, building materials, and manufacturing.The mineral fiber sheet board machine pricelist release comes as a response to the increasing demand for advanced machinery in the production of mineral fiber sheet boards. As the construction and building materials market continues to expand, there is a growing need for efficient and cost-effective solutions to meet the demands of this thriving industry.The new mineral fiber sheet board machine from {Company Name} is designed to meet the specific requirements of manufacturers looking to enhance their production capabilities. The machine boasts advanced features and cutting-edge technology that ensure the production of high-quality mineral fiber sheet boards with consistent results.One of the key highlights of the mineral fiber sheet board machine is its efficient production process, which allows for increased output while maintaining high levels of precision and quality. This is made possible through the integration of state-of-the-art automation and control systems, as well as durable and reliable components that are designed to withstand the rigors of continuous operation.In addition to its superior performance, the mineral fiber sheet board machine also offers a user-friendly interface and intuitive operation, making it easy for operators to set up and manage the production process. This streamlined operation not only enhances productivity but also minimizes the need for manual intervention, thereby reducing the risk of errors and ensuring consistent output.Furthermore, {Company Name} has emphasized the importance of affordability and cost-effectiveness in the development of the mineral fiber sheet board machine. By optimizing the design and engineering of the machine, the company has successfully managed to offer a competitive pricing structure without compromising on the quality and performance of the equipment.The unveiling of the mineral fiber sheet board machine pricelist demonstrates {Company Name}'s commitment to meeting the evolving needs of its customers and the market. By providing a comprehensive solution for mineral fiber sheet board production, the company aims to support manufacturers in achieving their production goals while maintaining high standards of quality and efficiency.The release of the mineral fiber sheet board machine pricelist is expected to generate significant interest from companies operating in the construction, building materials, and manufacturing sectors. With its proven track record of delivering reliable and innovative machinery, {Company Name} is poised to strengthen its position as a leading supplier of industrial equipment in the global market.In summary, {Company Name} has introduced its latest mineral fiber sheet board machine pricelist, catering to the increasing demand for advanced production solutions in the construction and building materials industry. With its focus on performance, reliability, and affordability, the company is set to provide customers with a competitive edge in their production operations, solidifying its position as a trusted and innovative supplier of industrial machinery.

Affordable 12mm Calcium Silicate Board Production Line Price List

A leading manufacturer of building materials, has recently released its new 12mm Calcium Silicate Board Production Line, offering a competitive price list for customers looking for high-quality construction materials. The company has established a strong reputation in the industry for producing reliable and durable products, and their new production line reaffirms their commitment to providing top-notch solutions for the construction sector.The 12mm Calcium Silicate Board Production Line is designed to meet the increasing demand for high-performance building materials in the market. With its advanced technology and efficient manufacturing process, the production line is capable of producing calcium silicate boards with a thickness of 12mm, which are ideal for various applications in the construction industry. These boards are known for their high strength, durability, and resistance to fire, making them a popular choice for building projects that require reliable and long-lasting materials.The company's new production line is equipped with state-of-the-art machinery and equipment, allowing for the efficient and cost-effective manufacturing of calcium silicate boards. This ensures that customers can benefit from high-quality products at a competitive price, making it an attractive option for contractors, builders, and developers looking to optimize their construction budgets without compromising on quality.In addition to offering a competitive price list for its new production line, the company also emphasizes the importance of sustainability and environmental responsibility in its manufacturing process. The 12mm Calcium Silicate Board Production Line is designed to minimize waste and maximize resource efficiency, ensuring that the production of calcium silicate boards is carried out in an environmentally friendly manner. This aligns with the company's commitment to sustainability and its efforts to reduce the environmental impact of its operations.The company's dedication to quality and customer satisfaction is reflected in its extensive experience in the industry. With a strong track record of delivering reliable and durable building materials, the company has built a solid reputation for excellence, earning the trust and loyalty of its customers. This reputation is further solidified with the introduction of the new 12mm Calcium Silicate Board Production Line, which showcases the company's continued focus on innovation and product development to meet the evolving needs of the construction industry.By offering a competitive price list for its new production line, the company aims to make high-quality calcium silicate boards more accessible to a wider range of customers. This not only benefits contractors and builders who require cost-effective solutions for their projects but also contributes to the overall advancement of the construction industry by promoting the use of reliable and durable building materials.In conclusion, the release of the new 12mm Calcium Silicate Board Production Line with a competitive price list reflects the company's ongoing commitment to excellence, innovation, and sustainability. By combining advanced technology with efficient manufacturing processes, the company is able to offer high-quality construction materials at a competitive price point, meeting the needs of a diverse customer base. With its strong reputation in the industry and dedication to customer satisfaction, the company is well-positioned to make a significant impact in the construction sector with its new production line.

High-quality Magnesium Oxide Board Machine for Sale - Complete Solutions

[Company Introduction]With years of experience in the magnesium oxide board industry, our company has become a leading manufacturer and supplier of magnesium oxide board machines. Our cutting-edge technology and innovative machinery have enabled us to meet the growing demand for high-quality magnesium oxide board production equipment.We have a team of experienced engineers and technicians who are dedicated to designing and manufacturing state-of-the-art magnesium oxide board machines that are efficient, reliable, and cost-effective. Our commitment to quality and customer satisfaction has earned us a strong reputation in the industry, and we are proud to serve customers from all around the world.[News Content]Magnesium oxide board, also known as MgO board, is a versatile and environmentally friendly building material that has gained popularity in recent years due to its excellent fire resistance, moisture resistance, and durability. As the demand for magnesium oxide board continues to rise, the need for advanced production equipment has become increasingly important.In response to this growing demand, our company has introduced a new and improved magnesium oxide board machine that is set to revolutionize the industry. The new machine incorporates the latest technological advancements in magnesium oxide board production, offering increased efficiency, precision, and output capacity.One of the key features of the new magnesium oxide board machine is its advanced automation system, which allows for seamless and precise control of the production process. This not only improves the overall quality of the magnesium oxide boards but also significantly reduces production time and resource wastage.Additionally, the machine is equipped with state-of-the-art sensors and monitoring systems that enable real-time data collection and analysis, ensuring consistent and uniform board quality. These technological advancements not only streamline the production process but also reduce the margin of error, resulting in higher-quality magnesium oxide boards.Furthermore, the new magnesium oxide board machine has been designed with sustainability in mind. It utilizes energy-efficient components and processes, reducing overall energy consumption and environmental impact. This reflects our company’s commitment to sustainable and eco-friendly manufacturing practices, aligning with the global trend towards green building materials.The introduction of the new magnesium oxide board machine marks a significant milestone for our company, showcasing our dedication to innovation and advancement in the magnesium oxide board industry. We are confident that the new machine will set a new standard for magnesium oxide board production, providing our customers with a reliable and efficient solution for their manufacturing needs.In addition to the new magnesium oxide board machine, our company offers a comprehensive range of services, including technical support, equipment installation, and training programs. We are committed to ensuring that our customers receive the highest level of support and expertise, allowing them to maximize the potential of their magnesium oxide board production operations.As we continue to push the boundaries of magnesium oxide board manufacturing, we are excited to embark on this new chapter with the launch of our state-of-the-art magnesium oxide board machine. We are dedicated to providing our customers with the tools and resources they need to succeed in the competitive magnesium oxide board market, and we are confident that our new machine will help them achieve their production goals efficiently and effectively.

Affordable Machine for Manufacturing Magnesium Wall Panels

Title: New Magnesium Wall Panels Manufacturing Machine Revolutionizes Construction IndustryIntroduction:In a groundbreaking development for the construction industry, an innovative company recently unveiled an advanced magnesium wall panels making machine. This cutting-edge technology promises to streamline the production process of magnesium-based building materials, revolutionizing the construction sector.The Importance of Magnesium Wall Panels:Magnesium wall panels have gained rapid popularity in recent years due to their exceptional properties. These panels are lightweight, fire-resistant, and possess excellent acoustic qualities. They are also resistant to mold and pests, making them an ideal solution for both residential and commercial projects.Company Background:{Company Name}, a well-established and renowned manufacturing company, has long been recognized as a leading provider of advanced construction materials. With a strong commitment to innovation, they have invested heavily in research and development, constantly striving to deliver superior products that address industry challenges.Introduction of the Magnesium Wall Panels Making Machine:{Company Name}'s latest breakthrough comes in the form of a highly efficient automated machine specifically designed for the mass-production of magnesium wall panels. This state-of-the-art equipment integrates advanced technology with precision engineering to meet the rising demands of the construction industry.Key Features and Advantages:This new machine offers several key features and advantages, cementing its position as a game-changer in the field of construction materials:1. Increased Production Capacity: The machine allows for a significant increase in production output, fulfilling market demands more efficiently than ever before. This will help alleviate supply shortages and reduce project completion time.2. Enhanced Precision and Quality: By employing advanced automation and artificial intelligence, the machine ensures precise molding and cutting, resulting in consistently high-quality magnesium wall panels. This will provide builders and contractors with reliable and durable construction materials.3. Reduced Labor Requirements: With automated processes, the need for extensive manual labor is greatly minimized. This reduces overall production costs and allows employees to focus on more intricate tasks, ensuring greater productivity.4. Environmentally Friendly: Magnesium wall panels are inherently sustainable due to their low carbon footprint. The new manufacturing machine is designed to further optimize resource utilization, minimizing waste and decreasing energy consumption during production.Impact on the Construction Industry:The introduction of this revolutionary manufacturing machine is set to have a transformative impact on the construction industry. Key benefits include:1. Cost-effectiveness: The increased production capacity and reduced labor requirements will result in significant cost savings for builders and developers. This, in turn, will enable more affordable housing options and stimulate economic growth.2. Enhanced Safety: Magnesium wall panels are renowned for their fire-resistant properties. Widespread adoption of this technology can lead to safer buildings, reducing the risk of fire-related incidents and improving overall occupant safety.3. Sustainable Development: The machine's eco-friendly features align with global efforts to promote sustainable development. With greater accessibility to high-quality magnesium wall panels, the construction industry can contribute to a greener built environment.Conclusion:The unveiling of {Company Name}'s advanced magnesium wall panels making machine marks a major milestone in the construction sector. With its focus on increased production capacity, enhanced precision, and reduced labor requirements, this technology is poised to transform the industry landscape. As the demand for cost-effective and sustainable building materials continues to rise, this innovation promises to meet these evolving needs and shape the future of construction.

Affordable Automatic Gypsum Cornice Equipment Manufacturers: Enhance Search Engine Optimization

Title: Leading Automatic Gypsum Cornice Equipment Factories Revolutionize Manufacturing ProcessIntroduction:Gypsum cornices are an integral part of interior design, adding a touch of elegance and sophistication to any space. In an exciting development, a leading automatic gypsum cornice equipment factory is transforming the manufacturing process, propelling the industry forward. This groundbreaking technology, combined with the company's commitment to innovation, is revolutionizing the production of gypsum cornices. With unmatched precision and efficiency, these state-of-the-art equipment factories are shaping the future of interior decor.Body:1. The Rise of Automatic Gypsum Cornice Equipment Manufacturing:Over the past decade, there has been a considerable increase in the demand for high-quality gypsum cornices. To meet this growing demand, automatic gypsum cornice equipment factories have emerged, catering to the needs of interior designers, architects, and construction companies. These factories utilize cutting-edge technology to streamline production processes, ensuring increased efficiency and reduced costs.2. Cutting-Edge Technology and Manufacturing Process:The automatic gypsum cornice equipment factories incorporate advanced machinery and automation systems to optimize the manufacturing process. By utilizing computer numerical control (CNC) and robotics, these factories can produce gypsum cornices with unparalleled precision, consistency, and intricate designs. This groundbreaking technology not only enhances the overall quality but also significantly reduces manual labor.3. Benefits of Automatic Gypsum Cornice Equipment:a. Improved Efficiency: The use of automatic equipment has revolutionized gypsum cornice manufacturing, enabling factories to produce a larger quantity of products in a shorter period. This efficiency boost results in an enhanced customer experience and increased satisfaction levels.b. Consistent Quality: The precision offered by automatic machinery ensures consistent quality across all gypsum cornices produced by these factories. Each product adheres to the highest standards, showcasing fine details and impeccable craftsmanship.c. Cost-Effective: By combining automation with precise material usage, these factories can minimize material waste, thereby reducing costs. This cost-effectiveness translates to competitive pricing for customers, attracting a broader range of clients and promoting widespread adoption of gypsum cornices.4. Focus on Innovation:The leading automatic gypsum cornice equipment factories are driven by a relentless focus on innovation and research. They continuously strive to improve their manufacturing processes, developing new techniques and machinery to push the boundaries of what is possible within the industry. By investing in research and development, these companies ensure that their customers have access to the latest advancements in gypsum cornice manufacturing.5. Sustainability and Environmental Responsibility:In addition to technological advancements, automatic gypsum cornice equipment factories also prioritize sustainable production methods. By adhering to environmentally friendly practices, these factories minimize waste, reduce energy consumption, and utilize recyclable materials wherever possible. This commitment to sustainability aligns with contemporary demands for eco-friendly construction materials and contributes to the preservation of our planet.Conclusion:The automatic gypsum cornice equipment factories have ushered in a new era of manufacturing, bringing innovation, precision, and efficiency to the production of gypsum cornices. By embracing cutting-edge technology and focusing on sustainability, these factories provide a competitive advantage while meeting customer demands. With their commitment to innovation, these industry leaders are undoubtedly shaping the future of interior decor, transforming spaces with bespoke gypsum cornice designs that reflect a perfect combination of artistry and automation.