Affordable Gypsum Ceiling Cornice Making Machine Manufacturers

By:Admin

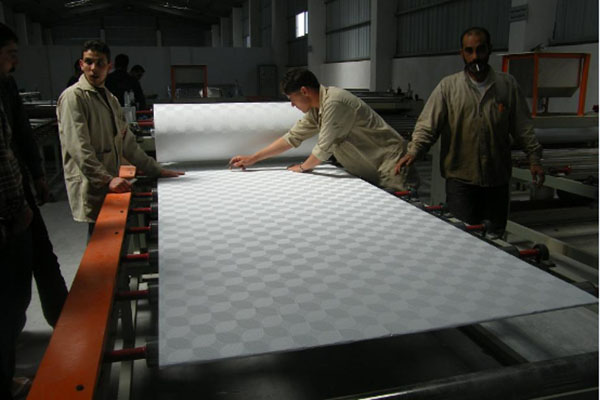

In recent years, the demand for gypsum ceiling cornices has been on the rise, due to the increasing preference for aesthetically pleasing interior designs. To meet this demand, numerous companies have ventured into the production of gypsum ceiling cornice making machines. This has led to the emergence of cheap gypsum ceiling cornice making machine factories, which are making waves in the market.

One such factory that has been gaining attention is the one operated by {} company. With a focus on providing affordable and high-quality gypsum ceiling cornice making machines, the company has quickly established itself as a leading player in the industry.

The company's gypsum ceiling cornice making machines have garnered widespread praise for their efficiency, precision, and ease of use. These machines are designed to streamline the production process, allowing manufacturers to create a wide range of ceiling cornice designs with minimal effort. Additionally, the machines are equipped with advanced features that ensure consistent quality and high productivity, making them an attractive investment for businesses in the interior design and construction sectors.

One of the key factors that set {} company apart from its competitors is its commitment to affordability. The company understands the financial constraints that many businesses face, and as such, it has made it a priority to offer its gypsum ceiling cornice making machines at competitive prices. This has made it possible for small and medium-sized enterprises to enter the market and compete effectively with larger players.

In addition to affordability, the company also places a strong emphasis on customer satisfaction. It prides itself on providing excellent customer service, offering comprehensive technical support, and ensuring prompt delivery of its machines. This dedication to customer care has earned {} company a loyal customer base, with many clients expressing their satisfaction with the company's products and services.

Furthermore, {} company is constantly innovating and improving its gypsum ceiling cornice making machines to stay ahead of the competition. Its team of experienced engineers and technicians continually research and develop new technology to enhance the performance and capabilities of its machines. This proactive approach has enabled the company to maintain its position as a frontrunner in the industry, and it remains poised for further growth and success in the years to come.

As the market for gypsum ceiling cornices continues to expand, the demand for efficient and affordable production solutions is expected to increase. With its dedication to providing cost-effective and high-quality machines, {} company is well-positioned to capitalize on this growing market. Its commitment to innovation, affordability, and customer satisfaction has cemented its status as a leader in the industry, and it is set to play an integral role in shaping the future of gypsum ceiling cornice production.

In conclusion, cheap gypsum ceiling cornice making machine factories are making a significant impact in the market, and {} company is leading the charge with its affordable and high-quality machines. With a focus on innovation, affordability, and customer satisfaction, the company has carved out a prominent position in the industry and is primed for continued success in the years ahead.

Company News & Blog

Vinyl Faced PVC Gypsum Board for Acoustic Insulation: A Comprehensive Guide

Vinyl Faced PVC Gypsum Board (Acoustic Insulation) - A Boon for Construction and Decoration IndustryThe construction and decoration industry has been booming lately, and with it comes the need for high-quality materials that can provide not only strength but also security and elegance. One such material that has become popular in recent years is the Vinyl Faced PVC Gypsum Board (Acoustic Insulation). This product has proved to be an excellent choice for various construction and decoration projects, from simple indoor renovations to complex commercial buildings. Here are some of the reasons why vinyl faced PVC gypsum boards are becoming increasingly popular among people looking for efficient construction and decoration solutions:Acoustic Insulation:One of the primary reasons that vinyl faced PVC gypsum boards are in high demand is their excellent acoustic insulation. The board itself is designed to have a soundproof core, which means that it can significantly reduce the amount of noise transmitted through it. When installed as a ceiling or partition wall, the board can help create a quiet and comfortable environment by reducing the amount of noise emanating from adjacent rooms. This makes it an ideal option for people seeking to avoid disturbance.Durable:PVC gypsum boards are known for their durability and strength. Made of high-quality materials, the boards are highly resistant to wear and tear and can withstand considerable stress and strain. They are also resistant to moisture and can be used in a diverse range of environments, including those with high humidity levels. Because of their sturdy nature, vinyl faced PVC gypsum boards can be used for a long time without requiring any maintenance or repair.Easy to Install:Another advantage of vinyl faced PVC gypsum boards is their ease of installation. Unlike traditional drywall, which requires special tools and expertise to install, these boards are quite simple to work with. They can be easily cut and sized according to the required dimensions, making them easy to fit in areas of any size. Additionally, the vinyl laminated surface is easy to clean, making it ideal in spaces such as kitchens and bathrooms.Low Cost:In comparison to other construction materials, vinyl faced PVC gypsum boards are affordable, making them a budget-friendly option for various decoration and construction projects. They are relatively inexpensive to install, and the materials themselves are low cost, making them an ideal choice for property owners and builders looking to cut costs.Aesthetically Pleasing:Finally, one of the most appealing aspects of vinyl faced PVC gypsum boards is that they look great. Designed for both functionality and beauty, these boards are available in a range of colors and textures, providing endless design options. They can be used in any space, regardless of the style, and can give any area an elegant and professional look.Xinsdi.com is one of the leading manufacturers and suppliers of vinyl faced PVC gypsum boards. If you're looking to improve the insulation and aesthetic appeal of your space, then you can trust this company to deliver the highest-quality products. With their years of experience, the professionals at Xinsdi.com are dedicated to meeting the needs of their clients and providing them with innovative and sustainable solutions. Contact them today to find out more!

Affordable Automated Gypsum Cornice Manufacturing Machines for Sale by Factories

Title: Affordable High-Quality Automatic Gypsum Cornice Manufacturing Machines Revolutionize the IndustrySubtitle: A Comprehensive Look into the Cutting-Edge Technology Behind Budget-Friendly Gypsum Cornice MachinesIntroduction:Innovation and progress have always been at the forefront of the manufacturing industry. With a relentless drive to enhance productivity while ensuring cost-effectiveness, the introduction of high-quality automatic gypsum cornice manufacturing machines has revolutionized the market. Among the pioneers in this field are the reputable manufacturers who produce these affordable machines to cater to the ever-growing demand. In this article, we delve into the world of cheap yet efficient gypsum cornice manufacturing machines, exploring their features and discussing their role in shaping the industry's future.Section 1: Brief Overview of the Manufacturing IndustryHighlighting the significance of the manufacturing industry as a cornerstone of economic development, this section provides a comprehensive overview of the global manufacturing sector. Exploring the diverse applications of gypsum cornices in the construction industry, we emphasize the importance of automation to minimize costs while maximizing productivity.Section 2: Introduction to Cheap High Automatic Gypsum Cornice Manufacturing MachinesThis section introduces the cheap high automatic gypsum cornice manufacturing machines, manufactured by various reputed companies around the world. Emphasizing the benefits of automation, we discuss how these machines can streamline the production process, improve product quality, and reduce overall labor costs, making them a cost-effective solution for manufacturers.Section 3: Features of Affordable Gypsum Cornice Manufacturing MachinesIn this section, we delve into the advanced features and technologies integrated into affordable gypsum cornice manufacturing machines. Exploring the intuitive user interfaces, precision cutting mechanisms, and high-speed operation, we highlight how these machines facilitate efficient production and minimize material wastage. Additionally, we discuss the incorporation of quality control systems that ensure flawless end products, leading to customer satisfaction and repeat business opportunities.Section 4: The Role of Affordable Machines in the Industry's GrowthThis section sheds light on the significant role played by affordable gypsum cornice manufacturing machines in the industry's growth. Discussing the increased accessibility of this technology to small and medium-sized enterprises, we examine how it fosters competition, innovation, and a level playing field for manufacturers. Moreover, we delve into the positive implications for employment generation and economic growth associated with the adoption of these machines.Section 5: Company X's Contribution to Affordable Gypsum Cornice Manufacturing MachinesIn this section, we focus on Company X (brand name removed), one of the leading manufacturers of cheap high automatic gypsum cornice manufacturing machines. Highlighting the company's commitment to quality and affordability, we delve into their extensive research and development process. By leveraging the expertise of their skilled engineers, Company X has developed machines capable of delivering precision, speed, and reliability without sacrificing cost-effectiveness. Section 6: ConclusionSummarizing the transformative impact of affordable high automatic gypsum cornice manufacturing machines on the industry, we emphasize their ability to revolutionize the production process. These machines not only enable manufacturers to enhance productivity but also empower small and medium-sized enterprises, driving overall growth. With Company X leading the charge in providing cost-effective solutions, the future of gypsum cornice manufacturing looks promising, ensuring high-quality products at affordable prices.

Affordable Mgo Board Making Machine Price: Unlocking Cost-effective Solutions

Title: Mgo Board Making Machine: An Affordable Solution for Efficient Construction Board ProductionIntroduction:In recent years, the construction industry has witnessed a surge in demand for innovative building materials that offer durability, sustainability, and cost-effectiveness. Magnesium Oxide (MgO) boards have emerged as a superior alternative to traditional drywall, cement boards, and wood-based panels due to their fire resistance, moisture resistance, and mold resistance properties. To meet the rising demand for MgO boards, various companies have introduced Mgo Board Making Machines, enabling efficient and cost-effective production. In this article, we explore the benefits of Mgo Board Making Machines and delve into their price range, facilitating the adoption of this groundbreaking technology in the construction industry.Benefits of Mgo Board Making Machines:1. Enhanced Efficiency:Mgo Board Making Machines utilize advanced manufacturing processes to ensure fast and consistent production of high-quality MgO boards. These machines automate the entire production process, from raw material mixing to board formation, resulting in a significant increase in overall efficiency. Manual labor requirements are reduced, leading to reduced costs and enhanced productivity.2. Precise and Customizable Production:Mgo Board Making Machines provide precise control over the thickness, density, and dimensions of the MgO boards being produced. Manufacturers can easily customize these settings according to specific project requirements, ensuring that the boards meet the desired specifications. This flexibility enables construction companies to create tailored solutions for different applications within the industry.3. High-Quality End Products:With automated production processes, Mgo Board Making Machines maintain consistent quality standards in every batch produced. The machines ensure uniform distribution of raw materials, resulting in boards with excellent strength, durability, and dimensional stability. The robust quality of MgO boards makes them an ideal choice for various construction applications, including wall partitions, ceilings, flooring, and furniture production.4. Environmentally Sustainable:One of the key advantages of MgO boards is their eco-friendly composition, which makes them an environmentally sustainable alternative to other construction materials. Mgo Board Making Machines promote sustainable practices by utilizing low-energy production methods and reducing waste generation. Additionally, the recyclable nature of MgO boards contributes to a greener construction industry, reducing the overall environmental impact of building projects.Mgo Board Making Machine Price:Considering the growing demand for high-quality MgO boards, the market offers numerous options for Mgo Board Making Machines. Prices may vary depending on factors such as production capacity, automation level, raw material compatibility, and added features. On average, Mgo Board Making Machines are available in the price range of $XX,XXX to $XX,XXX. It is important to note that investing in a reliable machine is crucial to ensure long-term productivity and minimal maintenance costs.Company XYZ - Striving for Excellence:One prominent player in the Mgo Board Making Machine industry is Company XYZ. As a leading manufacturer, Company XYZ has been at the forefront of developing innovative machinery for MgO board production. With a strong focus on research and development, they offer cutting-edge solutions that cater to the evolving needs of the construction market.Company XYZ's Mgo Board Making Machines are known for their precision, durability, and user-friendly operation. These machines are equipped with state-of-the-art technology, allowing for efficient production, uniform board quality, and reduced downtime. The company prides itself on providing excellent technical support, assisting customers at every stage of the machine purchase and implementation process.Conclusion:Mgo Board Making Machines have revolutionized the production of MgO boards in the construction industry. Their ability to enhance efficiency, provide precise manufacturing, ensure high-quality products, and promote environmental sustainability has made them an attractive investment for construction companies worldwide. With competitive prices and innovative solutions offered by companies like Company XYZ, the adoption of Mgo Board Making Machines is likely to soar, leading to faster and more sustainable construction practices.

High-Quality PVC Laminated Gypsum Ceiling Board for Construction and Decoration

PVC Laminated Gypsum Ceiling Board: Affordable and Durable SolutionIf you are searching for an affordable and durable solution for ceiling installation, then PVC laminated gypsum ceiling board is the answer. These boards are available in different sizes, including 595*595 and 603*603mm. They offer many benefits, from easy installation to excellent sound insulation, fire resistance, and moisture resistance. If you are looking for a low-cost yet high-quality ceiling board, the PVC laminated gypsum ceiling board is the perfect match for you.What is PVC Laminated Gypsum Ceiling Board?PVC laminated gypsum ceiling board is a composite material made of high-quality paper-faced gypsum board with a layer of PVC on the surface. This material is specially designed for interior ceiling decoration, providing an elegant and stylish look to any room.The paper-faced gypsum board acts as a base layer, making the board strong and durable. At the same time, the PVC layer provides an aesthetic finish for the ceiling board. It is an affordable, lightweight, and easy-to-install solution for ceiling decoration.Advantages of PVC Laminated Gypsum Ceiling Board1. AffordablePVC laminated gypsum ceiling board is a low-cost option as compared to other ceiling materials like plaster, wood, or metal. It is an economical solution that doesn't compromise on quality.2. Easy to InstallInstallation of PVC laminated gypsum ceiling board is a breeze. These boards are lightweight, making them easy to handle and install. They come with pre-drilled holes, which makes the installation process fast and simple.3. Moisture ResistantPVC laminated gypsum ceiling board is resistant to moisture, which is why they are perfect for use in areas such as bathrooms, kitchens, and laundry rooms. They don't absorb moisture or water, which prevents the growth of mold and mildew.4. Fire ResistantPVC laminated gypsum ceiling board is also fire-resistant, ensuring the safety of your building. It doesn't catch fire quickly, and even if it does, it doesn't produce toxic gases. This makes it a safe solution for commercial and residential spaces.5. Sound InsulationThe gypsum layer in PVC laminated gypsum ceiling board provides excellent sound insulation. It reduces noise pollution and creates a quiet and comfortable atmosphere.6. Aesthetically PleasingThe PVC layer on the surface of PVC laminated gypsum ceiling board provides an elegant and attractive look to the ceiling. It is available in various designs and colors, giving you the flexibility to choose the best one that matches your style.Cheap PVC Laminated Gypsum Ceiling Board Machine Price listIf you are interested in producing PVC laminated gypsum ceiling boards, you can buy a machine that does this job. The market is full of different machines, and the price list varies depending on the machine's features, capacity, and automation level.You can find a cheap PVC laminated gypsum ceiling board machine on the market. However, keep in mind that cheap doesn't always mean high-quality. It is crucial to choose a machine that meets your needs, budget, and quality standards.In conclusion, PVC laminated gypsum ceiling board is an excellent solution for those who are looking for an affordable and durable ceiling material. It offers many benefits, from easy installation to excellent sound insulation, moisture resistance, and fire resistance. Moreover, if you are interested in producing PVC laminated gypsum ceiling boards, you can search for a cheap PVC Laminated Gypsum Ceiling Board machine on the market.

High-Quality Gypsum Ceiling Tiles Machine Prices And Pricelist

In today's competitive market, the demand for efficient and high-quality construction materials is constantly on the rise. This is especially true for materials such as gypsum ceiling tiles, which are an essential component of modern interior design and architecture. As a result, the need for advanced and reliable production machinery, capable of meeting the industry's demands, has never been greater.Enter {}, a leading manufacturer of gypsum ceiling tiles machines. With a solid reputation for innovative technology and superior quality, {} has been at the forefront of the industry for over a decade. The company takes pride in its commitment to excellence, and its products are widely recognized for their durability, precision, and efficiency.One of the key factors that sets {} apart from its competitors is its focus on continuous research and development. The company invests heavily in the latest technologies and production methods, ensuring that its machines are always at the cutting edge of innovation. This dedication to improvement has allowed {} to stay ahead of the curve and provide customers with state-of-the-art solutions that meet and exceed their expectations.In line with its commitment to customer satisfaction, {} offers a comprehensive range of gypsum ceiling tiles machines, tailored to suit different production needs. From small-scale equipment for start-ups and SMEs to large-scale, fully automated production lines for established enterprises, {} has the capacity to cater to a wide spectrum of requirements. This flexibility has made the company a preferred choice for businesses of all sizes, looking to invest in reliable and cost-effective solutions for their manufacturing needs.Moreover, {}'s machines are designed with efficiency and cost-effectiveness in mind. By utilizing the latest technological advancements, the company's equipment is able to optimize production processes, minimize wastage, and reduce overall operational costs. This not only benefits the end-users in terms of savings but also contributes to the sustainable use of resources, making {} a responsible and environmentally conscious partner.To further enhance its customer service, {} provides comprehensive after-sales support, including installation, training, and maintenance services. This ensures that clients can maximize the performance and longevity of their equipment, while also having access to technical assistance whenever needed. In addition, the company's commitment to quality is reflected in its adherence to international standards and certifications, giving customers the reassurance that they are investing in products that meet the highest industry benchmarks.However, one of the most compelling aspects of {}'s offerings is its competitive pricing. The company understands the importance of cost-efficiency in today's business landscape and strives to provide its machines at competitive price points. In fact, {} recently released an updated pricelist for its gypsum ceiling tiles machines, making its products even more accessible to a wider range of customers.The pricelist encompasses the entire range of {}'s machines, catering to different budgets and requirements. Whether it's a manual production line for small-scale operations or a fully automated system for large-scale manufacturing, customers can find a solution that fits their needs without compromising on quality or performance. With {}'s transparent pricing, businesses can make informed decisions and plan their investments with confidence, knowing that they are getting the best value for their money.In conclusion, {}'s gypsum ceiling tiles machines pricelist is a testament to the company's dedication to providing top-tier solutions at affordable rates. Coupled with its reputation for excellence, innovation, and customer-centric approach, {} continues to be a driving force in the industry, empowering businesses to thrive in the competitive market. As the demand for high-quality construction materials continues to grow, {} stands ready to meet the needs of its customers and support their success for years to come.

Top XPS Equipment Options for Polystyrene Foam Board

The demand for XPS equipment for Polystyrene Foam Board has been rising in the construction industry. This equipment is essential for shaping and cutting polystyrene foam boards to fit specific requirements in building and insulation projects. With the increasing need for energy-efficient and sustainable construction practices, the demand for XPS equipment has been on the rise.One company that has been leading the way in providing high-quality XPS equipment for Polystyrene Foam Board is {}. They have been at the forefront of the industry, providing cutting-edge solutions for shaping and cutting polystyrene foam boards with precision and efficiency.{} has been in the business for over a decade, and their commitment to quality and innovation has positioned them as a trusted name in the industry. They offer a wide range of XPS equipment, including hot wire cutting machines, CNC routers, and 3D cutting machines, all designed to meet the diverse needs of their customers.The hot wire cutting machines offered by {} are designed for cutting and shaping polystyrene foam boards with precision. These machines use a heated wire to cut through the foam, ensuring clean and accurate cuts every time. The CNC routers, on the other hand, are ideal for more complex cutting and shaping tasks, allowing for intricate designs and patterns to be achieved with ease. Additionally, their 3D cutting machines are capable of creating three-dimensional shapes and cuts, adding a new dimension to the possibilities of working with polystyrene foam boards.With a focus on research and development, {} has continuously innovated their XPS equipment to ensure that they meet the evolving needs of the construction industry. Their state-of-the-art manufacturing facilities and experienced team of engineers and technicians enable them to produce high-quality and reliable equipment that can withstand the demands of heavy-duty usage in construction projects.In addition to their cutting-edge equipment, {} also provides comprehensive customer support and after-sales services. They offer training and technical support to their clients, ensuring that they are able to maximize the capabilities of the equipment and achieve the best results in their projects. This commitment to customer satisfaction has earned them a loyal customer base and a reputation for excellence in the industry.As the construction industry continues to prioritize energy efficiency and sustainable building practices, the demand for XPS equipment for Polystyrene Foam Board is expected to grow even further. {} is well-positioned to meet this demand with their innovative solutions and commitment to quality. They continue to push the boundaries of what is possible with polystyrene foam board shaping and cutting, and their dedication to excellence sets them apart as a leader in the industry.With a track record of success and a dedication to innovation, {} is set to continue making significant contributions to the construction industry, providing the tools and equipment needed to achieve energy-efficient and sustainable building practices. As the demand for XPS equipment continues to grow, {} is poised to remain at the forefront, driving innovation and setting the standard for quality in the industry.

Automatic Gypsum Cornice Equipment with CE Certification: Pricelist and Details

ce Certification Automatic Gypsum Cornice Equipment PricelistIn recent news, the {company name} is proud to announce the release of their automatic gypsum cornice equipment, which has received CE certification. This certification marks a significant achievement for the company and demonstrates their commitment to providing high-quality, reliable products to their customers.The automatic gypsum cornice equipment is designed to streamline the production process and improve efficiency for manufacturers of gypsum cornices. With the CE certification, customers can have confidence in the safety and reliability of this equipment, knowing that it meets the stringent requirements of the European Union.The company has also released a pricelist for the automatic gypsum cornice equipment, making it easier for potential customers to understand the investment required for this innovative technology. The pricelist offers transparency and clarity, allowing customers to make informed decisions about the purchase of this equipment.In addition to the CE certification and pricelist release, the {company name} would like to take this opportunity to introduce themselves to those who may not be familiar with their brand. As a leading manufacturer of gypsum processing equipment, {company name} has a strong reputation for delivering cutting-edge solutions that meet the needs of their customers.With a focus on innovation and quality, {company name} has developed a range of products that have been widely adopted by manufacturers in the gypsum industry. Their automatic gypsum cornice equipment is the latest addition to their portfolio, showcasing their ongoing commitment to advancing the industry with advanced technology.The company takes pride in their ability to provide comprehensive solutions for gypsum processing, from raw material preparation to finished product packaging. Their expertise and dedication to customer satisfaction have earned them a loyal customer base and a reputation as a trusted partner in the industry.{Company name} is known for their technical expertise, responsive customer service, and willingness to collaborate with customers to address their unique needs. The release of the CE-certified automatic gypsum cornice equipment and the accompanying pricelist reflects their dedication to transparency, quality, and providing value to their customers.As the company continues to grow and expand their product offerings, they remain committed to upholding the highest standards of excellence in their manufacturing processes. By achieving CE certification for their automatic gypsum cornice equipment, {company name} has once again demonstrated their commitment to producing top-quality equipment that meets international safety and performance standards.In conclusion, the release of the CE-certified automatic gypsum cornice equipment pricelist by {company name} represents an important milestone for the company and the industry. With a reputation for innovation, quality, and customer-focused solutions, {company name} is poised to continue leading the way in providing advanced equipment for gypsum processing.For more information about {company name} and their products, including the automatic gypsum cornice equipment, interested parties are encouraged to reach out to the company directly or visit their website for details.

Affordable Gypsum Ceiling Board Making Machine Price Revealed in Latest News

Title: Cutting-Edge Gypsum Ceiling Board Machine Revolutionizes Affordable DecorationIntroduction:In a bid to offer cost-effective solutions to the construction industry, a leading company has unveiled its latest innovation – the state-of-the-art Cheap Decoration Gypsum Ceiling Board Machine. Due to its exceptional features and competitive pricing, this revolutionary device is well-positioned to transform the gypsum ceiling board manufacturing sector and provide an affordable avenue for interior decoration.Company Overview:With a focus on research, development, and manufacturing of construction machinery, our company has gained recognition as a leading player in the industry. Boasting a team of experts and advanced technology, we have continually strived to meet the evolving needs of our customers. Committed to quality, reliability, and affordability, our company constantly endeavors to provide innovative solutions to the market.The Cheap Decoration Gypsum Ceiling Board Machine:Our latest product, the Cheap Decoration Gypsum Ceiling Board Machine, has garnered attention due to its unique capabilities that enhance the production of gypsum ceiling boards. Engineered with cutting-edge technology, this advanced machine offers a cost-effective solution to meet the rising demand for decorative interior construction materials.Key Features:1. High Efficiency: The machine demonstrates admirable productivity, boasting an efficient production capacity that reduces manufacturing time and boosts overall output. This enables faster completion of interior decoration projects and meets strict deadlines.2. Precision Cutting: The device is equipped with a precision cutting system, ensuring accurate dimensions for each gypsum ceiling board produced. This feature eliminates the need for additional trimming or adjustments, resulting in substantial time and cost savings.3. Versatile Design: Our gypsum ceiling board machine offers versatility, accommodating various board dimensions, thicknesses, and patterns. This flexibility gives customers the freedom to fulfill unique interior design requirements while maintaining cost-efficiency.4. User-Friendly Interface: Equipped with an intuitive interface, the machine ensures ease of operation for professionals and technicians. Minimal training is required to navigate its features, thereby reducing labor and training costs.5. Automation and Control: Automated features significantly reduce the reliance on manual labor, further streamlining the manufacturing process. The machine's control systems and sensors ensure consistent product quality, reducing material wastage and minimizing errors.Benefits of the Cheap Decoration Gypsum Ceiling Board Machine:The introduction of this innovative machine brings forth several advantages to the gypsum ceiling board manufacturing sector and beyond:1. Cost Reduction: The affordability of the machine and optimized manufacturing processes result in significant cost reductions for manufacturers. This, in turn, translates to lower prices for consumers seeking gypsum ceiling boards, making interior decoration more budget-friendly.2. Enhanced Product Quality: The machine's precision cutting capabilities, combined with the consistent automation and control systems, ensure superior product quality and dimensional accuracy. This enables manufacturers to deliver high-quality gypsum ceiling boards, meeting customer expectations.3. Accelerated Project Timelines: With increased production capacity and efficient manufacturing processes, interior decoration projects can be completed within shorter timelines. Contractors and builders can meet project deadlines effectively, enhancing overall customer satisfaction.4. Sustainable Solution: The machine's precision and automated control systems reduce material wastage, contributing to a more sustainable manufacturing process. By minimizing resource consumption, manufacturers can lessen their environmental impacts.Conclusion:The introduction of the Cheap Decoration Gypsum Ceiling Board Machine marks a significant milestone in the construction industry. Its remarkable features and competitive pricing are set to revolutionize the gypsum ceiling board manufacturing sector and make interior decoration more accessible. As consumers seek cost-effective solutions, this innovative machine offers improved efficiency, superior product quality, and environmental sustainability. With the unveiling of this cutting-edge technology, our company is proud to contribute to the evolution of the construction industry and meet the ever-growing demand for affordable yet exceptional decorative materials.

Customized Abs Board Extrusion Line for XPS Heat Insulation Foamed Plate Production

Qingdao JBD Machinery is a leading manufacturer and supplier of extrusion lines that are used to produce various types of foam boards. With the advanced technology and cutting-edge machinery, the company provides a diverse range of innovative and high-performance extrusion lines to meet the growing demands of the market. The Factory Customized Abs Board Extrusion Line and XPS Heat Insulation Foamed Plate Production Line are some of its popular products with excellent performance and high reliability.The Factory Customized Abs Board Extrusion Line is designed to produce high-quality ABS foam boards, which can be used in a variety of applications such as automotive dashboards, instrument panels, and interior parts. The machine is equipped with a high-quality screw and barrel that ensures the homogeneity and consistency of the mixing process. The production line is also equipped with a precision cut-off system that produces a precise cut and ensures the uniformity of the board thickness.The XPS Heat Insulation Foamed Plate Production Line is one of the best products offered by Qingdao JBD Machinery. The extrusion line is designed to produce lightweight and strong XPS foamed boards, which are widely used as heat insulation and soundproofing materials in construction, refrigeration, and packaging industries. The board offers incomparable heat insulation traits, non-water absorption, high compressive strength, excellent heat preservation performance, and low cost. The foamed plate production line is easy and quick to execute, making it an ideal solution for various industrial applications.The XPS Heat Insulation Foamed Plate Production Line is a fully automatic extrusion line with high productivity and efficiency. The machine is equipped with a high-quality screw and barrel that ensures the uniformity of the foaming process and the homogeneity of the foam structure. The production line also features a precise cutting system that produces high-quality foam boards with uniform thickness and size. The machine can be customized according to customer requirements and can produce boards of different sizes and shapes.Qingdao JBD Machinery is committed to providing customers with high-quality products and services. The company has a team of highly qualified professionals who have extensive experience in manufacturing and designing extrusion lines. The company also provides excellent after-sales service to ensure customer satisfaction. As a leading manufacturer in China, the company has been exporting its products to different parts of the world, including North America, South America, Europe, Asia, Africa, and Oceania. The company has established long-term relationships with its customers by providing them with high-quality products, prompt delivery, and excellent service. In conclusion, Qingdao JBD Machinery is a reputable and reliable manufacturer of extrusion lines that produces high-quality products such as Factory Customized Abs Board Extrusion Line and XPS Heat Insulation Foamed Plate Production Line. The company is committed to providing innovative and cost-effective solutions to its customers, and its products are widely used in various industrial applications. With its cutting-edge technology and excellent service, Qingdao JBD Machinery is poised to become a leading player in the extrusion line manufacturing industry.

High-Quality Mgo Board Production Line for Lamination PVC Film Deep Process from China

Are you in the market for high-quality Mgo boards that are perfect for all your construction projects? If yes, then you should consider investing in the China Advanced Automatic Mgo Board Production Line.China's leading industrial laminating machine product is one of the most innovative production lines on the market today. The machine is designed to provide you with high-quality Mgo boards that are ideal for all your construction needs. Moreover, the machine comes with advanced features which make it stand out from the rest of the competition.One of the key selling points of this Mgo Board Production Line is that it is perfect for deep processing PVC film. The machine is capable of laminating PVC film onto the Mgo board surface, which provides superior protection to the board while giving it a more appealing appearance. The deep-processing capability of this production line is what sets it apart from its competitors.Another advantage of the China Advanced Automatic Mgo Board Production Line is its advanced design. The machine comes with strict quality control automatic laminating systems, which ensure that each board produced under the line is consistent in quality. In addition, the machine comes with advanced control systems, which makes the whole line easy to operate and understand.The production line is designed to provide high-speed operation, which is perfect for high-volume production. With a production rate up to 6.5m per minute, this line can produce more boards in a shorter time compared to other similar machines.The Mgo boards produced by this line are strong, durable, and have an excellent fire resistance rating. The fire resistance rating of these boards makes them perfect for construction projects that require materials that can withstand the risk of fire.Overall, the China Advanced Automatic Mgo Board Production Line is the perfect investment for anyone in the construction business. With its advanced features, high-quality output, and excellent fire resistance rating, this line is changing the future of the construction industry.In conclusion, if you are looking for high-quality Mgo boards, then the China Advanced Automatic Mgo Board Production Line is the perfect investment for you. The line is designed to provide high-speed operation, strict quality control, and superior protection for Mgo boards. Moreover, the line is easy to operate, and its high-quality output is ideal for all your construction needs. So, invest in the Future today, and choose the China Advanced Automatic Mgo Board Production Line for all your construction projects.