Affordable Foam Board Making Machine for Sale

By:Admin

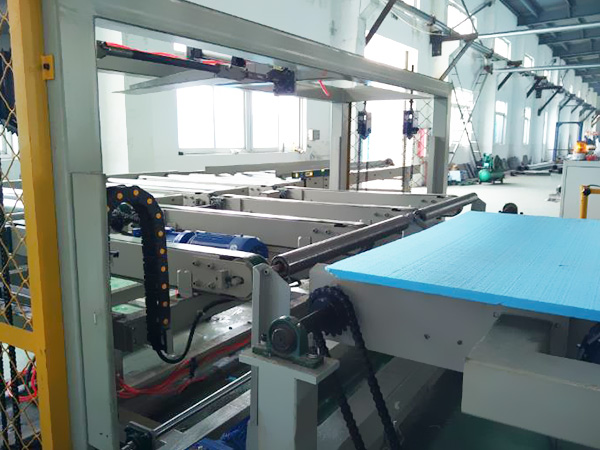

As the demand for energy-efficient and cost-effective insulation materials continues to rise, the development of advanced production technology has become increasingly important. In response to this, the renowned machinery manufacturer, [Company Name], has introduced a groundbreaking XPS foam board making machine that is set to revolutionize the insulation manufacturing industry.

The XPS foam board making machine is designed to produce high-quality extruded polystyrene (XPS) foam boards, which are widely used in construction for thermal insulation. This innovative machine boasts a range of advanced features that set it apart from traditional manufacturing equipment, making it a game-changer for insulation material production.

One of the key advantages of the XPS foam board making machine is its cost-effectiveness. By utilizing state-of-the-art technology, the machine is able to significantly reduce production costs, making it an attractive investment for companies in the insulation manufacturing sector. This cost-efficient manufacturing process is expected to have a positive impact on the availability and affordability of XPS foam boards in the market.

Furthermore, the XPS foam board making machine is highly efficient, with the ability to produce a large volume of insulation materials in a relatively short period of time. This increased production capacity is expected to address the growing demand for XPS foam boards in the construction industry, where energy-efficient insulation solutions are in high demand.

In addition to its cost-effectiveness and efficiency, the XPS foam board making machine also boasts a high level of precision and quality control. This ensures that the produced foam boards meet the highest standards of quality and performance, providing customers with reliable and durable insulation materials for their construction projects.

[Company Name] has a long-standing reputation for innovation and excellence in the manufacturing machinery industry. With a strong commitment to research and development, the company has consistently introduced cutting-edge technology to meet the evolving needs of various industries. The introduction of the XPS foam board making machine is a testament to [Company Name]'s dedication to providing state-of-the-art solutions for the insulation manufacturing sector.

Furthermore, [Company Name] prides itself on its customer-centric approach, striving to deliver products and services that exceed the expectations of its clients. The XPS foam board making machine is a result of extensive market research and feedback from industry professionals, ensuring that it meets the specific requirements and demands of insulation manufacturers.

With its advanced technology, cost-efficiency, and high-quality production capabilities, the XPS foam board making machine is expected to have a significant impact on the insulation manufacturing industry. As companies seek to meet the growing demand for energy-efficient construction materials, this innovative machine is poised to become a vital tool in the production of XPS foam boards.

In conclusion, the introduction of the XPS foam board making machine by [Company Name] represents a major advancement in the insulation manufacturing industry. With its cost-effective production process, high efficiency, and precision quality control, the machine is set to revolutionize the production of XPS foam boards, providing a reliable and affordable solution for the construction industry's insulation needs. As [Company Name] continues to lead the way in technological innovation, the future of insulation manufacturing looks brighter than ever.

Company News & Blog

High-quality Fireproof Board Machine for Magnesium Oxide Production

The demand for fireproof building materials has been on the rise in recent years, particularly in the construction industry. As a result, (company name) has been at the forefront of developing innovative solutions to meet these demands. Their latest advancement is the Magnesium Oxide Fireproof Board Machine, which is set to revolutionize the industry.The Magnesium Oxide Fireproof Board Machine is the result of years of research and development by (company name). It is designed to produce high-quality fireproof boards using magnesium oxide as the main ingredient. This advanced machine is equipped with state-of-the-art technology and features that ensure the production of boards that are not only fireproof but also durable and sustainable.One of the key benefits of the Magnesium Oxide Fireproof Board Machine is its ability to produce boards that are resistant to fire, water, and impact. This makes them an ideal choice for use in a wide range of building applications, including walls, ceilings, and flooring. In addition, these boards are also resistant to mold and mildew, making them a reliable and long-lasting option for construction projects.The production process of the Magnesium Oxide Fireproof Board Machine is highly efficient and environmentally friendly. It minimizes waste and reduces energy consumption, making it a sustainable and cost-effective solution for manufacturers. This is in line with (company name)'s commitment to sustainability and eco-friendly practices in all of its operations.In addition to the advanced technology and features of the machine, (company name) also provides comprehensive training and support for its customers. This ensures that manufacturers are able to operate the machine effectively and maximize its capabilities. The company's team of experts is dedicated to helping customers integrate the Magnesium Oxide Fireproof Board Machine into their production processes and achieve the best results.The introduction of the Magnesium Oxide Fireproof Board Machine is a significant milestone for (company name) and the industry as a whole. It represents a major advancement in the production of fireproof building materials and sets a new standard for quality, performance, and sustainability. With this innovative machine, (company name) is well-positioned to meet the growing demand for fireproof boards and to continue leading the way in the development of cutting-edge solutions for the construction industry.In conclusion, the Magnesium Oxide Fireproof Board Machine is a game-changer for the industry. Its advanced technology, sustainable production process, and comprehensive support make it a valuable asset for manufacturers looking to meet the demand for fireproof building materials. With this groundbreaking machine, (company name) is demonstrating its commitment to innovation, quality, and sustainability, and is poised to shape the future of the construction industry.

Gypsum Cornice Production Line Prices in China

China has emerged as a global leader in the production of gypsum cornice, a key component in the construction industry. With the increasing demand for high-quality gypsum cornice, manufacturers in China have been at the forefront of developing innovative production lines to meet the growing needs of the market. As a result, China's gypsum cornice production line has become a popular choice for builders and contractors around the world.One of the leading companies in China's gypsum cornice production industry is {}, a well-established manufacturer with a strong reputation for delivering top-notch products. The company has recently introduced its latest gypsum cornice production line, which has garnered considerable attention from industry professionals and observers. With its advanced technology and high production capacity, the new production line is expected to set a new standard in the industry.The company's gypsum cornice production line is designed to maximize efficiency and productivity while maintaining the highest standards of quality. The production line is equipped with state-of-the-art machinery and equipment, ensuring that each piece of gypsum cornice is precisely manufactured to meet the exact specifications and requirements of customers. Additionally, the production line incorporates the latest automation and control systems, allowing for seamless operation and minimal human intervention, further enhancing the overall efficiency of the manufacturing process.In addition to its exceptional technical capabilities, the company's gypsum cornice production line is also notable for its environmental sustainability. The production line is designed to minimize waste and energy consumption, incorporating eco-friendly practices to reduce its environmental impact. As sustainability becomes an increasingly important consideration in the construction industry, the company's commitment to environmentally conscious production methods is viewed as a significant advantage in the market.The introduction of the new gypsum cornice production line has generated significant interest among industry professionals and potential customers. With its impressive technical specifications and commitment to quality and sustainability, the production line is poised to make a significant impact on the global gypsum cornice market. Builders and contractors around the world are expected to benefit from the availability of high-quality gypsum cornice produced by the company's advanced production line.In a statement, a spokesperson for the company highlighted the significance of the new gypsum cornice production line, emphasizing its potential to meet the evolving needs of the construction industry. The spokesperson noted that the company is dedicated to delivering the highest quality products to its customers, and the new production line represents a significant step forward in achieving that goal. The company's investment in advanced technology and sustainable manufacturing practices is a reflection of its commitment to innovation and excellence.Industry analysts have also taken note of the company's new gypsum cornice production line, recognizing it as a game-changing development in the industry. The advanced capabilities of the production line and its potential to drive efficiency and quality in gypsum cornice manufacturing have positioned the company as a leading player in the global market. As the demand for high-quality gypsum cornice continues to rise, the company's new production line is anticipated to play a key role in meeting that demand and solidifying China's position as a dominant force in the industry.Overall, the introduction of the new gypsum cornice production line by {} represents a significant milestone in the construction industry. With its advanced technology, commitment to quality and sustainability, and potential to meet the evolving needs of the market, the production line is set to make a lasting impact on the global gypsum cornice industry. Builders, contractors, and industry professionals can look forward to accessing high-quality gypsum cornice products manufactured by the company's state-of-the-art production line, contributing to the advancement of construction practices and standards around the world.

Efficient Automatic Mgo Board Production Line in China

China Automatic Mgo Board Production Line is set to revolutionize the construction industry with its state-of-the-art technology and efficient production process. This groundbreaking production line is the result of years of research and development by a team of dedicated engineers and experts in the field of construction materials.The Automatic Mgo Board Production Line is designed to produce high-quality magnesium oxide (Mgo) boards that are lightweight, fire-resistant, and durable. These boards are widely used in the construction industry for walls, ceilings, and flooring due to their excellent performance and sustainability. With the demand for eco-friendly and energy-efficient building materials on the rise, the Automatic Mgo Board Production Line is poised to meet the growing needs of the market.The production line is fully automated, allowing for a continuous and efficient manufacturing process. It is equipped with cutting-edge technology that ensures the precise mixing of raw materials, accurate shaping of boards, and thorough curing of the finished products. This high level of automation not only increases production efficiency but also guarantees the consistency and quality of the Mgo boards.The company behind the Automatic Mgo Board Production Line, {}, has a strong reputation for innovation and excellence in the construction industry. With years of experience in developing advanced production machinery and equipment, the company has established itself as a leader in the field. Its commitment to research and development has led to the creation of cutting-edge solutions that are tailored to meet the evolving needs of the construction market.In addition to its technological expertise, {} is also known for its commitment to sustainability and environmental responsibility. The company places a strong emphasis on using eco-friendly materials and processes in its production line, ensuring that its products have a minimal impact on the environment. As the construction industry continues to move towards more sustainable practices, the Automatic Mgo Board Production Line is well-positioned to support this trend with its commitment to eco-friendly manufacturing.The introduction of the Automatic Mgo Board Production Line is expected to have a significant impact on the construction industry in China and beyond. By providing a reliable source of high-quality Mgo boards, the production line will help meet the growing demand for innovative and sustainable building materials. Its efficient production process will also contribute to streamlining construction projects and reducing the overall environmental footprint of buildings.The Automatic Mgo Board Production Line is set to become a game-changer in the construction industry, offering a reliable and sustainable solution for builders, contractors, and developers. With its cutting-edge technology, efficient production process, and commitment to sustainability, it represents a significant step forward in the evolution of construction materials. As the demand for eco-friendly and high-performance building materials continues to grow, the Automatic Mgo Board Production Line is well-positioned to lead the way towards a more sustainable and innovative future for the construction industry.

Magnesium Oxide Board Selling Leads - Find Quality Exporters at EC21

Are you in search of high-quality Mgo board exporters? Look no further than EC21, where you can choose from a wide array of exporters who offer top-notch Mgo board products. Mgo board is becoming increasingly popular in the construction industry due to its exceptional features. It is a versatile and cost-effective building material that is perfect for a wide range of applications.Whether you are working on residential, commercial, or industrial construction projects, Mgo board is an excellent choice. It is a non-toxic, fire-resistant, and durable building material that resists moisture, mold, and mildew. Mgo board also offers excellent sound insulation and thermal insulation properties, making it an excellent choice for energy-efficient buildings.If you are searching for Mgo board exporters, the first step is to consider the quality of their products. The quality of the boards will depend on the type of equipment used in the manufacturing process. That’s where Mgo board machine comes into play.Mgo board machine is a high-tech piece of equipment that is specifically designed for the production of Mgo board. It is an essential component of the production process and plays a vital role in ensuring the quality of the final output. The machine has a control panel that allows you to monitor various parameters, such as temperature, pressure, and speed. This ensures that the manufacturing process is consistent and produces high-quality boards.When looking for Mgo board exporters, it is essential to inquire about the type of Mgo board machine they use. Manufacturers who use modern and advanced equipment typically produce better quality boards than those who use outdated technology. The machine's price is also a crucial factor to consider, as it can significantly impact the final cost of the product.At EC21, you can find various Mgo board machine pricelist options, allowing you to choose a machine that best suits your budget. The price will depend on the size, capacity, and technology of the machine. The pricelist will enable you to compare prices from different manufacturers and choose the one that offers the best value for your money.In conclusion, Mgo board is an excellent building material that offers fantastic properties for a wide range of applications. If you are searching for Mgo board exporters, make sure to inquire about the quality of their products and the type of Mgo board machine they use. You can find a range of Mgo board exporters on EC21, with various pricelist options for Mgo board machine. Choose the one that fits your needs and budget to ensure a successful construction project.

Affordable Automatic Gypsum Cornice Equipment Manufacturers: Enhance Search Engine Optimization

Title: Leading Automatic Gypsum Cornice Equipment Factories Revolutionize Manufacturing ProcessIntroduction:Gypsum cornices are an integral part of interior design, adding a touch of elegance and sophistication to any space. In an exciting development, a leading automatic gypsum cornice equipment factory is transforming the manufacturing process, propelling the industry forward. This groundbreaking technology, combined with the company's commitment to innovation, is revolutionizing the production of gypsum cornices. With unmatched precision and efficiency, these state-of-the-art equipment factories are shaping the future of interior decor.Body:1. The Rise of Automatic Gypsum Cornice Equipment Manufacturing:Over the past decade, there has been a considerable increase in the demand for high-quality gypsum cornices. To meet this growing demand, automatic gypsum cornice equipment factories have emerged, catering to the needs of interior designers, architects, and construction companies. These factories utilize cutting-edge technology to streamline production processes, ensuring increased efficiency and reduced costs.2. Cutting-Edge Technology and Manufacturing Process:The automatic gypsum cornice equipment factories incorporate advanced machinery and automation systems to optimize the manufacturing process. By utilizing computer numerical control (CNC) and robotics, these factories can produce gypsum cornices with unparalleled precision, consistency, and intricate designs. This groundbreaking technology not only enhances the overall quality but also significantly reduces manual labor.3. Benefits of Automatic Gypsum Cornice Equipment:a. Improved Efficiency: The use of automatic equipment has revolutionized gypsum cornice manufacturing, enabling factories to produce a larger quantity of products in a shorter period. This efficiency boost results in an enhanced customer experience and increased satisfaction levels.b. Consistent Quality: The precision offered by automatic machinery ensures consistent quality across all gypsum cornices produced by these factories. Each product adheres to the highest standards, showcasing fine details and impeccable craftsmanship.c. Cost-Effective: By combining automation with precise material usage, these factories can minimize material waste, thereby reducing costs. This cost-effectiveness translates to competitive pricing for customers, attracting a broader range of clients and promoting widespread adoption of gypsum cornices.4. Focus on Innovation:The leading automatic gypsum cornice equipment factories are driven by a relentless focus on innovation and research. They continuously strive to improve their manufacturing processes, developing new techniques and machinery to push the boundaries of what is possible within the industry. By investing in research and development, these companies ensure that their customers have access to the latest advancements in gypsum cornice manufacturing.5. Sustainability and Environmental Responsibility:In addition to technological advancements, automatic gypsum cornice equipment factories also prioritize sustainable production methods. By adhering to environmentally friendly practices, these factories minimize waste, reduce energy consumption, and utilize recyclable materials wherever possible. This commitment to sustainability aligns with contemporary demands for eco-friendly construction materials and contributes to the preservation of our planet.Conclusion:The automatic gypsum cornice equipment factories have ushered in a new era of manufacturing, bringing innovation, precision, and efficiency to the production of gypsum cornices. By embracing cutting-edge technology and focusing on sustainability, these factories provide a competitive advantage while meeting customer demands. With their commitment to innovation, these industry leaders are undoubtedly shaping the future of interior decor, transforming spaces with bespoke gypsum cornice designs that reflect a perfect combination of artistry and automation.

Top Gypsum Cornice Machine Factories: A Complete Overview

Mini Gypsum Cornice Machine Factories has recently made strides in revolutionizing the production of gypsum cornice by developing advanced machinery that streamline the manufacturing process. The company, which specializes in manufacturing and supply of construction materials, has been at the forefront of innovation in the industry for over a decade.The new machinery developed by Mini Gypsum Cornice Machine Factories is designed to significantly improve efficiency and productivity in the production of gypsum cornices. By automating certain aspects of the manufacturing process, the machine is able to produce high-quality gypsum cornices at a much faster rate than traditional methods. This not only reduces production time, but also minimizes the margin for error, resulting in a more consistent and reliable end product.In addition to its advanced technology, the Mini Gypsum Cornice Machine Factories places a strong emphasis on sustainability and environmental responsibility. The company is committed to reducing its carbon footprint and minimizing waste throughout the production process. The new machinery is designed with these principles in mind, utilizing energy-efficient systems and minimizing material waste.Furthermore, the company also prioritizes the safety and well-being of its employees. The new machinery is equipped with state-of-the-art safety features to ensure the protection of workers during the manufacturing process. This demonstrates Mini Gypsum Cornice Machine Factories' dedication to creating a safe and sustainable work environment.The introduction of this advanced machinery has positioned Mini Gypsum Cornice Machine Factories as a leader in the industry, setting new standards for efficiency, quality, and sustainability. By investing in innovation, the company has not only improved its own operations, but has also contributed to the advancement of the construction materials manufacturing sector as a whole."We are thrilled to introduce our new gypsum cornice machine, which represents a significant advancement in our manufacturing capabilities," said a spokesperson for Mini Gypsum Cornice Machine Factories. "This machinery not only enables us to produce high-quality gypsum cornices more efficiently, but also aligns with our commitment to sustainability and worker safety. We are proud to be at the forefront of innovation in our industry."The impact of Mini Gypsum Cornice Machine Factories' new machinery extends beyond its own operations. The increased efficiency and productivity it offers have the potential to benefit construction companies and contractors who rely on high-quality gypsum cornices for their projects. By streamlining the manufacturing process, the new machinery may ultimately contribute to cost savings and improved project timelines for construction industry stakeholders.In addition to the new machinery, Mini Gypsum Cornice Machine Factories offers a wide range of gypsum cornices in various designs, sizes, and finishes to meet the diverse needs of its customers. The company is known for its commitment to customer satisfaction, providing reliable products and exceptional service to clients worldwide.As Mini Gypsum Cornice Machine Factories continues to lead the industry with its innovative approach to manufacturing, the company looks toward the future with optimism. By staying true to its values of quality, sustainability, and safety, the company seeks to make a lasting impact on the construction materials sector and solidify its position as a trusted partner for construction industry professionals globally. With its advanced machinery and dedication to excellence, Mini Gypsum Cornice Machine Factories is poised to shape the future of gypsum cornice production.

Automated Gypsum Ceiling Board Laminating Machine for PVC Material

PVC Gypsum Ceiling Board Laminating Machine Revolutionizes Interior DesignThe interior design industry has been revolutionized with the introduction of the PVC Gypsum Ceiling Board Laminating Machine by {Company Name}. This cutting-edge technology has opened up a world of possibilities for interior designers and architects, allowing them to create stunning and innovative ceiling designs that were previously only imagined.The PVC Gypsum Ceiling Board Laminating Machine is a state-of-the-art piece of equipment that is designed to apply PVC film to gypsum ceiling boards, creating a high-quality finish that is both stylish and durable. This innovative machine has the capability to laminate ceiling boards with precision, ensuring a seamless and professional result every time.One of the key features of the PVC Gypsum Ceiling Board Laminating Machine is its versatility. It can be used to laminate a wide range of ceiling board sizes and shapes, allowing for endless design possibilities. Whether it's a traditional flat ceiling or a more complex, multi-level design, this machine can handle it all with ease.Additionally, the PVC Gypsum Ceiling Board Laminating Machine is incredibly efficient, significantly reducing the time and labor required to laminate ceiling boards compared to traditional methods. This means that projects can be completed more quickly and cost-effectively, benefiting both designers and their clients.{Company Name} has a rich history of innovation in the interior design industry. Since its establishment, the company has been at the forefront of developing advanced technologies and equipment to enhance the capabilities of interior designers and architects. The introduction of the PVC Gypsum Ceiling Board Laminating Machine is yet another example of the company's commitment to driving progress and pushing the boundaries of design.With a team of experienced engineers and designers, {Company Name} has combined cutting-edge technology with a deep understanding of the needs of the industry to create the PVC Gypsum Ceiling Board Laminating Machine. The company's dedication to quality and innovation is evident in the performance and reliability of this machine, which has quickly become an essential tool for interior designers and architects around the world.The impact of the PVC Gypsum Ceiling Board Laminating Machine on the industry has been profound. Interior designers and architects are now able to bring their creative visions to life in ways that were previously impossible. The machine's ability to produce high-quality, customized ceiling designs has opened up new possibilities for creating unique and captivating interior spaces.Furthermore, the PVC Gypsum Ceiling Board Laminating Machine has also had a positive impact on the efficiency and cost-effectiveness of interior design projects. By streamlining the lamination process, designers can complete projects more quickly and with greater precision, resulting in a higher standard of work and greater satisfaction for their clients.In conclusion, the introduction of the PVC Gypsum Ceiling Board Laminating Machine by {Company Name} has been a game-changer for the interior design industry. Its innovative technology and versatile capabilities have empowered designers and architects to push the boundaries of creativity and efficiency, leading to a new era of possibilities in interior design. As the industry continues to evolve, it's clear that this machine will continue to play a crucial role in shaping the future of interior design.

Vinyl Faced PVC Gypsum Board for Acoustic Insulation: A Plasterboard Ceiling Solution

Are you searching for the perfect solution to enhance the look and feel of your home or office interior space? Look no further than vinyl faced PVC gypsum board or acoustic insulation! At Xinsdi.com, we specialize in providing high-quality construction and decoration products, including our top-of-the-line vinyl faced PVC gypsum board.Our sunshine brand PVC laminated gypsum ceiling tile is the perfect solution for homeowners and business owners alike who are in need of a cost-effective way to improve the acoustics of a room, while simultaneously benefiting from superior insulation properties. Made of the highest quality paper-faced materials, our vinyl faced PVC gypsum board is both durable and long-lasting, ensuring that you get the most out of your investment.But what sets our PVC laminated gypsum ceiling tile apart from the competition? One of the key features is its exceptional acoustic insulation properties, making it the perfect choice for anyone who is looking to reduce noise pollution within their home or office space. The additional benefit of improved insulation means that our vinyl faced PVC gypsum board can help to reduce your energy costs, by keeping your space warm and cozy throughout the year.But that's not all - our vinyl faced PVC gypsum board is also affordable, making it an excellent choice for those who are looking for a budget-friendly option for their construction needs. At Xinsdi.com, we understand that cost is an important factor for our customers, which is why we have worked hard to ensure that our products are competitively priced, without compromising on quality.If you're looking for a way to improve the aesthetics of your home or office space, our vinyl faced PVC gypsum board can also provide a stylish solution. The laminated finish adds a touch of elegance and sophistication to any room, whether you're going for a modern or traditional look.At Xinsdi.com, we pride ourselves on providing our customers with the highest quality construction and decoration products, including our top-of-the-line vinyl faced PVC gypsum board. So, whether you're in need of acoustic insulation, improved insulation, or a stylish alternative to traditional ceiling tiles, we have the perfect solution for you.And for those searching for a cheap plasterboard ceiling machine, look no further than Xinsdi.com. We offer a wide range of affordable options to suit your specific needs and requirements, with a focus on quality and durability. Contact us today to learn more about our products and services!

Top Manufacturers of Magnesium Plate Board Machines Revealed in Latest News

[News Title]: A Breakthrough in Magnesium Plate Board Production: Innovative Machine Introduced by Leading Manufacturers[News Content]:[date]Magnesium has long been recognized as a versatile metal with numerous industrial applications. Its lightweight, high strength, and exceptional resistance to corrosion have made it a popular choice for manufacturers across various sectors. Considered a superior alternative to traditional materials such as aluminum, steel, and plastic, magnesium plates have become increasingly sought after in recent years for use in construction, automotive, aerospace, and other industries. In line with the growing demand, {Company Name}, a leading manufacturer in the field, has introduced an innovative magnesium plate board machine that promises to revolutionize the production process.{Company Name}, operating for over [number of years] years, has established itself as a trusted name in the industry. Driven by a commitment to innovation, the company has continuously invested in research and development to improve the efficiency and quality of their products. The introduction of their new magnesium plate board machine represents a significant milestone for both the company and the industry as a whole.The cutting-edge machine, developed by a team of skilled engineers and technicians, combines state-of-the-art technology with years of experience in magnesium processing. The unique design of the machine allows for precise control over the production process, resulting in magnesium plates of unparalleled quality. With the ability to produce a wide range of thicknesses and sizes, the machine caters to the diverse needs of customers in various sectors.One of the key features of the new machine is its enhanced automation capabilities. Through an advanced control system, the machine can streamline production, ensuring a faster and more efficient manufacturing process. This not only maximizes output but also reduces human error, leading to consistently high-quality magnesium plates. Furthermore, the machine's automated material feeding system optimizes resource utilization, minimizing waste and improving overall sustainability.In addition to its exceptional performance, the magnesium plate board machine developed by {Company Name} prioritizes worker safety. Equipped with multiple safety features, including emergency stop buttons and protective barriers, the machine ensures a safe operating environment for its operators. This focus on occupational health and safety reflects the company's dedication to promoting a responsible and sustainable manufacturing process.{Company Name}'s commitment to quality extends beyond the machine itself. As a socially responsible manufacturer, the company sources its magnesium from certified suppliers, ensuring compliance with international standards and best practices. This not only guarantees the integrity of the final product but also contributes to a more sustainable supply chain overall.Given the ever-growing demand for magnesium plates, {Company Name}'s introduction of this advanced machine marks a significant step forward for the industry. By combining cutting-edge technology, efficient production processes, and a commitment to quality and safety, the company solidifies its position as a leader in the magnesium plate board manufacturing sector.Looking ahead, {Company Name} plans to continue its research and development efforts, aiming to further improve the machine's capabilities. Through ongoing innovation, they strive to meet evolving market demands, enhance customer satisfaction, and contribute to the advancement of the magnesium industry as a whole.In conclusion, the introduction of {Company Name}'s innovative magnesium plate board machine represents a groundbreaking development for the industry. With its advanced automation, emphasis on safety, and commitment to quality, the machine is set to reshape the production of magnesium plates, catering to the increasing demand across various sectors. As a leading manufacturer, {Company Name} continues to demonstrate its dedication to pushing boundaries and driving progress within the magnesium industry.

Affordable Automatic Gypsum Cornice Making Machine Manufacturers

Cheap Automatic Gypsum Cornice Making Machine Factories are becoming increasingly popular in the manufacturing industry. These factories are revolutionizing the way gypsum cornice products are produced, making it more efficient and cost-effective for companies to meet their production needs. One such company that is leading the charge in this industry is {}.{} is a renowned company that specializes in the manufacturing of automatic gypsum cornice making machines. With their state-of-the-art technology and innovative approach to production, they have quickly become a top choice for businesses looking to invest in high-quality and affordable machinery.One of the key factors that set {} apart from other competitors in the industry is their commitment to providing cheap, automatic gypsum cornice making machines that are of the highest quality. By utilizing advanced manufacturing techniques and cutting-edge technology, {} is able to produce top-of-the-line machinery at a fraction of the cost of their competitors.In addition to their focus on affordability, {} is also committed to providing excellent customer service and support. They understand that investing in machinery is a significant decision for any business, and they strive to ensure that their clients have all the information and assistance they need to make the best choices for their production needs.With a team of highly skilled and experienced professionals, {} is able to offer comprehensive support to their clients at every stage of the process. From initial consultations to installation and ongoing maintenance, {} is dedicated to providing a seamless and stress-free experience for their customers.The automatic gypsum cornice making machines produced by {} are designed to maximize efficiency and productivity. These machines are capable of producing a wide range of gypsum cornice products with precision and consistency, making them an ideal solution for businesses looking to streamline their production processes.Furthermore, {} is constantly innovating and improving their machinery to stay ahead of the curve in the industry. They are always exploring new technologies and methodologies to enhance the performance and capabilities of their machines, ensuring that their clients have access to the most advanced and reliable equipment on the market.In addition to their commitment to quality and innovation, {} also prioritizes sustainability and environmental responsibility in their manufacturing processes. They are dedicated to minimizing waste and reducing their carbon footprint, making them a responsible and conscientious choice for businesses that are mindful of their impact on the environment.As a leading manufacturer of cheap automatic gypsum cornice making machines, {} is well-positioned to meet the growing demand for efficient and cost-effective production solutions in the industry. With their unwavering dedication to quality, affordability, and customer satisfaction, {} is poised to continue making a positive impact on businesses looking to optimize their production processes.In conclusion, the rise of cheap automatic gypsum cornice making machine factories is reshaping the manufacturing landscape, and companies like {} are at the forefront of this revolution. By offering high-quality, affordable machinery and exceptional customer support, {} is helping businesses around the world achieve their production goals with ease and efficiency. As the industry continues to evolve, {} will undoubtedly remain a key player in driving this positive change.