Affordable Automatic Gypsum Cornice Making Machine Manufacturers

By:Admin

{} is a renowned company that specializes in the manufacturing of automatic gypsum cornice making machines. With their state-of-the-art technology and innovative approach to production, they have quickly become a top choice for businesses looking to invest in high-quality and affordable machinery.

One of the key factors that set {} apart from other competitors in the industry is their commitment to providing cheap, automatic gypsum cornice making machines that are of the highest quality. By utilizing advanced manufacturing techniques and cutting-edge technology, {} is able to produce top-of-the-line machinery at a fraction of the cost of their competitors.

In addition to their focus on affordability, {} is also committed to providing excellent customer service and support. They understand that investing in machinery is a significant decision for any business, and they strive to ensure that their clients have all the information and assistance they need to make the best choices for their production needs.

With a team of highly skilled and experienced professionals, {} is able to offer comprehensive support to their clients at every stage of the process. From initial consultations to installation and ongoing maintenance, {} is dedicated to providing a seamless and stress-free experience for their customers.

The automatic gypsum cornice making machines produced by {} are designed to maximize efficiency and productivity. These machines are capable of producing a wide range of gypsum cornice products with precision and consistency, making them an ideal solution for businesses looking to streamline their production processes.

Furthermore, {} is constantly innovating and improving their machinery to stay ahead of the curve in the industry. They are always exploring new technologies and methodologies to enhance the performance and capabilities of their machines, ensuring that their clients have access to the most advanced and reliable equipment on the market.

In addition to their commitment to quality and innovation, {} also prioritizes sustainability and environmental responsibility in their manufacturing processes. They are dedicated to minimizing waste and reducing their carbon footprint, making them a responsible and conscientious choice for businesses that are mindful of their impact on the environment.

As a leading manufacturer of cheap automatic gypsum cornice making machines, {} is well-positioned to meet the growing demand for efficient and cost-effective production solutions in the industry. With their unwavering dedication to quality, affordability, and customer satisfaction, {} is poised to continue making a positive impact on businesses looking to optimize their production processes.

In conclusion, the rise of cheap automatic gypsum cornice making machine factories is reshaping the manufacturing landscape, and companies like {} are at the forefront of this revolution. By offering high-quality, affordable machinery and exceptional customer support, {} is helping businesses around the world achieve their production goals with ease and efficiency. As the industry continues to evolve, {} will undoubtedly remain a key player in driving this positive change.

Company News & Blog

Affordable PVC Laminated Gypsum Board Machine Price List Unveiled in Recent News

PVC Laminated Gypsum Board Machine Aims to Reinforce Efficiency and Quality in Manufacturing ProcessIn recent industry news, a leading company in the manufacturing and distribution of gypsum board machinery, known for their commitment to innovative technology and exceptional quality, announced the introduction of a new PVC laminated gypsum board machine. This advanced machinery aims to provide a solution for enhancing efficiency and elevating the quality of gypsum board production.The machinery, which leverages cutting-edge technology and industry expertise, offers numerous advantages to manufacturers in the gypsum board industry. With a focus on increasing productivity, this machine can significantly reduce the production time required for manufacturing gypsum boards while maintaining high-quality standards. By streamlining the entire manufacturing process, companies can optimize their production output, allowing for greater profitability and customer satisfaction.One of the key features of this PVC laminated gypsum board machine is its ability to integrate the lamination process directly into the manufacturing line, eliminating the need for a separate lamination process. This integration not only saves time and labor but also ensures consistent and superior adhesion between the PVC layer and the gypsum board. By eliminating the risk of delamination, manufacturers can guarantee a longer lifespan for their gypsum boards, making them more reliable for various construction applications.Furthermore, this state-of-the-art machinery incorporates advanced control systems that enable real-time monitoring and adjustment of production parameters. This ensures precision in the manufacturing process, resulting in consistently high-quality boards with accurate dimensions and smooth surfaces. Manufacturers can also benefit from the machine's versatility, as it offers customizable settings to meet specific industry requirements or produce various board sizes and designs.With sustainability being a significant concern in today's manufacturing industry, this PVC laminated gypsum board machine incorporates eco-friendly features to reduce its environmental impact. The machinery optimizes energy consumption through efficient power management systems, minimizing energy waste during production. Additionally, it utilizes low-emission technology, reducing harmful emissions and promoting cleaner air quality in the workplace.Alongside the introduction of this new machinery, the company aims to provide comprehensive technical support and after-sales service to their clients. Their team of highly skilled engineers and technicians will be available to assist manufacturers with machine installation, training, and troubleshooting, ensuring a seamless transition into the new production process. By offering ongoing support, the company establishes a strong partnership with their clients, strengthening their reputation as a reliable and customer-oriented provider.As global demand for gypsum board continues to rise, driven by the booming construction industry, manufacturers must invest in advanced machinery to remain competitive. This new PVC laminated gypsum board machine addresses the industry's need for improved efficiency, productivity, and quality standards. By adopting this innovative solution, manufacturers can enhance their production capabilities, streamline their operations, and deliver superior gypsum board products to meet market demands.In conclusion, the introduction of the PVC laminated gypsum board machine represents a significant milestone for the manufacturing industry. With its advanced technology, integration of lamination processes, precise control systems, and eco-friendly features, this machinery aims to revolutionize the gypsum board manufacturing process. The company's commitment to providing technical support and after-sales service further demonstrates their dedication to customer satisfaction. As manufacturers embrace this groundbreaking solution, they will be well-equipped to meet the growing demand for high-quality gypsum boards in construction projects worldwide.

High-Quality Machinery for Mgo Board Production

Mgo Board Machinery Factory is a leading manufacturer of machinery for producing Mgo (Magnesium Oxide) boards. The company has been in the industry for over 20 years and has gained a reputation for producing high-quality and efficient machinery for the construction material industry. The factory is located in an industrial zone, covering an area of 10,000 square meters, and employs over 100 skilled workers.The machinery produced by Mgo Board Machinery Factory is used for the production of Mgo boards, which are widely used in the construction industry for their fire-resistant, waterproof, and durable properties. The company's machinery is designed with the latest technology and is known for its high efficiency and low energy consumption.Recently, the factory has been making headlines in the industry for its latest innovation in Mgo board production machinery. The company has introduced a new fully automated production line that is set to revolutionize the Mgo board manufacturing process. This new production line is capable of producing Mgo boards of various sizes and thickness with minimal human intervention, significantly increasing production efficiency and reducing labor costs.The new automated production line is equipped with state-of-the-art sensors and control systems that ensure the precise mixing of raw materials and accurate pressing of the Mgo boards. The machinery is also designed for easy maintenance and has a user-friendly interface, making it easy for operators to monitor and control the production process.According to the company's spokesperson, the new automated production line is a result of years of research and development. The company's team of engineers and technical experts have worked tirelessly to design and build a production line that meets the growing demand for Mgo boards in the construction industry.The introduction of the new automated production line is expected to have a significant impact on the market. With the increased efficiency and reduced labor costs, manufacturers of Mgo boards will be able to produce higher volumes at a lower cost, making the construction material more affordable and accessible to a wider range of customers.In addition to the new automated production line, Mgo Board Machinery Factory is also known for its excellent after-sales service and technical support. The company has a team of experienced engineers who provide on-site installation and training for customers, ensuring that the machinery is set up and operated correctly for optimal performance.The company's commitment to innovation and customer satisfaction has earned it a strong reputation in the industry. Many Mgo board manufacturers and construction companies rely on the machinery produced by Mgo Board Machinery Factory for their production needs.Looking ahead, Mgo Board Machinery Factory is focused on further research and development to continue improving its machinery and staying ahead of the competition. The company aims to expand its reach to new markets and work closely with customers to meet their specific production requirements.With its latest innovation in Mgo board production machinery, Mgo Board Machinery Factory is set to maintain its position as a leader in the industry and drive the growth of the construction material market. The company's dedication to quality, efficiency, and customer satisfaction makes it a reliable partner for manufacturers and construction companies looking to invest in top-of-the-line machinery for Mgo board production.

New Gypsum Cornice Production Line with Automated Features for Increased Efficiency

If you’re in the market for the best automatic gypsum cornice equipment, then look no further than Feixian Dongyue Gypsum Equipment Co., Ltd. They have a comprehensive range of products that are sure to meet all of your needs and exceed your expectations.One of their standout products is the gypsum cornice production line. This line is perfect for those looking to produce high-quality cornices efficiently and quickly. Let’s take a closer look at some of the features that make this production line one of the best on the market.Firstly, the equipment comes with a 10t gypsum bin. This feature is particularly advantageous as it saves labor time and effort. The gypsum bin ensures that you have a steady supply of gypsum powder available, which is necessary for the production of cornices.Secondly, the system is fully automated. This means that the proportion of water and powder is controlled by a PLC computer, which ensures that each batch is consistent and of the highest quality. Additionally, the beating machine is fully automated which further increases the efficiency of the production line.The equipment is also very easy to operate and requires a minimal amount of training. This feature makes it ideal for those who are new to the production of cornices or for those who are looking to expand their business and need to train new staff.Furthermore, the equipment can produce a wide range of different shapes and sizes of cornices. This flexibility allows you to cater to a range of different customer needs and preferences.Finally, the equipment is very reliable and durable. It is built to last and will require minimal maintenance over its lifetime, making it a cost-effective investment.In conclusion, if you’re in the market for the best automatic gypsum cornice equipment, then the Feixian Dongyue Gypsum Equipment Co., Ltd production line is an excellent option. Its range of features make it efficient, easy to use, flexible, and reliable. So why not upgrade your production line today and take your business to the next level?

New Equipment for Manufacturing MGO Board Announced

Innovative Mgo Board Equipment to Revolutionize Construction IndustryA new Mgo board equipment is poised to revolutionize the construction industry. The advanced manufacturing technology offered by this equipment is designed to deliver top-quality Mgo board products for various building applications.The equipment, whose name cannot be disclosed for competitive and legal reasons, has been developed by a leading manufacturer of Mgo board and related products. The company has been producing high-quality Mgo board for more than a decade, and has gained a solid reputation for delivering top-rated products.With a focus on innovative design and advanced technology, the company's new Mgo board equipment combines precision engineering, high-quality components, and user-friendly features that are intended to make the manufacturing process more efficient and cost-effective.The equipment features a robust workstation that is easy to operate, with a user-friendly interface that provides seamless control and precise measurement. The workstation is designed to process Mgo boards of various sizes and thickness, ensuring that the output meets the required specifications.The Mgo board equipment also features advanced mixing technology, which is essential for producing high-quality Mgo boards. The mixing process is automated and controlled, resulting in a consistent and uniform mixture that meets the required standards.In addition, the equipment is equipped with advanced cutting technology, which ensures that the Mgo boards are accurately cut to the required size and shape. The cutting process is automated and precise, providing clean and smooth edges for the finished product.One of the standout features of the new Mgo board equipment is its innovative automation capabilities. The equipment is designed to automate most of the manufacturing process, reducing the need for manual labor and minimizing the risk of human error. This results in a more efficient and cost-effective production process, while also ensuring consistently high-quality Mgo board products.Moreover, the equipment is designed to be environmentally friendly, with reduced energy consumption and minimal waste. This is achieved through advanced energy-saving technology and improved production processes that optimize material usage, while minimizing waste.The company prides itself on being committed to sustainability and environment-friendly manufacturing practices. All of its products are ISO certified, ensuring that they meet the highest standards of quality and safety.With the introduction of the new Mgo board equipment, the company aims to provide its customers with an even better experience and more high-quality products. The equipment is already in high demand, with several orders already placed by both local and international customers.The company believes that the new Mgo board equipment is poised to transform the construction industry by delivering high-quality and sustainable building materials. The company's dedication to innovation, quality, and sustainability has been one of the driving factors behind its success and continued growth in the industry.In conclusion, the new Mgo board equipment is a game-changer for the construction industry. With its advanced technology and innovative features, it promises to deliver high-quality and sustainable building materials that meet the needs of today's modern construction projects. As the demand for environmentally friendly and cost-effective building materials continues to grow, the company's new Mgo board equipment is perfectly positioned to lead the way.

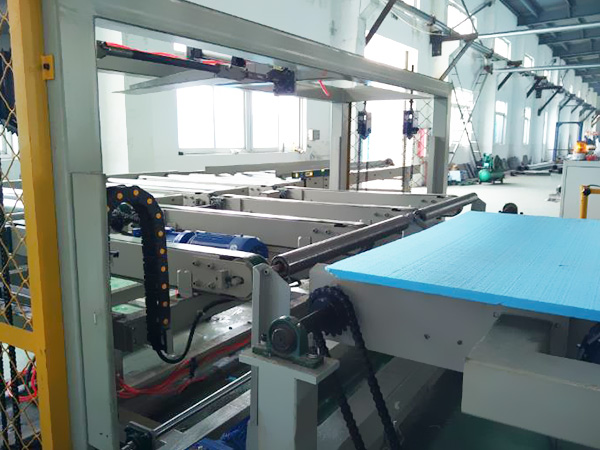

Affordable XPS Foam Board Making Machine: Find a Competitive Pricelist

Title: Revolutionary XPS Foam Board Making Machine Redefines Manufacturing EfficiencySubtitle: Pioneering Company Leads the Way in Sustainable and Cost-effective Insulation Production[City], [Date] - The demand for energy-efficient and eco-friendly construction materials has been growing steadily in recent years. In response to this market need, a renowned manufacturing company, with years of industry experience, has introduced an innovative XPS Foam Board Making Machine that revolutionizes the production process. This advanced technology brings forth a range of benefits, including increased efficiency, reduced costs, and enhanced sustainability.The XPS Foam Board Making Machine, developed by [Company Name], is an automated manufacturing solution that simplifies and optimizes the production of extruded polystyrene (XPS) foam boards. XPS foam boards have become popular for their exceptional insulation properties, moisture resistance, and durability. However, traditional manufacturing methods for XPS foam boards were often labor-intensive, time-consuming, and environmentally unfriendly.Recognizing these challenges, [Company Name] has developed an intuitive and fully automated machine that streamlines the entire production process. Equipped with cutting-edge technology and extensive customization options, this XPS Foam Board Making Machine addresses the limitations of conventional manufacturing practices.One of the key features of this machine is its ability to create XPS foam boards of different thicknesses and sizes, catering to various construction requirements. With precise control over dimensions, the machine ensures consistent quality, eliminating wastage and reducing overall production costs. Additionally, the machine's user-friendly interface allows operators to easily monitor and adjust the manufacturing parameters, promoting efficiency and accuracy.The XPS Foam Board Making Machine incorporates state-of-the-art heating and cooling systems, ensuring optimal results with minimal energy consumption. By utilizing smart insulation technology, the machine reduces heat loss during the production process, resulting in significant energy savings. This eco-friendly approach aligns with global efforts to combat climate change and reduces the carbon footprint associated with traditional manufacturing methods.[Company Name], with its commitment to sustainable practices, also emphasizes the usage of environmentally friendly materials. The machine utilizes bio-based blowing agents, thereby eliminating the use of hazardous chemicals in the insulation production. This advancement not only enhances the safety of workers but also contributes to the concept of green construction.Furthermore, the XPS Foam Board Making Machine incorporates advanced quality control mechanisms to uphold stringent industry standards. Real-time monitoring systems and automated sensors detect any deviations in parameters, ensuring consistent product quality throughout the manufacturing process. This attention to quality guarantees exceptional insulation properties and durability, meeting the demands of discerning customers.With a focus on customer satisfaction, [Company Name] also offers comprehensive technical support and expert guidance to their clients. They provide training sessions for operating the machine, troubleshooting assistance, and ongoing maintenance services to ensure a seamless production experience.The introduction of the XPS Foam Board Making Machine by [Company Name] is set to revolutionize the insulation manufacturing industry. This innovative technology promises increased efficiency, reduced costs, improved product quality, and enhanced sustainability. As construction practices shift towards energy-efficient and environmentally friendly materials, this cutting-edge machine presents itself as a game-changer in the market.About [Company Name]:[Include company's introduction here. Mention their expertise in manufacturing and commitment to sustainable practices. Highlight their track record of delivering high-quality products and exceptional customer service.]In conclusion, the XPS Foam Board Making Machine is a revolutionary advancement in manufacturing technology, delivering exceptional efficiency, sustainability, and cost-effectiveness. With its focus on quality control, customizable options, and eco-friendly production, this machine positions [Company Name] as an industry leader in the insulation manufacturing sector.

Professional Plastering Services for New Builds, Repairs, and Renovations

Brad McKinnon Plastering: The Leading Plastering Service ProviderLooking to renovate your home or building a new house from scratch? Then, Brad McKinnon Plastering has got you covered! Providing top-notch plastering services, Brad McKinnon Plastering is the leading company in New Zealand, known for delivering quality and timely services to clients.At Brad McKinnon Plastering, we understand the vital role that plastering plays in the construction industry, and our dedicated team of experts takes great pride in providing top-quality services that exceed our clients' expectations. Our commitment to quality and excellence has made us one of the most preferred plastering providers in the industry.New Build ServicesBuilding a house from scratch is a significant investment in one's life, and we understand that. Hence, we offer New Build services like no other. Our team of experts is knowledgeable, reliable and equipped with the latest technology and tools to ensure that your new build is perfect. We pay attention to every detail, from layout to design, and from plastering to painting. We ensure that our clients' vision comes to fruition, and their dream home is realized.Repair ServicesAt some point, even the most robust of buildings require repairs. Whether it's a small crack or significant damage, fret no more, as Brad McKinnon Plastering offers reliable repair services to maintain the aesthetics and integrity of your walls and ceilings. Our team of experts is equipped with the necessary skills and tools to tackle any repair job, no matter how big or small the issue may seem.Renovation ServicesThinking of a home makeover? Brad McKinnon Plastering is here to help. Our renovation services are bespoke and tailored to suit our clients' needs. We understand that every client has unique taste, and we take pride in listening and working with our clients to achieve their desired results. We employ the latest techniques to ensure that the result is not only visually appealing but exceeds our clients' expectations.Full Skim Level 5 ServicesIf you require the most polished finish, then our Full Skim Level 5 services are perfect for you. Our experts use the latest technology and tools to provide beautiful, level five finishes that will leave your walls and ceiling with the most beautiful, polished finish. Our team is dedicated to delivering exceptional work and will ensure that every detail is perfect.GIB CoveBrad McKinnon Plastering offers GIB Cove services, one of the most distinguishing features of any room. Our expert team ensures that the GIB Cove in your room is bespoke and tailored to your requirements and style. With our GIB Cove services, you can rest assured that your room will be transformed into a beautiful space.Plaster CorniceOne of the most essential aspects of plastering is Plaster Cornice. It enhances the aesthetics of any room and provides that extra finishing touch that can make all the difference. At Brad McKinnon Plastering, we specialize in Plaster Cornice and offer bespoke services that will transform your room.ConclusionBrad McKinnon Plastering is the most trusted and reliable plastering service provider in New Zealand. Our team of dedicated experts is equipped with the latest technology and tools to ensure that every job is perfect. We pay great attention to detail and are committed to delivering quality and timely services that exceed our clients' expectations. Contact us today, and let's help you transform your home.

Affordable CO2 Foam Extrusion Board Line Prices

Title: Innovative Co2 Foam XPS Extrusion Board Line Revolutionizes the Construction IndustryIntroduction:In an era where sustainability and environmental concerns have become paramount, companies across various industries are actively seeking alternatives to reduce their carbon footprint. As a response to these global challenges, a leading manufacturing company has developed an innovative Co2 Foam XPS Extrusion Board Line, poised to revolutionize the construction industry. By offering a highly efficient and eco-friendly solution, this state-of-the-art technology aims to address the growing demand for sustainable building materials. Body:1. Introduction to the Co2 Foam XPS Extrusion Board Line:The Co2 Foam XPS Extrusion Board Line is a cutting-edge manufacturing system that produces extruded polystyrene (XPS) foam boards utilizing carbon dioxide (Co2) as the foaming agent. This groundbreaking technology eliminates the use of commonly employed materials, such as hydrofluorocarbons (HFCs), which are known to have a high global warming potential.2. Advantages and Features:a. Reduced Environmental Impact: By leveraging Co2 as the foaming agent, this new-line manufacturing process significantly reduces greenhouse gas emissions. The elimination of HFCs translates into a substantially lower carbon footprint, contributing to a cleaner and more sustainable future for the construction industry.b. Energy Efficiency: The Co2 Foam XPS Extrusion Board Line boasts enhanced energy efficiency. The system employs advanced temperature and pressure control mechanisms, optimizing the manufacturing process. This results in reduced energy consumption compared to conventional XPS production methods.c. Superior Thermal Insulation: The foam boards produced by this innovative line possess excellent thermal insulation properties. Their closed-cell structure provides high-density insulation with a low thermal conductivity coefficient, effectively reducing energy consumption in buildings and enhancing overall energy efficiency.d. Durability and Versatility: The Co2 Foam XPS boards exhibit exceptional durability, making them suitable for various applications. These boards are resistant to moisture, decomposition, and mold growth, ensuring longevity and reliability, even in challenging environmental conditions.3. Application in the Construction Industry:a. Building Insulation: The Co2 Foam XPS Extrusion Board Line paves the way for energy-efficient buildings by offering superior insulation capabilities. By minimizing heat transfer through walls, floors, and roofs, these foam boards help reduce heating and cooling demands, resulting in significant energy savings for property owners.b. Soundproofing: The acoustic properties of the Co2 Foam XPS boards make them valuable in soundproofing applications. They efficiently absorb and dampen sound waves, contributing to a quieter and more comfortable indoor environment.c. Foundation Protection: The high compressive strength of these foam boards renders them ideal for applications involving foundation protection. Their ability to distribute and bear loads effectively safeguards structures against soil movements and natural disasters.4. Company Introduction:[Company Name] is a pioneering manufacturer and industry leader in sustainable building materials. With a commitment to pushing the boundaries of innovation, the company has invested significantly in research and development to create eco-friendly products that meet the needs of a rapidly changing world. By introducing the Co2 Foam XPS Extrusion Board Line, [Company Name] further solidifies its position as a frontrunner in the construction industry's quest for sustainable solutions.Conclusion:The introduction of the Co2 Foam XPS Extrusion Board Line represents a significant breakthrough in the construction industry, offering an eco-friendly alternative to traditional insulation materials. By utilizing Co2 as the foaming agent, this advanced manufacturing technology not only reduces greenhouse gas emissions but also provides enhanced energy efficiency and outstanding thermal insulation properties. With its durability, versatility, and application in various construction projects, these Co2 foam boards are poised to revolutionize the way buildings are constructed, paving the way for a greener and more sustainable future.

Revolutionizing Mgo Board Production: China's Advanced Automatic Production Line

Title: Advanced Automatic MGO Board Production Line Revolutionizes Manufacturing Industry in ChinaIntroduction:China's manufacturing industry has received a major boost with the introduction of an advanced automatic MGO (Magnesium Oxide) Board Production Line. This ground-breaking technology has already taken the country by storm, streamlining operations and revolutionizing the production of MGO boards. The automated production line is a significant development, reflecting China's commitment to innovation and sustainable manufacturing practices.The company, which specializes in the design and manufacture of cutting-edge machinery, has invested considerable resources into research and development to create this state-of-the-art production line. By adopting the latest technological advancements and adhering to stringent quality control standards, they have successfully developed an automated system that improves efficiency, reduces labor costs, and enhances the overall production process.Streamlined Production Process:The advanced automatic MGO Board Production Line incorporates a range of innovative features, significantly increasing the efficiency of the production process. Robotics and AI technology have been implemented to automate various stages of manufacturing, starting from raw material inspection, mixing, and board formation, all the way to final quality control checks. This fully automated system reduces the need for manual intervention, minimizing errors and inconsistencies, and ensuring uniformity in each board produced.The implementation of robotics and AI technology also contributes to a reduction in labor costs and significantly increases productivity. With the automated production line in place, more boards can be manufactured within a shorter timeframe, meeting the ever-increasing demand for MGO boards in China's construction and interior design industries.Quality Control and Product Consistency:Apart from enhancing production efficiency, the automated MGO Board Production Line also focuses on maintaining the highest quality standards. The integration of AI-powered quality control systems ensures that every board produced meets the required specifications. Real-time monitoring and inspection throughout the production process guarantee that only superior quality boards reach the market, building trust and satisfaction among consumers.Sustainable Manufacturing:In line with China's commitment to sustainable development, the advanced automatic MGO Board Production Line incorporates eco-friendly practices. The system optimizes the usage of raw materials, minimizing waste and promoting resource efficiency. Moreover, the production line is designed to reduce energy consumption and minimize environmental impact, aligning with China's green goals and global sustainability initiatives.Market Impact:The introduction of this advanced technology is expected to have a profound impact on the MGO board manufacturing industry in China. With increased production capacity, enhanced automation, and improved product consistency, manufacturers using this production line will be able to meet growing market demands effectively. The automated production process will also enable manufacturers to deliver their products in a more timely manner, further strengthening their market position and competitiveness.Looking to the Future:The successful development and adoption of the advanced automatic MGO Board Production Line mark a significant milestone for the company and the manufacturing industry in China as a whole. With continuous improvements and technological advancements, this production line will likely become a benchmark for the industry, driving further growth and innovation.Conclusion:The introduction of an advanced automatic MGO Board Production Line signifies China's commitment to technological innovation and sustainable manufacturing practices. The automated system ensures streamlined production, superior product consistency, and reduced environmental impact. By revolutionizing the manufacturing process, this groundbreaking technology paves the way for a more efficient and sustainable future for MGO board production in China.

Efficient Gypsum Ceiling Board Lamination Machine: Enhance Productivity and Quality!

OEM Gypsum Ceiling Board Lamination Machine Revolutionizes the Construction Industry[City, Date] - In a groundbreaking development for the construction industry, a leading manufacturer has introduced a state-of-the-art OEM Gypsum Ceiling Board Lamination Machine, offering cutting-edge technology that is set to revolutionize the way gypsum ceilings are manufactured.This innovative machine, produced by a company that specializes in construction equipment, is the result of years of research and development. The company’s commitment to delivering high-quality products has cemented its position as a global leader in the field.The OEM Gypsum Ceiling Board Lamination Machine boasts an array of advanced features that enable efficiency and precision in the manufacturing process, ultimately resulting in superior quality gypsum ceilings. By eliminating the manual component from the lamination process, this machine not only streamlines production but also guarantees consistency in every board manufactured.One of the key features of this cutting-edge machine is its ability to automate the lamination process. In the past, this process required tedious manual labor that left room for human error and inconsistencies. With this new machine, however, operators can simply input the specifications, and the machine takes care of the rest. This ensures a seamless production process, reducing the risk of errors and increasing overall productivity.The OEM Gypsum Ceiling Board Lamination Machine also incorporates advanced adhesive application technology. The precise and even distribution of adhesive ensures a strong bond between the gypsum board and the laminate, resulting in long-lasting and durable ceilings. This technology not only increases the quality of the end product but also improves the safety and reliability of the finished ceiling.Furthermore, this machine offers a range of customizable options, allowing manufacturers to produce ceiling boards according to their unique requirements. From selecting the desired core material to choosing the type of laminate and thickness, this machine offers unparalleled flexibility, empowering manufacturers to meet the varied demands of their customers.In terms of environmental sustainability, the OEM Gypsum Ceiling Board Lamination Machine also excels. By optimizing the adhesive application process and minimizing waste, this machine contributes to the reduction of material consumption. It also incorporates energy-saving features, ensuring minimal environmental impact throughout the manufacturing process.The introduction of this state-of-the-art OEM Gypsum Ceiling Board Lamination Machine is expected to reshape the construction industry. Its ability to enhance productivity, improve product quality, and prioritize sustainability will undoubtedly attract construction companies seeking to streamline their operations and deliver outstanding results.Speaking about the new machine, a spokesperson for the company said, “We are thrilled to introduce this game-changing technology to the market. The OEM Gypsum Ceiling Board Lamination Machine represents our ongoing commitment to innovation and providing excellent solutions to our customers. We are confident that this machine will not only revolutionize the way gypsum ceilings are manufactured but also optimize processes for construction companies worldwide.”As the industry adapts to increasing demands for efficiency, sustainability, and high-quality products, the OEM Gypsum Ceiling Board Lamination Machine offers a glimpse into the future of construction. With its advanced features and customizable options, this machine is set to transform the way gypsum ceilings are manufactured, bringing greater efficiency, quality, and reliability to the construction industry.About [Company Name]:[Company Name] is a renowned manufacturer specializing in cutting-edge construction equipment. With a strong focus on innovation, the company has been at the forefront of delivering high-quality products to construction companies worldwide. With a commitment to sustainability and excellence, [Company Name] has established itself as a trusted partner in the construction industry.

Affordable and Lightweight Yarn Recommendations for a Warm Winter Shawl

article focusing on affordable and lightweight yarn options for winter knitting projects.)Winter is the perfect season for knitting cozy shawls, scarves and blankets. But when it comes to choosing the right yarn for the project, many knitters face a dilemma. On one hand, you want a material that will keep you warm and snug, but on the other hand, you don't want it to be too heavy or expensive. The good news is that there are plenty of affordable and lightweight yarn options to choose from, as we explore in this article.Merino WoolOne of the most popular options for winter knitting is merino wool. This soft and warm yarn is made from the wool of merino sheep, known for their fine fleece. Merino wool is lightweight and breathable, making it ideal for layering and wearing indoors. It also has natural moisture-wicking properties, which means it will keep you dry and comfortable. Although merino wool can be on the pricier side, it's worth investing in for its durability and versatility.Acrylic YarnFor those looking for a more affordable option, acrylic yarn is a great choice. This man-made fiber is lightweight, easy to wash and available in a wide variety of colors and textures. Acrylic yarn is also hypoallergenic, making it a great option for those with sensitive skin. While it may not be as warm as some other fibers, it's a great option for layering or for wearing in milder winter weather.Alpaca YarnAlpaca yarn is another excellent option for winter knitting. This soft and insulating fiber comes from the fleece of the alpaca, a South American animal that's related to the llama. Alpaca yarn is incredibly warm and lightweight, making it ideal for winter accessories like scarves and hats. It is also hypoallergenic and comes in a variety of natural shades. While it can be more expensive than some other fibers, it's worth the investment for its warmth and comfort.Cotton YarnWhile many knitters associate cotton yarn with warm weather projects, it can also be a great option for winter knitting. Cotton is lightweight and breathable, making it ideal for layering or wearing indoors. It's also a more affordable option than some other fibers. While cotton may not be as warm as wool or alpaca, it's a great option for those who prefer natural fibers and want to avoid itchiness and irritation that can come from other materials.Bamboo YarnFinally, bamboo yarn is a great option for those looking for a lightweight and eco-friendly material. Bamboo is a sustainable and renewable resource, and bamboo yarn is incredibly soft and comfortable. It's also naturally antibacterial and hypoallergenic, making it a great option for those with sensitive skin. While it may not be as warm as other fibers, it's a great option for layering or for warmer winter weather.In conclusion, when it comes to finding the right yarn for your winter knitting project, there are plenty of affordable and lightweight options to choose from. Whether you prefer natural fibers like wool and alpaca, or man-made fibers like acrylic and bamboo, there's a yarn out there that's perfect for your needs. So stock up on your favorite materials and get ready to create cozy and stylish accessories to keep you warm all winter long.