High-Quality Mgo Board Machine Factories: Everything You Need to Know

By:Admin

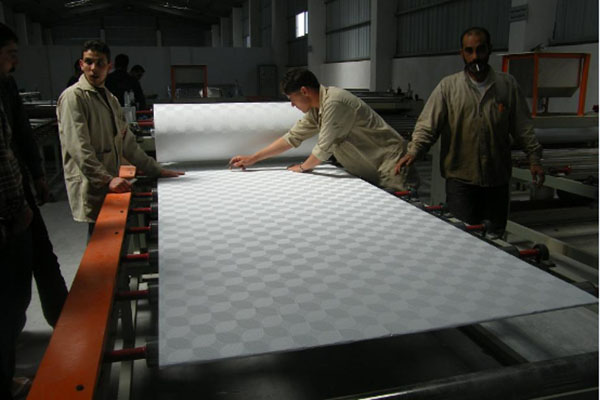

The Mgo board machine factories boast a comprehensive range of equipment, including board forming machines, board laminating machines, board cutting machines, and board packaging machines. These machines are designed to streamline the production process and ensure the consistent quality of MgO boards, which are known for their strength, durability, and fire resistance. With the increasing demand for sustainable and environmentally-friendly building materials, Mgo boards have become a popular choice for a wide range of construction applications.

The company takes great pride in their innovative approach to manufacturing and their dedication to delivering high-performance machinery to their clients. They are committed to staying ahead of the curve in terms of technological advancements in MgO board production, and they continuously invest in research and development to improve their machines' efficiency and performance. This commitment to innovation has allowed them to stay at the forefront of the industry and meet the evolving needs of their customers.

In addition to their cutting-edge machinery, the company also provides comprehensive technical support and after-sales service to ensure the smooth operation of their equipment. Their team of experienced engineers and technicians are readily available to assist clients with installation, maintenance, and troubleshooting, ensuring that their machines perform optimally at all times. This commitment to customer satisfaction has earned them a strong reputation in the industry and has led to long-standing relationships with many of their clients.

Furthermore, the company is dedicated to sustainability and environmental responsibility. They adhere to strict environmental standards in their manufacturing processes, and their machines are designed to minimize waste and energy consumption. This eco-friendly approach aligns with the growing demand for greener construction practices and has positioned the company as a responsible and ethical supplier in the industry.

The Mgo board machine factories take pride in their global reach, serving clients in various countries around the world. Their comprehensive network of distributors and partners ensures that their machinery is readily accessible to construction companies across different continents. This global presence has enabled them to make a significant impact on the construction industry and has solidified their position as a leading supplier of MgO board production equipment.

As the demand for MgO boards continues to grow, the Mgo board machine factories are poised to play a pivotal role in the construction industry. Their commitment to innovation, quality, and customer satisfaction will undoubtedly be key factors in their continued success. With a firm foothold in the global market and a strong reputation for excellence, they are well-positioned to capitalize on the opportunities presented by the increasing popularity of MgO boards in construction projects.

In summary, Mgo board machine factories are revolutionizing the construction industry with their cutting-edge machinery for MgO board production. Their commitment to quality, innovation, and customer satisfaction has positioned them as a trusted supplier in the global market. As the demand for sustainable and high-performance construction materials continues to rise, Mgo board machine factories are poised to lead the way with their state-of-the-art equipment and unwavering dedication to excellence.

Company News & Blog

Laminated Gypsum Ceiling Tiles Machine: Everything You Need to Know

PVC Laminated Gypsum Ceiling Tiles Machine: Revolutionizing the Ceiling IndustryIn today's modern world, the demand for stylish and durable ceilings is increasing rapidly. The use of PVC laminated gypsum ceiling tiles has become a popular choice for architects, interior designers, and homeowners alike. These tiles not only add beauty to the interiors but also provide thermal insulation and are fire-resistant. With the increasing demand for these tiles, the need for advanced manufacturing machines has also risen. This is where the innovative PVC Laminated Gypsum Ceiling Tiles Machine, offered by [company name], comes into play.[Company name] has been a prominent player in the manufacturing industry, specializing in producing high-quality machinery for the construction and interior design sectors. Their PVC Laminated Gypsum Ceiling Tiles Machine has revolutionized the way these ceiling tiles are manufactured. The machine is designed to produce PVC laminated gypsum ceiling tiles with precision and efficiency, meeting the industry's high standards.The machine is equipped with state-of-the-art technology, allowing for seamless production of high-quality tiles. It is capable of producing a wide range of sizes and designs, catering to the diverse needs of customers. The PVC Laminated Gypsum Ceiling Tiles Machine is highly automated, reducing the need for manual labor and improving overall productivity. This not only saves time but also lowers production costs, making it an ideal choice for manufacturers looking to stay competitive in the market.One of the key advantages of [company name]'s machine is its ability to produce PVC laminated gypsum ceiling tiles with excellent flatness and surface finish. This ensures that the tiles are aesthetically pleasing and free from any defects, meeting the aesthetic requirements of modern interior designs. Additionally, the machine is designed to handle various PVC film thicknesses, allowing for flexibility in production and customization options for customers.Furthermore, the PVC Laminated Gypsum Ceiling Tiles Machine is built to be durable and low maintenance, ensuring a longer lifespan and minimal downtime for manufacturers. It is also energy-efficient, contributing to sustainability efforts within the industry. The machine's user-friendly interface and simple operation make it easy for manufacturers to adapt to the system and produce high-quality tiles consistently.With the increasing demand for PVC laminated gypsum ceiling tiles, [company name] is committed to providing top-of-the-line machinery to meet the growing needs of the market. Their machine is not only a game-changer in the manufacturing process but also contributes to the overall quality and reliability of the final product.In conclusion, [company name] has once again raised the bar in the manufacturing industry with its innovative PVC Laminated Gypsum Ceiling Tiles Machine. With its advanced technology, precision production, and cost-saving benefits, this machine is set to make a significant impact on the ceiling industry. As the demand for PVC laminated gypsum ceiling tiles continues to grow, [company name] remains at the forefront, providing cutting-edge solutions for manufacturers worldwide.

Decorative Gypsum Cornice Production Line Pricelist in China

China Decorative Gypsum Cornice Production Line PricelistChina is a leading manufacturer and supplier of decorative gypsum cornice production lines. The company has been in the industry for many years and has gained a strong reputation for producing top-quality machinery for the production of decorative gypsum cornices. With a focus on innovation and customer satisfaction, the company has recently released a new pricelist for its decorative gypsum cornice production lines.The pricelist includes a range of production lines to suit different manufacturing needs and budgets. From small-scale production lines suitable for startups and small businesses, to large-scale production lines for high-volume manufacturing, the company offers a variety of options to meet the diverse needs of its customers. The pricelist also includes detailed specifications and features of each production line, as well as pricing information to help potential customers make informed decisions.One of the key features of the company's decorative gypsum cornice production lines is their high level of automation and efficiency. The production lines are designed to streamline the manufacturing process and minimize manual labor, resulting in higher productivity and lower production costs. Additionally, the company's production lines are known for their reliability and durability, ensuring long-term performance and minimal downtime for its customers.In addition to the new pricelist, the company continues to provide comprehensive support and services for its customers. From initial consultation and machinery selection, to installation, training, and after-sales support, the company's team of experts is dedicated to ensuring a seamless experience for its customers. This commitment to customer satisfaction has helped the company build long-lasting relationships with its clients, both domestically and internationally.The release of the new pricelist reflects the company's ongoing efforts to provide the best value for its customers. By offering competitive pricing and a wide range of options, the company aims to cater to the diverse needs of manufacturers in the gypsum cornice industry. This approach aligns with the company's mission to be a trusted partner for its customers, providing them with the tools and support they need to succeed in their businesses.As a leading player in the decorative gypsum cornice production line industry, the company is continuously investing in research and development to stay ahead of market trends and technology advancements. By leveraging its expertise and experience, the company is able to deliver innovative solutions that meet the evolving needs of its customers. This commitment to innovation positions the company as a reliable source for cutting-edge technology and machinery in the industry.With the release of the new pricelist, the company aims to reach a broader audience of manufacturers who are looking to enhance their production capabilities. Whether it's for creating unique and intricate designs, or for maximizing efficiency and output, the company's production lines offer versatile solutions that can meet various production requirements. The pricelist serves as a valuable resource for manufacturers to explore their options and make informed decisions about their machinery investments.In conclusion, the release of the new pricelist for decorative gypsum cornice production lines underscores the company's dedication to providing high-quality, innovative, and cost-effective solutions for its customers. With a focus on automation, efficiency, and comprehensive support, the company continues to be a trusted partner for manufacturers in the gypsum cornice industry. As the company looks towards the future, it remains committed to driving the industry forward and empowering its customers to achieve success in their businesses.

Revolutionary Automatic Equipment for Gypsum Board Cornice Production

Title: Revolutionizing Gypsum Board Cornice Production with Innovative Automatic Equipment Introduction:In the rapidly evolving construction industry, technological advancements continue to drive innovation and revolutionize traditional manufacturing processes. Among these innovations, the introduction of automatic equipment for gypsum board cornice production has emerged as a game-changer. This breakthrough solution, developed by an industry-leading company, is set to streamline production, enhance efficiency, and guarantee superior quality in the production of gypsum board cornices.Revolutionizing the Gypsum Board Cornice Manufacturing Process:The new automatic equipment, developed by an industry leader (), simplifies the labor-intensive and time-consuming process of creating gypsum board cornices. This cutting-edge equipment combines advanced technology with precision engineering to bring unprecedented efficiency to the production line. With its innovative features, the device is poised to transform the gypsum board cornice production landscape.Efficiency and Precision through Automation:The automatic equipment boasts an impressive array of features that optimize productivity and ensure consistent quality. Through automation, it eliminates the need for manual labor, significantly reducing production time and costs. By automating key steps such as gypsum mixture preparation, molding, drying, and finishing, the equipment guarantees precise and flawless results.Moreover, this state-of-the-art machinery eliminates human errors, such as inconsistencies in measurements and imprecise cutting. By adhering to pre-programmed instructions, the device ensures standardized dimensions and shapes for each cornice produced. This not only enhances the visual appeal of the final product but also reduces wastage, thus contributing to a greener and more sustainable manufacturing process.Intuitive Control System for Seamless Operation:The automatic equipment incorporates an intuitive control system that enables operators to effortlessly manage and monitor the entire production process. The user-friendly interface provides easy access to crucial parameters such as temperature, humidity, and drying time, allowing operators to make necessary adjustments on the go.Furthermore, the equipment's control system includes built-in safety features to safeguard operators and the overall production line. From emergency stops to error detection, the system effectively mitigates potential risks, ensuring a safe working environment for all involved.Reliable Durability and Low Maintenance:One of the key advantages of this automatic equipment is its exceptional durability. Constructed from high-quality materials and engineered to withstand demanding production environments, this equipment promises longevity and minimal downtime. Additionally, the machinery requires minimal maintenance and is built to withstand daily wear and tear, further reducing operational costs and maximizing productivity.The Company's Commitment to Innovation:The company behind this revolutionary automatic equipment has a strong focus on research and development to meet the ever-evolving needs of the construction industry. With years of experience and a track record of excellence, they have established themselves as pioneers in their field.By continuously investing in cutting-edge technologies, the company strives to push boundaries and exceed customer expectations. Their commitment to innovation is clearly showcased by the introduction of this groundbreaking automatic equipment, which revolutionizes gypsum board cornice production.Conclusion:The introduction of automatic equipment for gypsum board cornice production marks a significant milestone in the construction industry. With its ability to streamline manufacturing processes, enhance efficiency, and guarantee superior quality, this innovation promises to reshape the way gypsum board cornices are produced. As construction companies look for ways to improve their operation's efficiency and output, this automatic equipment provides an ideal solution that not only optimizes productivity but also ensures remarkable precision and consistency.

High-Quality Mineral Fiber Tiles Production Line in China

China's mineral fiber tiles production line has seen a significant boost in activity in recent times. The production line, provided by a company that specializes in the manufacturing and exporting of mineral fiber tiles, has been instrumental in meeting the growing demand for these products.The company, with its state-of-the-art production line, has been at the forefront of supplying high-quality mineral fiber tiles to various construction projects in China and abroad. With a strong focus on innovation and product development, the company has been able to establish itself as a leading player in the mineral fiber tiles industry.The mineral fiber tiles production line is designed to meet the diverse needs of customers, offering a wide range of products that cater to different design preferences and functional requirements. The production line is equipped with advanced machinery and technology, allowing for efficient and precise manufacturing processes.One of the key features of the production line is its ability to produce mineral fiber tiles in a variety of sizes, shapes, and patterns. This flexibility has enabled the company to meet the specific requirements of each project, while also offering a high level of customization to its customers.In addition to its focus on product quality and customization, the company has also prioritized sustainability and environmental responsibility in its production processes. The mineral fiber tiles production line has been designed to minimize waste and energy consumption, ensuring that the company's operations are as eco-friendly as possible.Furthermore, the company has implemented rigorous quality control measures throughout the production process, ensuring that each mineral fiber tile that leaves the production line meets the highest standards of quality and durability. This dedication to quality has earned the company a strong reputation among its customers and stakeholders.The company's commitment to excellence extends beyond its products, as it also provides exceptional customer service and support. With a team of experienced professionals, the company is able to offer technical assistance, design consultation, and project management expertise to its clients, ensuring that their needs are met at every step of the process.The success of the mineral fiber tiles production line can be attributed to the company's relentless pursuit of excellence and its ability to adapt to the ever-changing needs of the market. By staying ahead of industry trends and investing in cutting-edge technology, the company has been able to maintain its competitive edge and continue to grow its market share.Looking ahead, the company plans to further expand its production capacity and capabilities, in order to meet the increasing demand for mineral fiber tiles both domestically and internationally. With a strong track record of success and a commitment to innovation, the company is well-positioned to play a leading role in the global mineral fiber tiles industry.In conclusion, the mineral fiber tiles production line provided by the company has been a game-changer for the industry, offering high-quality, customizable products that meet the diverse needs of customers. With a focus on sustainability, quality, and customer satisfaction, the company has established itself as a trusted partner for construction projects around the world. As the company continues to grow and innovate, it is poised to remain a dominant force in the mineral fiber tiles market for years to come.

Quality Wood Plastic Door Production Line for Board, Profile, and Frame Manufacturing in China

Wood Plastic Door Production Line (Board/Profile/Frame) China ManufacturerAs people become more aware of environmental issues and sustainable resources, there has been a growing demand for innovation in the construction industry. One of the latest trends taking the industry by storm is the wood plastic door production line. This technology combines the benefits of wood and plastic to create a durable and eco-friendly material that's perfect for doors, frames, and profiles. In this article, we'll explore the benefits of this technology and the leading China manufacturer of wood plastic door production line.What is a Wood Plastic Door Production Line?A wood plastic door production line is a modern manufacturing technology that combines natural wood fibers with plastic to create a composite material that's durable, lightweight, and eco-friendly. The wood fibers come from sustainable sources like sawdust, wood chips, or agricultural waste, which are then mixed with thermoplastic materials like PVC, PE, or PP. The resulting composite material has a higher strength-to-weight ratio than traditional wood and is resistant to water, decay, and insects.The wood plastic door production line can produce a range of products, including boards, profiles, and frames. These products can be used for different applications, such as doors, windows, decking, fencing, and more. The wood plastic composite products have a natural wood-like appearance and can be painted or stained to match any design requirement.Benefits of a Wood Plastic Door Production Line1. Eco-Friendly: One of the main benefits of a wood plastic door production line is that it's eco-friendly. The use of sustainable materials like wood fibers and recycled plastics reduces the carbon footprint of the production process and helps preserve natural resources. Moreover, the wood plastic composite products are recyclable, which further enhances their sustainability.2. Durability: Another benefit of a wood plastic door production line is that it produces products that are durable and long-lasting. The composite material is resistant to water, decay, and insects, which makes it ideal for outdoor applications. The products have a longer lifespan than traditional wood and require less maintenance, which saves time and money in the long run.3. Design Versatility: Wood plastic door production line can produce a wide range of designs and color options. The natural wood-like appearance of the products gives them a warm and inviting look, and they can be painted or stained to match any design requirement. The products can be molded into different shapes and sizes, which gives designers more flexibility in their projects.China Manufacturer of Wood Plastic Door Production LineIf you're looking for a reliable manufacturer of wood plastic door production line in China, then look no further than (need remove brand name). As a leading manufacturer and supplier of composite machinery, they have years of experience in the industry and are committed to providing high-quality products and services to customers worldwide.Their wood plastic door production line is designed to produce fireproof, waterproof, and eco-friendly products that meet international standards. The production line can manufacture a wide range of products, including boards, profiles, and frames, that are suitable for indoor and outdoor applications.Their wood plastic door production line is equipped with advanced machinery, such as twin-screw extruders, cooling baths, and cutting machines. The production process is fully automated, which ensures quality control and reduces the risk of errors.ConclusionIn conclusion, the wood plastic door production line is a modern technology that combines the benefits of wood and plastic to create a durable and eco-friendly material that's perfect for doors, frames, and profiles. The products produced by this line are eco-friendly, durable, and versatile, making them an ideal choice for designers and builders. If you're looking for a reliable manufacturer of wood plastic door production line in China, then (need remove brand name) is your go-to source. Their products are designed to meet international standards, and they're committed to providing high-quality products and services to customers worldwide.

Highest quality fiber cement board production machine

The production of Fiber Cement Board Production Machine by (company name) has been a significant development in the construction industry. This advanced machine has the ability to produce high-quality fiber cement boards, which are essential building materials known for their durability, fire resistance, and low maintenance.The Fiber Cement Board Production Machine by (company name) operates on advanced technology and automation, which ensures precision and efficiency in the manufacturing process. It is capable of producing a wide range of fiber cement boards, including siding, roofing, and cladding materials, catering to the diverse needs of the construction sector.The production machine is designed to handle the entire production process, from raw material preparation to the final product finishing. It is equipped with cutting-edge machinery for mixing the raw materials, such as cement, cellulose fibers, and additives, in precise proportions to achieve the desired quality and properties in the fiber cement boards.In addition, the machine incorporates a sophisticated molding and pressing system, which ensures that the boards are accurately formed and compacted to the required dimensions and thickness. This level of precision is crucial in producing high-performance fiber cement boards that meet industry standards and regulations.Furthermore, the Fiber Cement Board Production Machine by (company name) is committed to sustainability and environmental responsibility. It is designed to minimize waste generation and energy consumption during the manufacturing process, contributing to a greener and more sustainable approach to construction material production.With its state-of-the-art technology and innovative features, the Fiber Cement Board Production Machine by (company name) has garnered attention in the global market. It has already been adopted by leading construction companies and manufacturers worldwide, who recognize the value of investing in high-quality and reliable production machinery for fiber cement boards.In addition to the machine's technical capabilities, (company name) also offers comprehensive support and expertise in fiber cement board production. They provide consultation services, training programs, and technical assistance to their clients, ensuring that they are equipped with the knowledge and skills to optimize the performance of the production machine and achieve the best results in fiber cement board manufacturing.As a company, (company name) has a strong track record in the construction industry and a commitment to innovation and excellence. They have continually invested in research and development to enhance their products and services, and the Fiber Cement Board Production Machine is a testament to their dedication to advancing the capabilities of construction materials manufacturing.The introduction of the Fiber Cement Board Production Machine by (company name) has set a new standard in the production of fiber cement boards. Its advanced technology, precision engineering, and commitment to sustainability make it a valuable asset for construction companies seeking high-performance and reliable manufacturing equipment.In conclusion, the Fiber Cement Board Production Machine by (company name) represents a significant advancement in the construction industry, offering a cutting-edge solution for the production of fiber cement boards. With its advanced technology, environmental responsibility, and comprehensive support services, it has established itself as a leader in the global market for construction material production machinery.

Top Factories for Quality Gypsum Ceiling Pressing Machines

Title: Revolutionizing Gypsum Ceiling Production: Cutting-edge Pressing Machine Factories Challenge Industry StandardsIntroduction:The global demand for high-quality gypsum ceilings has been on the rise, prompting manufacturers to explore innovative technologies to meet the increasing needs of the market. Several pioneering companies have stepped up, establishing themselves as leaders in the realm of gypsum ceiling pressing machines. In this article, we will delve into some of the best gypsum ceiling pressing machine factories, highlighting their contributions and commitment to revolutionizing the industry.Gypsum Ceiling Pressing Machine Factory A:One of the leading players in the industry, Factory A, has gained a formidable reputation for its breakthrough technologies and commitment to quality. With state-of-the-art facilities, Factory A has revolutionized the gypsum ceiling production process, streamlining efficiency while maintaining exceptional standards. By employing advanced automation and precision engineering, the factory assures optimal performance of their pressing machines, resulting in flawless, finely finished gypsum ceiling panels.Moreover, Factory A's dedication to sustainability is commendable. They have implemented eco-friendly measures throughout their manufacturing process, such as recycling and minimizing waste generation. The factory's adherence to sustainable practices underscores their commitment to creating a greener future for the construction industry.Gypsum Ceiling Pressing Machine Factory B:Factory B has carved a niche for itself by consistently delivering cutting-edge gypsum ceiling pressing machines. Recognized for their attention to detail and continuous innovation, this factory has successfully impressed industry experts and customers alike. Engineers at Factory B have developed pressing machines that leverage advanced computerized technology, ensuring unparalleled accuracy and precision.In addition to their technological expertise, Factory B prioritizes customer satisfaction. By working closely with their clients, the factory ensures that their machines are tailored to meet specific requirements and optimize production processes. This customer-centric approach has allowed Factory B to build lasting relationships and maintain a loyal customer base.Gypsum Ceiling Pressing Machine Factory C:Factory C has earned its place among the best gypsum ceiling pressing machine factories due to its relentless pursuit of excellence. Notably, the factory's state-of-the-art research and development division constantly strives to innovate machinery to enhance efficiency and convenience. Through extensive market research and collaboration with industry leaders, Factory C consistently introduces groundbreaking features that set new benchmarks in gypsum ceiling production.Furthermore, Factory C emphasizes the importance of quality control throughout the manufacturing process. Every machine undergoes rigorous testing to ensure exceptional performance and durability. This commitment to uncompromising quality has positioned Factory C as a reliable and preferred choice for gypsum ceiling manufacturers worldwide.Conclusion:The gypsum ceiling pressing machine factories mentioned above, Factory A, Factory B, and Factory C, represent the pinnacle of innovation and quality in the industry. Their dedication to advanced technology, sustainability, customer satisfaction, and stringent quality control sets them apart from their competitors. These factories continue to challenge industry standards through their continuous pursuit of excellence, revolutionizing the gypsum ceiling production landscape. As the demand for high-quality gypsum ceilings continues to grow, manufacturers can rely on these factories to provide them with state-of-the-art pressing machines, ensuring a bright future for the industry.

Fiberboard Insulation Developer Advances Plans to Convert Closed Paper Mill into Production Facility

A Maine-based startup company is set to take a significant step forward in the world of green building, as it plans to convert a closed paper mill into a new production facility for fiberboard insulation.The company behind the project has become known for its innovative approach to creating sustainable insulation materials, and its new facility represents a major milestone for both the company and the green building industry as a whole.Fiberboard insulation is a type of insulation made from wood fibers, usually combined with a resin binder. This type of insulation is known for its excellent thermal insulation properties and resistance to moisture, making it an ideal choice for use in buildings, especially those in colder climates.The new production facility will be located in the town of Millinocket, Maine, and will be capable of producing up to 100 million square feet of fiberboard insulation each year. This is a significant increase from the company's existing production capacity, and will allow it to meet growing demand for its products from around the world.According to the company's CEO, the new facility will be equipped with state-of-the-art production equipment, designed to ensure the highest levels of quality and efficiency. Additionally, the company plans to invest in innovative new technologies and processes to further improve the sustainability and environmental performance of its insulation products.The company's fiberboard insulation products are already highly regarded within the green building industry, thanks to their superior performance and eco-friendly credentials. The insulation is made from 100% recycled and reclaimed wood fibers, making it a highly sustainable and renewable material.Furthermore, the company's products are free from harmful chemicals and additives, making them an excellent choice for those with allergies or sensitivities to traditional insulation materials. This is a particularly important consideration for those building or renovating homes or commercial buildings in urban areas, where indoor air quality is a major concern.The CEO of the company, speaking about the new production facility, said: "This is a major milestone for our company and for the green building industry as a whole. We are excited to be bringing our innovative approach to insulation production to a wider audience, and to be able to meet growing demand for sustainable and eco-friendly building materials."The new production facility is expected to create a significant number of new jobs in the local area, providing a welcome boost to the local economy. Additionally, the company's commitment to sustainability and environmental responsibility is expected to have a positive impact on the wider community, both in terms of the materials it produces and the innovative technologies it develops.Overall, this is an exciting development for the green building industry, and one which is sure to be closely watched by those working in the field. With demand for sustainable building materials continuing to grow, the new production facility is a positive step towards a more sustainable and eco-friendly built environment.

Affordable and Lightweight Yarn Recommendations for a Warm Winter Shawl

article focusing on affordable and lightweight yarn options for winter knitting projects.)Winter is the perfect season for knitting cozy shawls, scarves and blankets. But when it comes to choosing the right yarn for the project, many knitters face a dilemma. On one hand, you want a material that will keep you warm and snug, but on the other hand, you don't want it to be too heavy or expensive. The good news is that there are plenty of affordable and lightweight yarn options to choose from, as we explore in this article.Merino WoolOne of the most popular options for winter knitting is merino wool. This soft and warm yarn is made from the wool of merino sheep, known for their fine fleece. Merino wool is lightweight and breathable, making it ideal for layering and wearing indoors. It also has natural moisture-wicking properties, which means it will keep you dry and comfortable. Although merino wool can be on the pricier side, it's worth investing in for its durability and versatility.Acrylic YarnFor those looking for a more affordable option, acrylic yarn is a great choice. This man-made fiber is lightweight, easy to wash and available in a wide variety of colors and textures. Acrylic yarn is also hypoallergenic, making it a great option for those with sensitive skin. While it may not be as warm as some other fibers, it's a great option for layering or for wearing in milder winter weather.Alpaca YarnAlpaca yarn is another excellent option for winter knitting. This soft and insulating fiber comes from the fleece of the alpaca, a South American animal that's related to the llama. Alpaca yarn is incredibly warm and lightweight, making it ideal for winter accessories like scarves and hats. It is also hypoallergenic and comes in a variety of natural shades. While it can be more expensive than some other fibers, it's worth the investment for its warmth and comfort.Cotton YarnWhile many knitters associate cotton yarn with warm weather projects, it can also be a great option for winter knitting. Cotton is lightweight and breathable, making it ideal for layering or wearing indoors. It's also a more affordable option than some other fibers. While cotton may not be as warm as wool or alpaca, it's a great option for those who prefer natural fibers and want to avoid itchiness and irritation that can come from other materials.Bamboo YarnFinally, bamboo yarn is a great option for those looking for a lightweight and eco-friendly material. Bamboo is a sustainable and renewable resource, and bamboo yarn is incredibly soft and comfortable. It's also naturally antibacterial and hypoallergenic, making it a great option for those with sensitive skin. While it may not be as warm as other fibers, it's a great option for layering or for warmer winter weather.In conclusion, when it comes to finding the right yarn for your winter knitting project, there are plenty of affordable and lightweight options to choose from. Whether you prefer natural fibers like wool and alpaca, or man-made fibers like acrylic and bamboo, there's a yarn out there that's perfect for your needs. So stock up on your favorite materials and get ready to create cozy and stylish accessories to keep you warm all winter long.

Top Perforated Plasterboard Machine Suppliers in China

China Perforated Plasterboard Machine Suppliers have been making waves in the construction industry with their innovative and high-quality products. With a focus on providing efficient and cost-effective solutions for perforated plasterboard production, these suppliers have gained a reputation for being reliable and trustworthy partners for construction companies around the world.The Perforated Plasterboard Machine Suppliers have a strong commitment to research and development, ensuring that they stay ahead of the curve when it comes to technological advancements in the industry. This dedication to innovation has allowed them to continually improve their products and processes, resulting in high-performance machines that are able to meet the demands of modern construction projects.One of the key factors that sets these suppliers apart from their competitors is their commitment to quality. They take great pride in the craftsmanship of their machines, ensuring that each one is built to exacting standards and undergoes rigorous testing before being delivered to customers. This attention to detail has earned them the trust and loyalty of their clients, who rely on their equipment to deliver exceptional results on every project.In addition to their focus on quality, the Perforated Plasterboard Machine Suppliers also prioritize customer satisfaction. They understand the unique needs of each of their clients and work closely with them to provide customized solutions that meet their specific requirements. Whether it's a small-scale operation or a large industrial project, these suppliers are able to tailor their machines to suit the needs of their customers, ensuring that they are able to achieve their production goals efficiently and effectively.Furthermore, the Perforated Plasterboard Machine Suppliers have a strong commitment to sustainability. They are continually looking for ways to reduce the environmental impact of their operations, from the materials they use in their machines to the energy they consume during production. By prioritizing sustainability, these suppliers are able to reduce waste and lower their carbon footprint, contributing to a greener and more sustainable construction industry.When it comes to the global market, the Perforated Plasterboard Machine Suppliers have made a name for themselves as reliable partners for construction companies around the world. Their machines are used in a wide range of projects, from residential and commercial developments to industrial and infrastructure projects. With a strong track record of delivering high-quality equipment and exceptional customer service, these suppliers have built a solid reputation that has allowed them to expand their reach into new markets.As the construction industry continues to evolve, the Perforated Plasterboard Machine Suppliers remain at the forefront of innovation and progress. They are constantly exploring new technologies and techniques to improve their products and processes, ensuring that they are able to meet the ever-changing needs of their clients. With a firm commitment to quality, customer satisfaction, and sustainability, these suppliers are well-positioned to continue their success in the global construction market for years to come.In conclusion, the Perforated Plasterboard Machine Suppliers in China have proven themselves to be reliable and innovative partners for construction companies around the world. With a focus on quality, customer satisfaction, and sustainability, these suppliers have established themselves as leaders in the industry and are well-positioned for continued success in the global market. Their commitment to research and development, coupled with their dedication to meeting the unique needs of their clients, sets them apart as a top choice for perforated plasterboard production equipment.